A kind of preparation method of epoxy resin composition prepared by using mixer

An epoxy resin and composition technology, which is applied in the field of epoxy resin composition preparation, can solve the problems of short mold cleaning cycle, air holes in the package body, and poor mold release properties, so as to improve the yield of finished products and reduce the incidence of air holes. , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

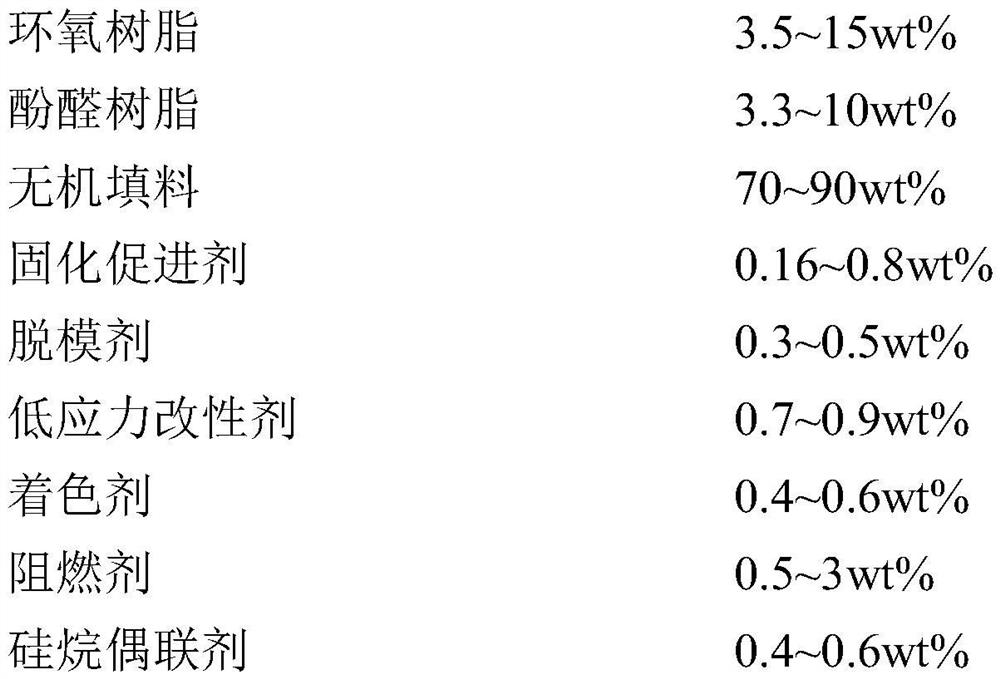

Method used

Image

Examples

Embodiment 1

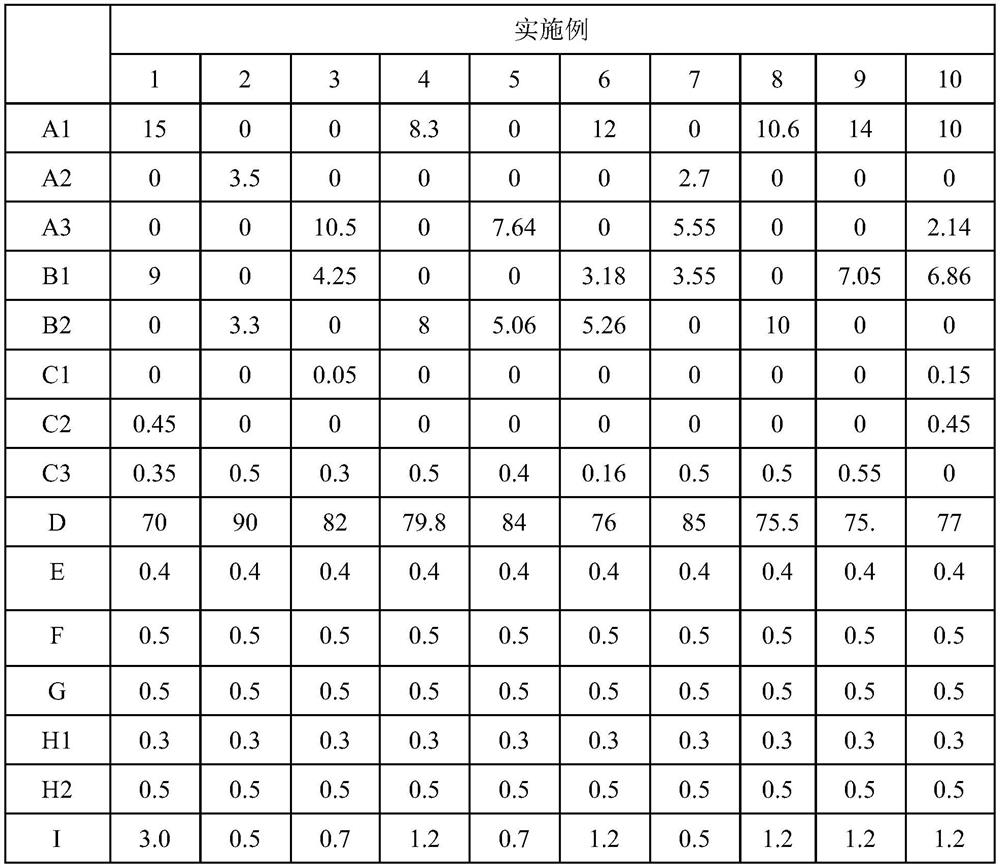

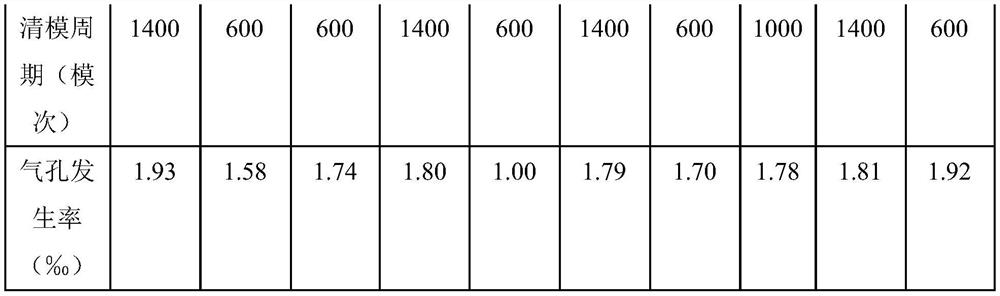

[0044] Weigh the above-mentioned various raw materials according to the content ratio in Table 1, and put the weighed A1, B1, C2 and C3, D, E, F, G, H1 and H2, I raw materials into the reactor, Hot-melt mixing was carried out at a temperature of 100° C., the temperature was lowered to room temperature after stirring evenly, and the hot-melted and lowered-to-room temperature mixture was pulverized to obtain an epoxy resin composition for semiconductor encapsulation. The obtained epoxy resin composition for semiconductor encapsulation was further molded, and the results of performance evaluation after encapsulating TO-220 with the molded epoxy resin composition are shown in Table 1.

Embodiment 2

[0046] Weigh the above-mentioned various raw materials according to the content ratio in Table 1, and put the weighed A2, B2, C3, D, E, F, G, H1 and H2, I raw materials into the reactor, at temperature When the temperature is 100°C, hot-melt mixing is carried out, the temperature is lowered to room temperature after stirring evenly, and the mixture which has been melted and cooled to room temperature is pulverized to obtain an epoxy resin composition for semiconductor encapsulation. The obtained epoxy resin composition for semiconductor encapsulation was further molded, and the performance evaluation results after TO-220 was packaged with the molded epoxy resin composition are shown in Table 1.

Embodiment 3

[0048]Weigh the above-mentioned various raw materials according to the content ratio in Table 1, and put the weighed A3, B1, C1 and C3, D, E, F, G, H1 and H2, I raw materials into the reactor, Hot-melt mixing was carried out at a temperature of 100° C., the temperature was lowered to room temperature after stirring evenly, and the hot-melted and lowered-to-room temperature mixture was pulverized to obtain an epoxy resin composition for semiconductor encapsulation. The obtained epoxy resin composition for semiconductor encapsulation was further molded, and the results of performance evaluation after encapsulating TO-220 with the molded epoxy resin composition are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com