Hot press molding technique for special optical glass element

A technology of optical glass and thermoforming, which is applied in glass forming, glass pressing, glass production, etc. It can solve problems such as glass adhesion and shorten heating and heating time, so as to prolong service life, save money and materials, and remove good modulus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and embodiment this patent is further described:

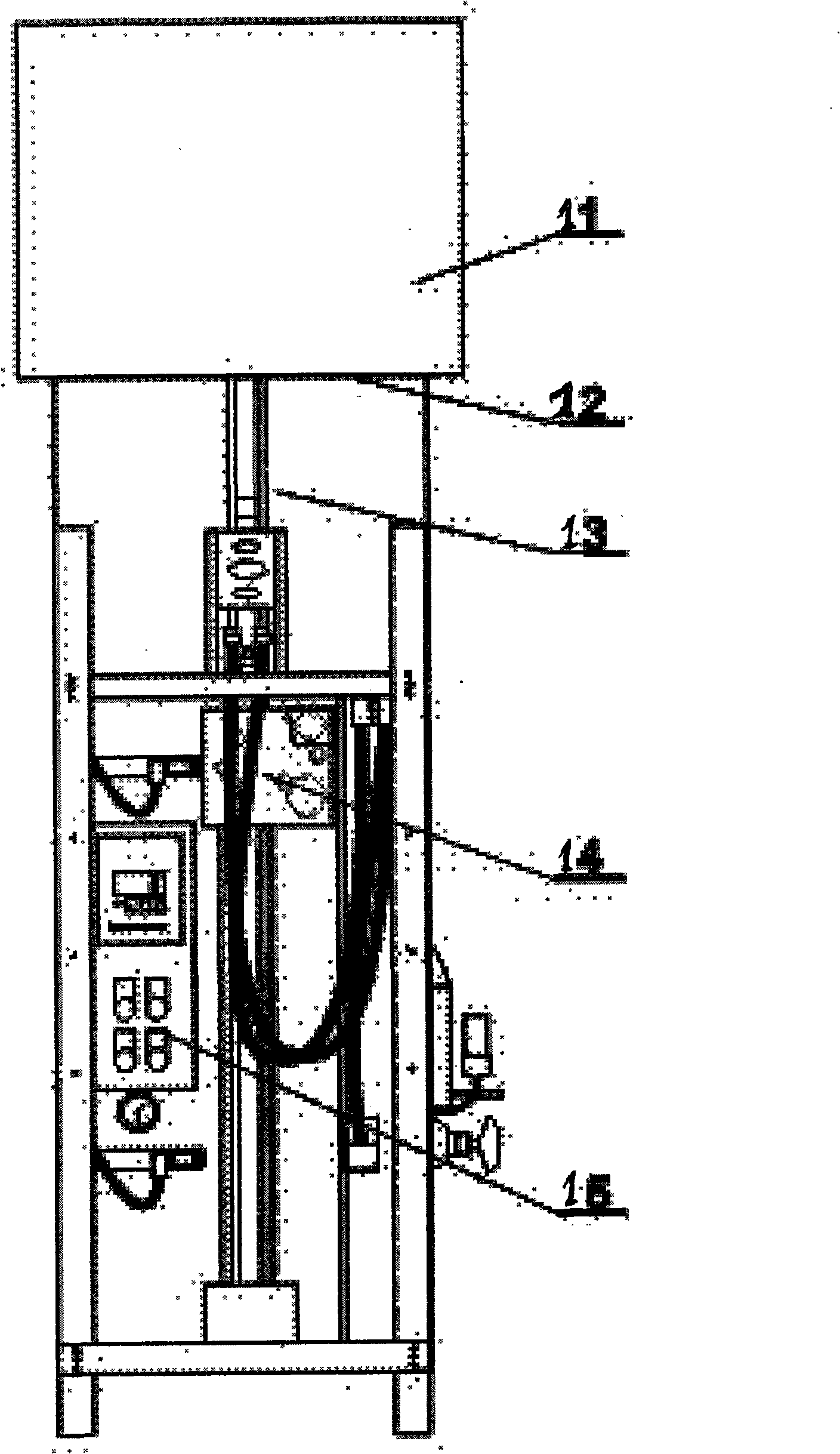

[0043] Such as figure 1 As shown, the thermocompression molding process of special optical glass components is carried out in 3 steps:

[0044] 1) Heating process: conduct conduction heating from the outside of the metal mold; use optical glass precision high-temperature softening furnace to heat special optical element optical glass raw materials to the softening temperature of optical glass at 1200°C, and heat up in a short time to make the heat uniform According to a certain time interval design, multiple optical glass precision high-temperature softening furnaces are used to heat special optical optical glass raw materials.

[0045] The hot-pressed special optical element optical glass precision high-temperature softening furnace is mainly used for the heating process to soften the hot-pressed special optical element optical glass. The aspherical optical glass precisio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com