Polypropylene (PP) material for automobile bumper

A technology for automobile bumpers and materials used in the field of PP materials, which can solve the problems of non-wear resistance, low temperature resistance, and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

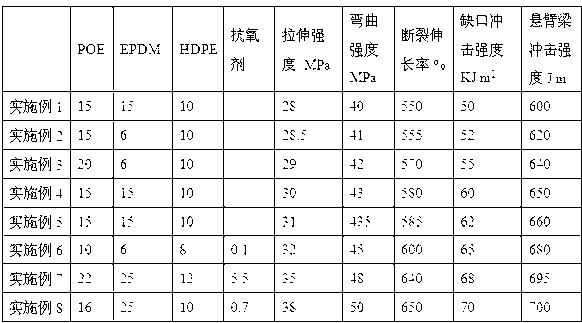

Examples

Embodiment 1

[0063] Step 1: Weigh various raw materials according to the ratio of mass and number as described below

[0064] PP-EPF30R 100;

[0065] ABS 30;

[0066] POE 15;

[0067] PP-g-MAH 10;

[0068] HDPE 10;

[0069] EPDM 15;

[0071] wollastonite 5;

[0073] Step 2: Mix the above PP, HDPE, and EPDM at 80°C for 5-10 minutes, raise the temperature to 100°C, add the rest of the materials, and stir for 10-15 minutes;

[0074] The third step: Extrude the mixed material in the second step to pelletize in a twin-screw extruder, and the extrusion temperature is 170°C, 165°C, 155°C, 150°C, 145°C.

[0075] The tensile strength of the product is 28MPa, the bending strength is 40MPa, the elongation at break is 550%, and the notched impact strength of the product is 50KJ / m 2 , Izod impact strength 600J / m.

Embodiment 2

[0077] Step 1: Weigh various raw materials according to the ratio of mass and number as described below

[0078] PP-EPF30R 100;

[0079] ABS 25;

[0080] POE 15;

[0081] PP-g-MAH 10;

[0082] HDPE 10;

[0083] EPDM6;

[0085] wollastonite 5;

[0087] Step 2: Mix the above PP, HDPE, and EPDM at 80°C for 5-10 minutes, raise the temperature to 100°C, add the rest of the materials, and stir for 10-15 minutes;

[0088] The third step: Extrude the mixed material in the second step to pelletize in a twin-screw extruder, and the extrusion temperature is 170°C, 165°C, 155°C, 150°C, 145°C.

[0089] The tensile strength of the product is 28.5MPa, the bending strength is 41MPa, the elongation at break is 555%, and the notched impact strength of the product is 52KJ / m 2 , Izod impact strength 620J / m.

Embodiment 3

[0091] Step 1: Weigh various raw materials according to the ratio of mass and number as described below

[0092] PP-EPF30R 100;

[0093] ABS 25;

[0094] POE 20;

[0095] PP-g-MAH 10;

[0096] HDPE 10;

[0097] EPDM6;

[0100] wollastonite 5;

[0101] Titanate coupling agent 5.

[0102] Step 2: Mix the above PP, HDPE, and EPDM at 80°C for 5-10 minutes, raise the temperature to 100°C, add the rest of the materials, and stir for 10-15 minutes;

[0103] The third step: Extrude the mixed material in the second step to pelletize in a twin-screw extruder, and the extrusion temperature is 170°C, 165°C, 155°C, 150°C, 145°C.

[0104] The tensile strength of the product is 29MPa, the bending strength is 42MPa, the elongation at break is 570%, and the notched impact strength of the product is 55KJ / m 2 , Izod impact strength 640J / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com