Epoxy resin composition for semiconductor packaging, and preparation method thereof

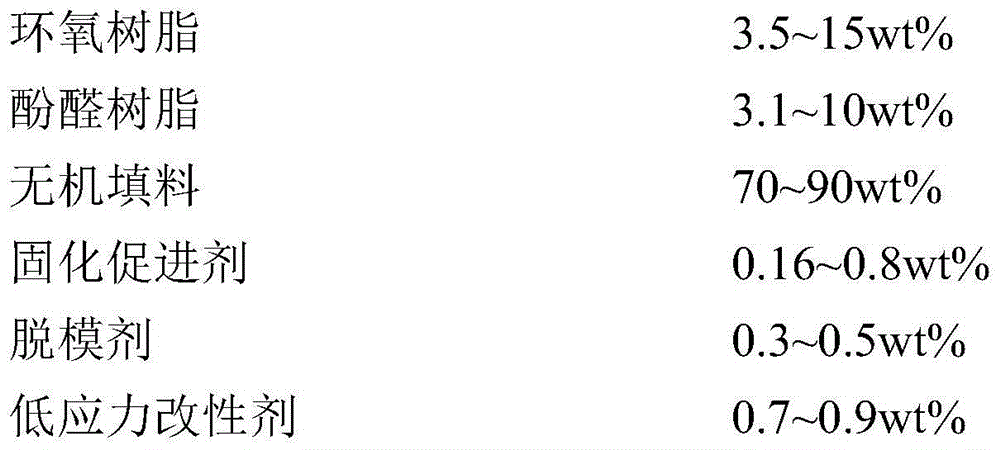

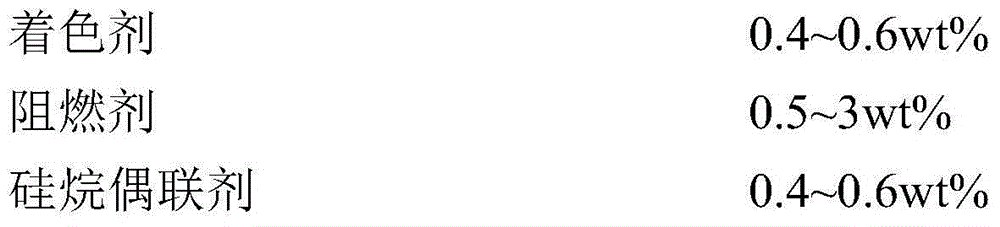

A technology of epoxy resin and novolac epoxy resin, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as poor mold release, air holes in the package, and short mold cleaning cycle, achieving stable performance, Excellent packaging moldability, the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

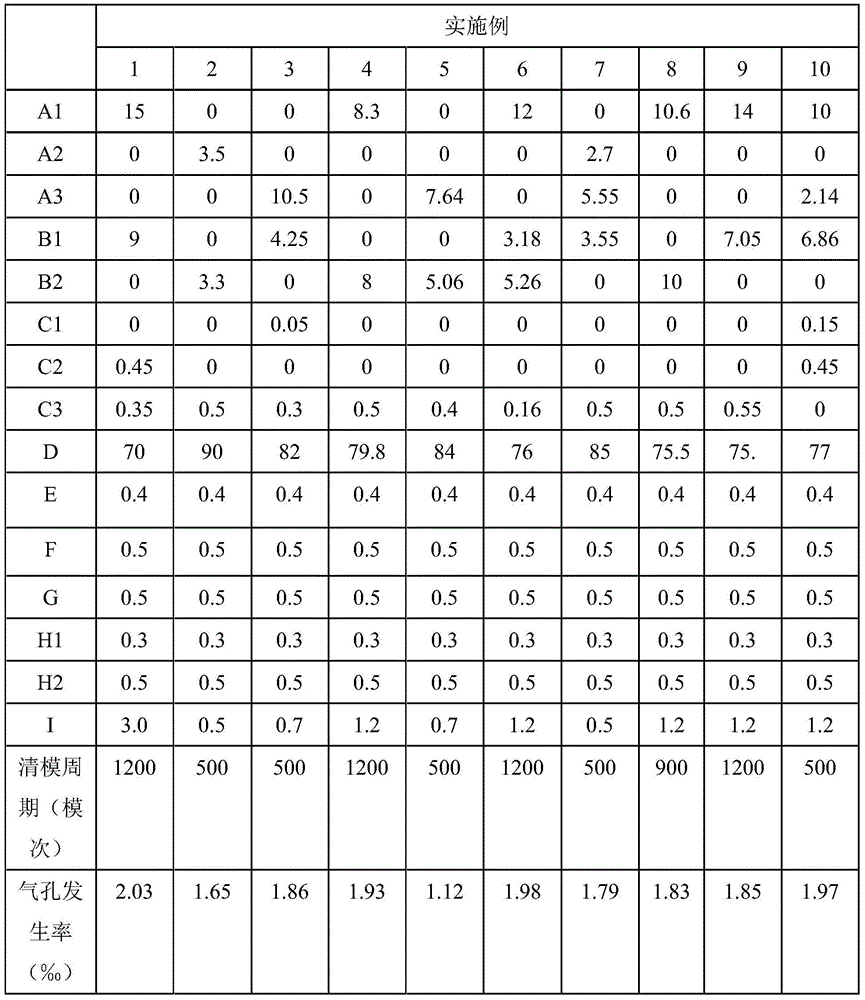

Embodiment 1

[0043] Weigh the above-mentioned various raw materials according to the content ratio in Table 1, and put the weighed B1, C2 and C3, E, H1 and H2, I raw materials into the reaction kettle, and carry out the process at a temperature of 120-180°C. Hot-melt and mix, stir evenly, cool down to room temperature, pulverize and ball-mill the mixture after hot-melt and cool down to room temperature, and pass through a 70-mesh sieve; mix the obtained powder with the weighed A1, D, F and G raw materials Stir uniformly in a high-speed mixer; melt, knead and extrude the uniformly stirred mixture in a twin-screw extruder, cool and pulverize to obtain an epoxy resin composition for semiconductor encapsulation. The obtained epoxy resin composition for semiconductor encapsulation was further molded, and the results of performance evaluation after encapsulating TO-22O with the molded epoxy resin composition are shown in Table 1.

Embodiment 2

[0045] Weigh the above-mentioned various raw materials according to the content ratio in Table 1, and put the weighed B2, C3, E, H1 and H2, I raw materials into the reaction kettle, and heat them at a temperature of 120-180°C Mix, stir evenly, cool down to room temperature, pulverize and ball mill the mixture that has been melted and cooled down to room temperature, and pass through a 70-mesh sieve; mix the obtained powder with weighed A2, D, F and G raw materials at high speed stirring uniformly in a mixer; melting, kneading and extruding the uniformly stirred mixture in a twin-screw extruder, cooling and pulverizing to obtain an epoxy resin composition for semiconductor encapsulation. The obtained epoxy resin composition for semiconductor encapsulation was further molded, and the results of performance evaluation after encapsulating TO-220 with the molded epoxy resin composition are shown in Table 1.

Embodiment 3

[0047] Weigh the above-mentioned various raw materials according to the content ratio in Table 1, and put the weighed B1, C1 and C3, E, H1 and H2, I raw materials into the reaction kettle, and carry out the process at a temperature of 120-180°C. Melt and mix, stir evenly, cool down to room temperature, pulverize and ball mill the mixture that has been melted and cooled to room temperature, and pass through a 70-mesh sieve; mix the obtained powder with the weighed A3, D, F and G raw materials Stir uniformly in a high-speed mixer; melt, knead and extrude the uniformly stirred mixture in a twin-screw extruder, cool and pulverize to obtain an epoxy resin composition for semiconductor encapsulation. The obtained epoxy resin composition for semiconductor encapsulation was further molded, and the results of performance evaluation after encapsulating TO-220 with the molded epoxy resin composition are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com