Halogen-free soldering flux for lead-free solder paste

A lead-free solder and flux technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of high halogen content, poor high temperature oxidation resistance, etc., and achieve high activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

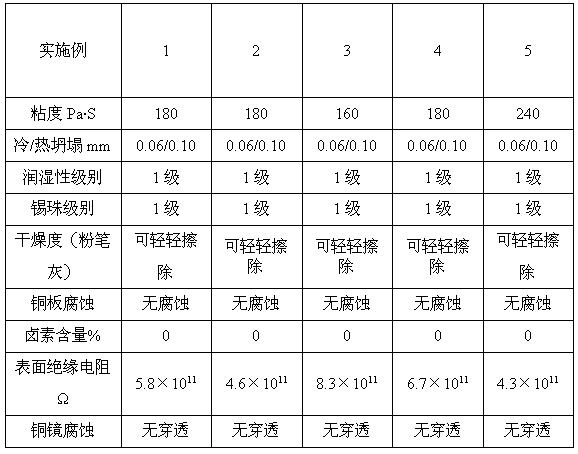

Examples

Embodiment 1

[0021] Add 48g of diethylene glycol monohexyl ether, 40g of hydrogenated rosin, 40g of polymerized rosin and 12g of TX-10 phosphate into the reaction vessel, heat up to 100°C, stir until completely dissolved; cool down to 85°C, add myristic acid 16g, succinic acid 3g, adipic acid 6g, glutaric acid 9g, suberic acid 2g, tolyltriazole 2g and methylimidazole 10g, stir until completely dissolved; cool down to 70°C, add modified hydrogenation Stir 12g of castor oil until completely dissolved, cool to 23°C, and use a three-roll mill to grind the solid particles in the uniformly mixed solution to a fineness of less than 10μm to obtain 196g of halogen-free flux for lead-free solder paste.

[0022]

Embodiment 2

[0024] A halogen-free flux for lead-free solder paste, add 46g of diethylene glycol butyl ether, 30g of hydrogenated rosin, 50g of polymerized rosin and 14g of Surfynol 104E into a reaction vessel, heat up to 108°C, stir until completely dissolved; cool down To 90°C, add 12g of p-tert-butylbenzoic acid, 4g of stearic acid, 4g of succinic acid, 7g of adipic acid, 8g of glutaric acid, 2g of suberic acid, 3g of CHIMASSORB 3030 and 12g of benzimidazole, and stir until completely Dissolve; cool down to 50°C, add 8g of ethylene bisstearic acid amide, stir until completely dissolved, cool to 20°C, use a three-roll mill to grind the solid particles in the mixed solution to a fineness of less than 10 μm, and obtain Halogen-free flux for lead solder paste 194g.

[0025]

Embodiment 3

[0027] A halogen-free flux for lead-free solder paste, 58g of diethylene glycol dibutyl ether, 36g of hydrogenated rosin, 40g of polymerized rosin and 10g of rosin ether surfactant are added to a reaction vessel, heated to 116°C, and stirred to Dissolve completely; cool down to 80°C, add 14g of dipropionic acid, 4g of succinic acid, 5g of adipic acid, 7g of glutaric acid, 2g of suberic acid, 2g of methylbenzotriazole and 12g of methylimidazole, and stir until completely dissolved; cool down to 65°C, add 10g of thixotropic agent 7500, stir until completely dissolved, cool to 22°C, use a three-roll mill to grind the solid particles in the mixed solution to a fineness of less than 10μm to obtain lead-free solder Paste with halogen-free flux 193g.

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com