Fire extinguisher uniform filling device and filling method thereof

The technology of filling device and fire extinguisher is applied in the field of uniform filling device of water-based fire extinguisher, which can solve the problems of many bubbles, affecting efficient filling operation, and more liquid coming out, and achieves less bubbles, reasonable structure design, and efficient filling operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

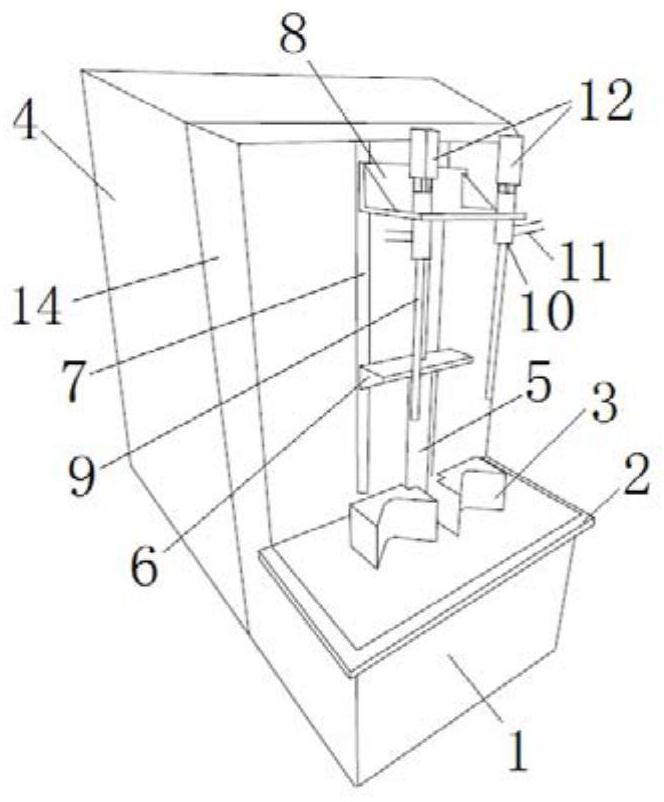

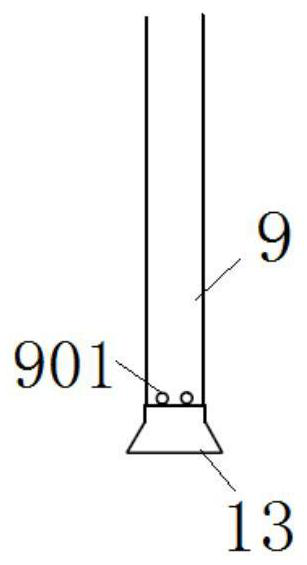

[0026] Such as figure 1 and figure 2 As shown, the fire extinguisher uniform filling device includes a workbench 1, a chemical water tank 4 and a water pipe 11 connected to the chemical water tank; the workbench is provided with a lifting platform 8 that can be lifted, and a connecting sleeve is provided on the lifting platform. 10. The connecting sleeve is connected with the water pipe, and the connecting sleeve is provided with a water valve, and the lower part of the connecting sleeve is provided with a filling intubation tube 9 for inserting into the fire extinguisher cylinder.

[0027] The filling cannula is inserted into the bottom of the fire extinguisher cylinder, and the water is discharged from the bottom of the filling cannula for filling. The filling is evenly filled with less air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com