Connector and production method

A connector and abutment surface technology, which is applied in the direction of vehicle connectors, connections, conductive connections, etc., can solve problems such as corrosion, and achieve the effects of improving moldability, moldability, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

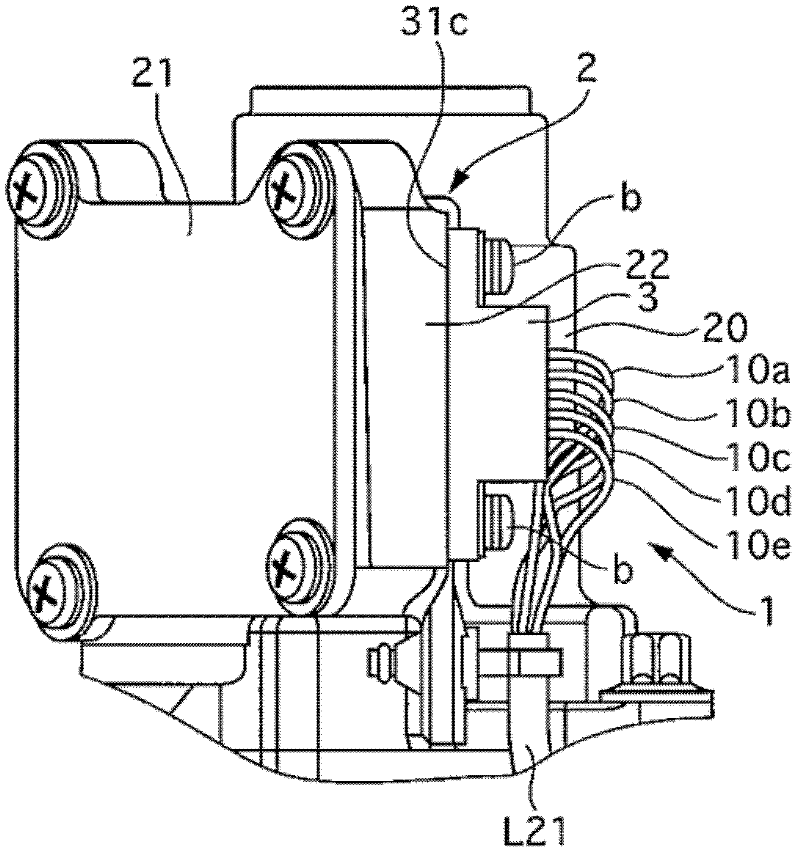

[0083] [Configuration of Embodiment 1]

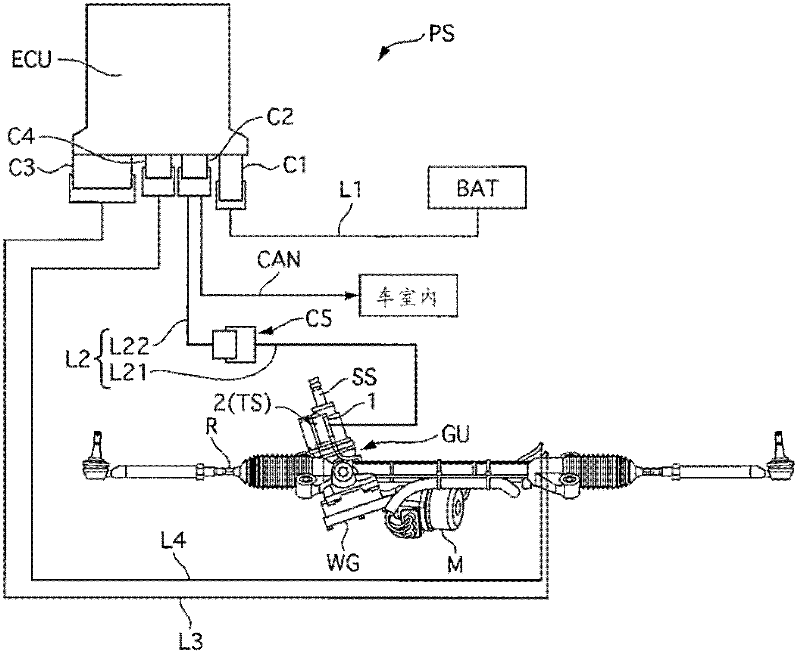

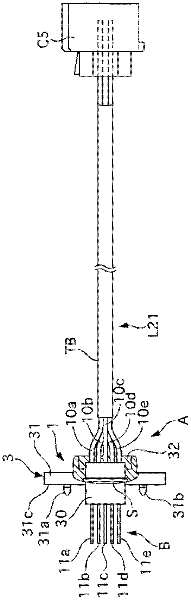

[0084]The connector 1 of the first embodiment is installed in an electric power steering device (hereinafter referred to as "device PS") of an automobile. It should be noted that the connector of the present invention and its manufacturing method can also be applied to devices other than the electric power steering system PS, and mounted on devices other than automobiles. figure 1 It is a system configuration diagram of the device PS provided with the connector 1 . The device PS has a gear unit GU (power steering gear unit) as an actuator and a control unit ECU as a control device. The connector 1 is provided on the gear unit GU, and electrically connects the outside and the inside of the gear unit GU.

[0085] The gear unit GU has a motor M as a motor, a worm gear WG as a reduction mechanism, and a torque sensor TS as steering torque detection means. The driving force of the motor M is transmitted to the worm R via the worm gear WG,...

Embodiment 2

[0156] The connector 1 of the second embodiment differs from the first embodiment in the shape of the wall portion 310 (recess 316 ) of the second molded part 31 . Figure 15 is the connector 1 and Figure 7 Same main view. In addition, illustration of the bolt penetration hole 319 etc. is abbreviate|omitted. like Figure 15 As shown, the annular wall portion 310 is formed within a predetermined range of the circumferential direction of the first molding part 30, specifically on both sides of the z-axis direction of the first molding part 30, from the first molding part 30 The outer peripheral surface is spaced apart and formed to adjoin (close to) the first mold member 30 in a portion other than a predetermined range in the above-mentioned circumferential direction, specifically, on both sides in the y-axis direction of the first mold member 30 . That is, the portions on both sides in the y-axis direction of the wall portion 310 are provided on the inner peripheral side th...

Embodiment 3

[0162] The connector 1 of Embodiment 3 is different from Embodiment 1 in the shape of the wall portion 310 (recess 316 ) of the second molded part 31 . Figure 16 is the connector 1 of Example 3 with Image 6 The same partial cross-sectional view only shows the part on the negative side of the y-axis. In addition, illustration of the seal groove 318, the pin 31b, etc. is abbreviate|omitted. like Figure 16 As shown, the second molding member 31 makes the inner peripheral surface of the wall portion 310 closer (on the inner peripheral side) to the positive x-axis side (the side of the bottom surface 315 ) from the negative x-axis direction side (opening side) The form of the first molding part 30 is formed in an inclined shape. In other words, a conical portion T is provided on the inner peripheral surface of the concave portion 316 for accommodating the adhesive 32 so that the dimension in the y-axis direction (inner diameter) becomes smaller toward the bottom in the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com