Non-graphite type lubricant for hot die forging of metal and preparation method of non-graphite type lubricant

A non-graphite and lubricant technology, which is applied in the field of lubricants for metal hot die forging and its preparation, can solve the problems of inconvenient transportation and storage, complex manufacturing process, and large mold wear, and achieve simple preparation process, good suspension performance, and easy cleaning easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

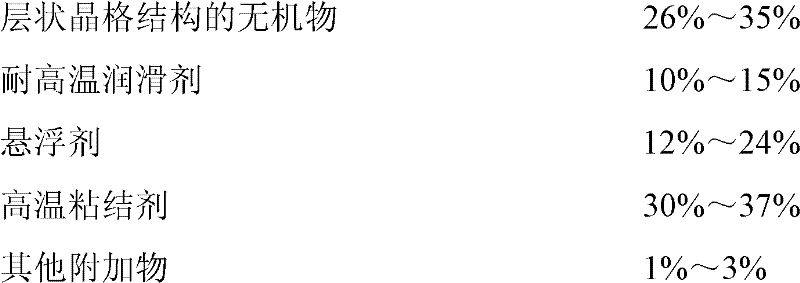

[0024] In the non-graphite lubricating coating for metal hot die forging of this embodiment, the weight percentage ratio of the constituent raw materials is as follows:

[0025]

[0026] Among them, water is the carrier.

[0027] The friction coefficient of the lubricating paint at different temperatures:

[0028] Ring temperature 750℃ 800℃ 850℃ 900℃

[0029] Coefficient of friction 0.067 0.067 0.062 0.063

Embodiment 2

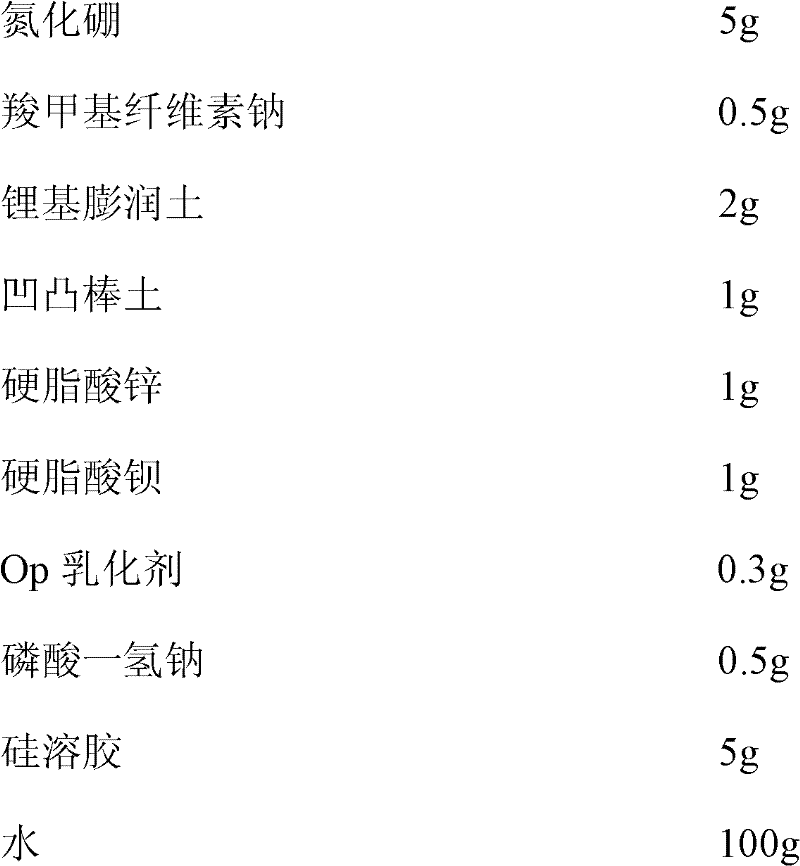

[0031] The non-graphite lubricating paint for metal hot die forging in this embodiment, the weight percentage ratio of the constituent raw materials is as follows:

[0032]

[0033] Among them, water is the carrier.

[0034] The friction coefficient of the lubricating paint at different temperatures:

[0035] Ring temperature 750℃ 800℃ 850℃ 900℃

[0036] Coefficient of friction 0.066 0.067 0.063 0.064

Embodiment 3

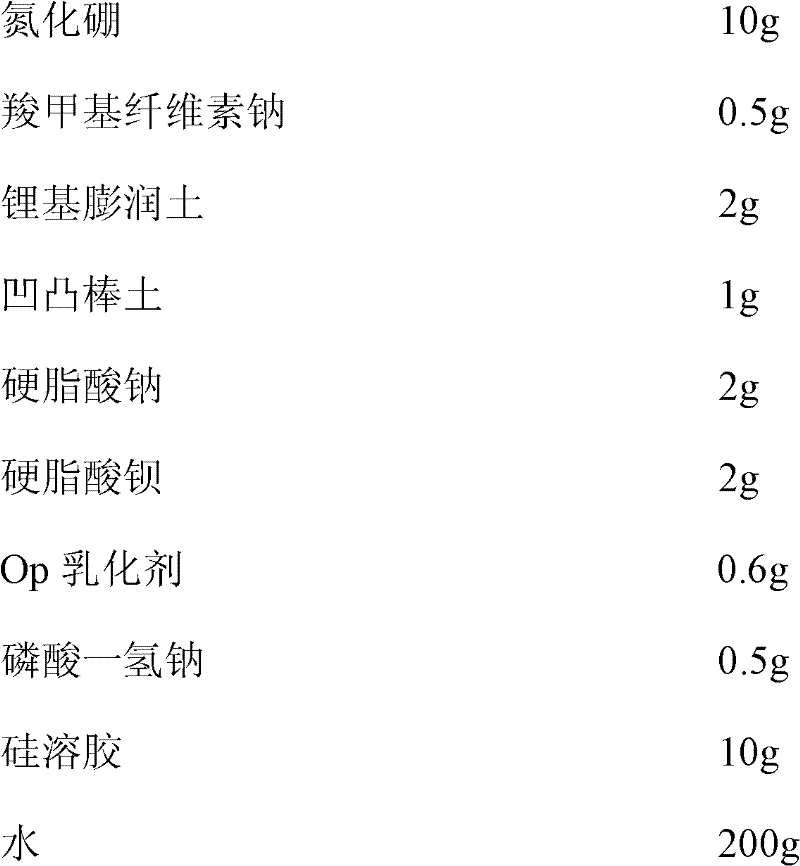

[0038] The non-graphite lubricating paint for metal hot die forging in this embodiment, the weight percentage ratio of the constituent raw materials is as follows:

[0039]

[0040]

[0041] Among them, water is the carrier.

[0042] The friction coefficient of the lubricating paint at different temperatures:

[0043] Ring temperature 750℃ 800℃ 850℃ 900℃

[0044] Coefficient of friction 0.065 0.067 0.061 0.063

[0045] In the above embodiments, water is used as the carrier, and its mass is more than 5 times the total mass of other additives. Boron nitride (BN) is an inorganic substance with a layered lattice structure. It can also consider other inorganic substances with a layered lattice structure, such as talc or mica. Generally, inorganic substances with a layered lattice structure are required The number of meshes is above 320.

[0046] The stearate in the embodiment is a typical high temperature resistant lubricant, such as sodium stearate, calcium stearate, barium stearate, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com