Halogen-free flame retardant thermoplastic polyamide composition

A technology of thermoplastic polyamide and composition, which is applied in the field of polyamide composition, and can solve the problems of low fluidity, surface blooming, poor flame retardant effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

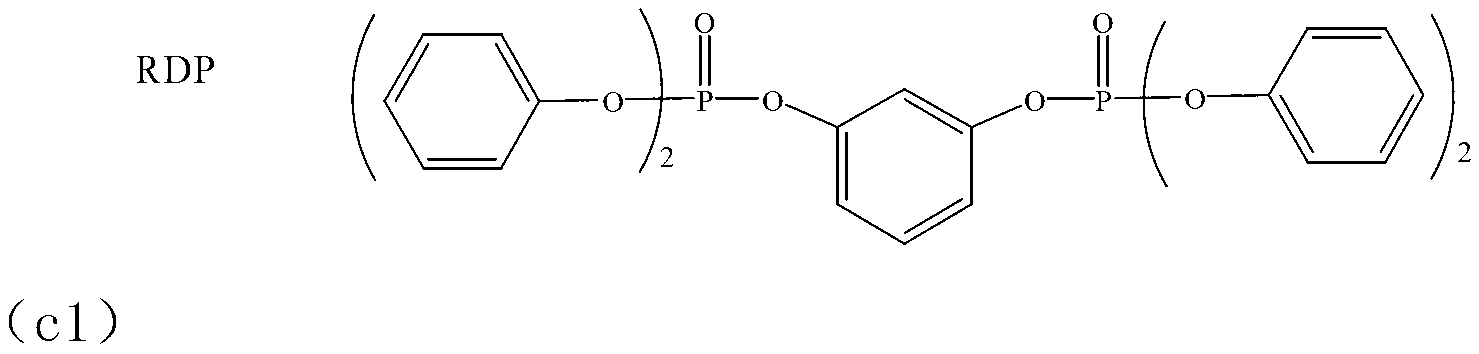

[0085] Weigh the thermoplastic polyamide resin EPR27 and polyester modified polydimethylsiloxane respectively according to the ratio shown in Table 2 H-Si6440P, organic phosphinate OP1240 and antioxidant IR1098 are pre-mixed evenly with a high-speed mixing and stirring device at room temperature, and the mixture is quantitatively transported from the main hopper to the main feeding port of the co-rotating twin-screw extruder, BDP And RDP is quantitatively transported to the liquid feeding port through the liquid metering pump, and the glass fiber ECS-301NF is quantitatively transported to the twin-screw through the side feeder for melt extrusion. The extrusion temperature is 265 ° C and the speed is 200 rpm. After cooling in the water tank, use a granulator to cut into granules with a length of about 3mm. After the granules are vacuum-dried at 120°C for 6 hours, they are injected into standard splines with an injection molding machine, and the UL94, flow properties and surface...

Embodiment 2

[0087] Weigh thermoplastic polyamide resin EPR27, polyamide resin C206F, olefin modified polysiloxane masterbatch respectively according to the ratio shown in Table 2 Antiscratch200, polyester modified polydimethylsiloxane H-Si6440P, phosphate ester PX200, organic phosphinate OP950, talc powder 8860 and antioxidant IR1098 are pre-mixed evenly with a high-speed mixing and stirring device at room temperature, and the mixture is quantitatively transported from the main hopper to the co-rotating twin-screw extruder. In the main feeding port of the machine, the glass fiber ECS-301NF is quantitatively conveyed to the twin-screw by side feeding, and then melted and extruded. The extrusion temperature is 265°C and the rotation speed is 200rpm. Cut into granules with a length of about 3mm. After the granules were vacuum-dried at 120°C for 6 hours, they were injection molded into standard strips with an injection molding machine, and the UL94, flow properties and surface quality were ...

Embodiment 3

[0089] Weigh thermoplastic polyamide resin EPR27 and olefin modified polysiloxane masterbatch respectively according to the ratio shown in Table 2 Antiscratch200, polyester modified polydimethylsiloxane H-Si6440P, phosphate ester PX200, organic phosphinate OP950, talc powder 8860 and antioxidant IR1098 are pre-mixed evenly with a high-speed mixing and stirring device at room temperature, and the mixture is quantitatively transported from the main hopper to the co-rotating twin-screw extruder. In the main feeding port of the machine, the glass fiber ECS-301NF is quantitatively conveyed to the twin-screw by side feeding, and then melted and extruded. The extrusion temperature is 265°C and the rotation speed is 200rpm. Cut into granules with a length of about 3mm. After the granules were vacuum-dried at 120°C for 6 hours, they were injection molded into standard strips with an injection molding machine, and the UL94, flow properties and surface quality were measured. The results...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com