Water-based alumium alloy releasing agent and preparing method thereof

A technology of aluminum alloy and release agent, applied in metal processing equipment, manufacturing tools, casting molding equipment, etc., can solve environmental pollution and other problems, achieve the effects of reducing environmental pollution, ensuring high temperature performance, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

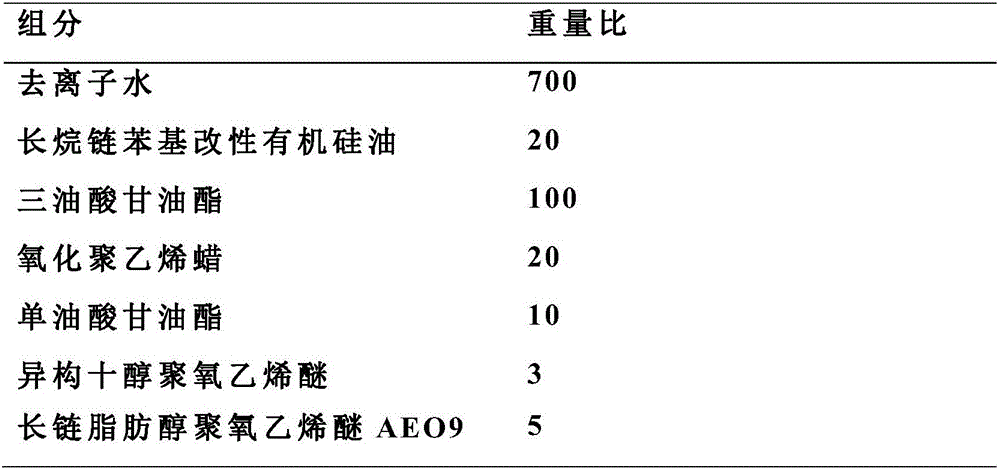

[0019] The preparation of embodiment 1 water-based aluminum alloy release agent

[0020]

[0021] The preparation method is as follows:

[0022] (1) Take long alkyl chain phenyl modified silicone oil, glyceryl trioleate, oxidized polyethylene wax, glycerol monooleate, isomerized decanol polyoxyethylene ether, long chain fatty alcohol polyoxyethylene ether, Ionized water, mixed and heated to melt.

[0023] (2) Stir the above components at a speed of about 3000 rpm for 20 minutes, cool down to 60°C,

[0024] (3) Then three batches of deionized water will be slowly dripped in, and then stirred for half an hour to prepare,

[0025] Most of the cast steel zircon powder coatings currently on the market are expensive and radioactive.

[0026] The water-based aluminum alloy release agent has low cost, stable performance and good release effect, and greatly reduces environmental pollution while ensuring the high-temperature performance of the release agent.

Embodiment 2

[0027] Example 2 The composition of the water-based aluminum alloy release agent according to the mass ratio is: 30 parts of long alkyl chain phenyl modified silicone oil, 120 parts of glyceryl trioleate, 20 parts of oxidized polyethylene wax with a melting point of 98-100 °C, 15 parts of mono Glyceryl oleate, 5 parts of isomeric decanol polyoxyethylene ether, 10 parts of AEO9, 750 parts of deionized water.

[0028] The preparation method is the same as in Example 1.

[0029] The water-based aluminum alloy release agent has low cost, stable performance and good release effect, and greatly reduces environmental pollution while ensuring the high-temperature performance of the release agent.

Embodiment 3

[0031] The composition of the water-based aluminum alloy release agent according to the mass ratio is: 30 parts of long alkyl chain phenyl modified silicone oil, 120 parts of glycerol trioleate, 40 parts of oxidized polyethylene wax with a melting point of 98-100 °C, and 15 parts of glycerin monooleate Esters, 8 parts of isomeric decanol polyoxyethylene ether, 10 parts of AEO9, 850 parts of deionized water.

[0032] The preparation method is the same as in Example 1.

[0033] The water-based aluminum alloy release agent has low cost, stable performance and good release effect, and greatly reduces environmental pollution while ensuring the high-temperature performance of the release agent.

[0034] The performance investigation of the die-casting release agent prepared by embodiment

[0035] The release performance test method is as follows: Dilute the die-casting release agent with deionized water in a certain proportion (150 times dilution here), spray the diluted solution e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com