Paint filling unit and paint filling device provided with the same

A filling device and coating technology, which is applied in the field of coating filling units and coating filling devices, can solve the problems of increasing the strength of the driving system, increasing the weight, and increasing frictional resistance, etc., and achieves the effect of easy filling operation and efficient coating filling operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

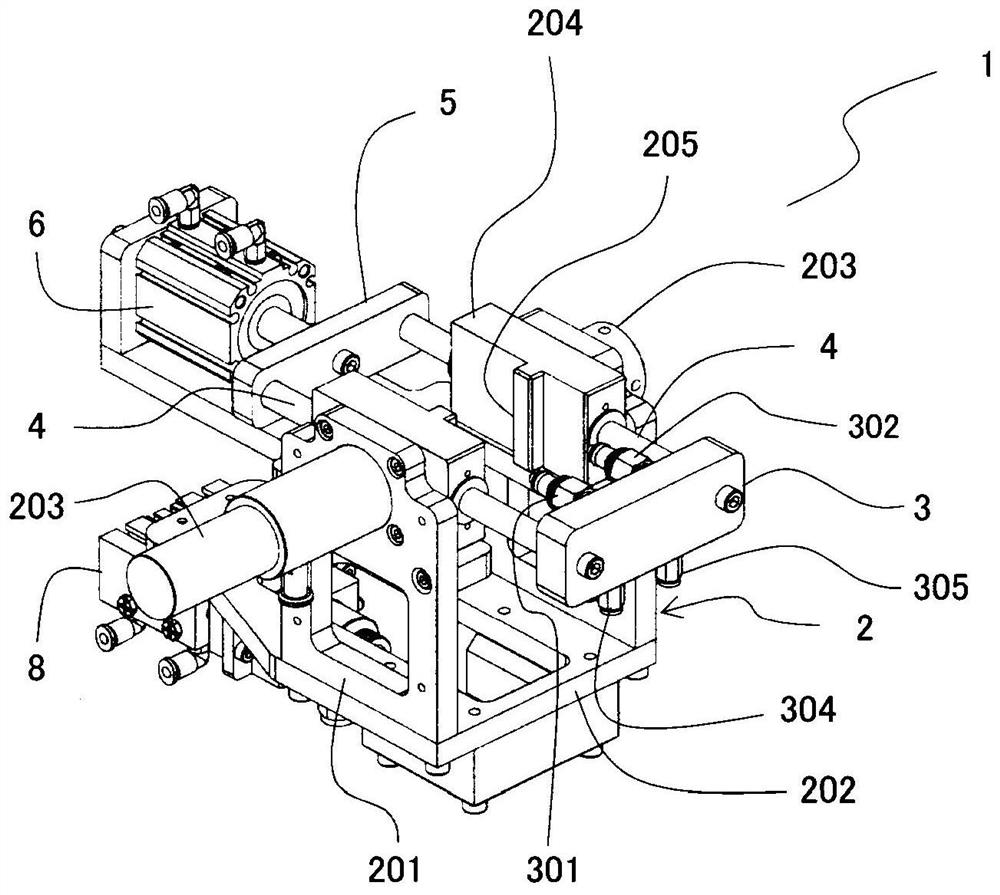

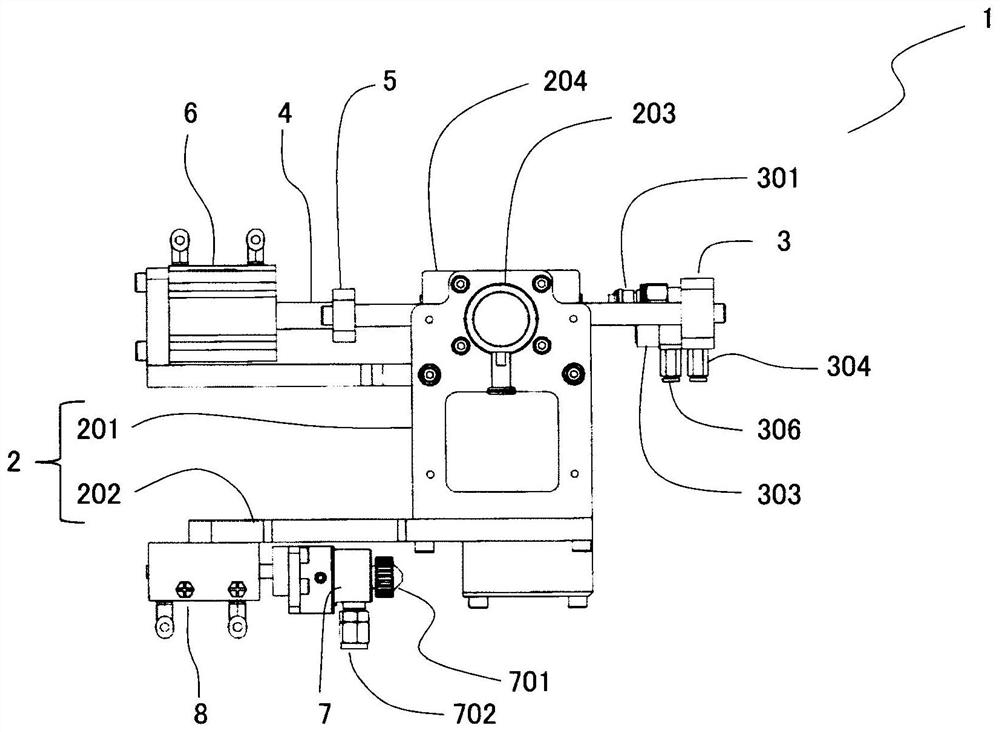

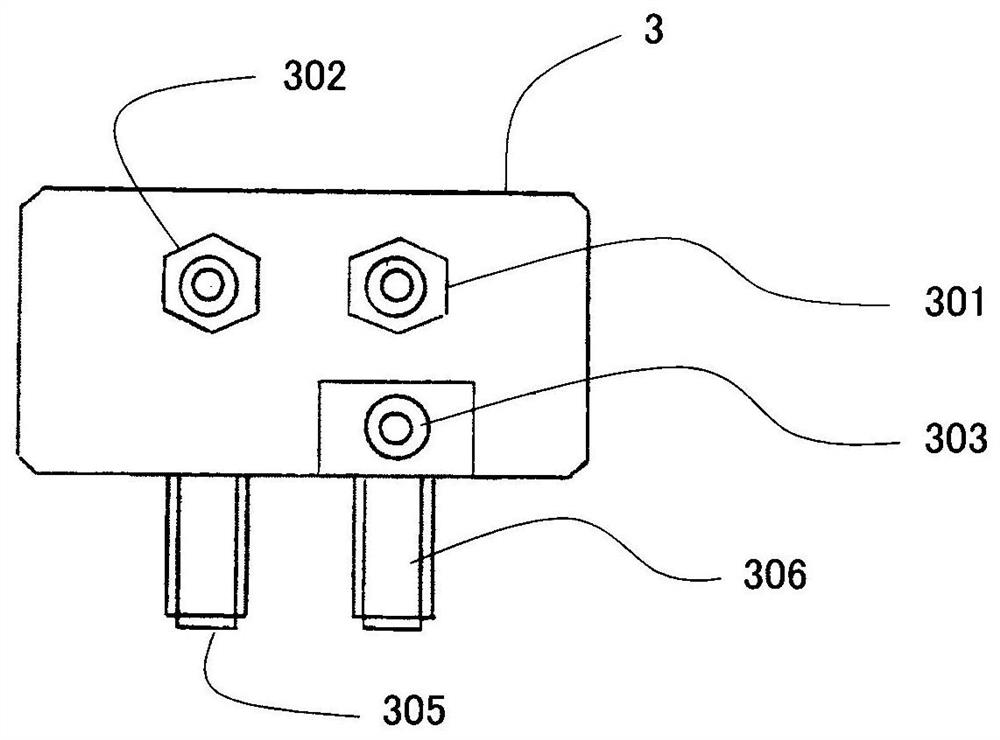

[0080] Embodiments of the paint filling unit of the present invention will be described with reference to the accompanying drawings, figure 1 is a perspective view of the paint filling unit of this embodiment, figure 2 It is a left side view, and 1 in the figure is the paint filling unit of this embodiment.

[0081] Furthermore, the paint filling unit of the present embodiment has a main body portion. That is, 2 in the figure is a main body part. In this embodiment, the main body part 2 has a pair of side walls 201 arranged at intervals and a bottom part 202 connecting the lower end parts of the side walls. Connecting shafts 203 are connected to the outer surfaces of the side walls 201 , respectively, facing outward and in a direction orthogonal to the surface of the side wall 201 , that is, in the side portion direction of the main body portion 2 . In addition, support plates 204 for supporting the spray gun are mounted on the inner sides of the side walls 201, respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com