Toner and preparation method thereof

A toner and surfactant technology, applied in the field of toner and its preparation, can solve the problems of insufficient compatibility, poor uniformity of toner particle size and shape, uneven dispersion of wax, etc., and achieve excellent low-temperature fixing and Preservability, improvement of storage stability, effect of ensuring thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] According to a first aspect of the present invention, a method for preparing a binder resin emulsion for toner is provided, comprising the following steps:

[0039] (A) adding polyester resin and isocyanate to the solvent formed by styrene monomer and acrylate monomer, polyester resin and isocyanate are reacted to obtain a mixed solution containing polyurethane-modified polyester resin;

[0040] The hydroxyl value of the polyester resin is 1-20 mg KOH / g, the molar ratio of the isocyanate group of the isocyanate to the hydroxyl group of the polyester resin is 0.8-1:1, and the weight average molecular weight of the polyester resin is 3000-25000 g / mol;

[0041] (B) add surfactant and water to the mixed solution that step (A) obtains, after emulsification, add initiator, carry out seed emulsion polymerization, obtain polyurethane seed emulsion;

[0042] (C) Provide a pre-emulsion formed by styrene monomers, acrylate monomers, surfactants and water, add the pre-emulsion and ...

Embodiment 1

[0102] A preparation method of toner, comprising the following steps:

[0103] (1) Mixed solution containing polyurethane modified polyester resin

[0104] In a 3-liter four-neck flask equipped with a constant temperature oil bath, a stirring device, a thermometer, a reflux condenser, a nitrogen inlet pipe, and a dropping funnel, first pass nitrogen gas to fully replace the oxygen and water in it, and then raise the temperature to 50°C , add 297g styrene, 64g n-butyl acrylate, 18g hydroxyethyl methacrylate, 6.706g isophorone diisocyanate and 211.59g polyester resin A [composition (molar ratio)=polyoxypropylene (2.2)-2 , 2-bis(4-hydroxyphenyl) propane: fumaric acid: dodecenyl succinic anhydride=102:90:10, weight average molecular weight (Mw)=8,500, glass transition temperature (Tg)=67 ℃, Hydroxyl value = 8mg KOH / g, acid value = 4mg KOH / g], keep stirring for 1 hour, polyester resin and isocyanate react to obtain a mixed solution containing polyurethane-modified polyester resin....

Embodiment 2-5

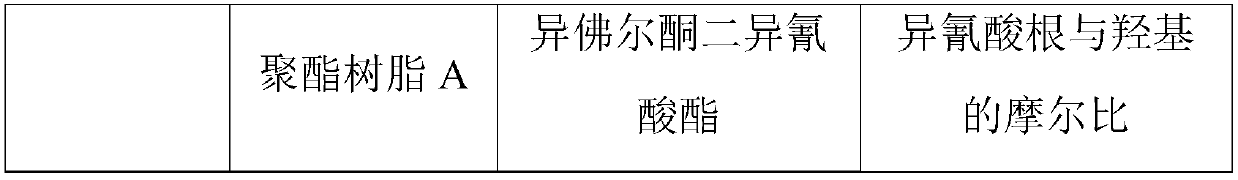

[0119] The difference between Examples 2-5 and Example 1 is that the amount of isophorone diisocyanate used in step (1), that is, the molar ratio of isocyanate to hydroxyl is different, as shown in Table 1.

[0120] The molar ratio of table 1 isocyanate and hydroxyl

[0121]

[0122]

[0123] The particle diameter of the binder resin emulsion for toner obtained in Example 4 was 155 nm. Example 5 After the polyester resin and isocyanate react completely in step (1), the measured isocyanate content is 8%. When deionized water is added in step (3), the system thickens and cannot form an emulsion, and subsequent steps cannot be carried out .

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com