Polysilsesquioxane (POSS) modified vegetable oil emulsion mold release agent and preparation method thereof

A technology for modifying vegetable oil and vegetable oil, which is applied in the petroleum industry, lubricating compositions, etc., which can solve the problems of mineral oil being lost in the environment, general release effect, and environmental pollution, and achieve excellent release performance and excellent release effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, the POSS modified vegetable oil emulsion release agent is constituted by mass percentage as follows:

[0024] Vegetable oil 10%, POSS-vegetable oil polymer 0.1%, emulsifier 2%, defoamer 0.2%, stabilizer 0.1%, and the balance is deionized water.

[0025] The preparation method of the POSS modified vegetable oil emulsion release agent of the present invention includes the synthesis of epoxy vegetable oil, the synthesis of vegetable oleyl alcohol, the synthesis of POSS-vegetable oil polymer, and the preparation of POSS modified vegetable oil emulsion, which are specifically operated as follows:

[0026] The synthesis of epoxy vegetable oil is to combine 20g rapeseed oil, 15g acetic acid and catalyst 732 # 1.2g of strong acid cationic resin was mixed and then added dropwise hydrogen peroxide, controlled dropwise addition for 2h, after the dropwise addition, kept at 60°C for 4 hours, washed the product to neutrality, and dried to obtain epoxy vegetable oil;

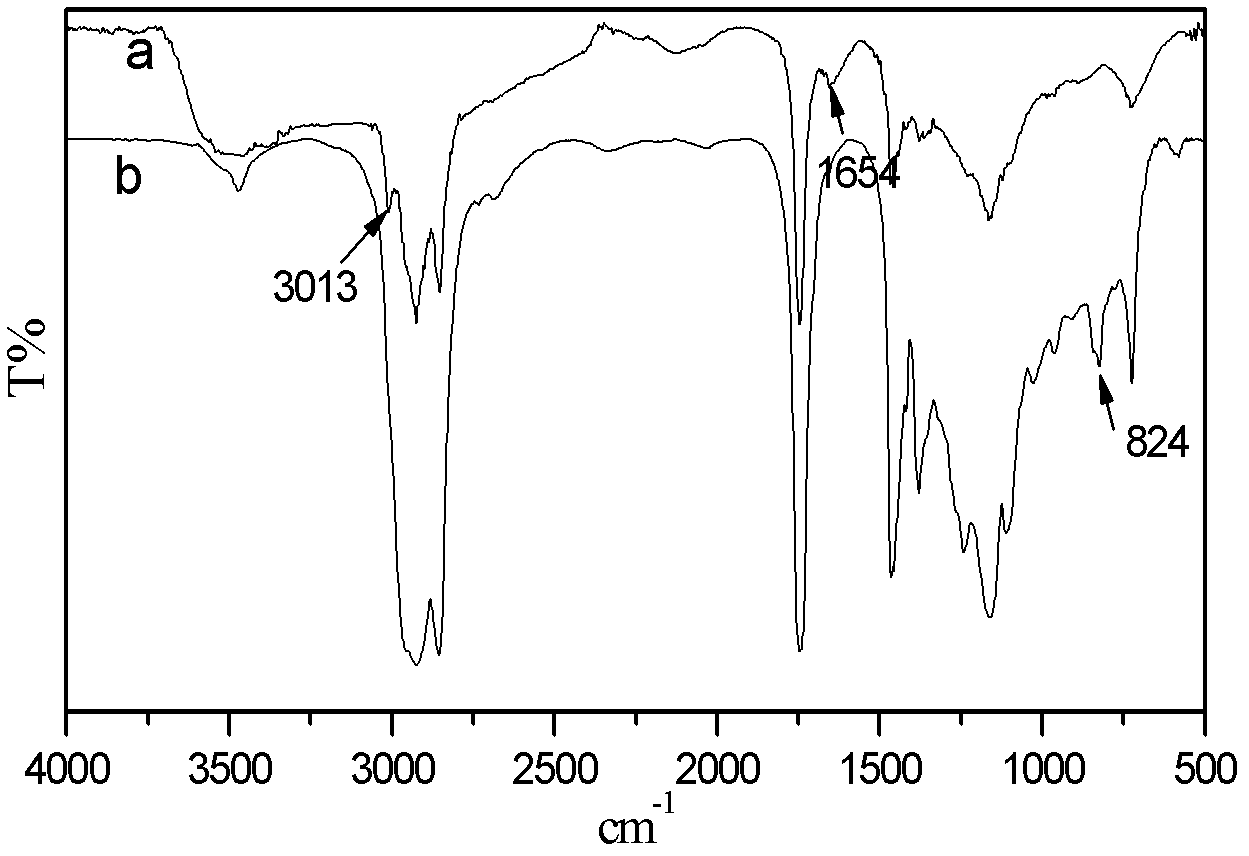

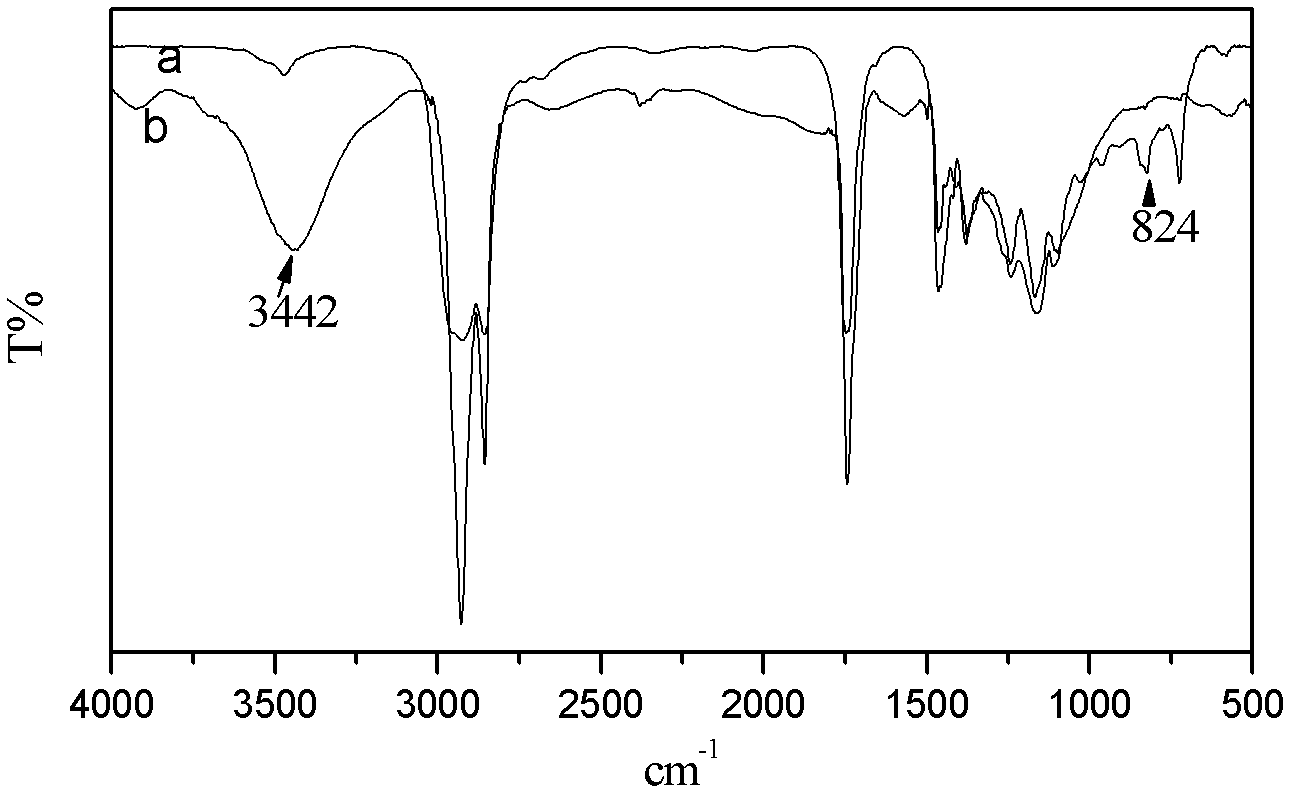

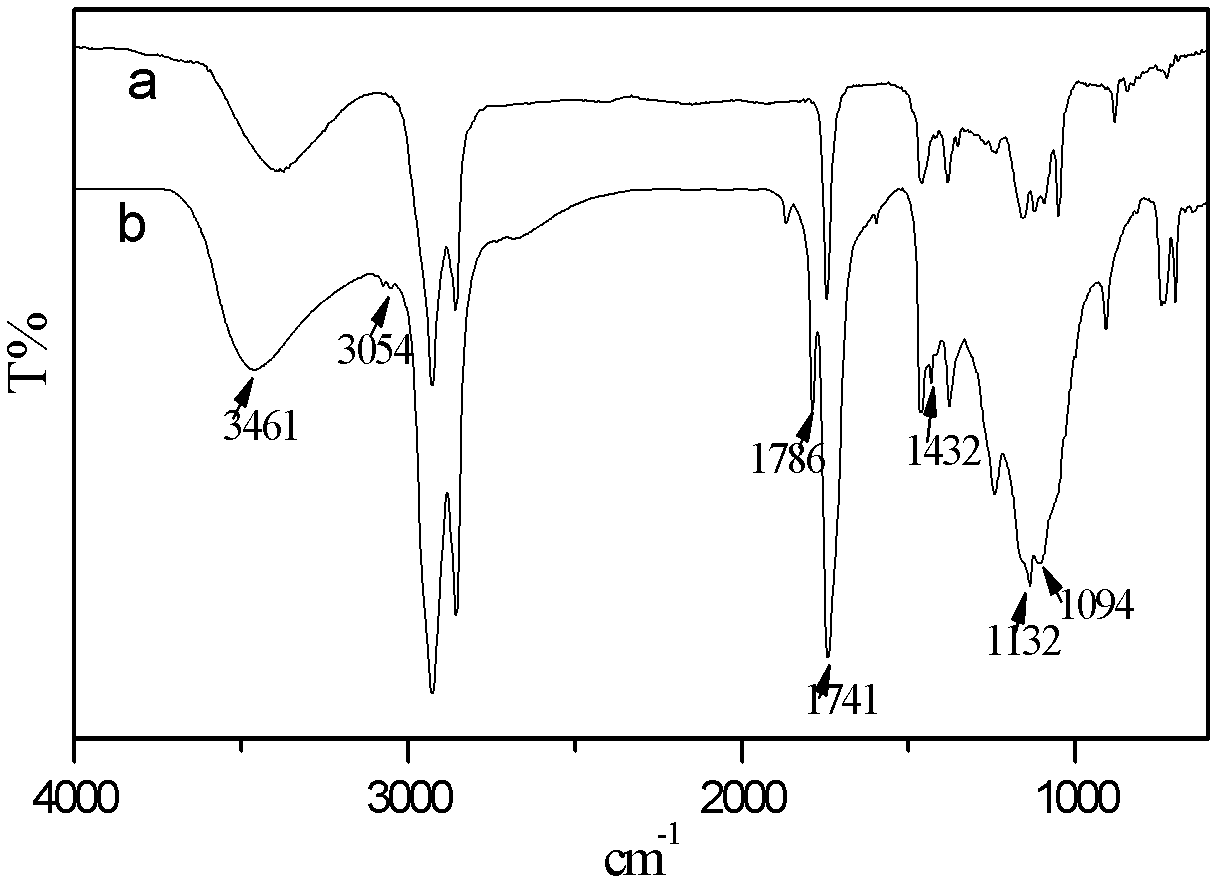

[002...

Embodiment 2

[0035] In this embodiment, the POSS modified vegetable oil emulsion release agent is constituted by mass percentage as follows:

[0036] Vegetable oil 13%, POSS-vegetable oil polymer 0.3%, emulsifier 2%, defoamer 0.2%, stabilizer 0.1%, and the balance is deionized water.

[0037] The preparation method of the POSS modified vegetable oil emulsion release agent of the present invention includes the synthesis of epoxy vegetable oil, the synthesis of vegetable oleyl alcohol, the synthesis of POSS-vegetable oil polymer, and the preparation of POSS modified vegetable oil emulsion, which are specifically operated as follows:

[0038] The synthesis of epoxy vegetable oil is to combine 20g rapeseed oil, 15g acetic acid and catalyst 732 # 1.2g of strong acid cationic resin was mixed and then added dropwise hydrogen peroxide, controlled dropwise addition for 2h, after the dropwise addition, kept at 60°C for 4 hours, washed the product to neutrality, and dried to obtain epoxy vegetable oil;

[003...

Embodiment 3

[0047] In this embodiment, the POSS modified vegetable oil emulsion release agent is constituted by mass percentage as follows:

[0048] Vegetable oil 16%, POSS-vegetable oil polymer 0.5%, emulsifier 2%, defoamer 0.2%, stabilizer 0.1%, and the balance is deionized water.

[0049] The preparation method of the POSS modified vegetable oil emulsion release agent of the present invention includes the synthesis of epoxy vegetable oil, the synthesis of vegetable oleyl alcohol, the synthesis of POSS-vegetable oil polymer, and the preparation of POSS modified vegetable oil emulsion, which are specifically operated as follows:

[0050] The synthesis of epoxy vegetable oil is to combine 20g rapeseed oil, 15g acetic acid and catalyst 732 # 1.2g of strong acid cationic resin was mixed and then added dropwise hydrogen peroxide, controlled dropwise addition for 2h, after the dropwise addition, kept at 60°C for 4 hours, washed the product to neutrality, and dried to obtain epoxy vegetable oil;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com