Fluorine-free aluminum zinc alloy water base release agent and preparation method thereof

A zinc alloy and release agent technology, applied in metal processing equipment, manufacturing tools, casting molding equipment, etc., can solve the problems of low dilution, large price fluctuations, uneven quality, etc., and achieve uniform and uneven film formation. Accumulation, reducing thermal and mechanical shock effects, and improving mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Weigh raw materials according to the following composition, and prepare 100kg of the fluorine-free aluminum-zinc alloy water-based release agent of the present invention:

[0042]

[0043] The preparation method is as follows:

[0044] Stir 3kg of Tween 80, 1.5kg of sodium oleate, 0.5kg of sodium polyacrylate, 0.5kg of Pluronic F127 and 0.3kg of stearyl alcohol in 10kg of water at room temperature, then add 20kg of polyethylene wax 2500 and 10kg of dimethylformaldehyde Base silicone oil, 1kg hydroxy silicone oil and 52.1kg water, after stirring and mixing evenly, the temperature was raised to 75°C, after constant temperature stirring for 1.5h, 0.1kg of 2-methyl-4-isothiazolin-3-one was added, and the mixture was prepared after stirring evenly. The aluminum-zinc alloy water-based release agent described in the invention.

Embodiment 2

[0046] Weigh raw materials according to the following composition, and prepare 100kg of the fluorine-free aluminum-zinc alloy water-based release agent of the present invention:

[0047]

[0048] The preparation method is the same as in Example 1, the stirring temperature is 60° C., and the stirring time is 3 hours.

Embodiment 3

[0050] Weigh raw materials according to the following composition, and prepare 100kg of the fluorine-free aluminum-zinc alloy water-based release agent of the present invention:

[0051]

[0052] The preparation method is the same as in Example 1, the stirring temperature is 80° C., and the stirring time is 1 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

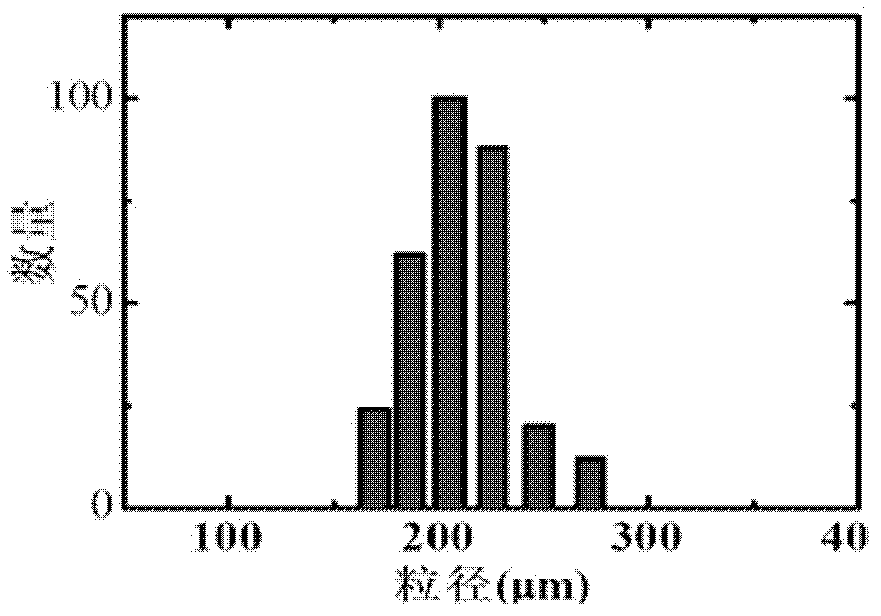

| Effective particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com