Time-delay drawing protection technical apparatus for injection mold slide block thimble and inclined jacking block thimble

A technology of injection mold and technical device, which is applied in the field of delayed extraction protection technical device for injection mold slider thimble and inclined top block thimble, which can solve problems such as unacceptable customer acceptance, unsatisfactory demoulding effect, and complex mold structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

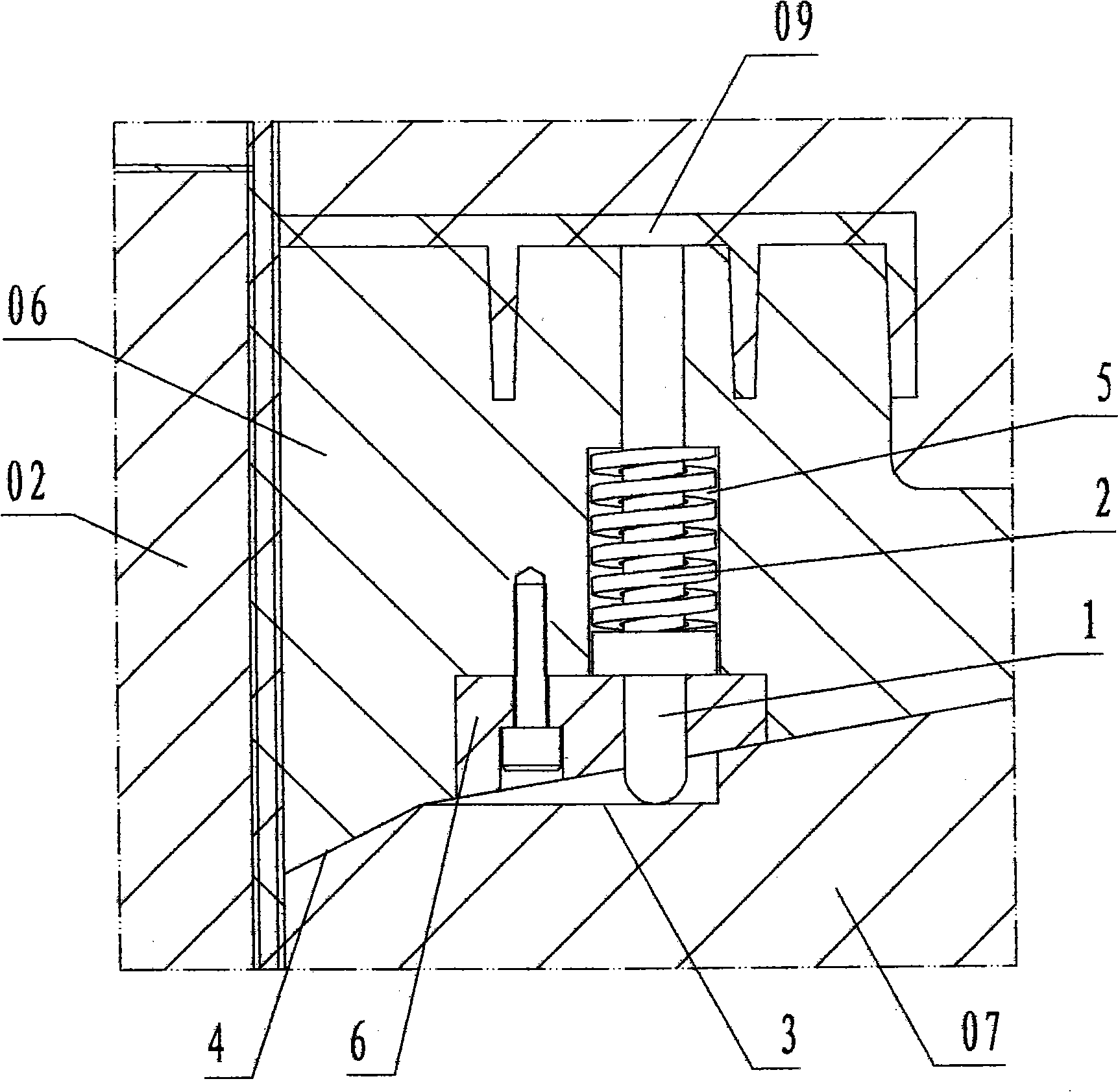

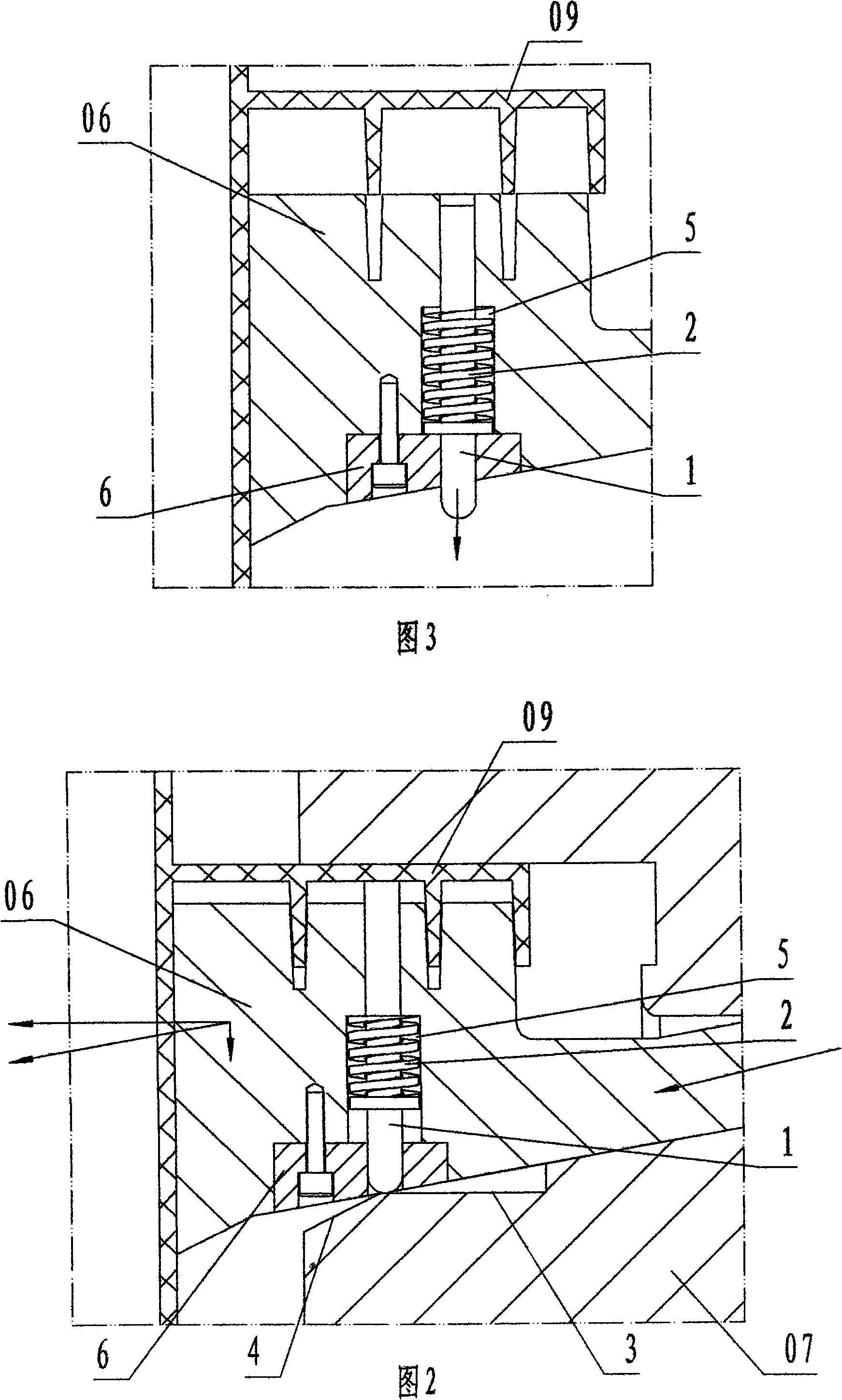

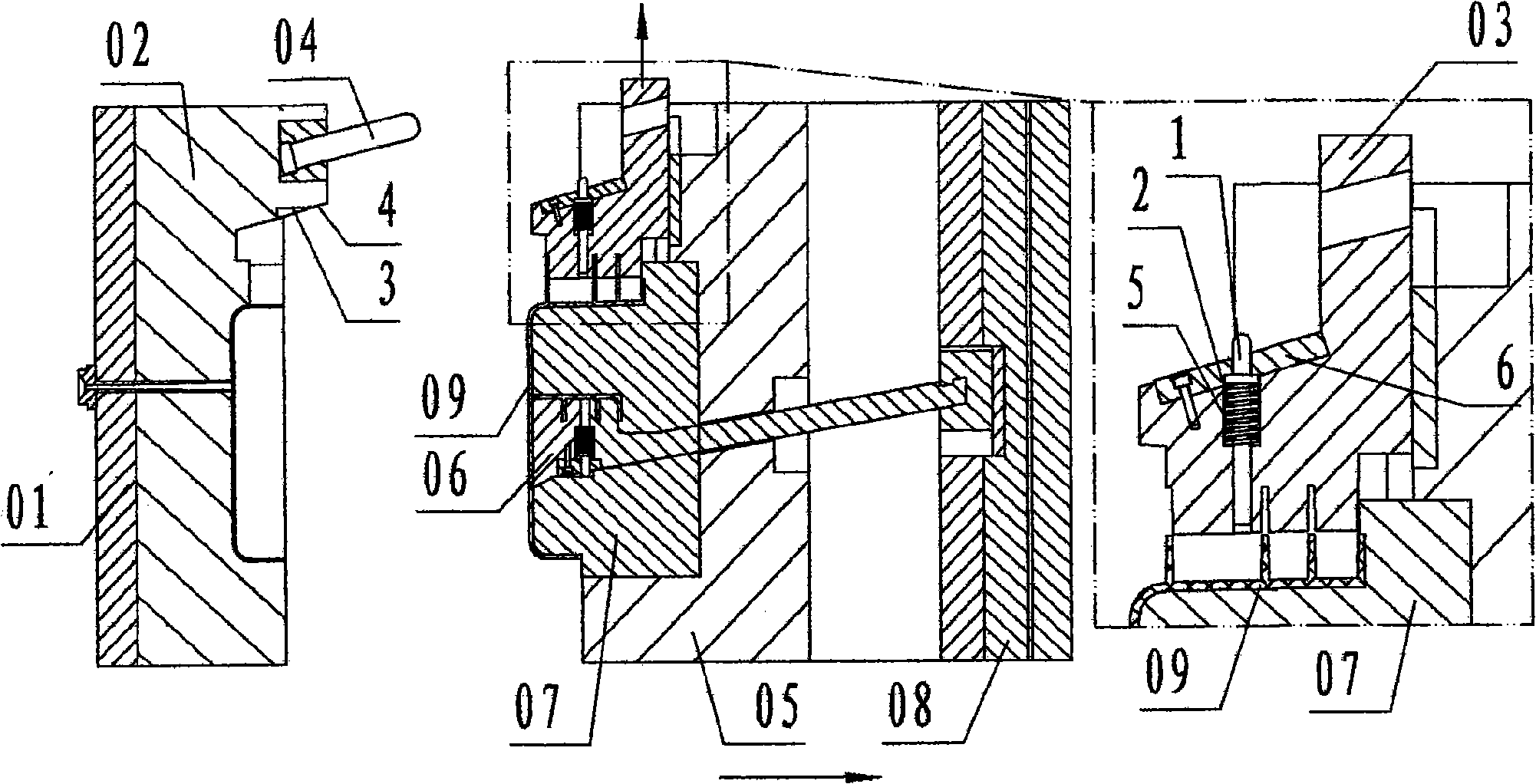

[0021] refer to figure 1 , Fig. 2, Fig. 3, a kind of injection mold slide block thimble and slanted ejector block thimble delay drawing protection technical device of the present invention comprises ejector pin 1, spring 2, time-delay straight face 3, reset slope 4, stopper 5, wherein: The thimble 1 is made of wear-resistant metal, one end face is a spherical end, the other end end is a curved end made according to the curved shape of a plastic product, and a retaining ring step is provided near the spherical end The cylindrical parts; the spring 2 is a cylindrical compression spring; the delay straight face 3 is located on the cavity plate 02 or the movable mold insert 07, parallel to the opening and closing direction of the fixed and movable molds, A section of straight slideway for the spherical end of ejector pin 1 to slide; the slope 4 is provided on the cavity plate 02 or the movable mold insert 07, one end intersects with the delay straight surface 3 and the other end c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com