Thermal pressuring separating type sheets and its mfg. method

A release sheet, manufacturing method technology, applied in the direction of chemical instruments and methods, instruments, layered products, etc., can solve the decline in productivity, the decrease in durability of thermally bonded release sheets, liquid crystal instrument panels, and driving semiconductors damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

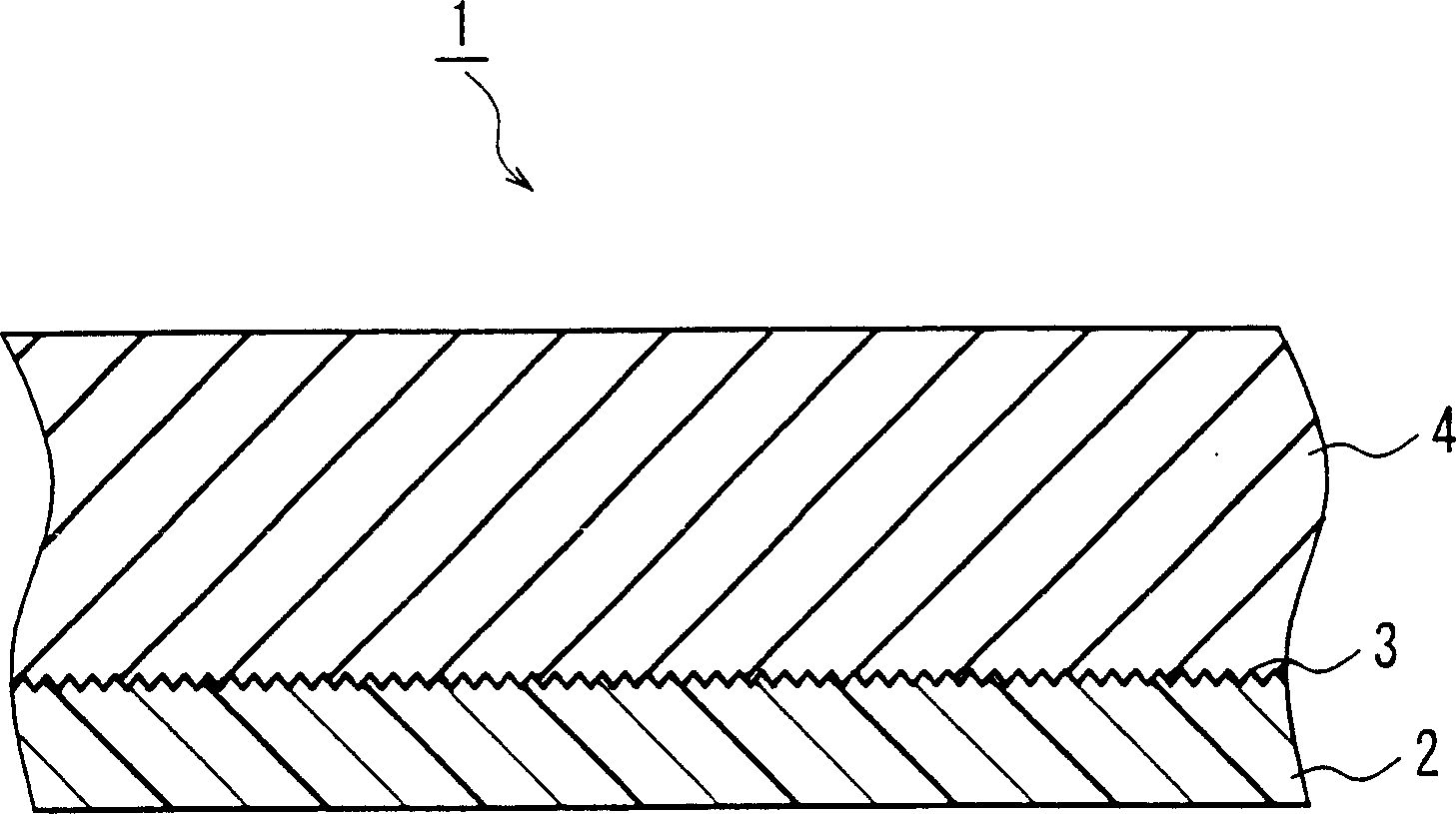

Image

Examples

Embodiment 1

[0024] (1) Glass cloth reinforced conductive fluororesin sheet

[0025] The base material of the glass cloth-reinforced conductive fluororesin sheet, which is a constituent element of the release sheet for thermocompression bonding, uses plain-woven alkali-free glass cloth (weight per unit area: 36g / m 2 ). A compound in which 1.0 parts by weight of carbon black for imparting conductivity was added to 100 parts by weight of polytetrafluoroethylene was coated on the above-mentioned glass cloth, dipped, and fired at 400° C. for 30 minutes. The surface resistance value of the obtained glass cloth reinforced conductive fluororesin sheet is 5×10 5 Ω, a thickness of 0.05 mm, a tensile strength of 40 N / cm, an elongation of 5% or less, and a polytetrafluoroethylene content of 65% by weight. As the glass cloth-reinforced conductive fluororesin sheet, "Honda Flow Fabric" (trade name manufactured by Honda Sangyo Co., Ltd.) can also be used.

[0026] (2) Surface activation treatment of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com