Method for remediating chromium polluted soil by enabling super fine iron powder to cooperate with microorganisms

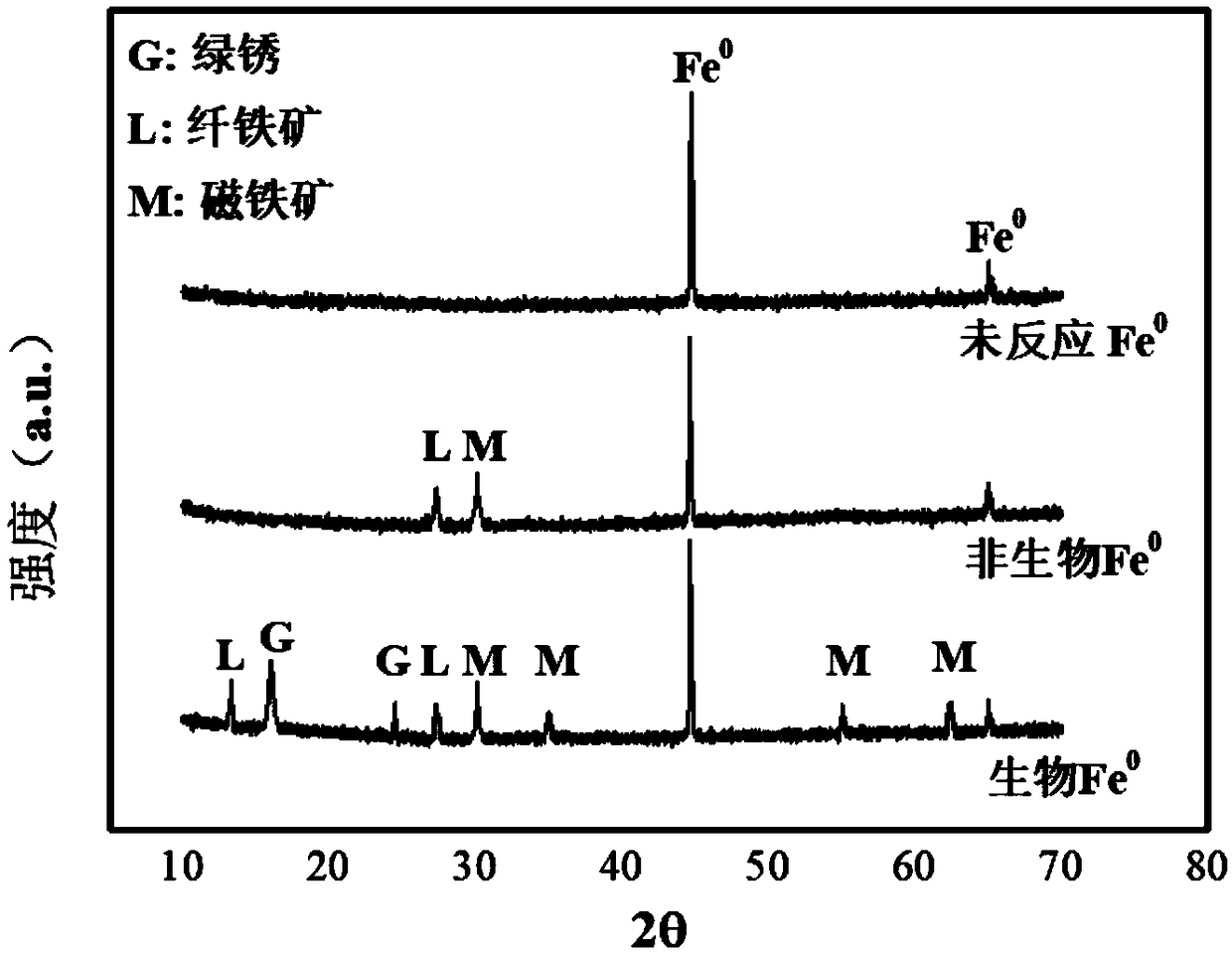

A technology for chromium-contaminated soil and microbial remediation, applied in the field of ultra-fine iron powder collaborative microbial remediation of chromium-contaminated soil, can solve problems such as reducing the remediation effect of zero-valent iron, and achieve the effect of promoting adsorption, high electron transport capacity, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] A method for superfine iron powder synergistically repairing chromium-contaminated soil with microorganisms, comprising the following steps:

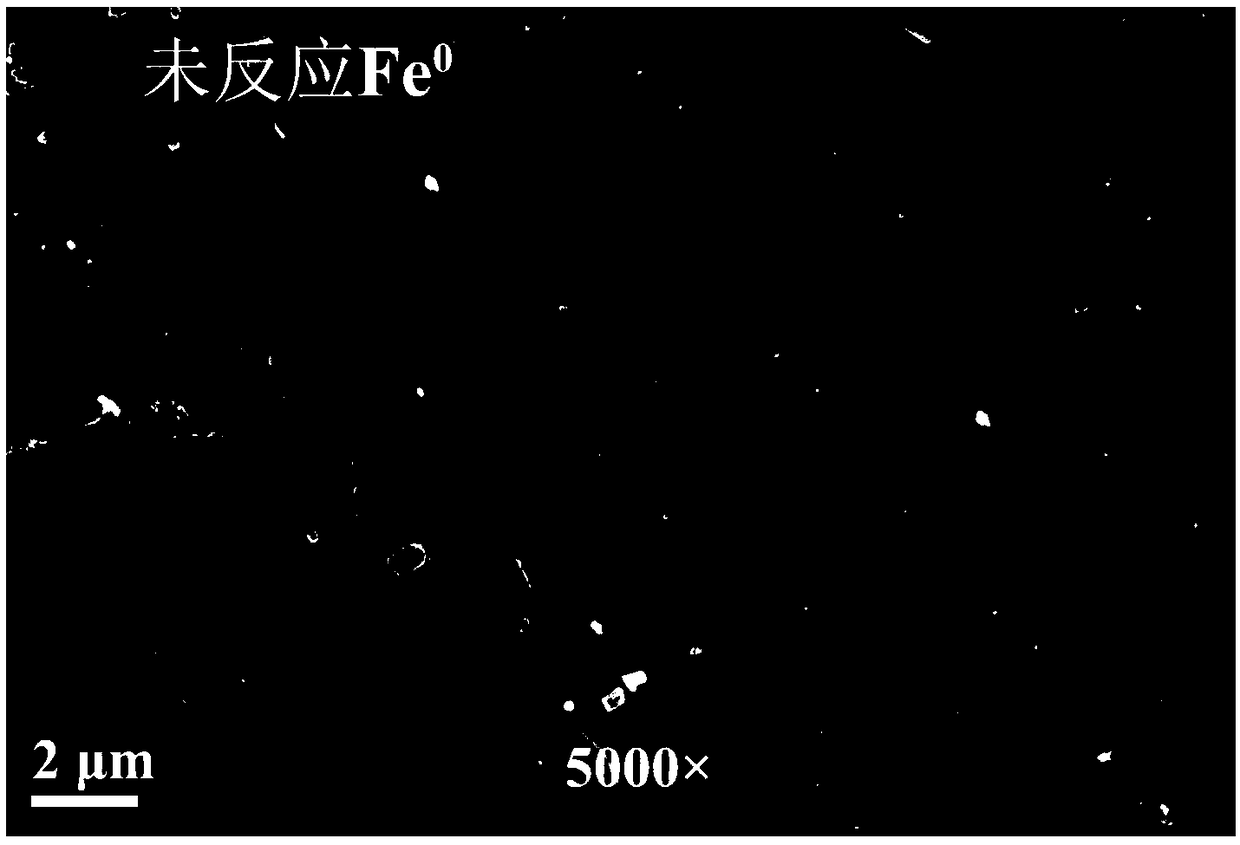

[0030] (1) Weigh 50g of ultra-fine iron powder with an iron content of 97% and a particle size of 0.1mm, and transfer it into 200mL of 0.1M hydrochloric acid solution, filter out the iron powder after ultrasonication for 5min, and use absolute ethanol and deoxygenated water in sequence Wash until neutral, and put it in a nitrogen-protected brown bottle for later use.

[0031] (2) Indigenous hydrogenophilic chromium-reducing bacteria, iron-reducing bacteria and sulfate-reducing bacteria were screened from the chromium-contaminated soil of the electroplating site. They were cultured in an anaerobic incubator with glucose and hydrogen as electron donors, and hexavalent bacteria were screened out. The strain with the strongest reducing ability of chromium, ferric iron and sulfate is prepared as a mixed strain at a ratio of 6:3:1 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com