Patents

Literature

32results about How to "Mitigate performance degradation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

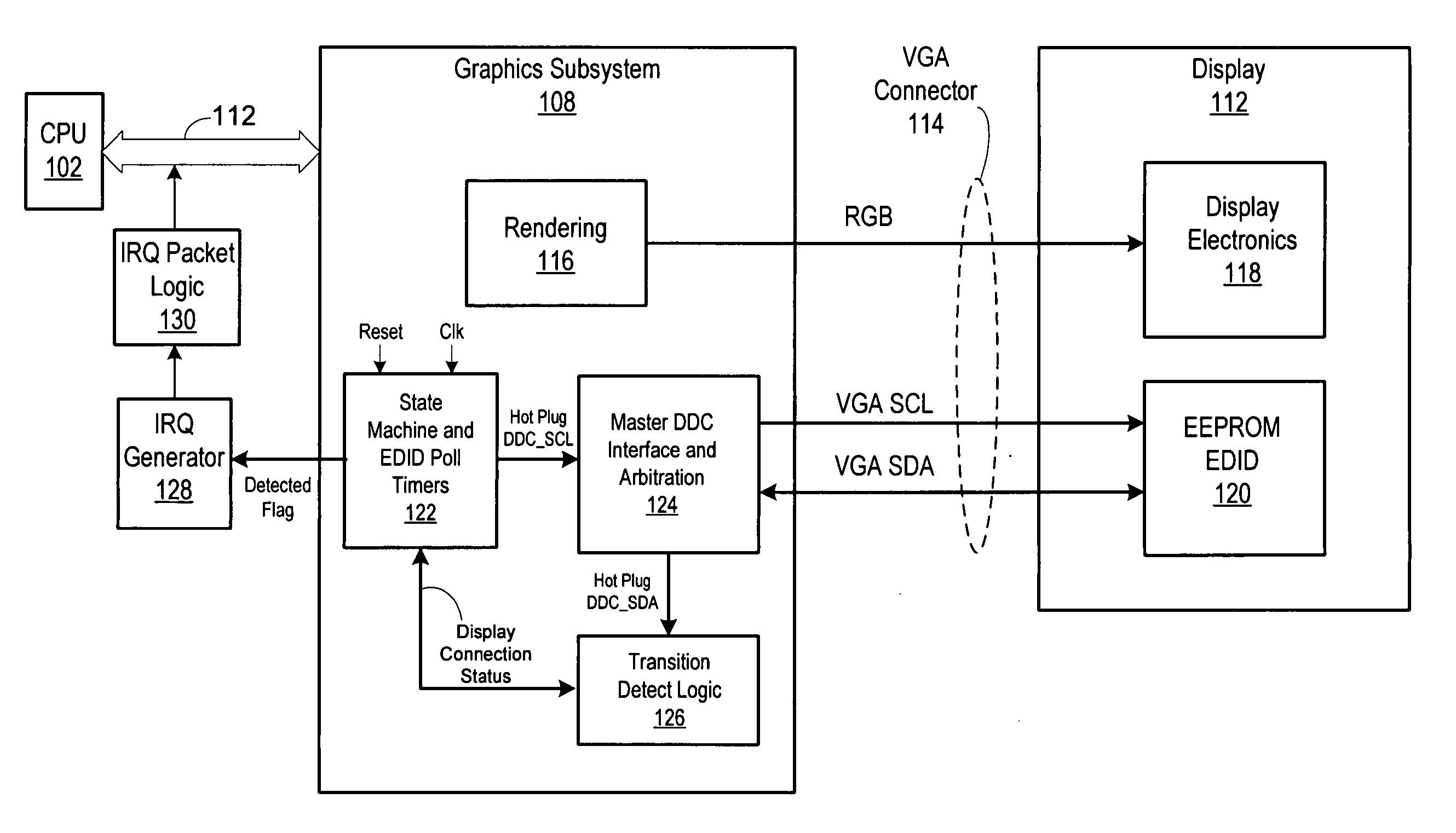

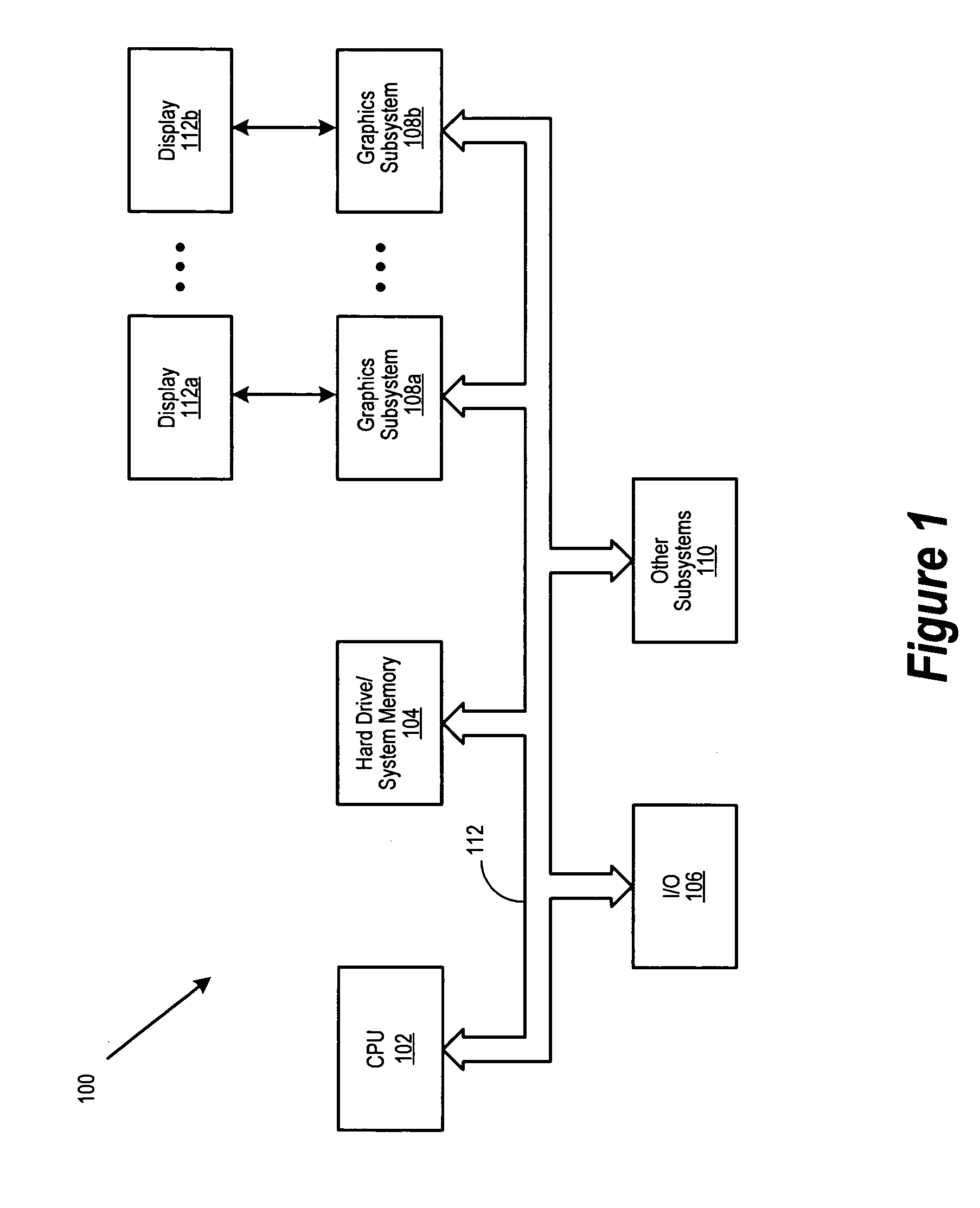

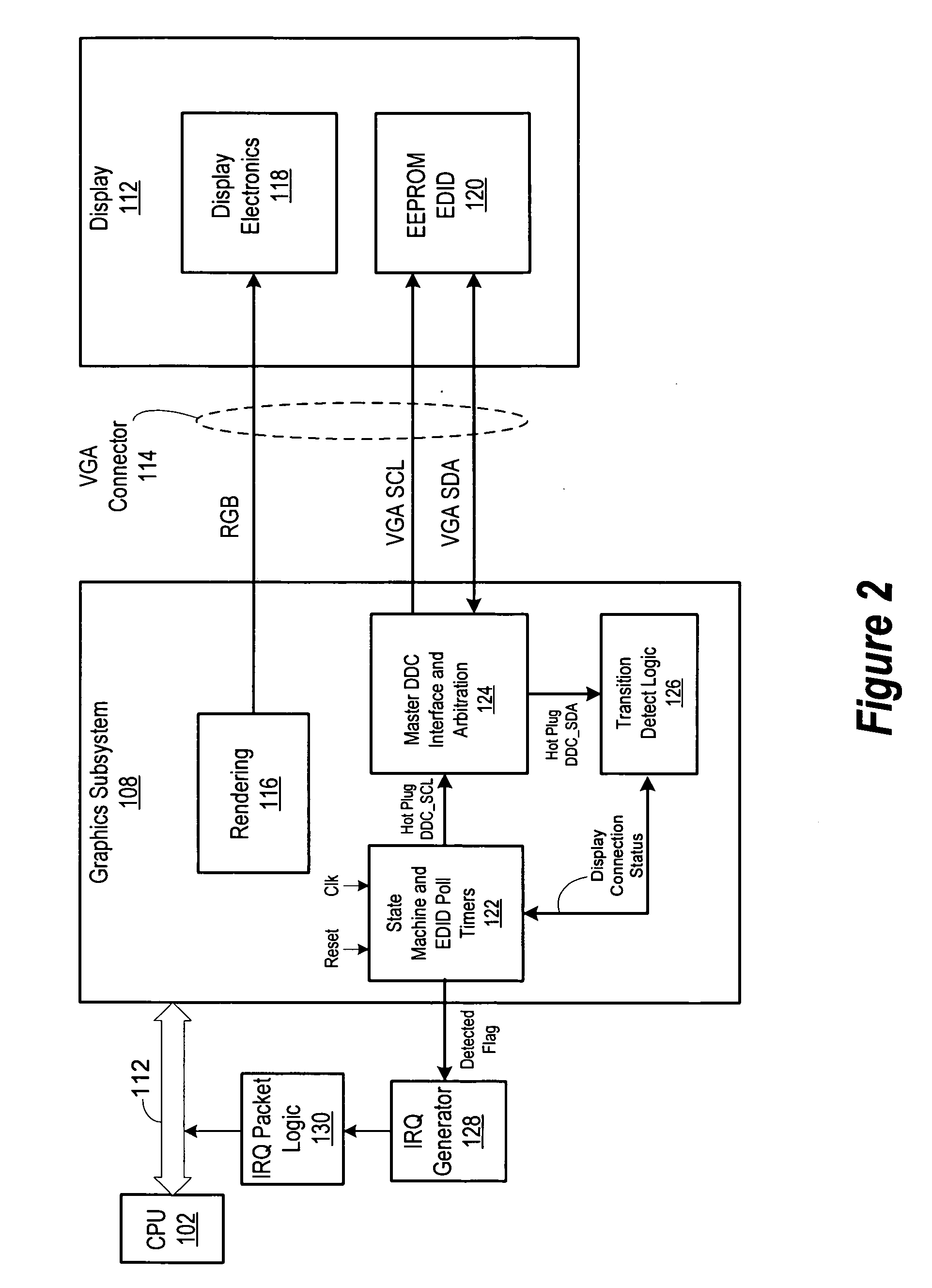

Robust hot plug detection for analog displays using EDID

InactiveUS20070076005A1Relieving performance degradationAutomatic detectionElectric digital data processingInformation processingData signal

The present invention provides a method and apparatus for automatically detecting whether an external monitor is connected to a video port of an information handling system. In various embodiments of the invention, detection of the display is accomplished by periodic polling to detect the presence of an Extended Display Identification Data (EDID) signal as an indication of whether a display has been plugged in or removed. In embodiments of the invention, hardware polling is implemented to provide the interrupt-driven mechanism, thereby relieving software of the performance degradation associated with polling the video port at very short time intervals.

Owner:DELL PROD LP

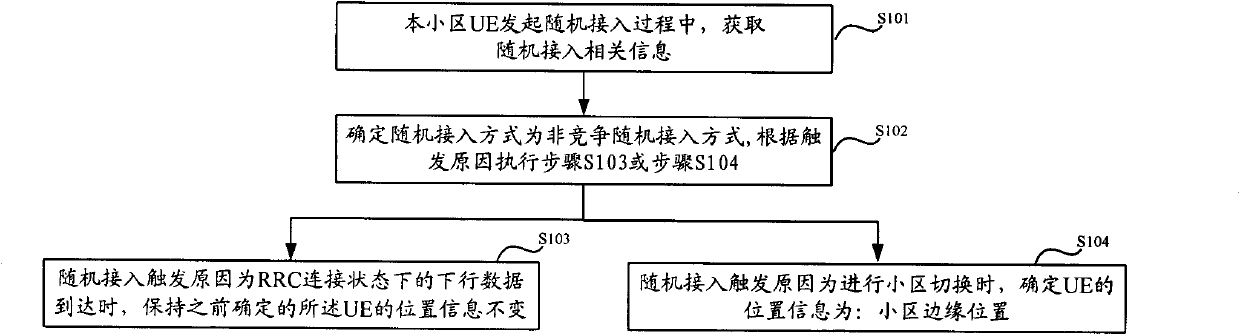

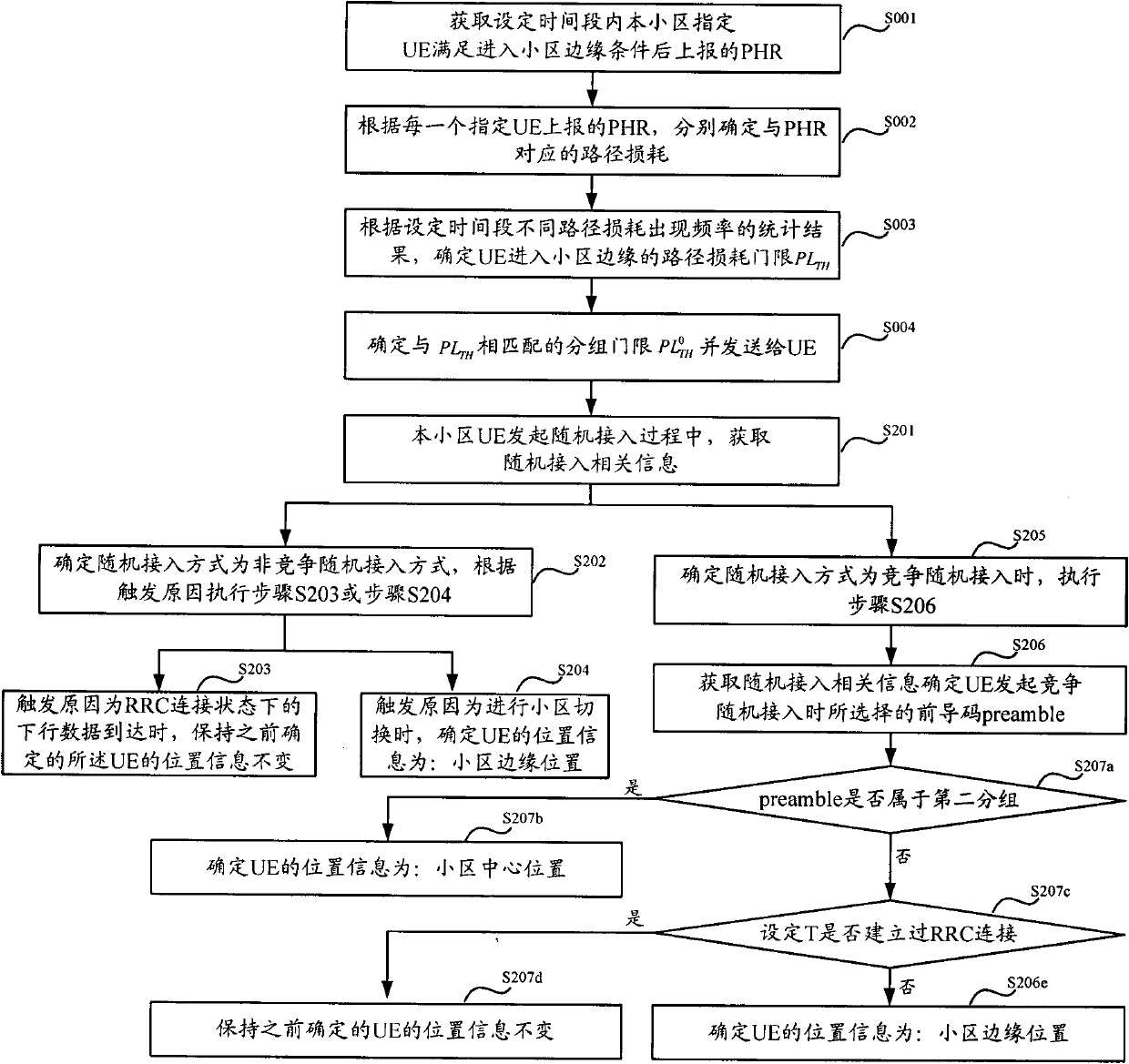

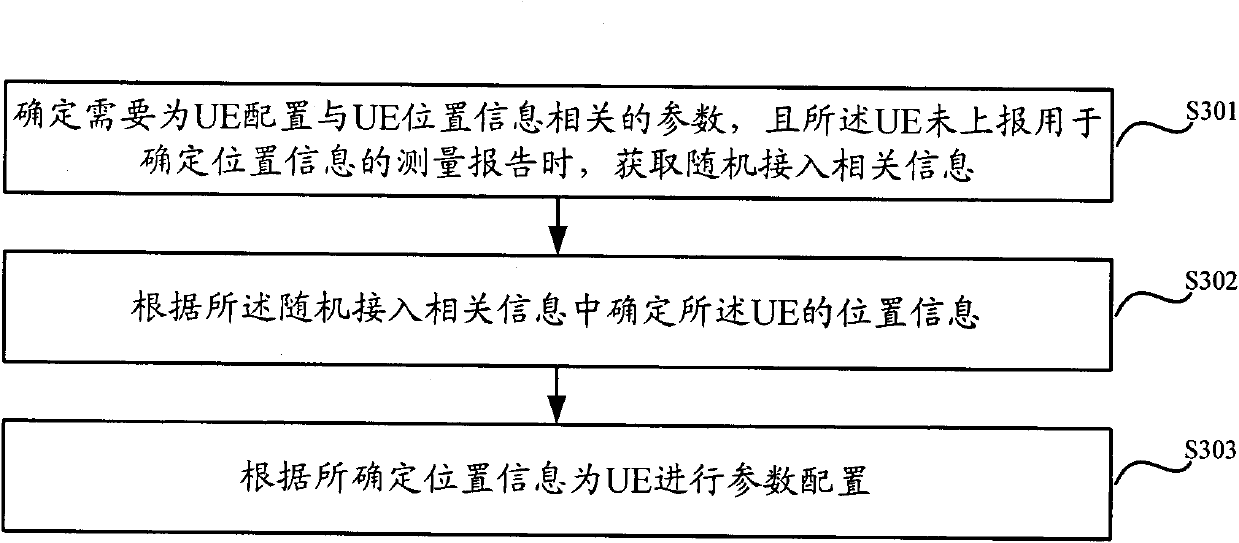

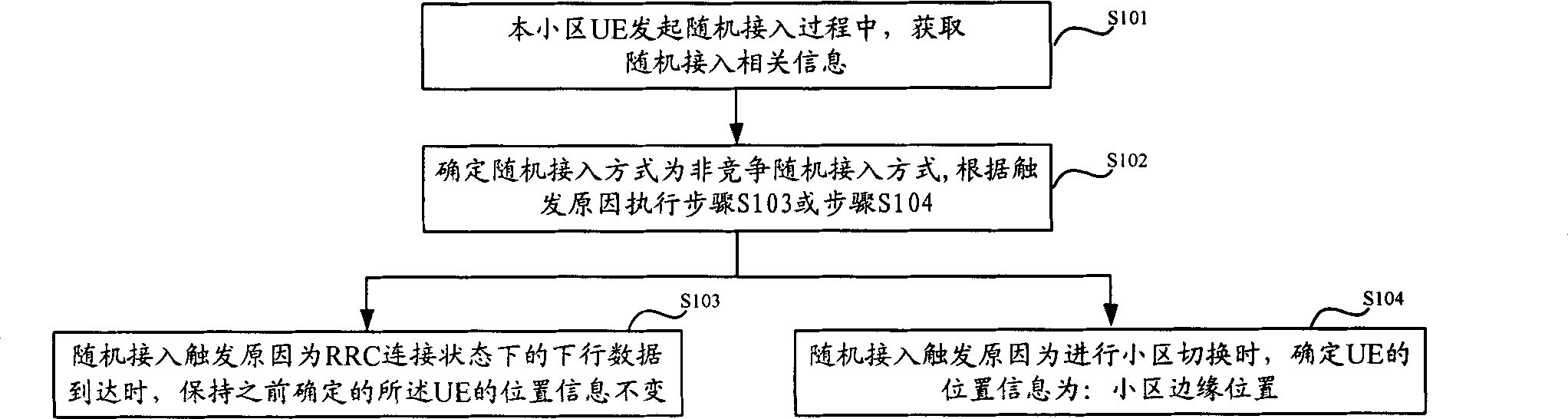

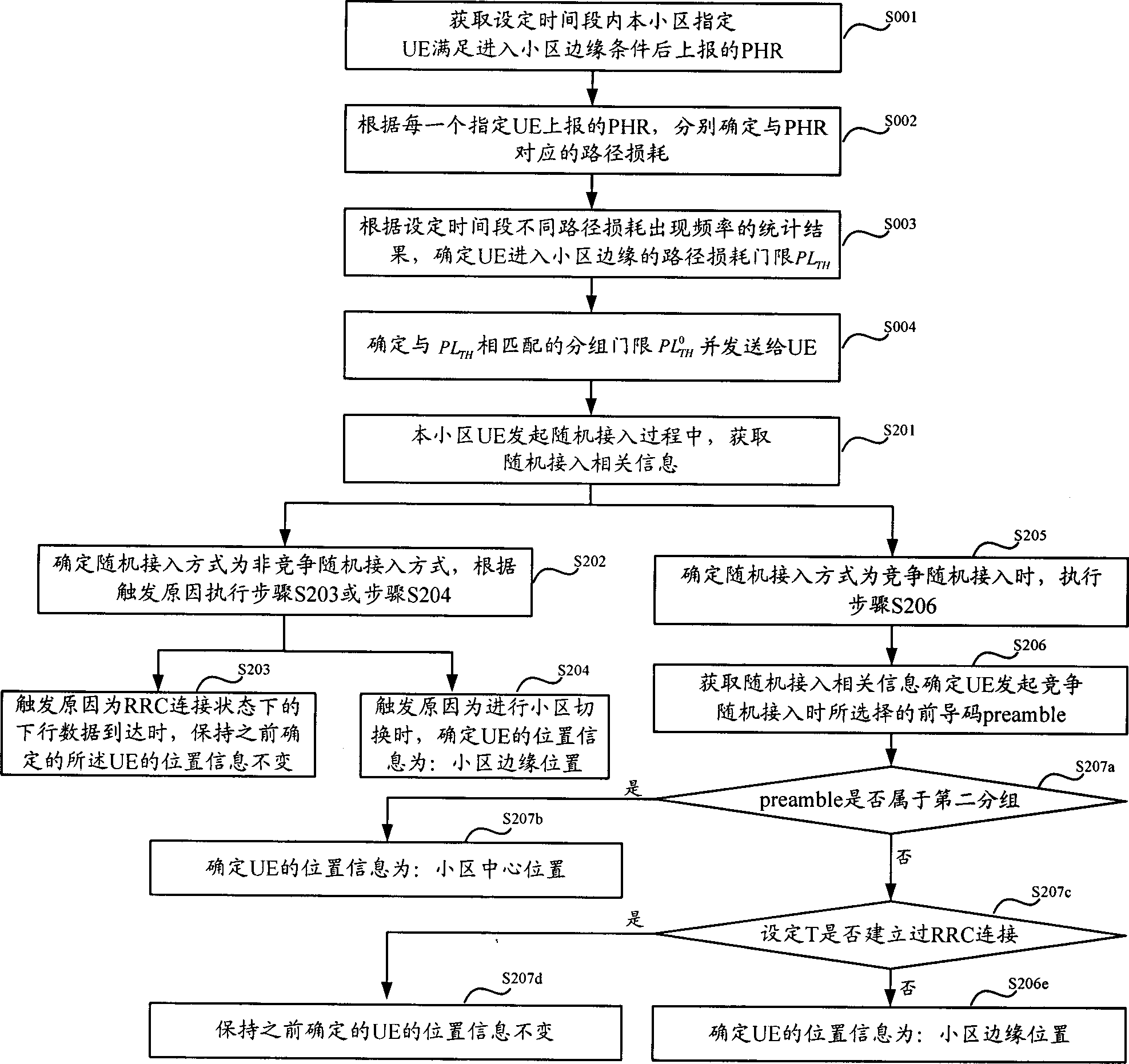

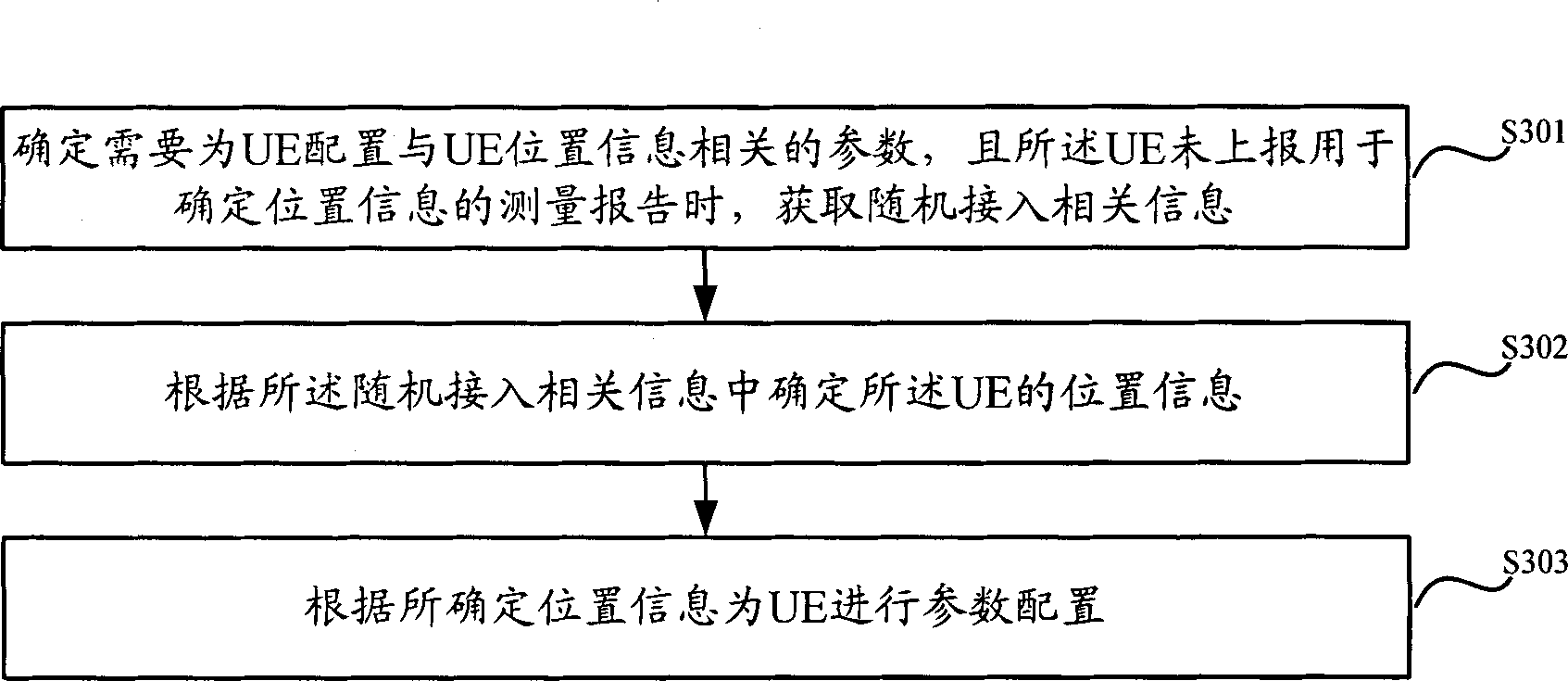

Method for determining location information of user terminal UE and network side equipment

ActiveCN102264095ASolve the unknowableGuaranteed service qualityWireless communicationTelecommunicationsAir interface

The present invention relates to the field of communications. In order to solve the problem that the determination of UE location information depends on the establishment of an RRC connection, a method for determining UE location information and configuring parameters for the UE is provided, including: determining the path loss threshold PLTH for the UE to enter the cell edge; determining The grouping threshold matched with the PLTH is sent to each UE in the cell, which is used as a path loss comparison reference when the UE initiates a competitive random access. The UE determines to select a preamble in a different group when initiating a competitive random access according to the comparison result ; During the random access process initiated by the UE, obtain the random access method selected by the UE; when the selected random access method is contention random access, obtain the preamble selected during random access; according to the selected The group to which the preamble belongs determines the location information of the UE. The invention can reduce the overhead of air interface signaling caused by blindly configuring parameters when the RRC is not established, and further improves the utilization rate of system resources.

Owner:DATANG MOBILE COMM EQUIP CO LTD

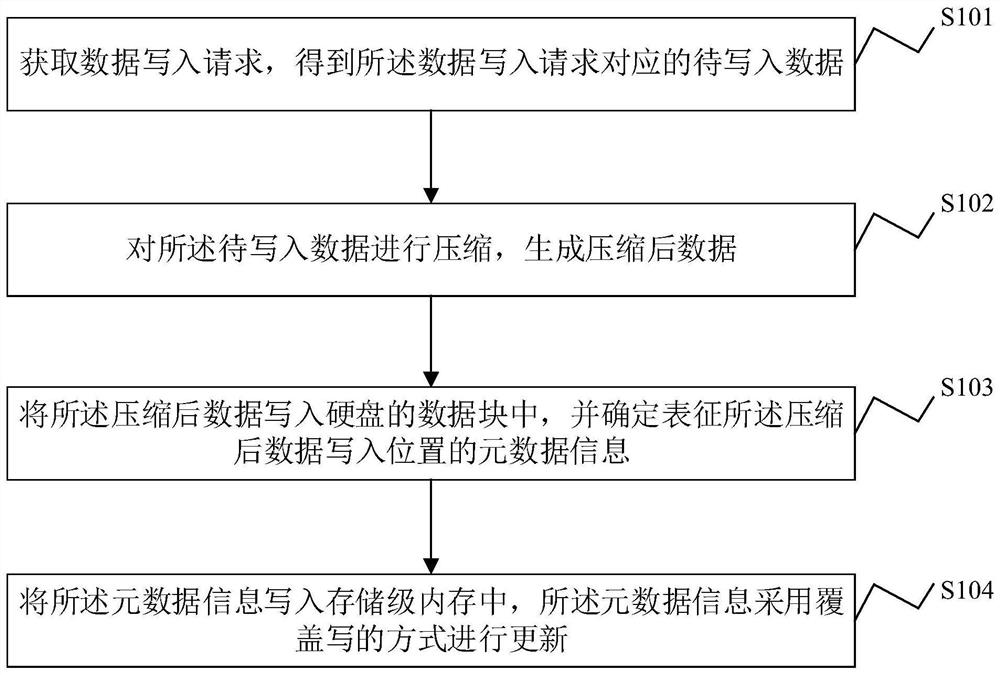

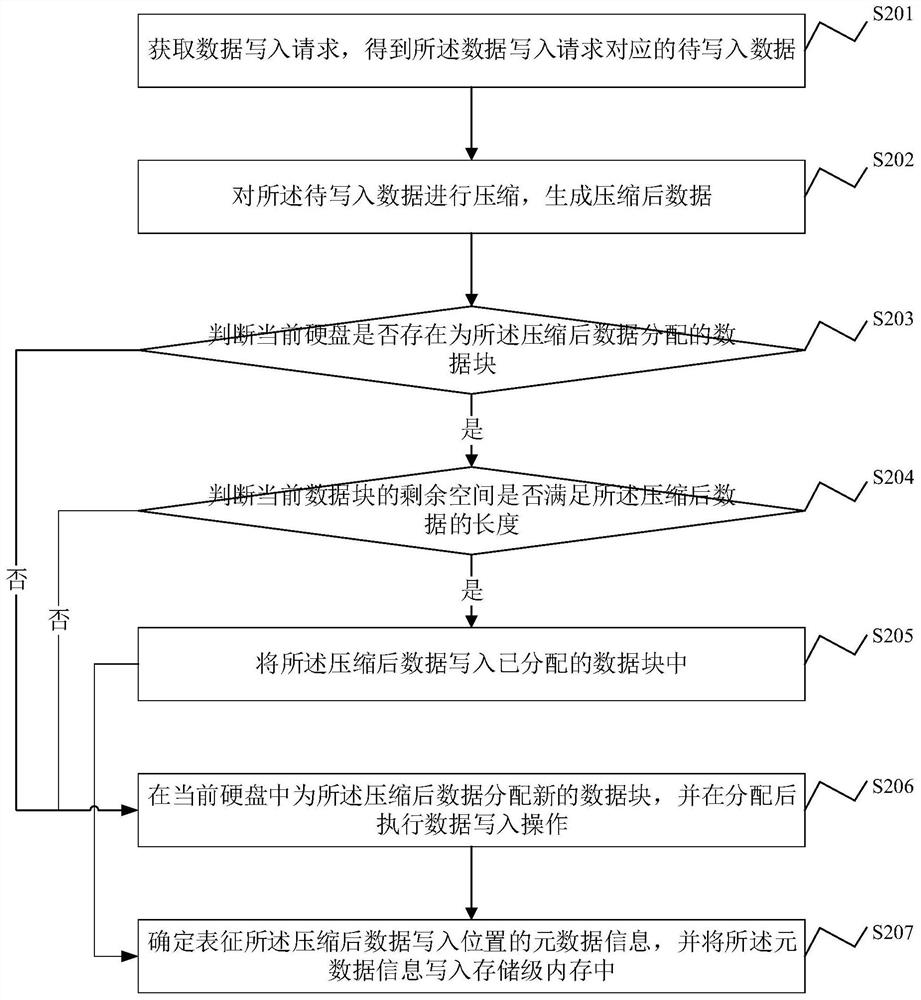

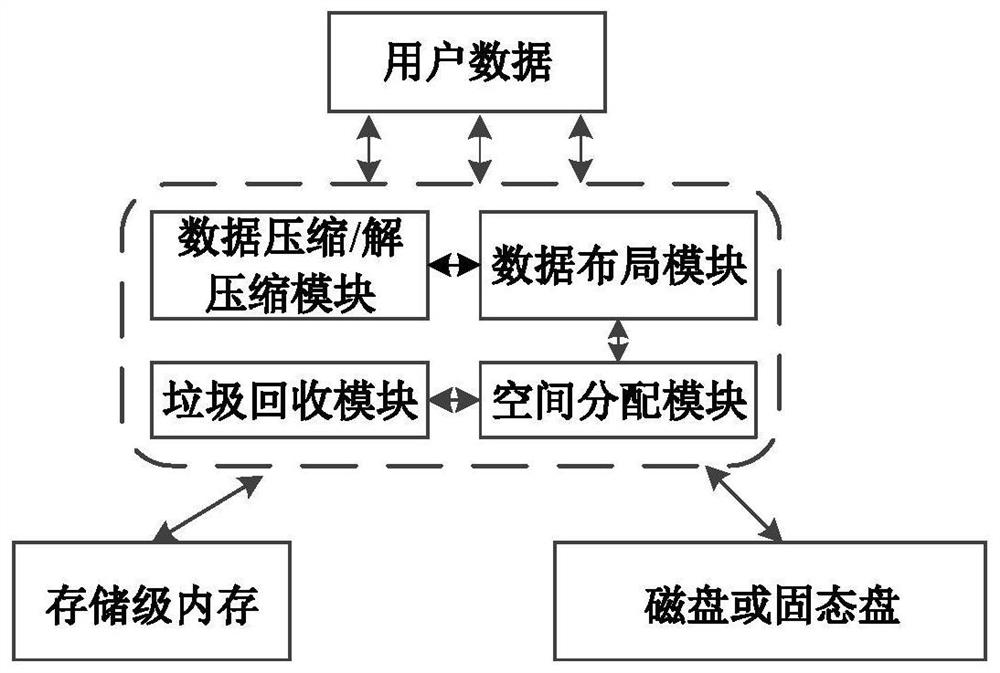

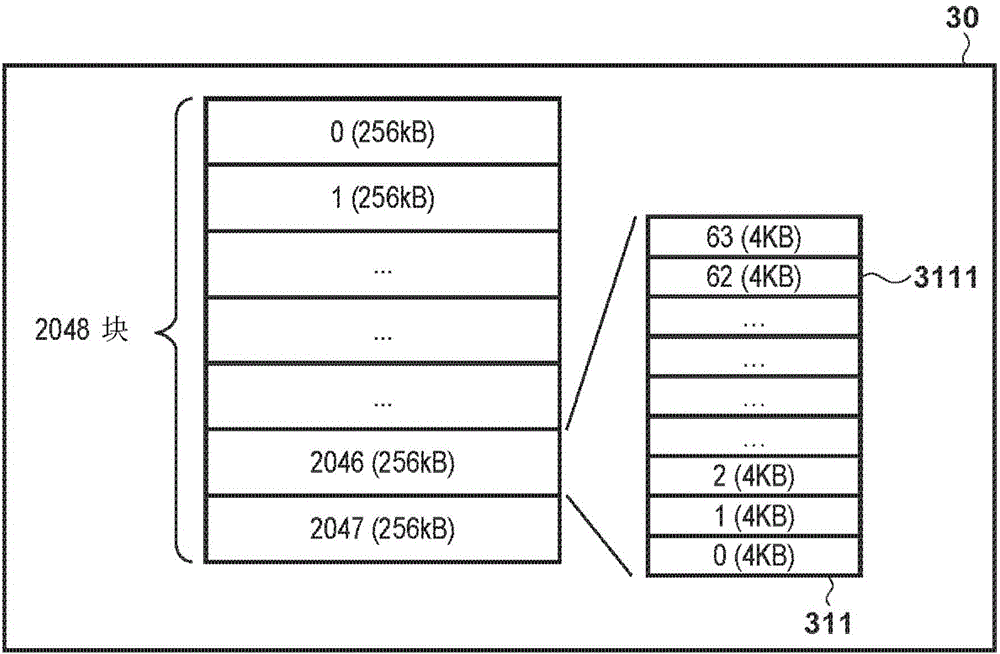

Data read-write method and device, electronic equipment and storage medium

InactiveCN111625191AImprove access performanceImprove performanceInput/output to record carriersData compressionSoftware engineering

The invention discloses a data reading and writing method and device, electronic equipment and a computer readable storage medium, and the method comprises the steps: obtaining a data writing request,and obtaining to-be-written data corresponding to the data writing request; compressing the to-be-written data to generate compressed data; writing the compressed data into a data block of a hard disk, and determining metadata information representing the writing position of the compressed data; and writing the metadata information into a storage-level memory, wherein the metadata information isupdated in an overwriting manner. Known from above, according to the invention, metadata and user data are separately stored; to-be-written user data is compressed and then written into a hard disk; the metadata information is written into the storage-level memory, the metadata is not compressed any more, an overwriting mode is adopted when the metadata is updated, the access performance of the metadata is improved, meanwhile, performance reduction caused by high-frequency garbage collection is relieved, and the performance of a real-time compression storage system is effectively improved.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

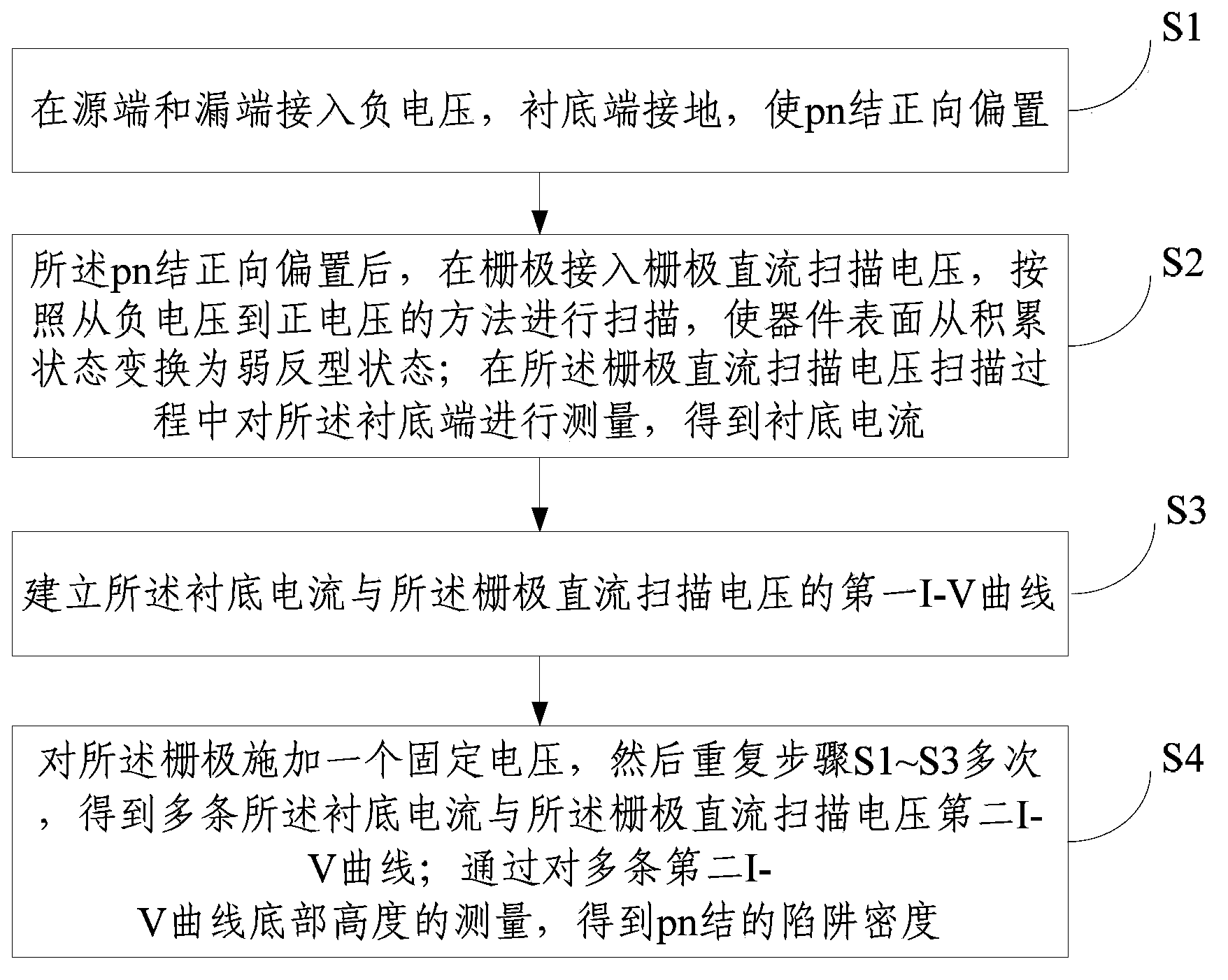

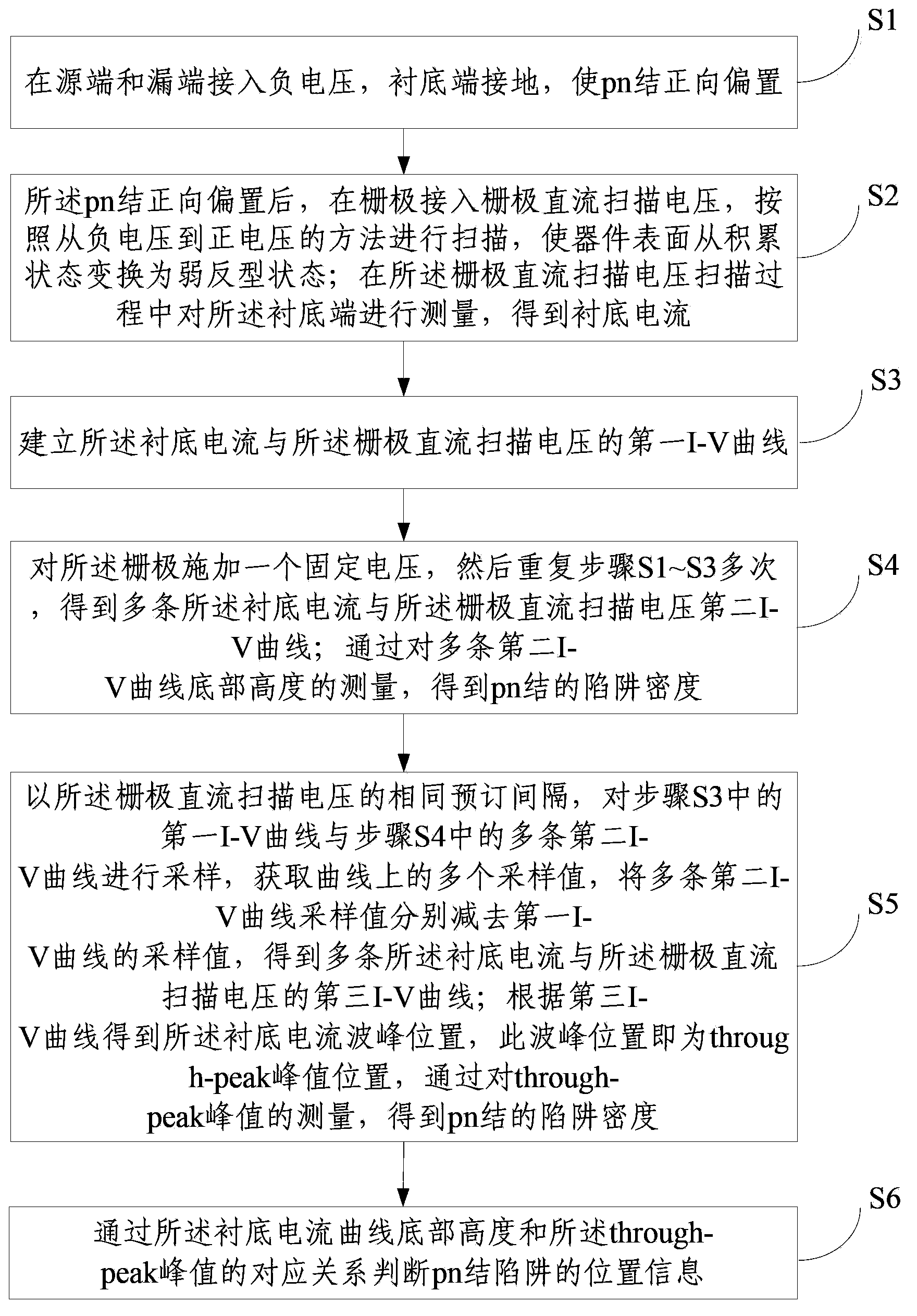

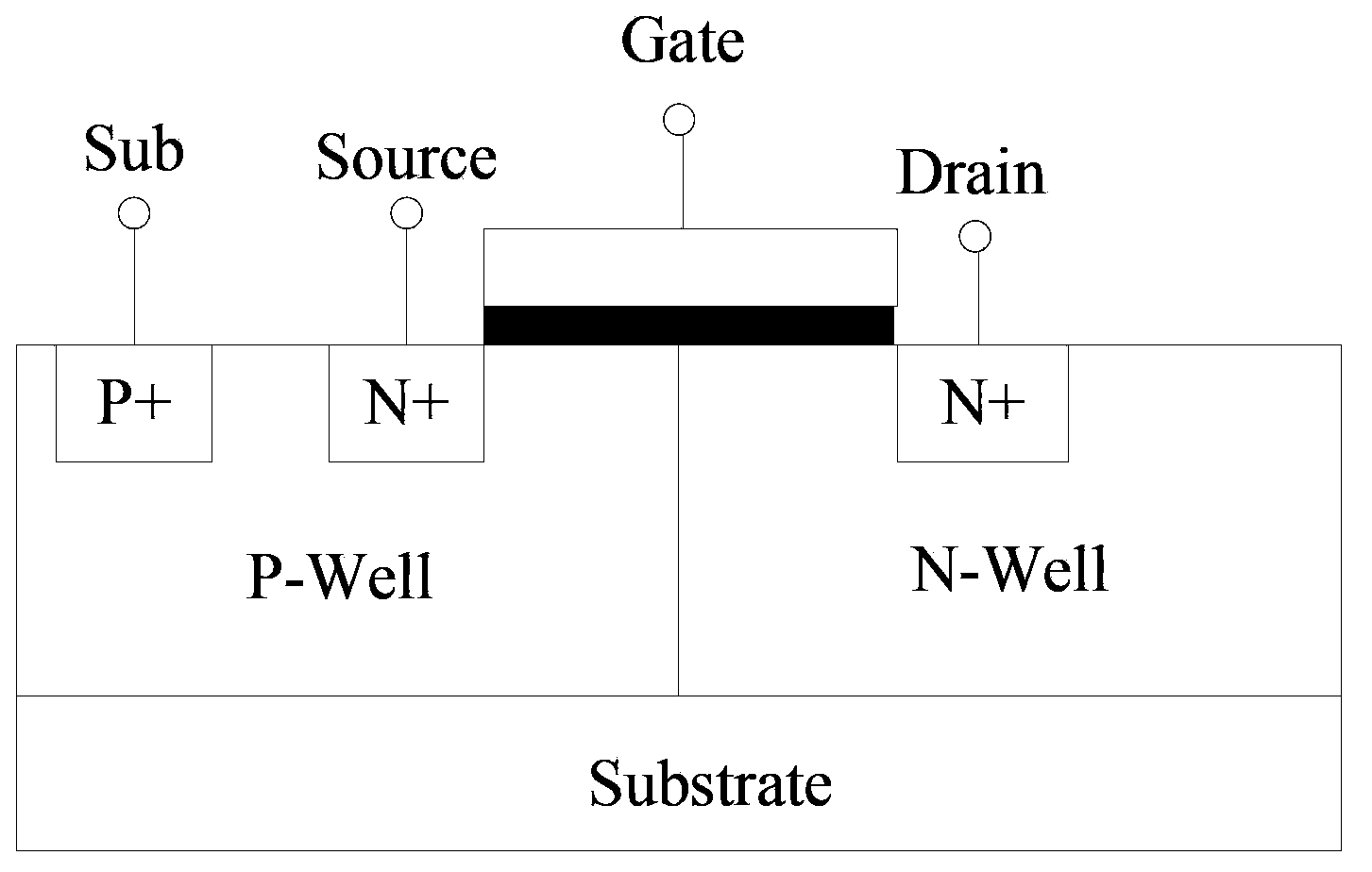

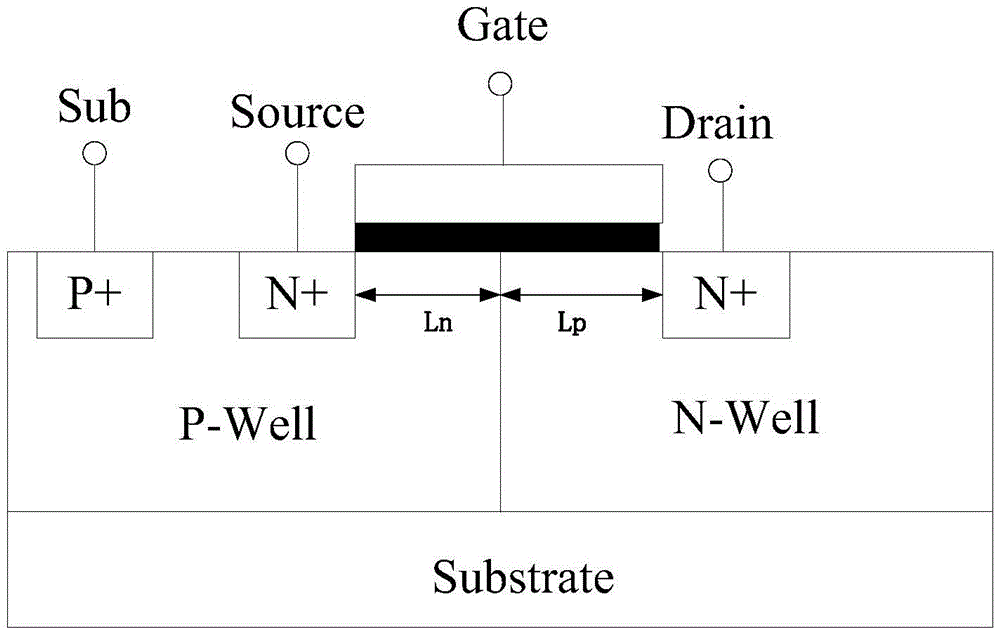

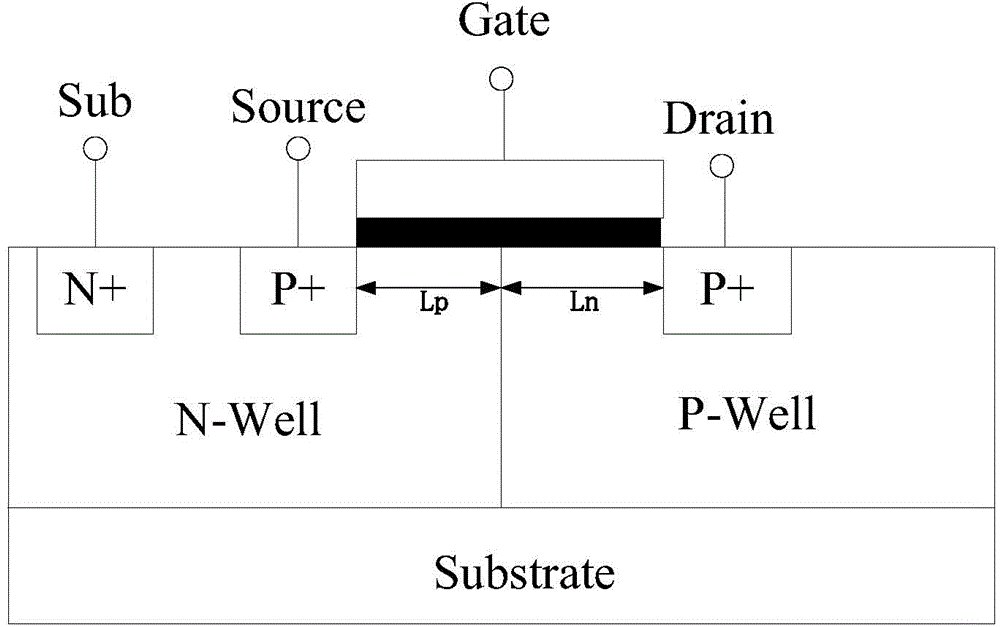

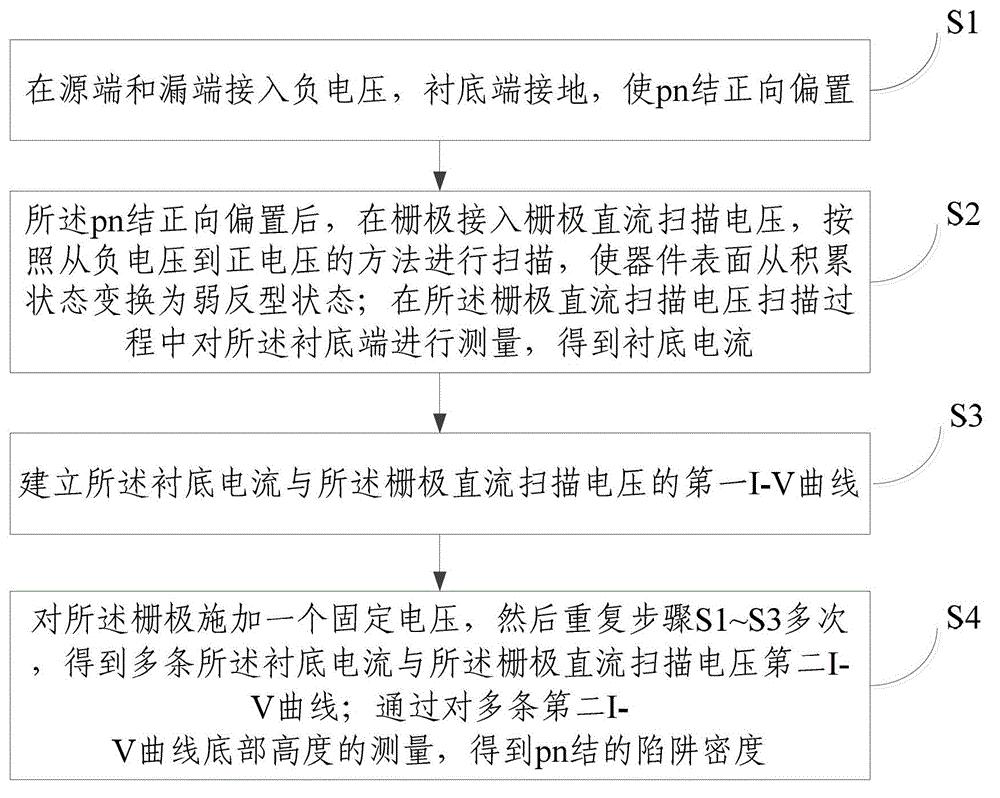

Method and device for testing trap density and position of gate oxide layer

ActiveCN103367193AReduce generationMitigate performance degradationSemiconductor/solid-state device testing/measurementPower flowEngineering

The invention provides a method and a device for testing trap density and position of a gate oxide layer, and relates to the technical field of quality and reliability testing of an MOS (Metal Oxide Semiconductor) device. The method comprises the following steps: S1, accessing negative voltage at a source end and a drain end, grounding at a substrate end, so that p and n nodes are forward bias; S2, after the p and n nodes are forward bias, accessing a grid direct-current scanning voltage at a grid, and scanning from negative voltage to positive voltage, so that the surface of the device becomes weak inversion state from accumulation state; measuring the substrate end during the scanning process so as to obtain substrate current; S3, establishing a first I-V curve of the substrate current and the grid direct-current scanning voltage; S4, applying a fixed voltage to the grid, repeating the steps S1 to S 3 for multiple times so as to obtain a plurality of second I-V curves; measuring the heights of bottoms of the second I-V curves so as to obtain the trap density of p and n nodes. According to the method and the device, the strap density of the p and no nodes can be measured and the positions of traps can be positioned, so that the design of the device is improved so as to reduce the traps.

Owner:PEKING UNIV

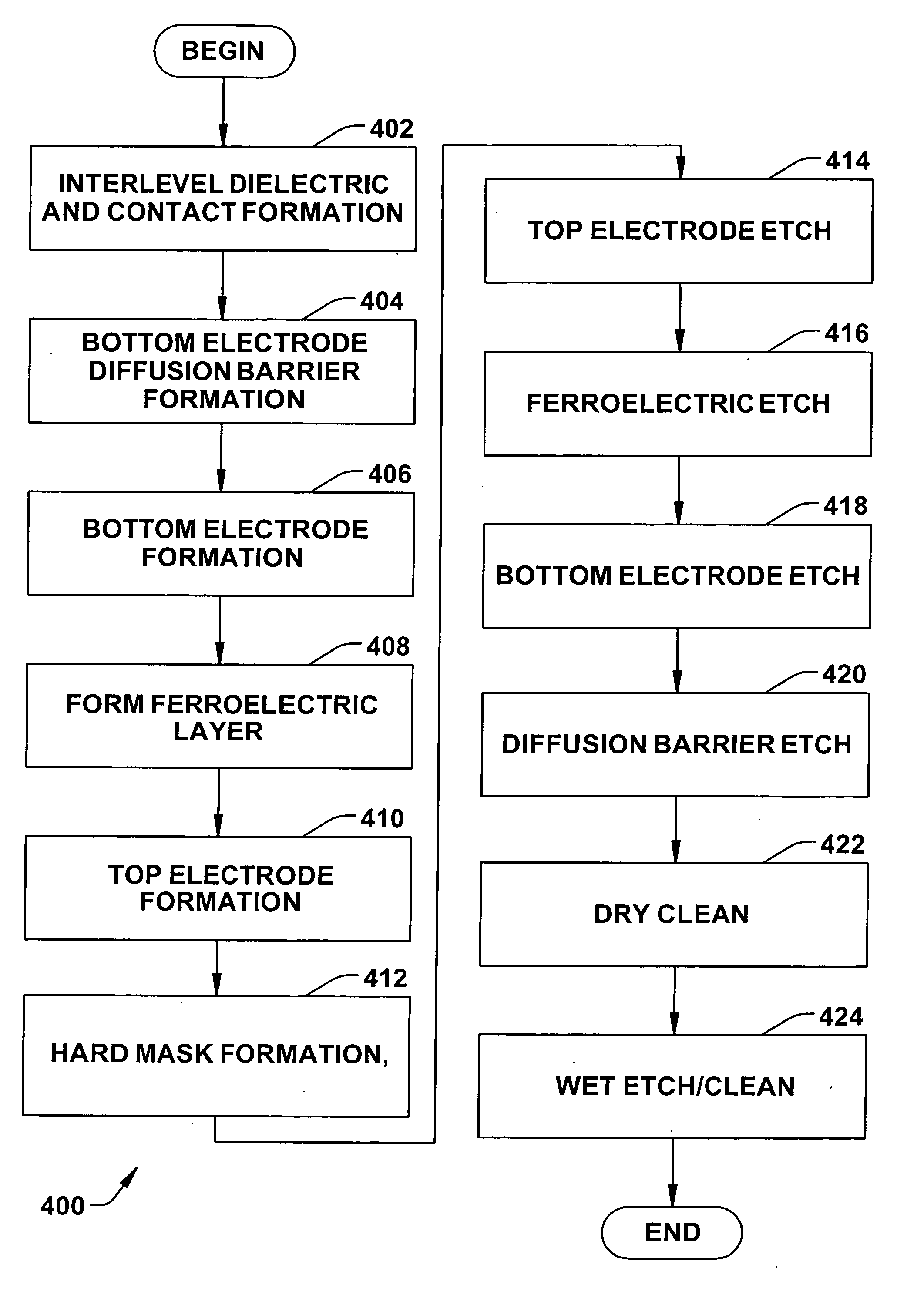

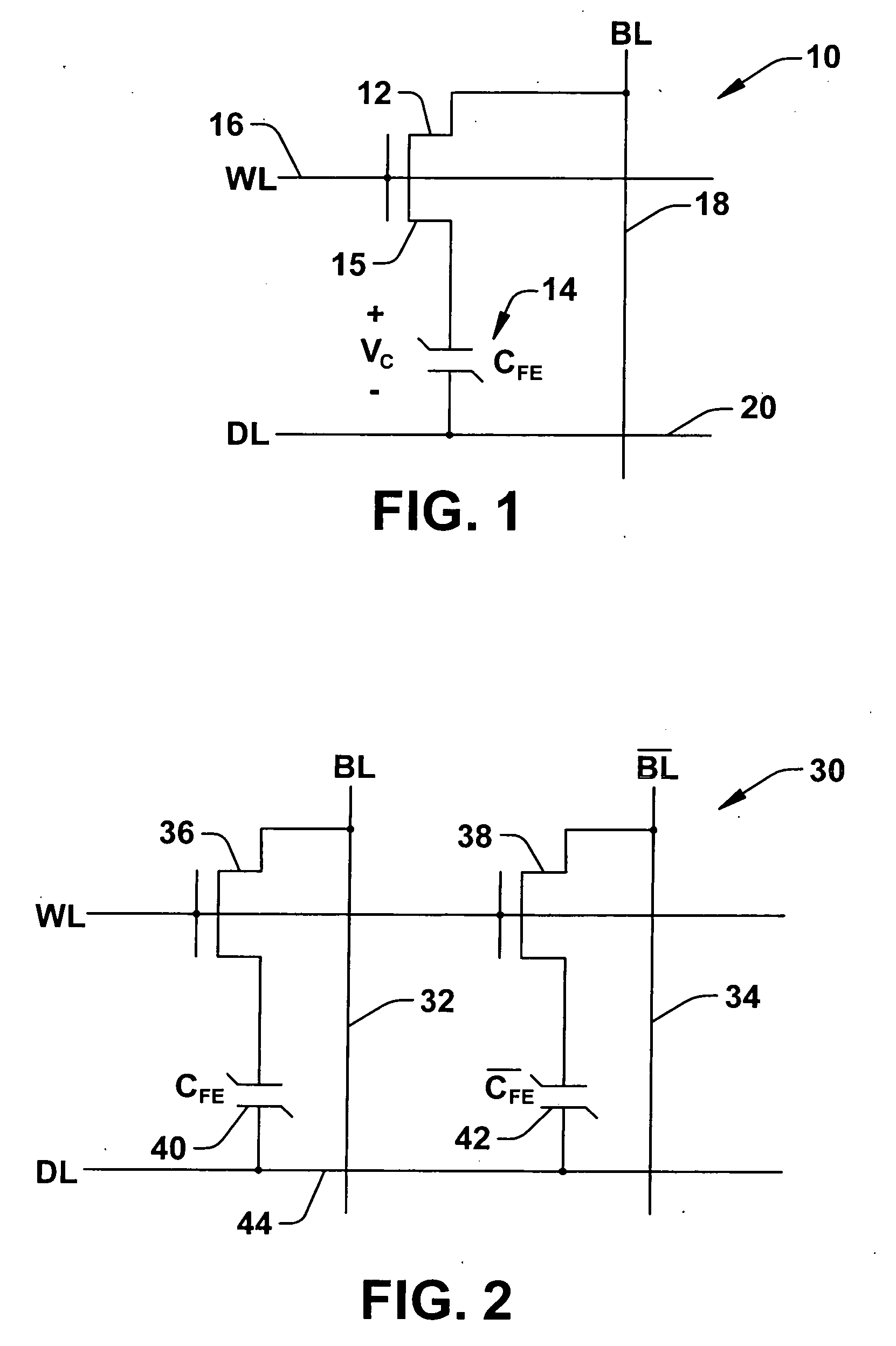

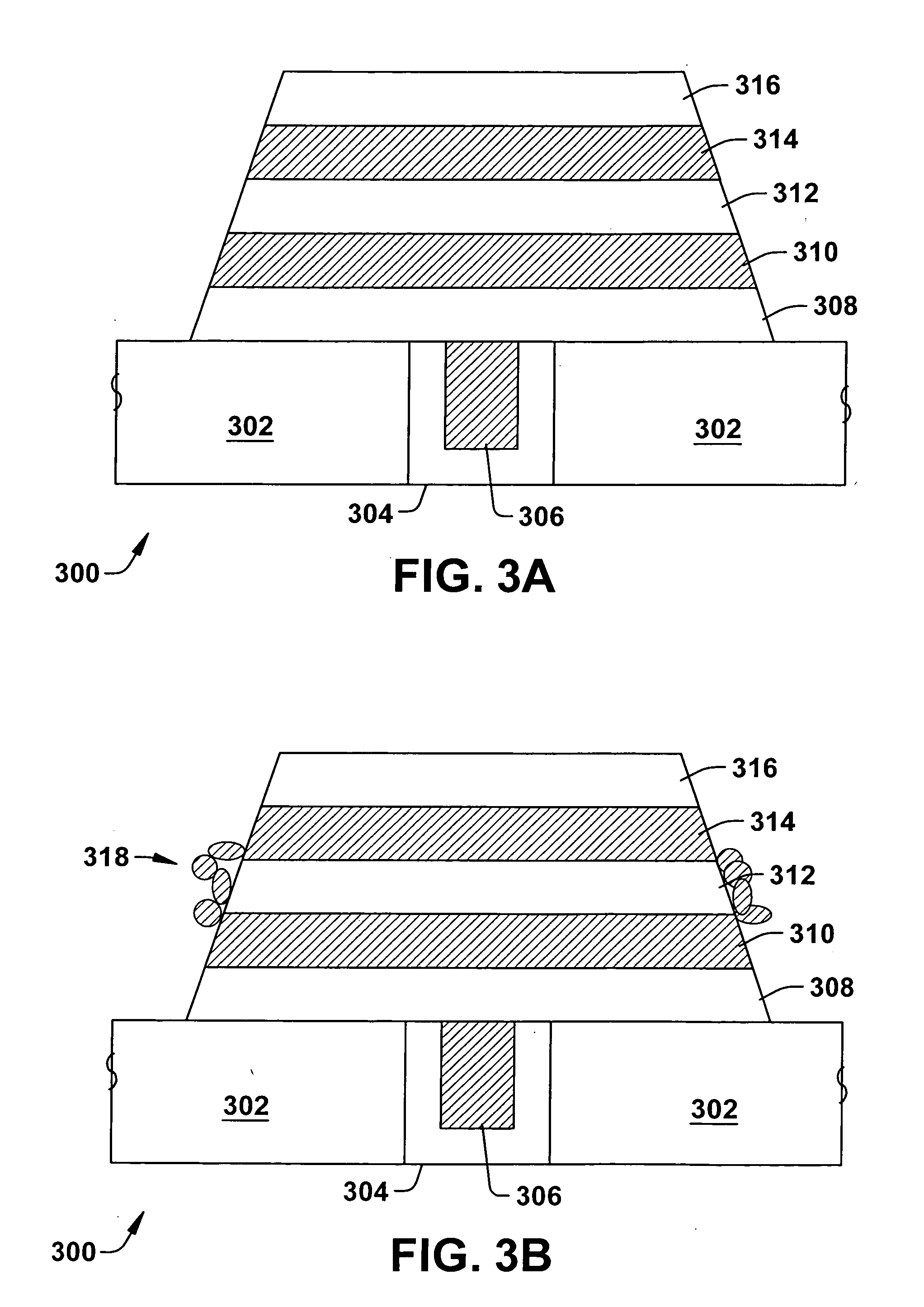

Mitigation of edge degradation in ferroelectric memory devices through plasma etch clean

ActiveUS20070281422A1Easy to operateFacilitate fabricationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A ferroelectric memory device is fabricated while mitigating edge degradation. A bottom electrode is formed over one or more semiconductor layers. A ferroelectric layer is formed over the bottom electrode. A top electrode is formed over the ferroelectric layer. The top electrode, the ferroelectric layer, and the bottom electrode are patterned or etched. A dry clean is performed that mitigates edge degradation. A wet etch / clean is then performed.

Owner:TEXAS INSTR INC

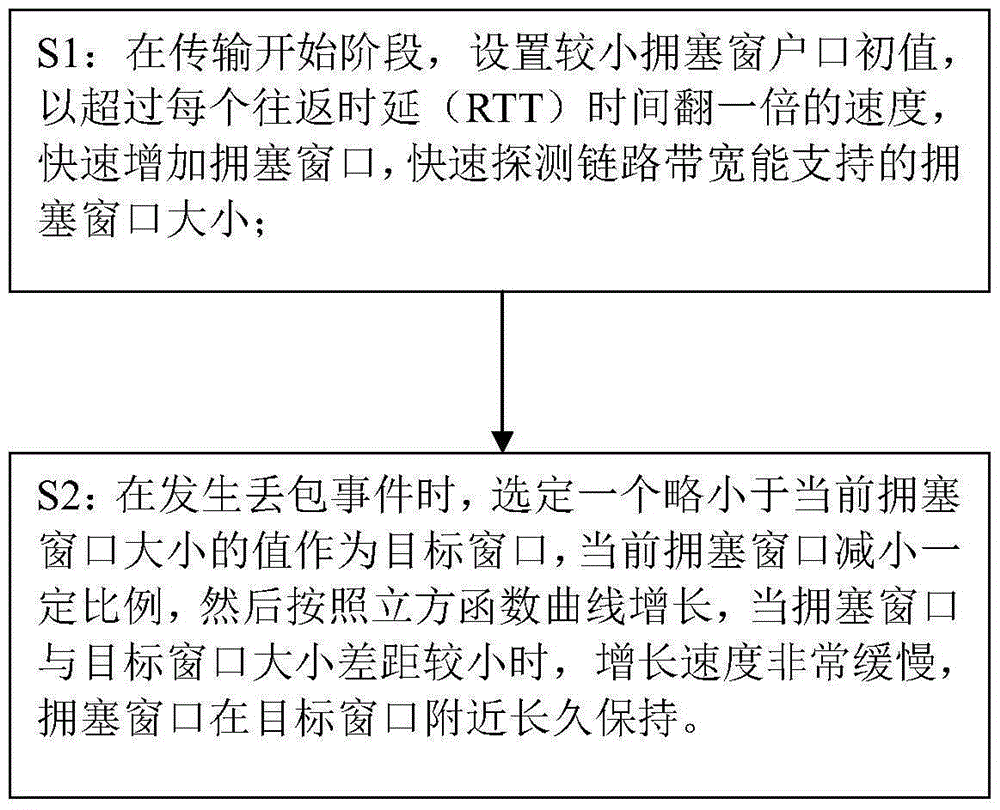

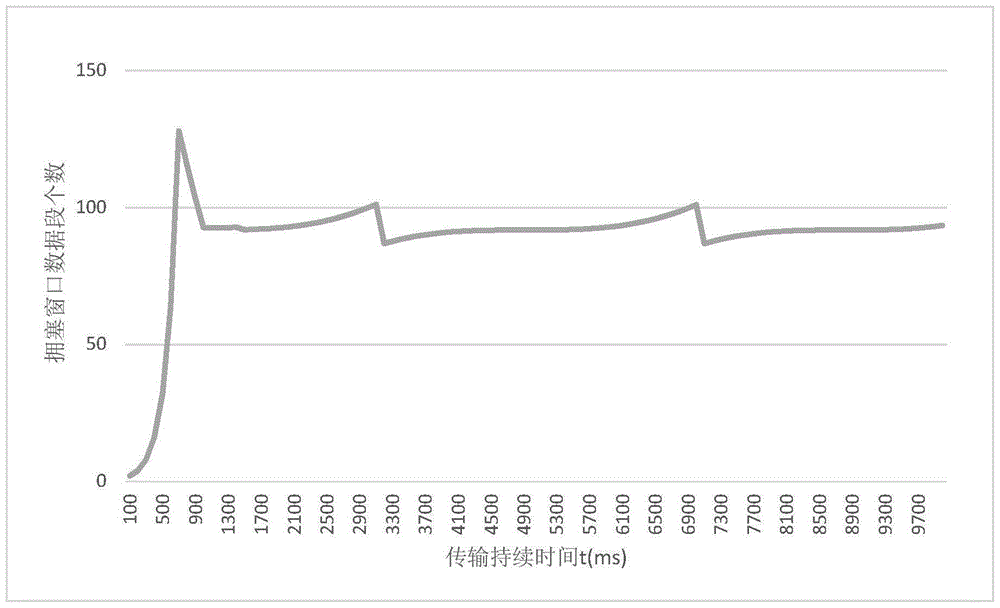

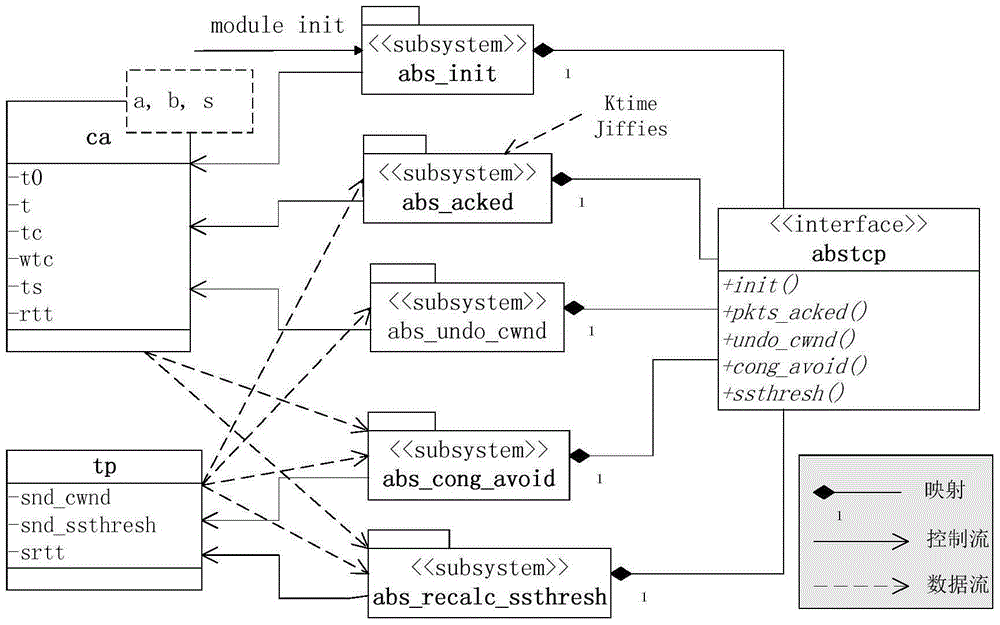

Data transmission control method for satellite network

The invention provides a data transmission control method for a satellite network. The data transmission control method comprises the following steps: S1: at a transmission beginning stage, setting an initial value of a smaller congestion window, quickly adding congestion windows at a speed larger than one time of each round-trip delay RTT time, and quickly detecting the size of congestion windows capable of being supported by a link bandwidth; and S2: in the case of a packet loss event, selecting a value smaller than the size of a current congestion window as a target window; reducing the current congestion window for a certain proportion, then increasing the current congestion window according to a cubic function curve, and when the difference between the congestion window and the target window is smaller, the growth speed is very slow, and the congestion window is maintained for a long time near the target window. The data transmission control method provided by the invention has the advantages of improving the data transmission performance.

Owner:NAT UNIV OF DEFENSE TECH

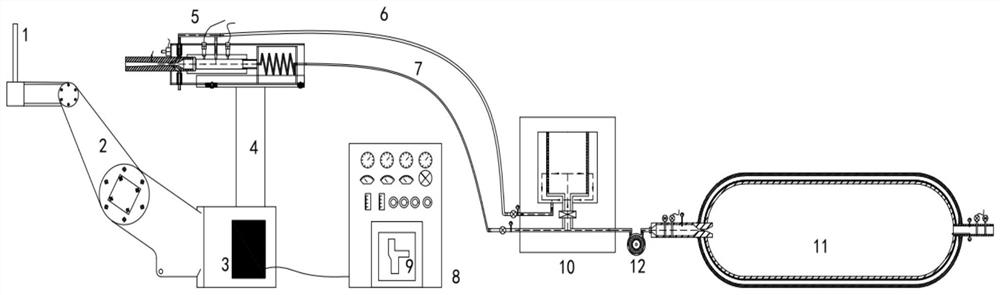

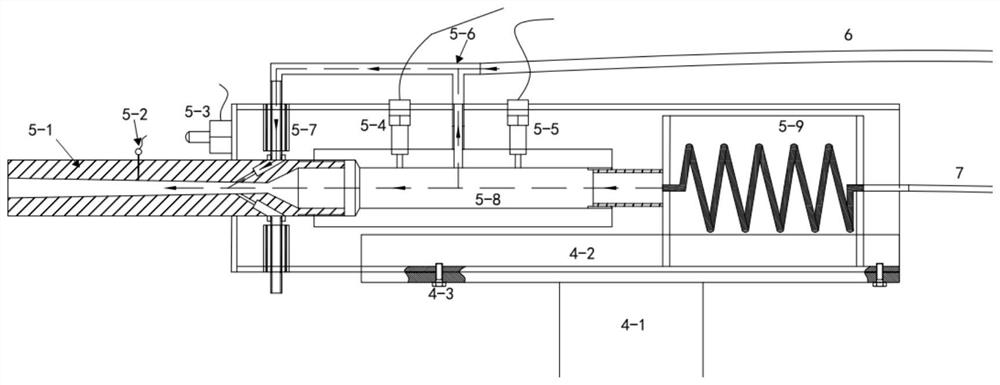

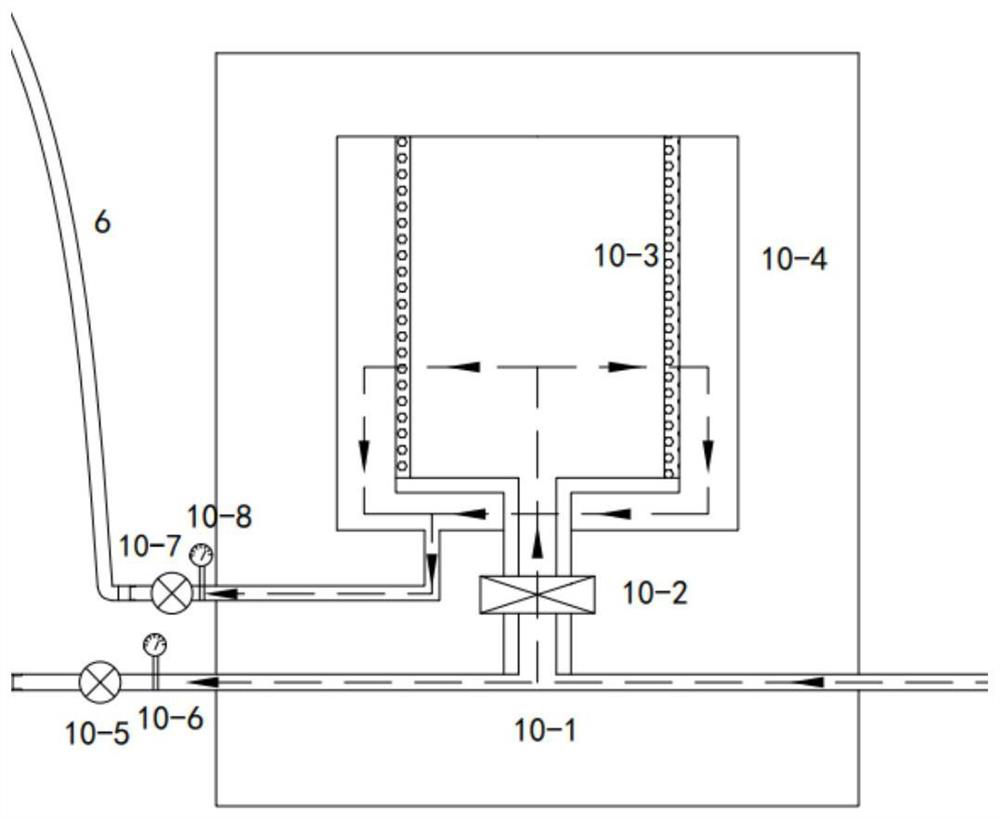

Solid 3D printing system for space component in-orbit manufacturing and repairing by using cold spraying and method

ActiveCN111962059AOvercoming difficulties that are difficult to combine effectivelyReduce burning lossAdditive manufacturing apparatusHeat inorganic powder coatingData controlData information

The invention relates to a solid 3D printing system for space component in-orbit manufacturing and repairing by using cold spraying and a method. The data information of a temperature sensor, a pressure sensor, a distance sensor and a flowmeter are all transmitted to a computer terminal, the computer terminal gives a control instruction according to the three-dimensional data, a three-dimensionalmobile platform is controlled by a three-dimensional mobile platform control chip, a matrix or a substrate moves according to the design path, and meanwhile, a valve and a heater are controlled according to the data of the temperature sensor, the pressure sensor and the flowmeter, so as to adjust the process parameters. The system and the method have the advantages that in the space environment, the problem that a melting state 3D printing technology is difficult to effectively combine under the weight loss condition is solved. In the system and method, powder has extremely high speed and accurate direction, and the kinetic energy generated by means of acceleration of gas through a Laval nozzle makes metallics completely overcome the weight loss environment in the space.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

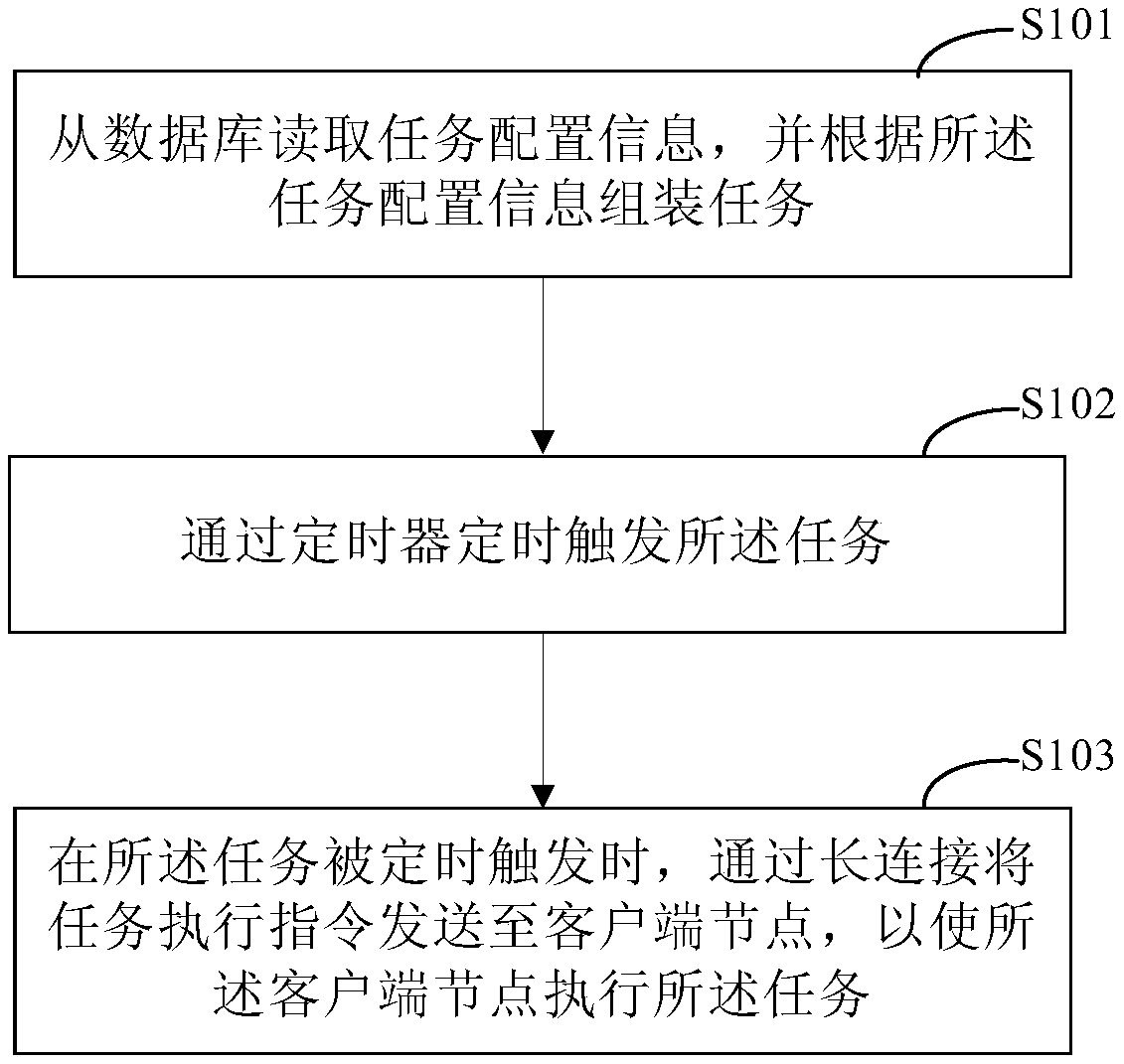

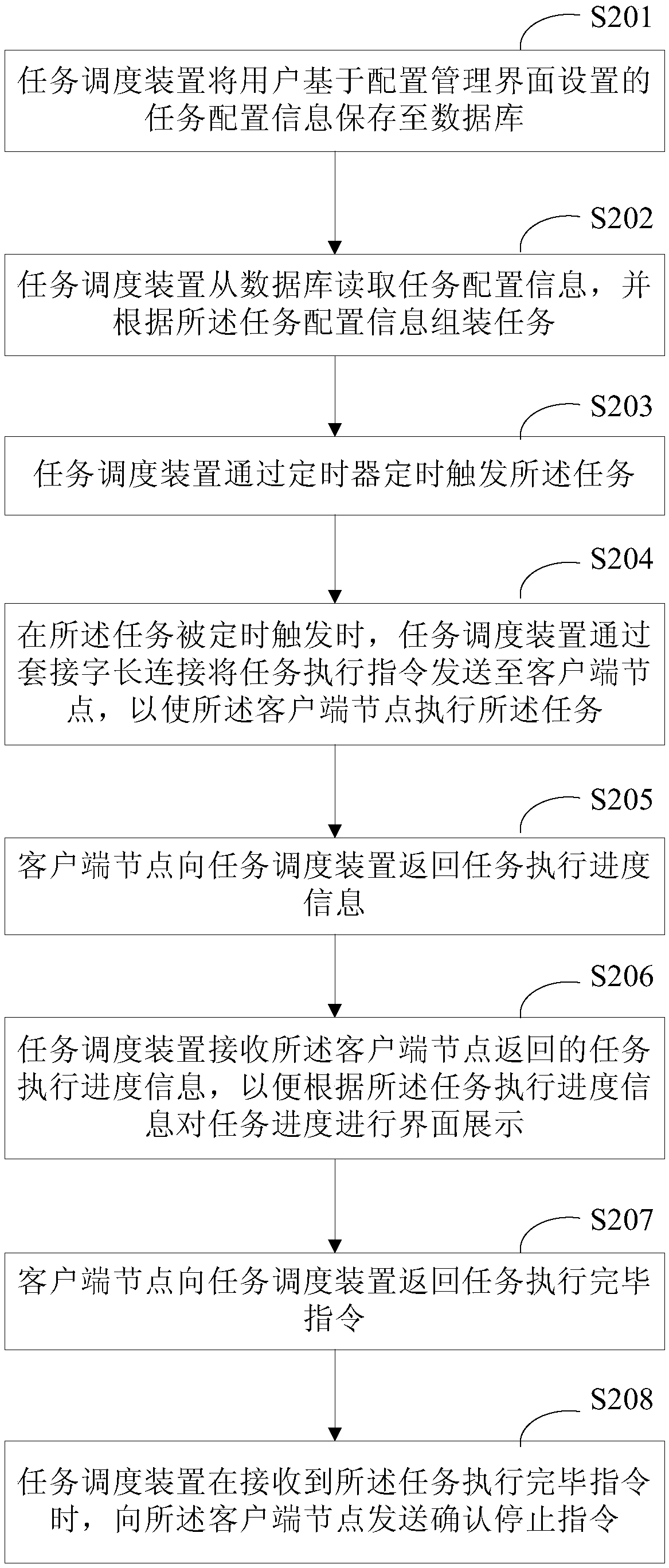

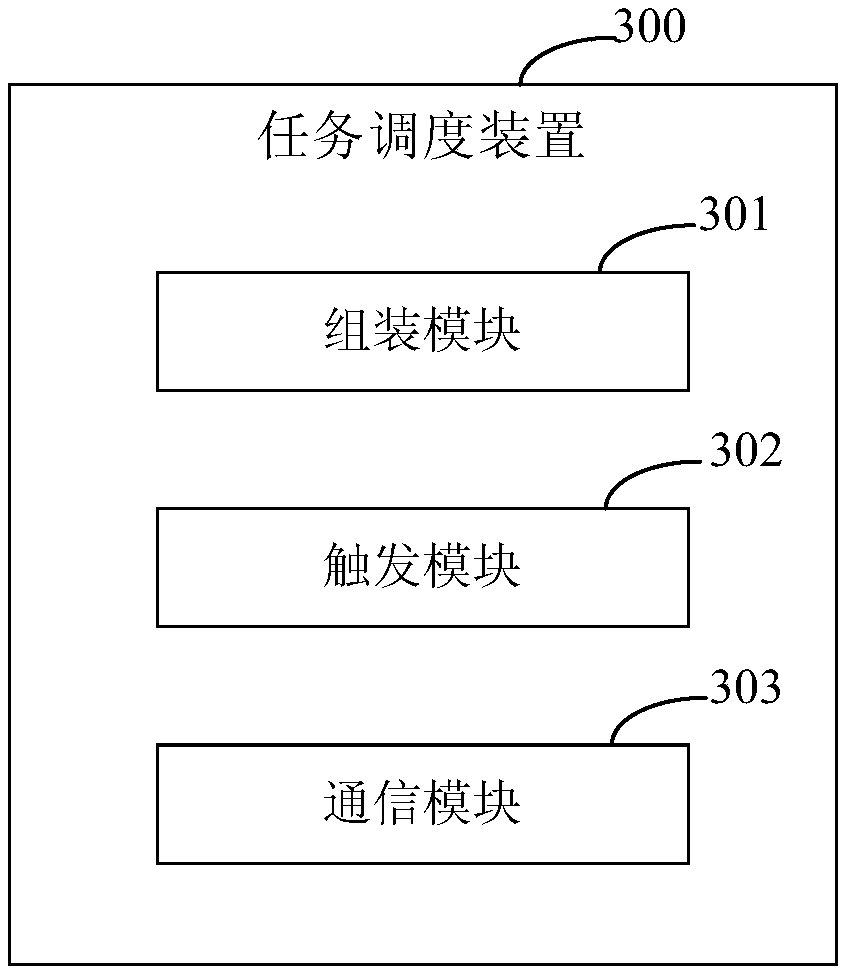

Task scheduling method and device

PendingCN111198753AMitigate performance degradationEasy to modifyProgram initiation/switchingThird partyApplication server

The invention discloses a task scheduling method and device, and relates to the technical field of computers. The method comprises the steps of reading task configuration information from a database,and assembling a task according to the task configuration information; triggering the task at regular time through a timer; and when the task is triggered regularly, sending a task execution instruction to a client node through long connection, so that the client node executes the task. Through the above steps, when task scheduling is carried out, the application server does not need to depend onQuartz, Crontable and other third-party components, and the problems that in existing task scheduling depending on the third-party components, the performance of the application server is reduced, andheterogeneous system compatibility is poor are effectively solved.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

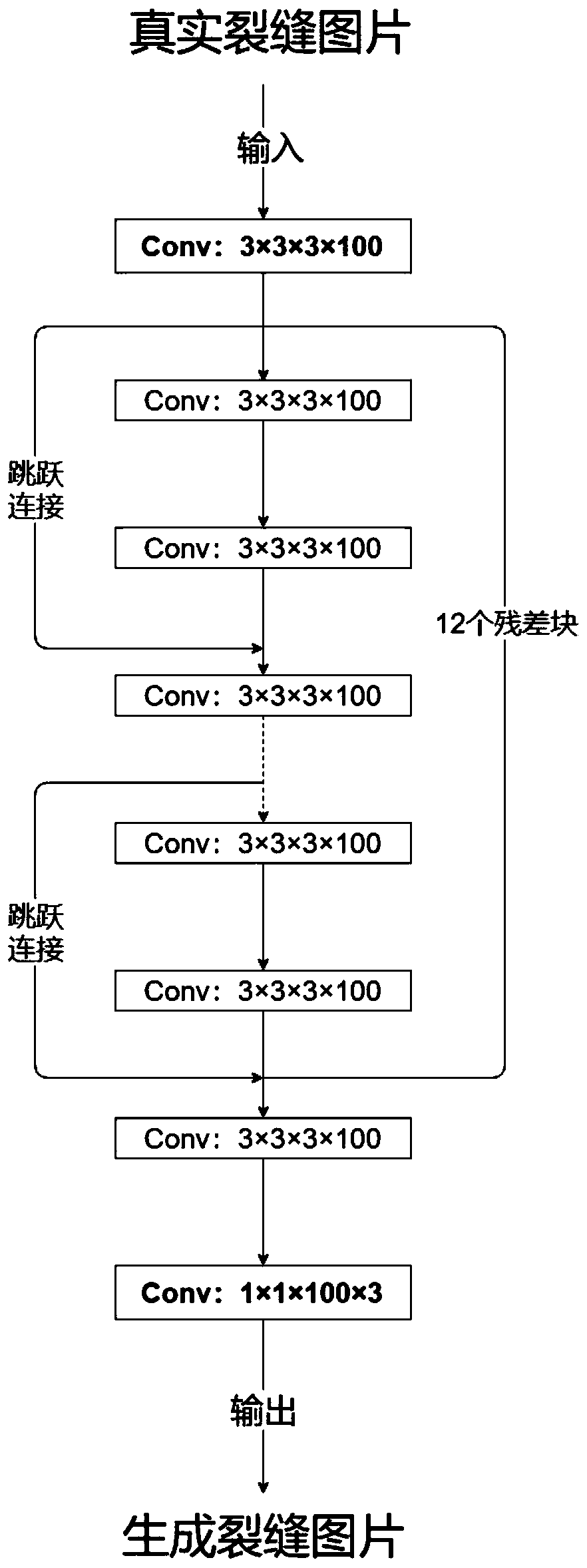

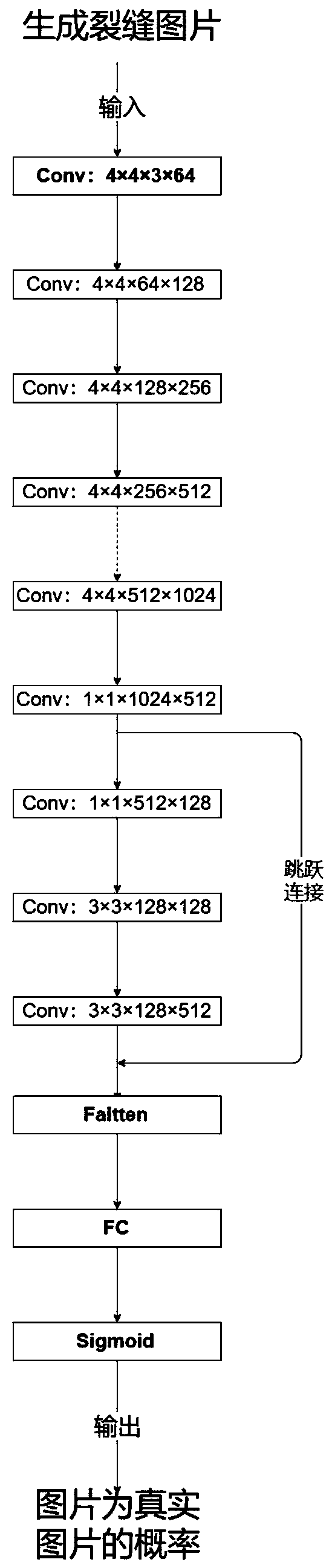

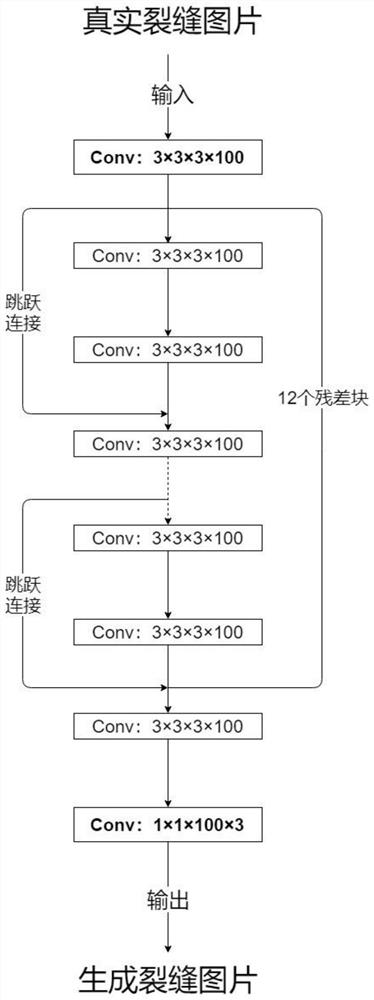

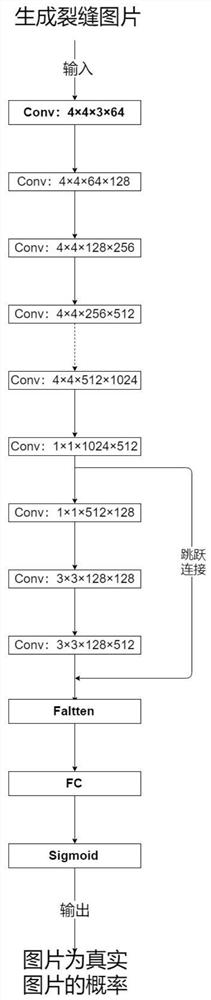

Dam crack image data enhancement method based on deep convolution generative adversarial network

ActiveCN110956591AImprove stabilityQuality improvementImage enhancementImage analysisPattern recognitionData set

The invention discloses a dam crack image data enhancement method based on a deep convolution generative adversarial network, and the method comprises the steps: (1), taking dam real crack image dataas the input, and generating a dam crack image; (2) judging the dam crack image generated in the step (1). According to the invention, on the basis of basic data enhancement operation, an image generator (DGM) based on a deep convolution generative adversarial network is used to generate the crack image, an image discriminator (DDM) based on a deep convolution generative adversarial network is used for discriminating the quality of a generated image, and a new dam crack sample data set is generated according to original small sample dam crack data, thereby meeting the requirements for the typeand data size of a training sample in the dam crack image recognition technology.

Owner:HOHAI UNIV +3

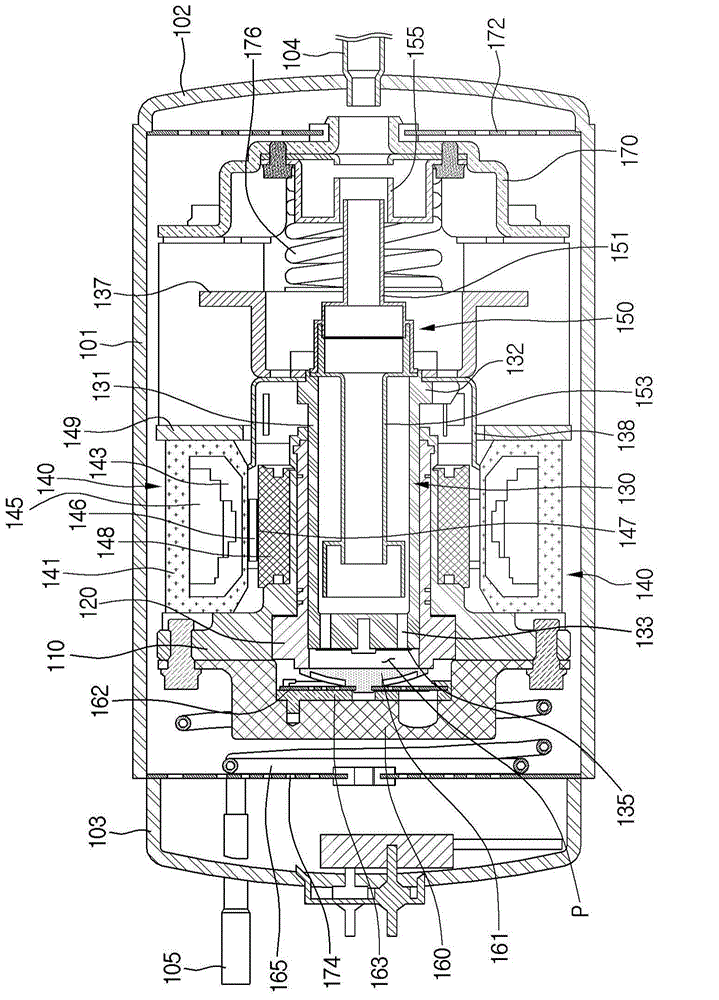

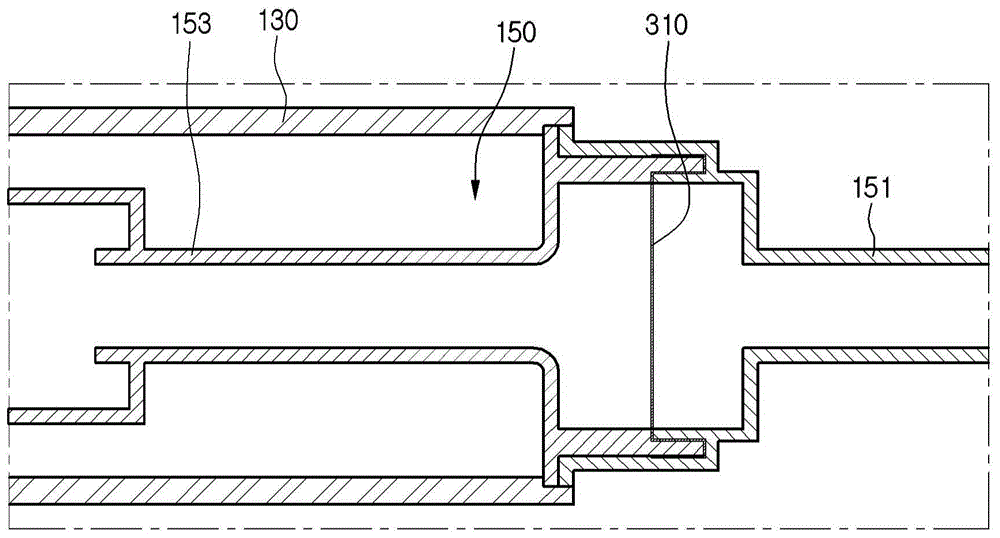

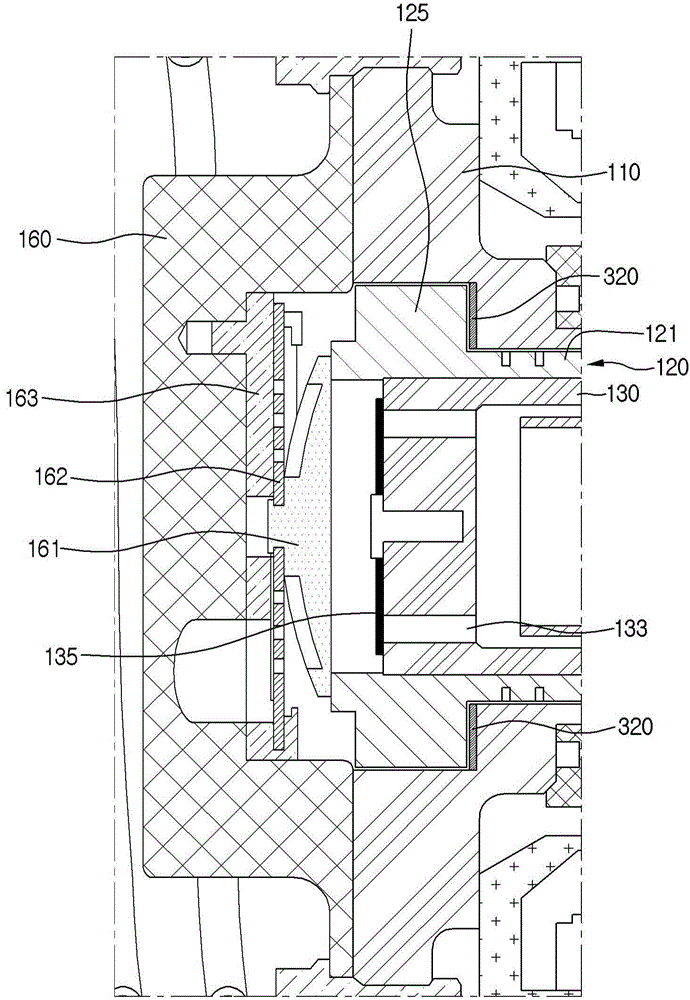

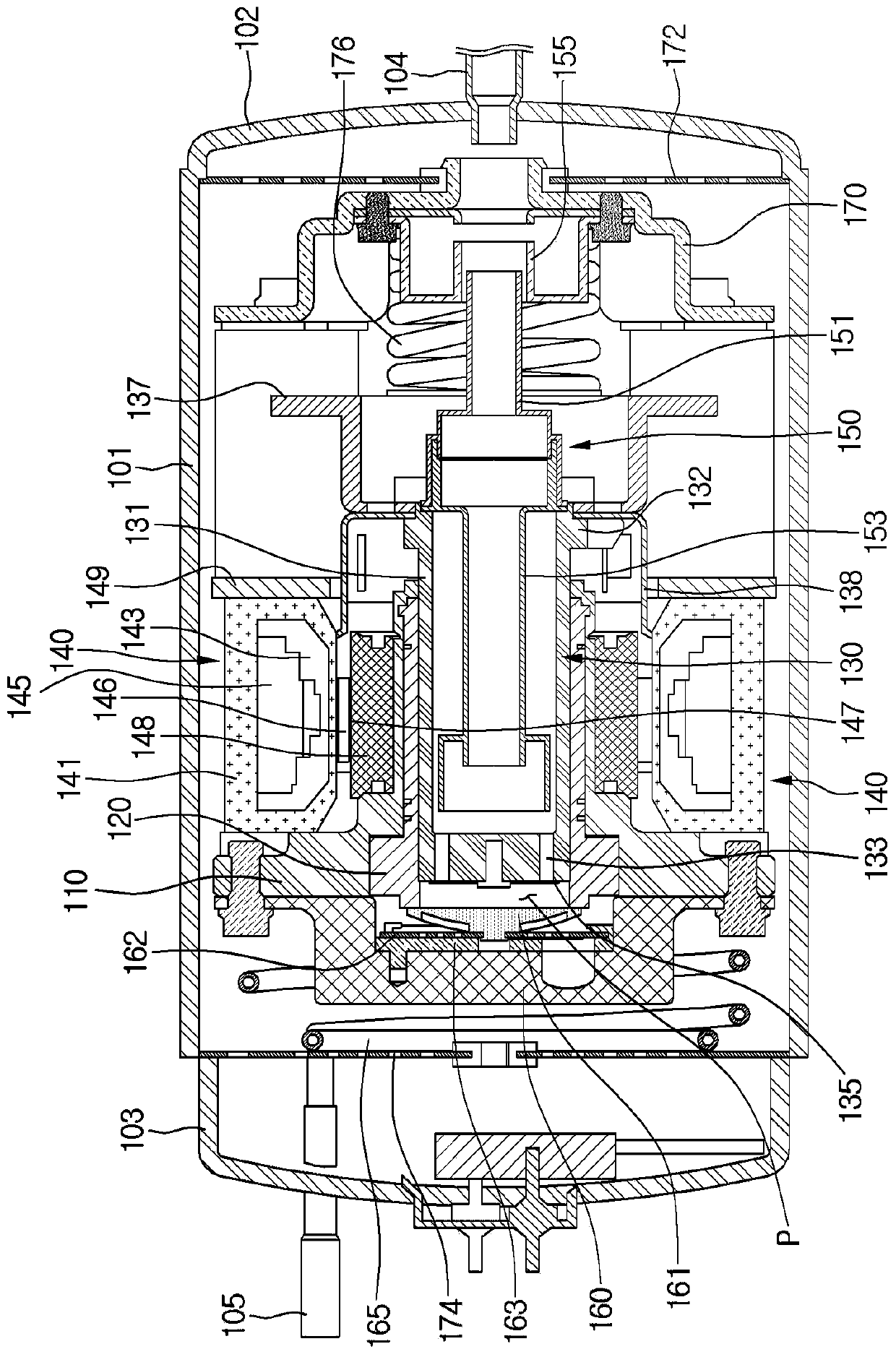

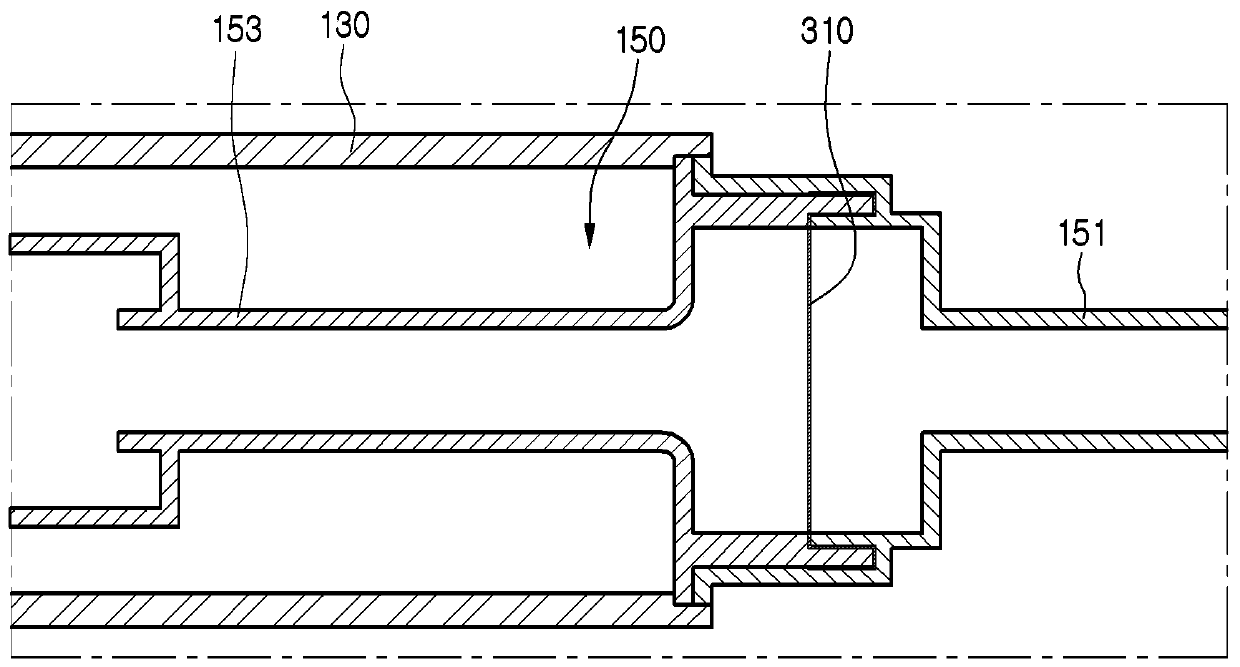

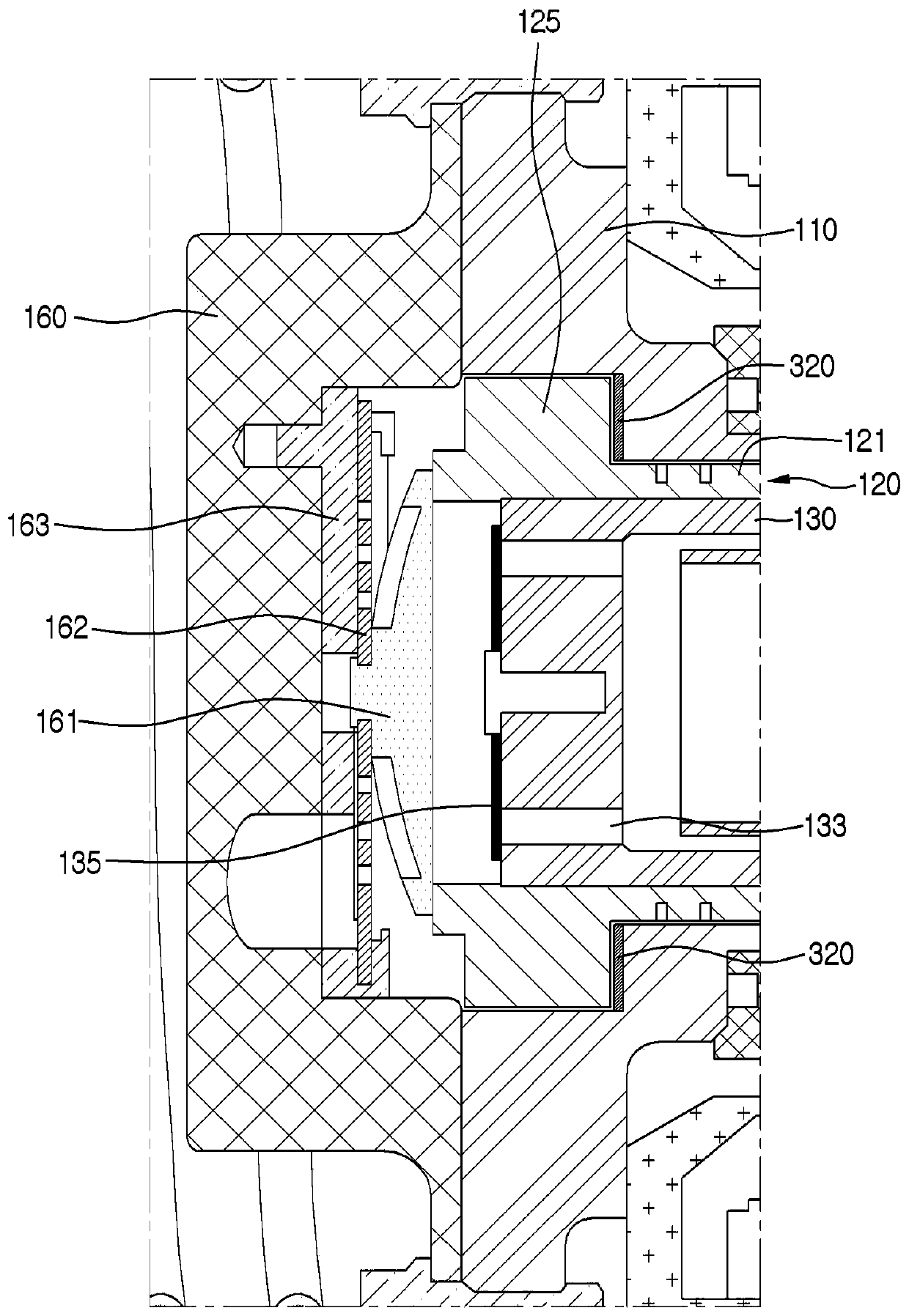

A linear compressor and a method for manufacturing the same

ActiveCN105317651AReduce sizeIncreased internal storage spacePositive displacement pump componentsWorking fluid for enginesLinear compressorReciprocating motion

The present invention relates to a linear compressor and a method for manufacturing the same. The linear compressor according to embodiments of the present invention comprises: a housing provided with a suction portion; a cylinder arranged inside the housing to form a compression space of refrigerant; a piston capable of performing reciprocating motion inside the cylinder in the axis direction; a discharge valve arranged to one side of the cylinder and selectively discharging the refrigerant compressed in the compression space of the refrigerant; a gas inflow portion formed on the periphery of the cylinder, at least a part of the refrigerant discharged via the discharge valve flowing into the gas inflow portion; a filter member arranged at the gas inflow portion; and a pressing member to apply pressure to the filter member.

Owner:LG ELECTRONICS INC

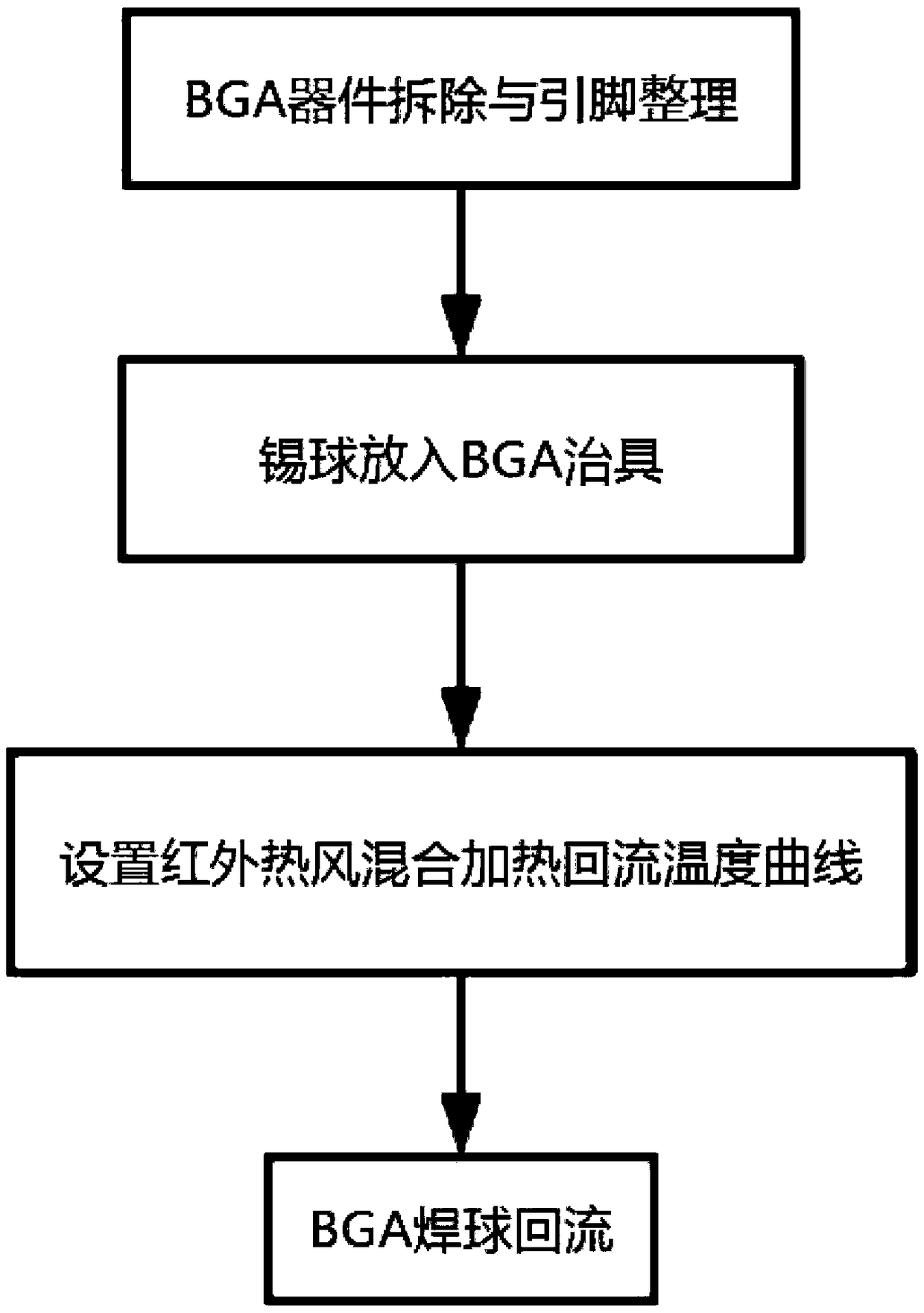

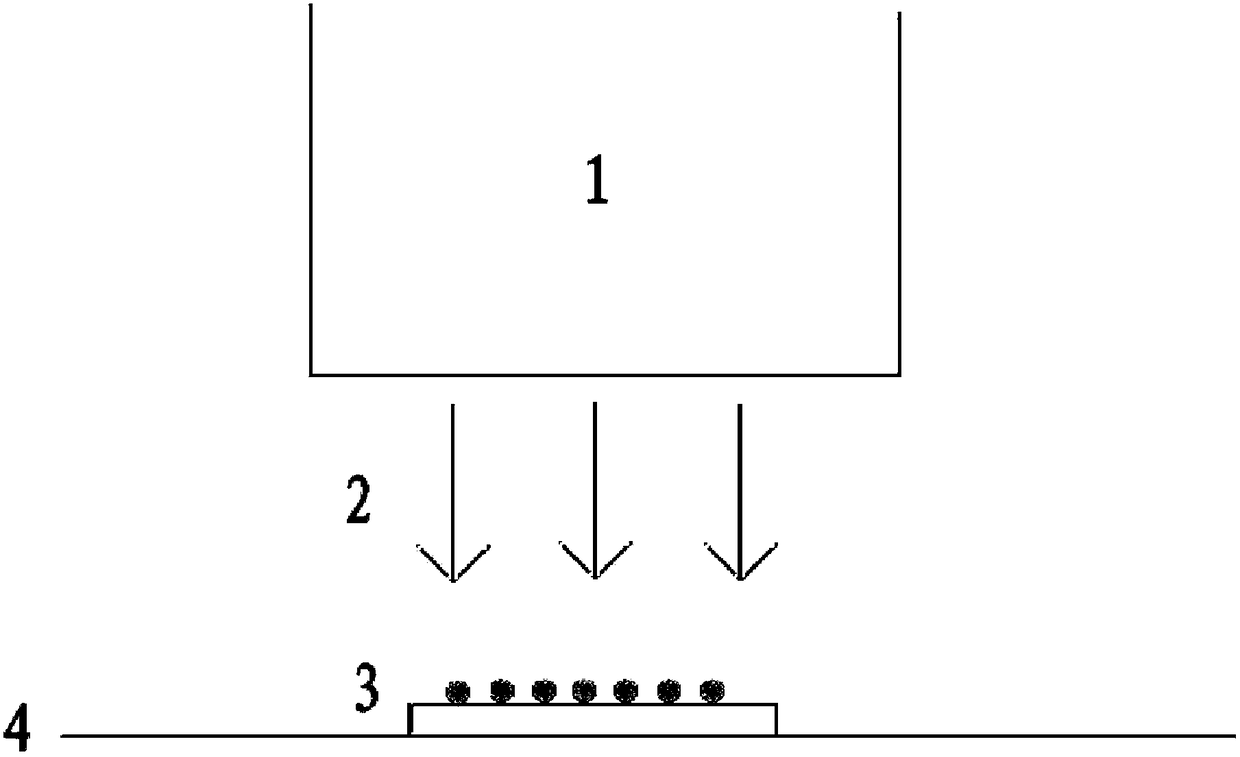

BGA (Ball Grid Array) ball mounting method based on infrared and hot air hybrid heating technology

InactiveCN109285785AMitigate performance degradationAvoid damageSemiconductor/solid-state device manufacturingTemperature curveSolder ball

The invention relates to a BGA (Ball Grid Array) ball mounting method based on an infrared and hot air hybrid heating technology, which comprises the steps of carrying out BGA device dismounting and pin arrangement, putting tin balls into a BGA fixture, setting an infrared and hot air hybrid heating reflow temperature curve, carrying out BGA solder ball reflow, mounting the tin balls on a BGA chipthrough a special fixture, and melting the tin balls by using the infrared and hot air hybrid heating system according to a preset infrared heating curve so as to complete mounting. The BGA ball mounting method uses the infrared and hot air hybrid heating technology, the heating uniformity is high, the temperature controllability is high, the ball mounting success rate is high, and the performance reduction or device body damage caused by repeated heating due to the failure of ball mounting is reduced.

Owner:国营芜湖机械厂

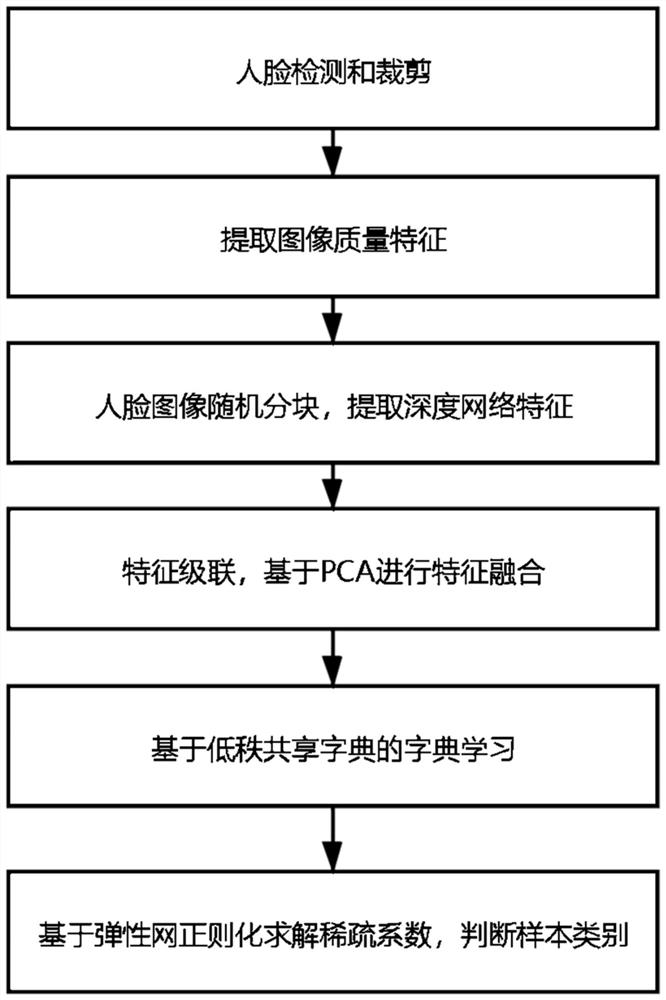

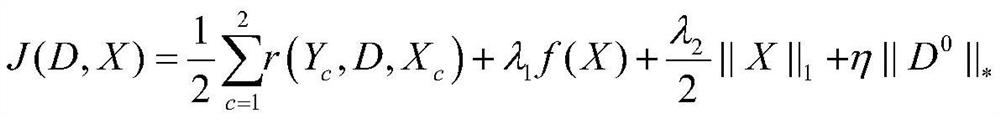

Face representation attack detection method and system based on fusion features and dictionary learning

ActiveCN111967331AImprove discrimination abilityAvoid the disadvantage of being prone to overfittingInternal combustion piston enginesNeural architecturesPattern recognitionDictionary learning

The invention discloses a face representation attack detection method and system based on fusion features and dictionary learning. The method comprises the steps of extracting image quality features of a complete face image according to a distortion source of secondary imaging of the face image; constructing a deep convolutional network model, and extracting deep network features of the face imageblocks through a deep convolutional network; cascading the two features to generate a final fusion feature through PCA; initializing dictionary atoms by using the fusion features, and training a dictionary learning classifier based on a low-rank shared dictionary; and judging the category of the test sample based on the size of the fusion feature reconstruction residual. According to the method,face representation attack detection is carried out by combining image quality features and deep network features for the first time, information provided by a single-frame image is better utilized, and the discrimination capability of extracted features is effectively enhanced; the same mode of true and false samples is stripped through the low-rank shared dictionary for the first time, so that the attack detection accuracy is successfully improved, and the method has good generalization.

Owner:SOUTH CHINA UNIV OF TECH

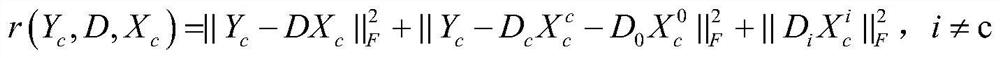

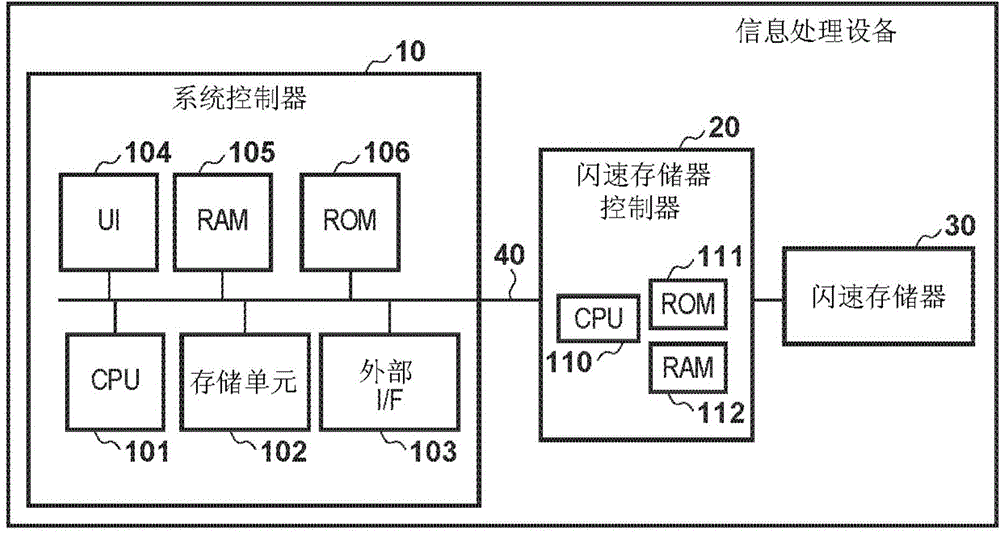

Memory control apparatus, information processing apparatus and control method thereof

InactiveCN104951249AMitigate performance degradationMemory architecture accessing/allocationInput/output to record carriersInformation processingData storing

A memory control apparatus associates logical addresses with corresponding physical addresses in a non-volatile storage device, and divides the physical addresses in the non-volatile storage device into addresses for complete erasure and other addresses and manages those addresses in the divided manner if a complete erasure mode is set. In the case where data stored in the non-volatile storage device has been instructed to be erased based on a logical address, the memory control apparatus completely erases data at the physical address associated with the logical address in the case where the physical address belongs to the addresses for complete erasure, and cancels a link to the data at the physical address associated with the logical address in the case where the physical address does not belong to the addresses for complete erasure.

Owner:CANON KK

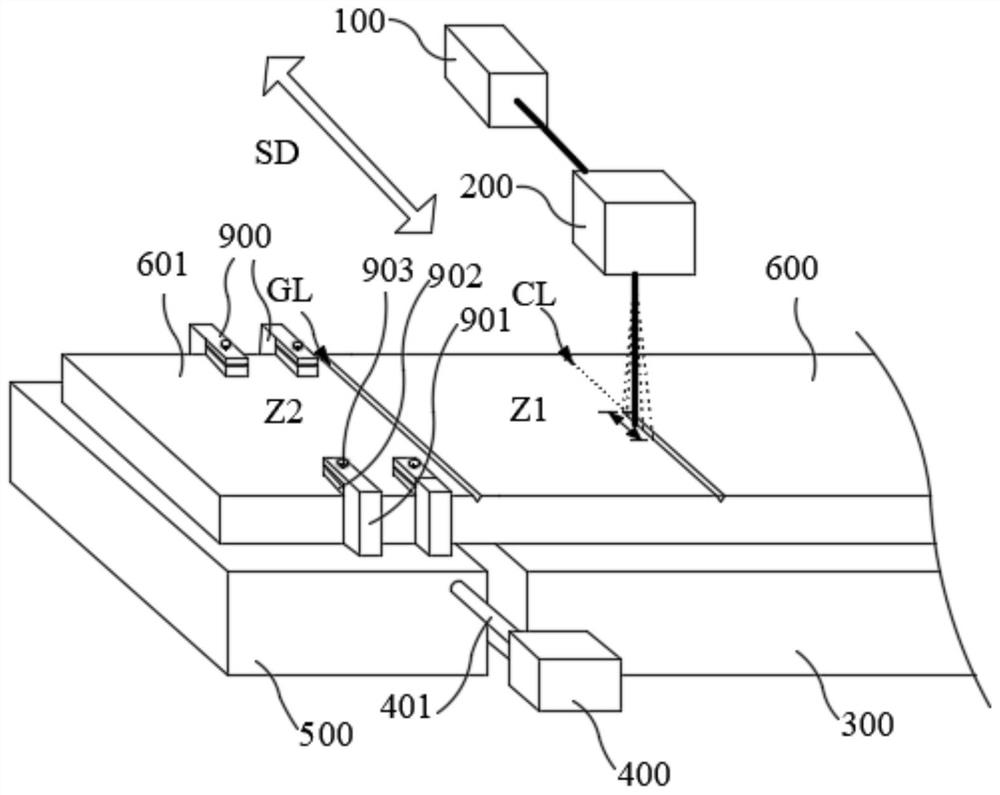

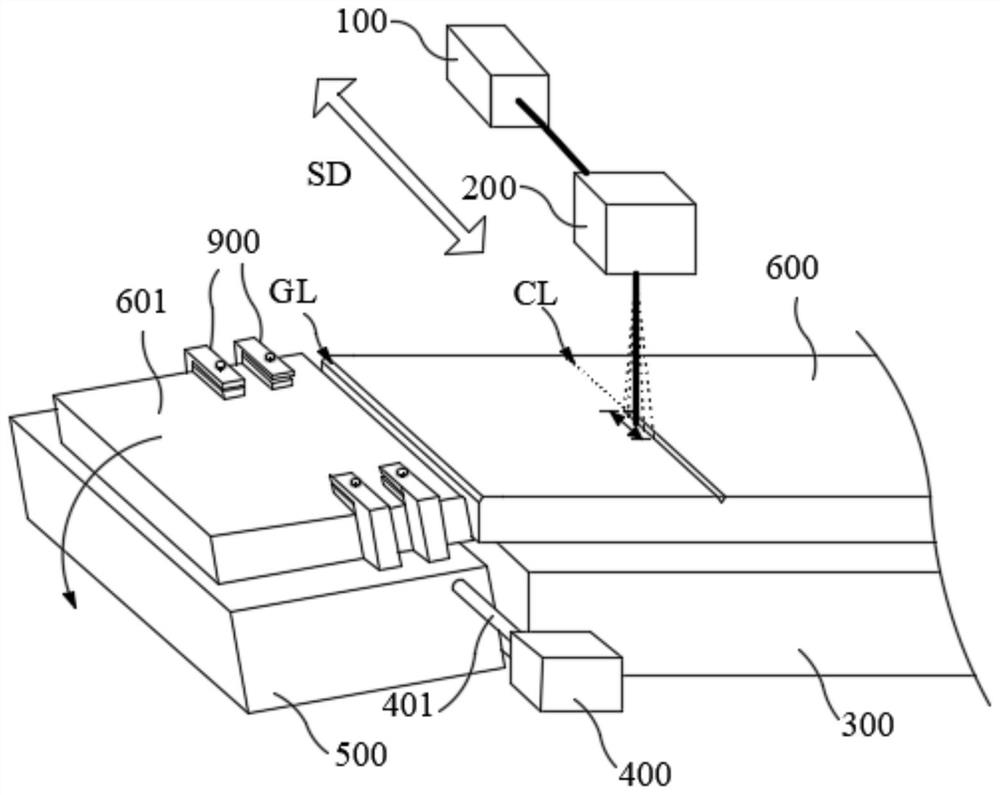

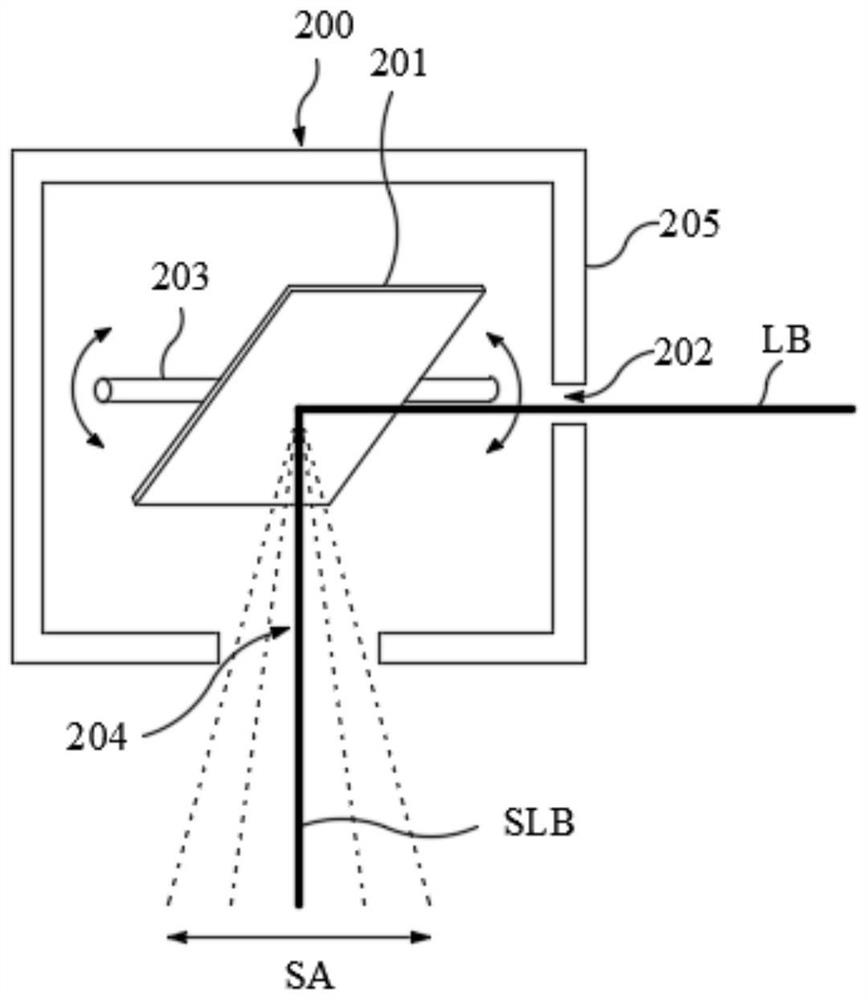

Display panel cutting device

PendingCN111807697AVibration minimizationAvoid deformationGlass severing apparatusIdentification meansRotational axisEngineering

The invention provides a display panel cutting device which comprises a first bearing platform; a second bearing platform and the first bearing platform are arranged at an interval; a first driving unit is connected with the second bearing platform, and the first driving unit drives the second bearing platform to rotate in the direction of the side, away from the display panel, of the second bearing platform with a rotating shaft parallel to a cutting groove as the rotating center so as to provide bending force for the cutting groove; at least one pair of clamping units is arranged on the table top, close to one end of the first bearing platform, of the second bearing platform. By means of the display panel cutting device, noise and vibration generated in the display panel cutting processcan be minimized, the cutting part of the display panel is prevented from deforming or being damaged due to striking, and therefore the yield and productivity of the cutting process are improved, andthe situation that the quality of the display panel is reduced due to scattered cutting powder can be prevented.

Owner:江苏亚威艾欧斯激光科技有限公司

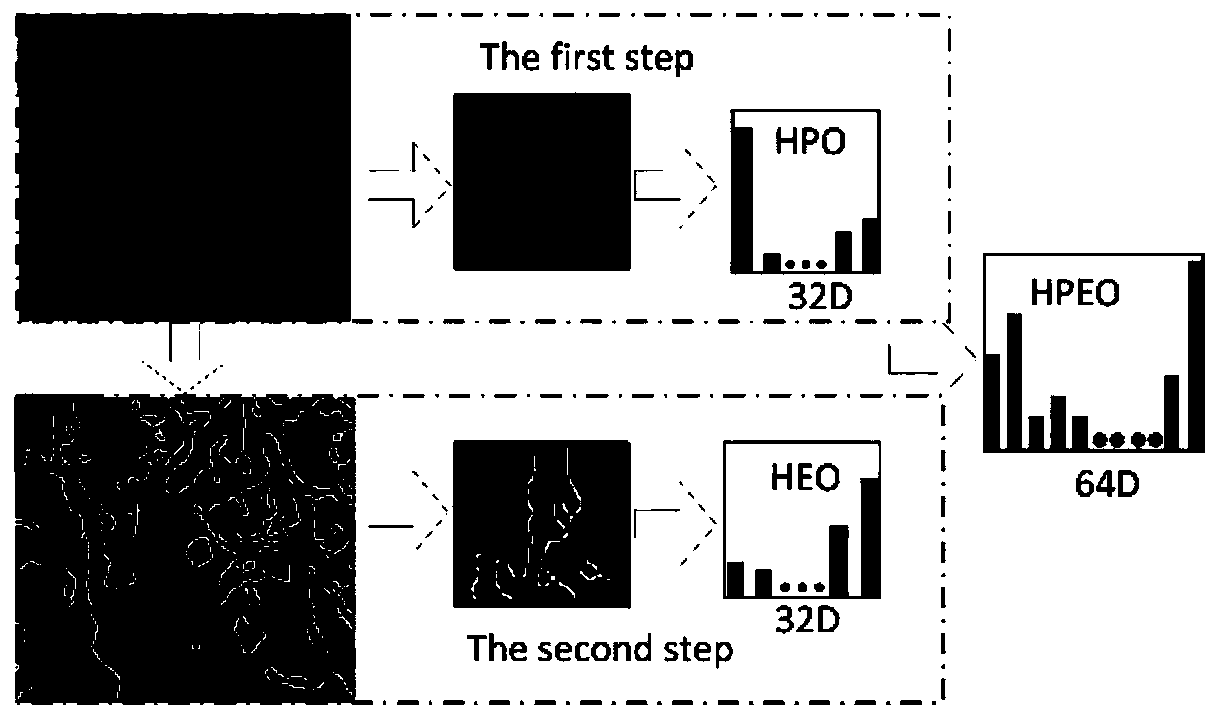

Maximum histogram different-source image matching method based on point-line features

ActiveCN111242139AProne to consistent featuresImprove matchCharacter and pattern recognitionSource imageImage matching

The invention discloses a maximum histogram different-source image matching method based on point-line features. A position-based boosting detector is adopted to extract a large number of feature points distributed on a thick edge, and a local maximum edge direction and a gradient direction of the feature points are selected from combined features to construct histogram features, so that the problem of time consumption of dense matching is expected to be solved; feature points of initial matching are extracted based on bilateral matching, the common mismatching problem in matching is solved byadopting the thought based on differential variance, and the matching accuracy is improved. What is ensured is that the matching system works in an uncertain environment, objective evaluation is carried out on the proposed different-source image matching algorithm, and accurate and densely matched matching point pairs can be stably output.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

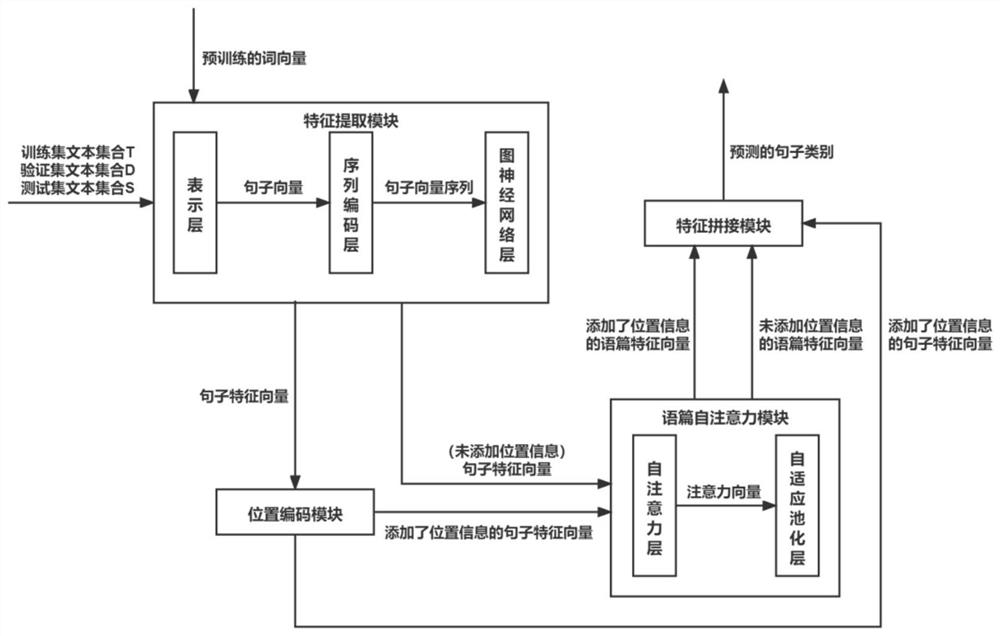

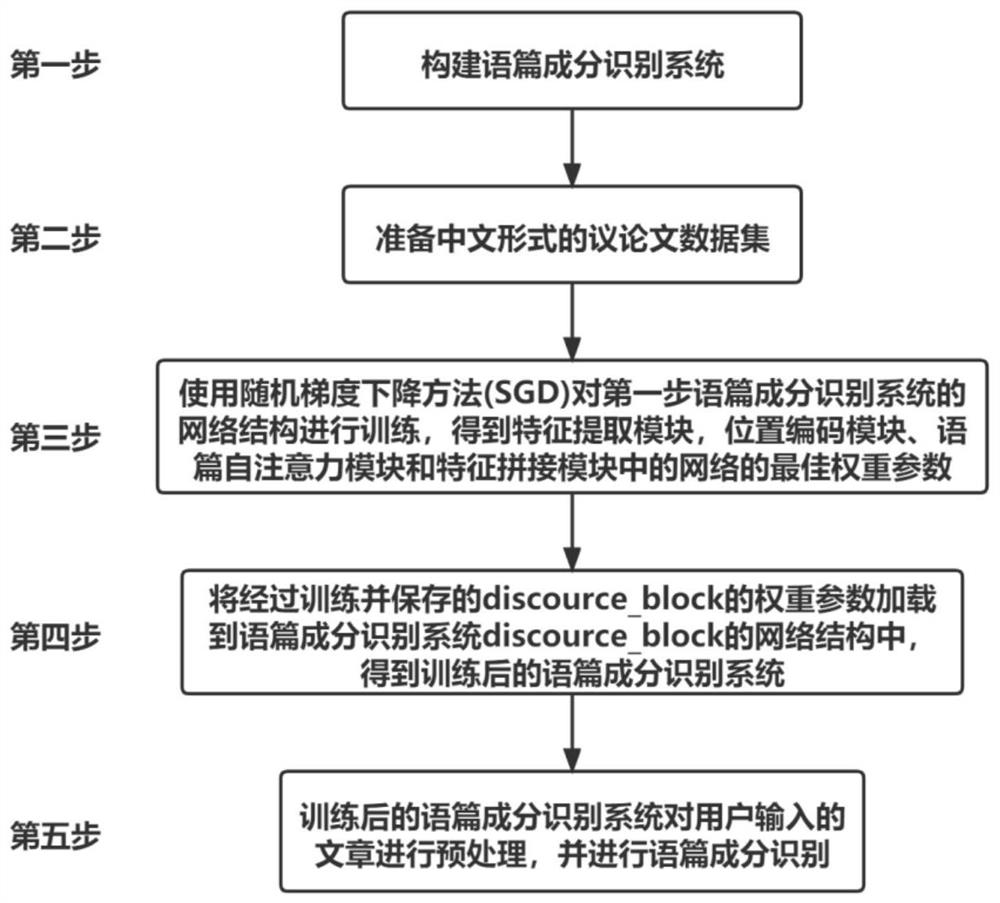

Method for identifying discourse components based on graph neural network

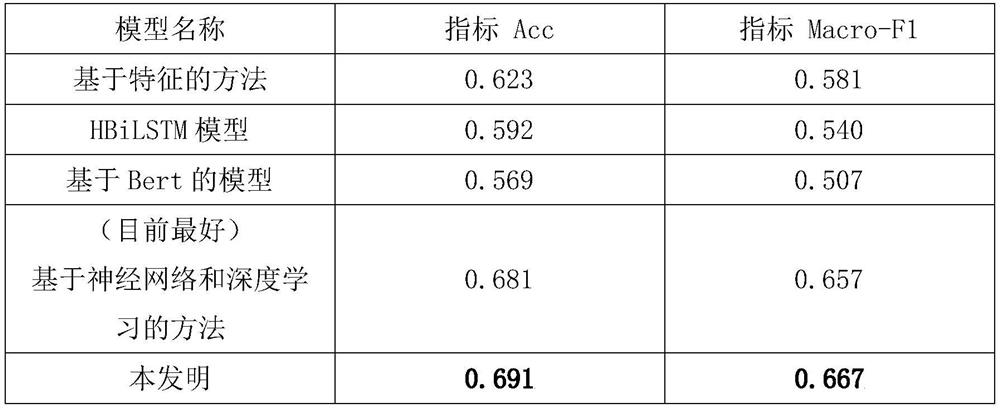

ActiveCN114880428AEasy to identifyGuarantee sufficiencyNatural language data processingNeural architecturesData setNetwork structure

The invention discloses a discourse component identification method based on a graph neural network. The objective of the invention is to improve the accuracy of discourse component identification and a Macro-F1 value. According to the technical scheme, firstly, a discourse component recognition system combined with a graph neural network is constructed; preparing a Chinese argument data set required for training the discourse component recognition system; and training the discourse component recognition system by adopting a multi-round circulation mode to obtain an optimal network structure weight parameter, and loading the weight parameter obtained by training to the discourse component recognition system to obtain a trained discourse component recognition system. And the trained discourse component recognition system preprocesses an article input by a user and performs discourse component recognition to obtain a recognition result of the article. According to the method, the purpose of improving the discourse component recognition effect by using the graph neural network technology is achieved, and compared with an existing discourse component recognition method, the Acc value and the Macro-F1 value are both improved.

Owner:NAT UNIV OF DEFENSE TECH

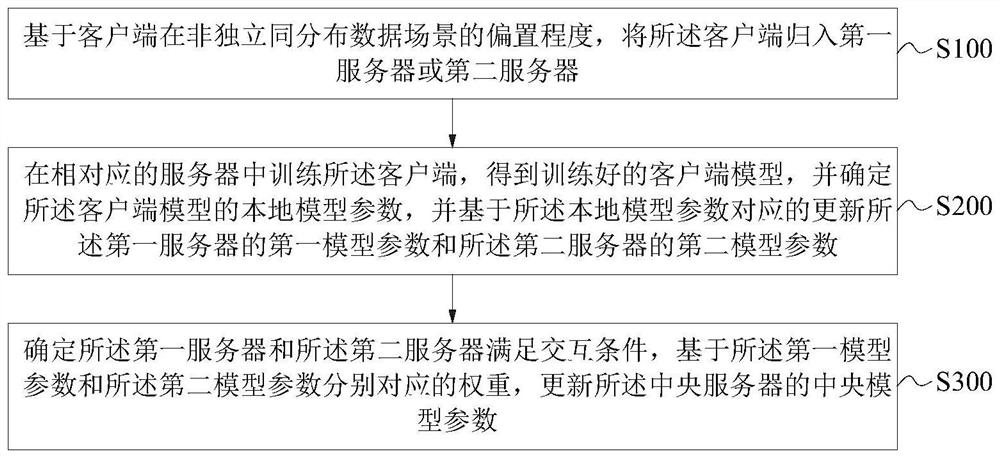

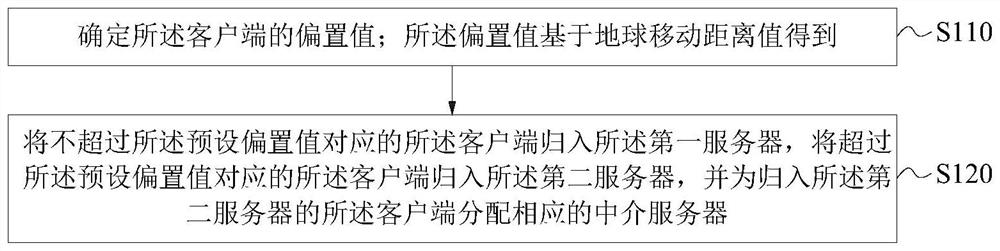

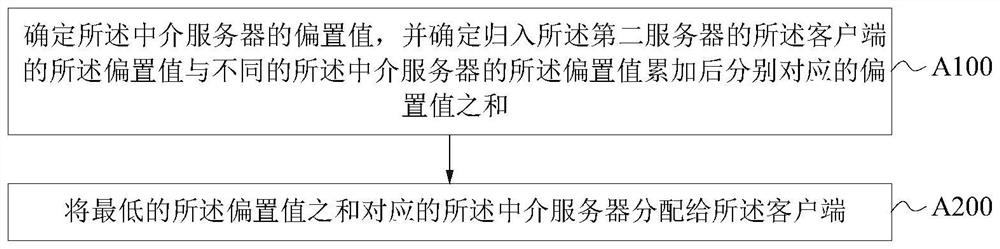

Federal learning method and device based on client classification and information entropy

ActiveCN114723071AAccurate processingEasy to handleCharacter and pattern recognitionMachine learningEngineeringData mining

The invention discloses a federal learning method and device based on client classification and information entropy, and relates to the technical field of machine learning, and the method comprises the steps: classifying a client into a first server or a second server based on the bias degree of the client in a non-independent identically distributed data scene; training the client in the corresponding server to obtain a trained client model, determining a local model parameter of the client model, and correspondingly updating a first model parameter of the first server and a second model parameter of the second server based on the local model parameter; and determining that the first server and the second server meet the interaction condition, and updating the central model parameter of the central server based on the weights corresponding to the first model parameter and the second model parameter respectively. According to the invention, the model accuracy of federal learning can be improved, so that the federal learning is suitable for Non-IID scenes with different mixing degrees.

Owner:HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN (INSTITUTE OF SCIENCE AND TECHNOLOGY INNOVATION HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN)

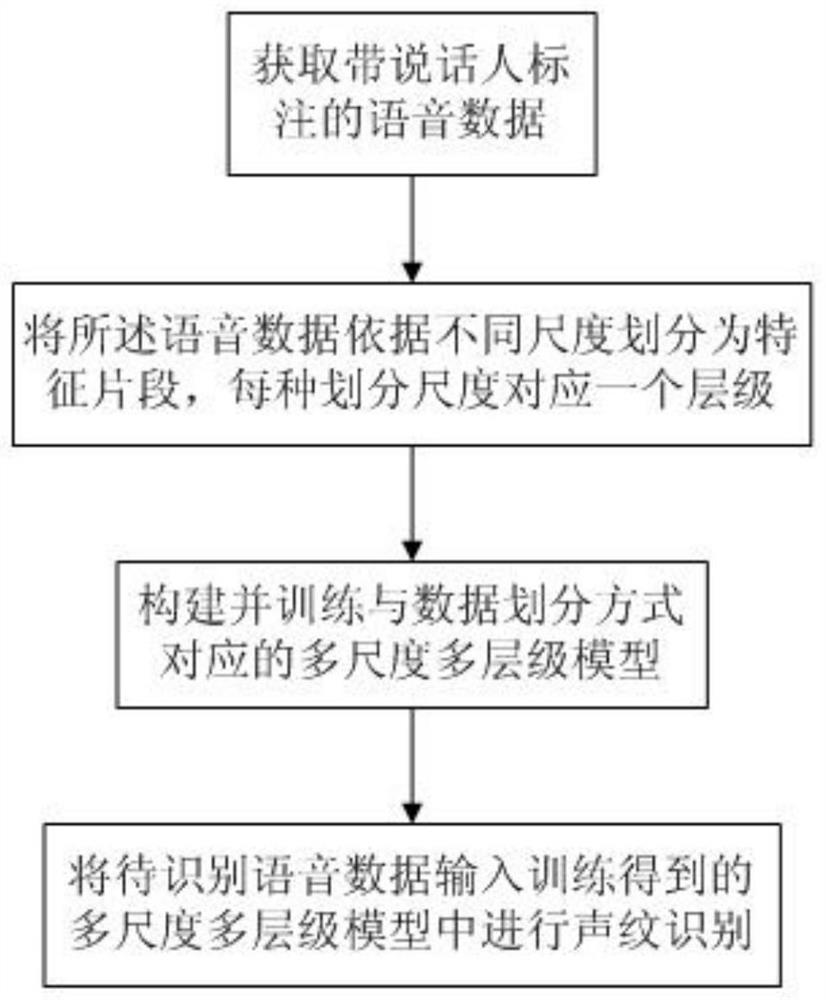

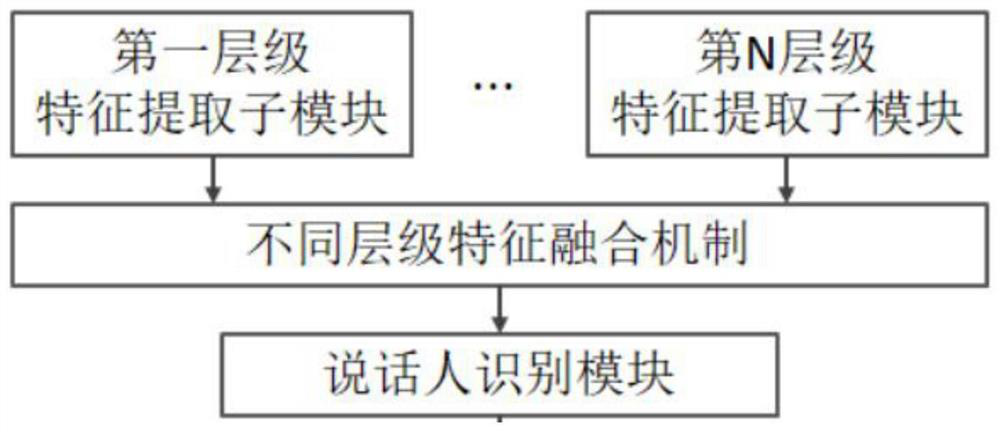

Voiceprint recognition system and method based on multi-scale multi-level model

PendingCN114220437AImprove the effect of the modelGood robustnessSpeech analysisVoice dataEngineering

The invention relates to the technical field of voiceprint recognition, and provides a voiceprint recognition method based on a multi-scale and multi-level model in order to improve the accuracy of voiceprint recognition, comprising the following steps: step 1, acquiring voice data with speaker labels; step 2, dividing the voice data into feature segments according to different scales, wherein each division scale corresponds to a hierarchy; step 3, constructing and training a multi-scale multi-level model corresponding to the data division mode; and 4, inputting to-be-recognized voice data into the multi-scale multi-level model obtained by training in the step 3 for voiceprint recognition. The invention discloses a voiceprint recognition system based on a multi-scale and multi-level model. The voiceprint recognition system comprises a data acquisition unit, a data division unit, a model construction unit, a model training unit and a voiceprint recognition unit. By adopting the mode, the accuracy of the voiceprint recognition model is improved.

Owner:四川启睿克科技有限公司

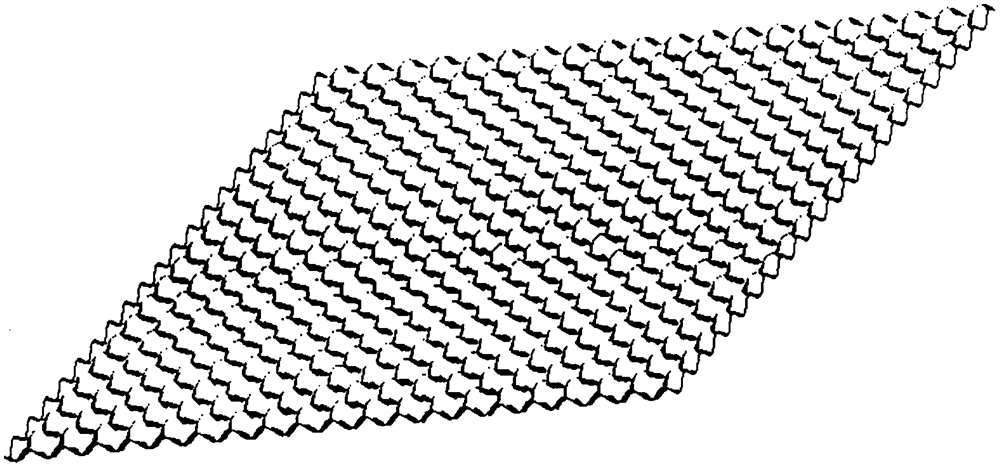

Composite buffer material

PendingCN110077082AHigh mechanical strengthGood weather resistanceSynthetic resin layered productsPaper/cardboard layered productsPolymerMaterials science

The invention discloses a composite buffer material which comprises a core material and a face material, wherein the core material is a bidirectional superimposed corrugate core material; a corrugateangle between two directions of the bidirectional superimposed corrugate core material is 1-90 degrees; and a corrugate cross-sectional shape in the two directions is a combination of function curvesor partial function curves. According to the invention, polymer materials are molded into a bidirectional corrugate structure through a mold, and then are used as the core material for directly replacing a corrugated board core paper material and then being combined with the face material to form the composite buffer material with the corrugated structure, thereby not only reducing dosage of paperpulp, but also reducing manufacturing process steps, also improving recovery utilization rate and reducing the problem of performance degradation of the corrugated board due to recycling.

Owner:TIANJIN UNIV OF SCI & TECH

Linear compressor and manufacturing method thereof

ActiveCN105317651BReduce sizeIncreased internal storage spacePositive displacement pump componentsWorking fluid for enginesLinear compressorReciprocating motion

The present invention relates to a linear compressor and a method for manufacturing the same. The linear compressor according to embodiments of the present invention comprises: a housing provided with a suction portion; a cylinder arranged inside the housing to form a compression space of refrigerant; a piston capable of performing reciprocating motion inside the cylinder in the axis direction; a discharge valve arranged to one side of the cylinder and selectively discharging the refrigerant compressed in the compression space of the refrigerant; a gas inflow portion formed on the periphery of the cylinder, at least a part of the refrigerant discharged via the discharge valve flowing into the gas inflow portion; a filter member arranged at the gas inflow portion; and a pressing member to apply pressure to the filter member.

Owner:LG ELECTRONICS INC

Degradable buffer material

PendingCN112549667AHigh mechanical strengthGood weather resistanceSynthetic resin layered productsPaper/cardboard layered productsPolymer sciencePolymer chemistry

The invention discloses a degradable buffer material. The degradable buffer material is composed of a core material and a surface material, the core material is in the shape of a two-way superimposedcorrugation, the corrugation included angle of the two directions of the two-way superimposed corrugation core material is 1-90 degrees, and the corrugation cross sections in the two directions are inthe shape of a function curve or a combination of partial function curves. According to the invention, a high polymer material is molded into a bidirectional corrugated structure through a mold, is used as a core material to directly replace a corrugated board core paper material, and then is combined with a surface material to form the degradable buffer material with the corrugated structure, sothat the consumption of paper pulp is reduced, the manufacturing process steps are reduced, the recycling rate can be increased, and the problem that the performance of the corrugated board is reduced due to cyclic utilization is reduced.

Owner:TIANJIN UNIV OF SCI & TECH

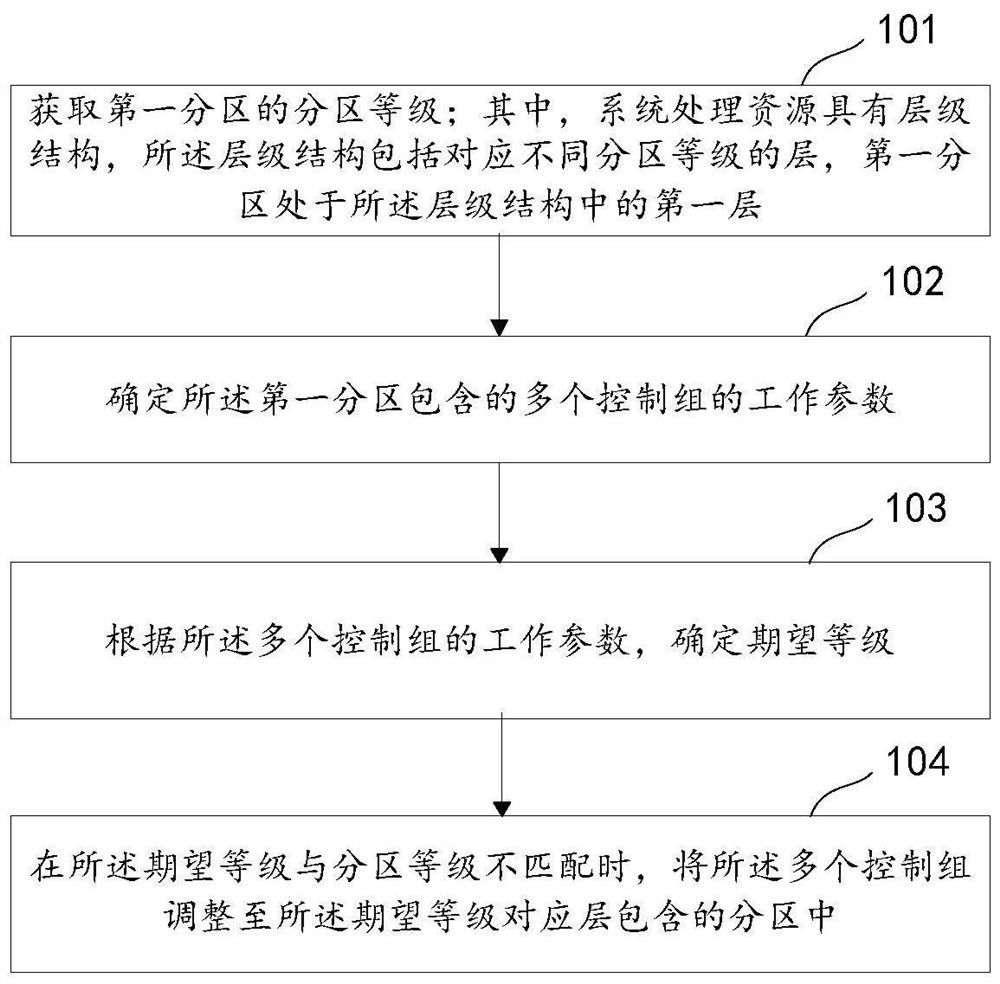

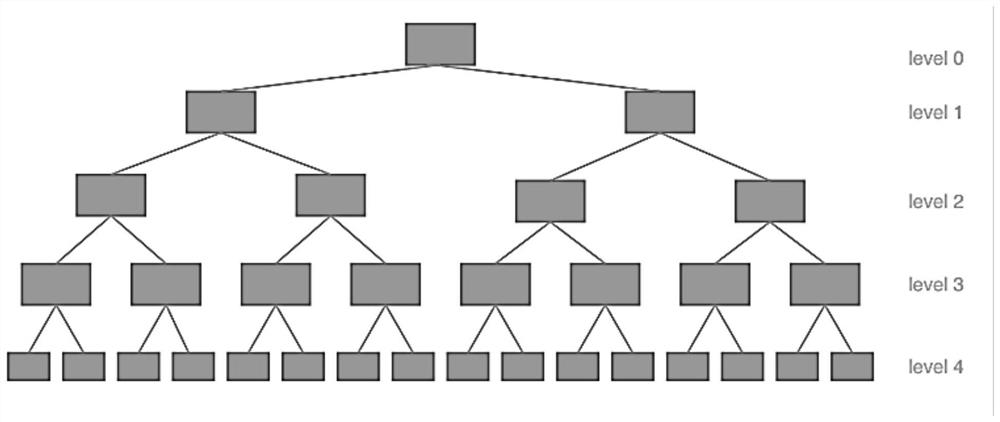

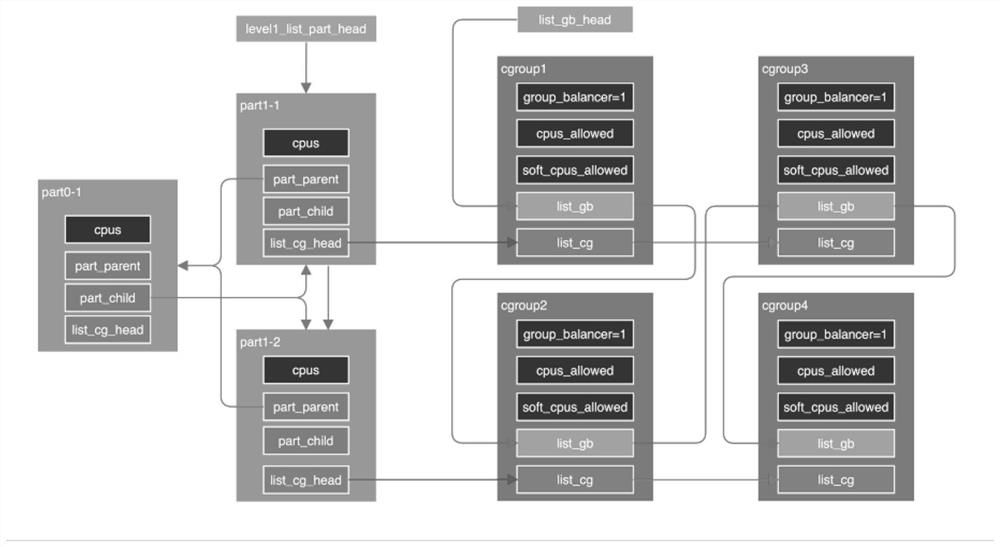

Dynamic partitioning method, system, equipment and medium

PendingCN114168319AMitigate performance degradationImprove performanceResource allocationProcessingDistributed computing

The embodiment of the invention provides a dynamic partitioning method, system and device and a medium. The method comprises the following steps: acquiring a first partition level of a first partition; wherein the system processing resource has a hierarchical structure, the hierarchical structure comprises layers corresponding to different partition levels, and the first partition is located in a first layer in the hierarchical structure; determining working parameters of a plurality of control groups contained in the first partition; determining a second partition level according to the working parameters of the plurality of control groups; and when the second partition level is not matched with the partition level, adjusting the plurality of control groups into the partitions contained in the layer corresponding to the second partition level. When dynamic partitioning needs to be carried out, adjustment can be carried out among layers corresponding to different partition levels of the same partition branch according to the processor pressure of the partition level corresponding to the first partition. And when the cross-affinity domain adjustment demand is carried out, the control group is taken as a division unit to carry out overall migration between different partitions of the layer where the same partition level is located, so that the performance of the overall processor can be effectively improved.

Owner:ALIBABA (CHINA) CO LTD

A Data Enhancement Method of Dam Crack Image Based on Deep Convolutional Generative Adversarial Network

ActiveCN110956591BQuality improvementIncrease the number ofImage enhancementImage analysisData setImaging quality

Owner:HOHAI UNIV +3

Test method and device for gate oxide layer trap density and position

ActiveCN103367193BReduce generationMitigate performance degradationSemiconductor/solid-state device testing/measurementV curveEngineering

The invention provides a method and a device for testing trap density and position of a gate oxide layer, and relates to the technical field of quality and reliability testing of an MOS (Metal Oxide Semiconductor) device. The method comprises the following steps: S1, accessing negative voltage at a source end and a drain end, grounding at a substrate end, so that p and n nodes are forward bias; S2, after the p and n nodes are forward bias, accessing a grid direct-current scanning voltage at a grid, and scanning from negative voltage to positive voltage, so that the surface of the device becomes weak inversion state from accumulation state; measuring the substrate end during the scanning process so as to obtain substrate current; S3, establishing a first I-V curve of the substrate current and the grid direct-current scanning voltage; S4, applying a fixed voltage to the grid, repeating the steps S1 to S 3 for multiple times so as to obtain a plurality of second I-V curves; measuring the heights of bottoms of the second I-V curves so as to obtain the trap density of p and n nodes. According to the method and the device, the strap density of the p and no nodes can be measured and the positions of traps can be positioned, so that the design of the device is improved so as to reduce the traps.

Owner:PEKING UNIV

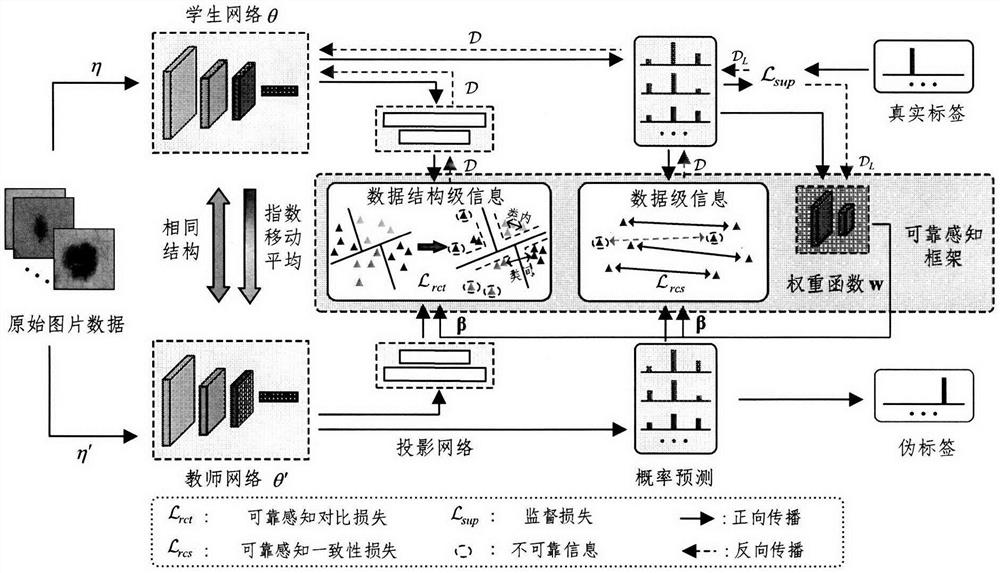

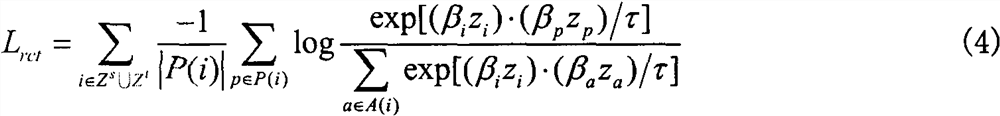

Semi-supervised medical image classification method based on security comparison self-integration framework

PendingCN114758172AReduce negative impactMitigate performance degradationNeural architecturesNeural learning methodsEngineeringData mining

The invention provides a semi-supervised medical image classification method based on a safety comparison self-integration framework, and the method comprises the following steps: firstly, selecting a batch of data composed of labeled and unlabeled data, adding data disturbance to the data, repeating the processing twice to obtain two groups of data, and inputting the two groups of data into a student network and a teacher network respectively; secondly, designing a weighting function, updating the weighting function by utilizing supervised loss, and automatically distributing a weight for each piece of unmarked data; the weight parameters and the probability output of the two networks are combined, and the consistency loss of reliable perception is established; further, normalized low-dimensional representations output by the two networks are obtained by combining weight parameters and utilizing a projection network, and comparison loss of reliable perception is established; and finally, respectively carrying out weighted summation on all the loss functions to form a final loss function, and alternately updating network parameters and weighting function parameters. According to the method provided by the invention, reliable data level and data structure level information can be learned at the same time, and the robustness and generalization of the model are improved.

Owner:NANJING UNIV OF TECH

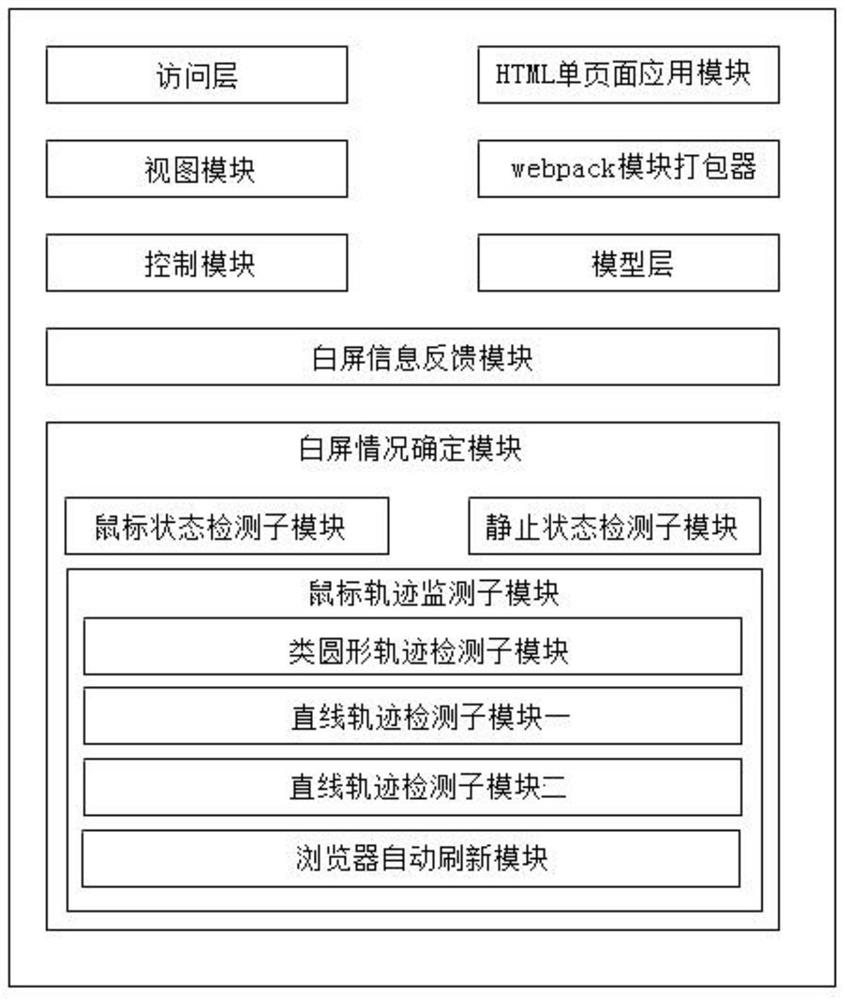

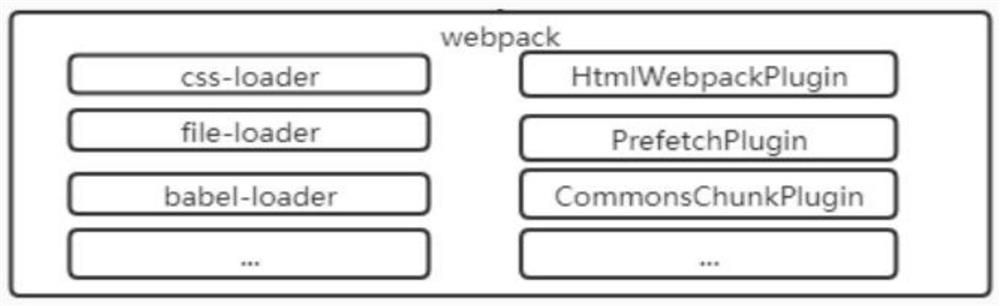

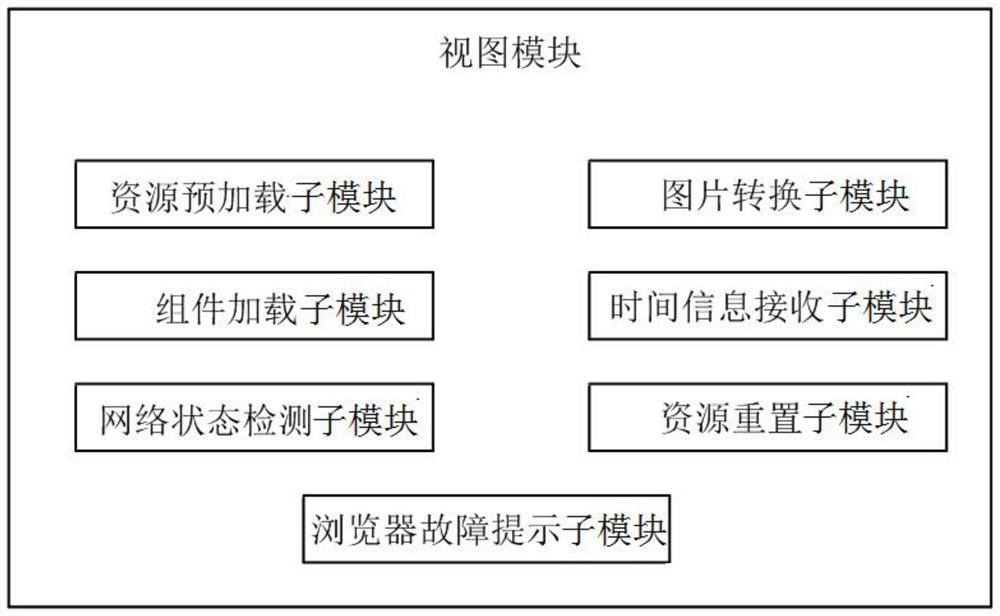

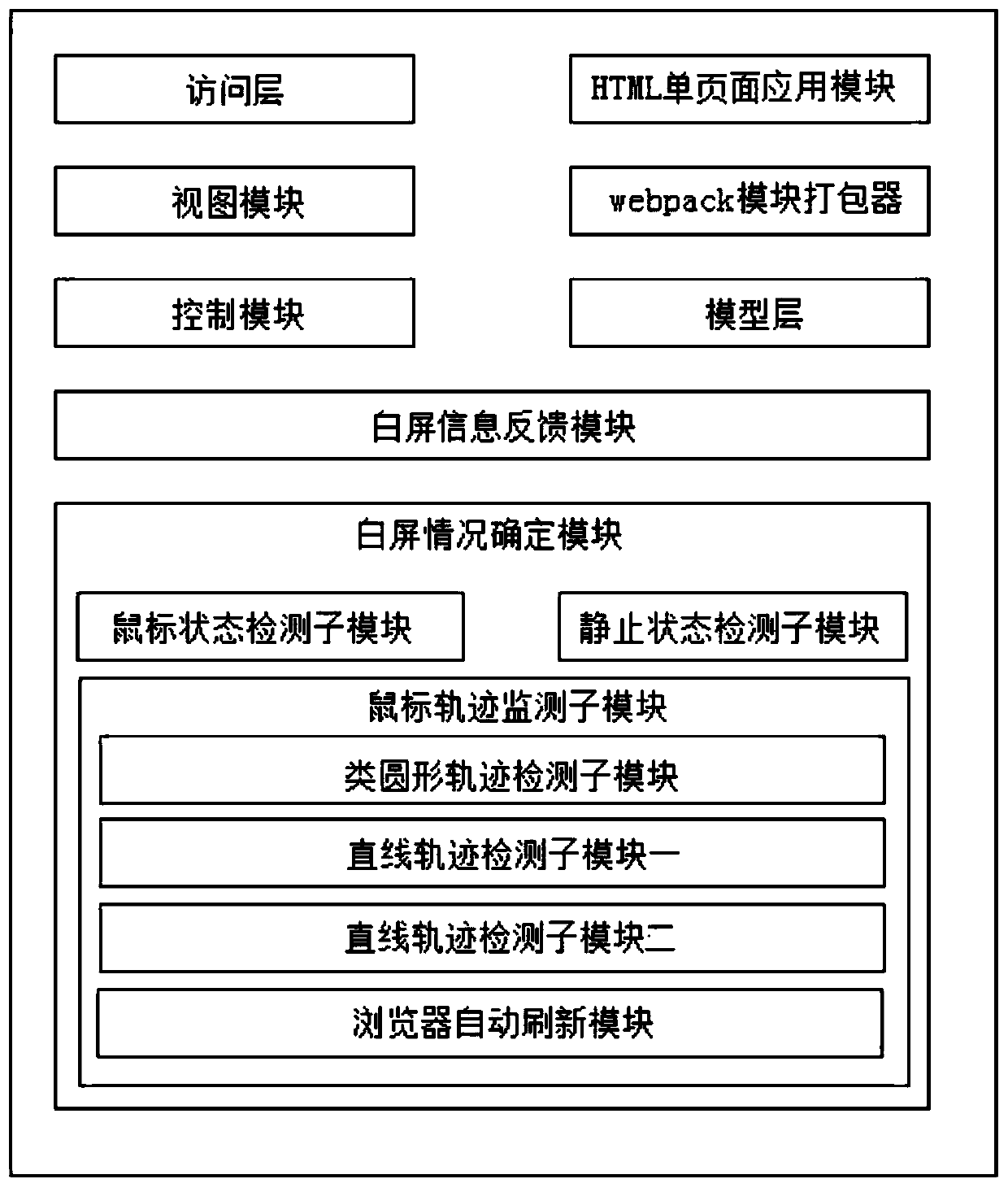

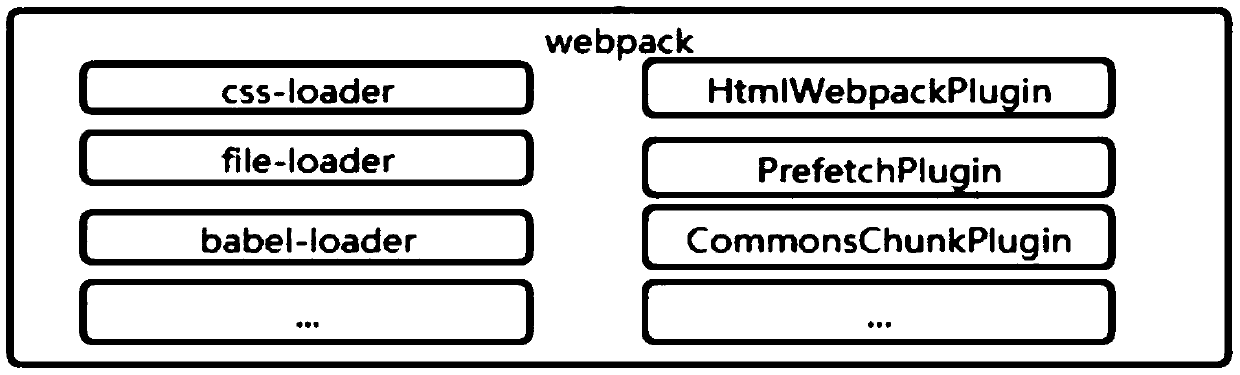

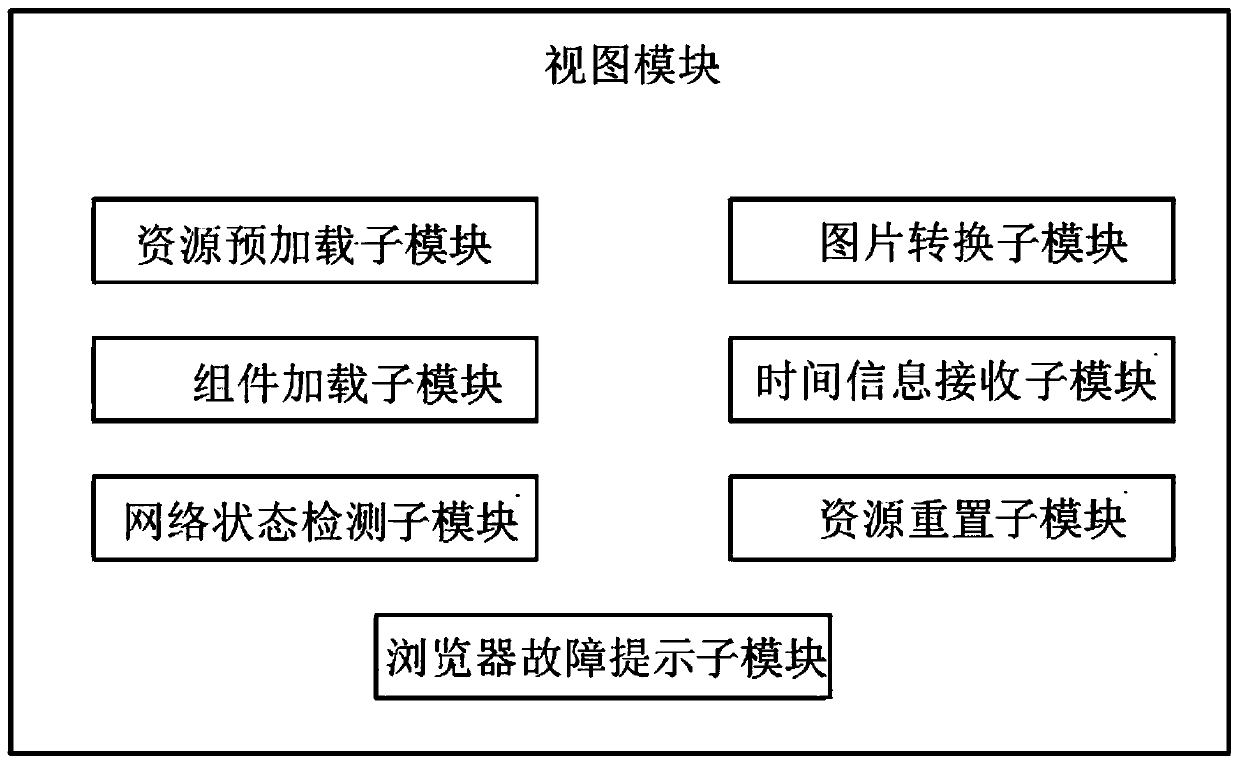

A browser front-end architecture system that can be developed separately from the back-end architecture

ActiveCN111428168BReduce volumeImprove loading speedWebsite content managementSpecial data processing applicationsComputer architectureEngineering

The invention provides a browser front-end architecture system capable of being developed separately from a rear-end architecture. The browser front-end architecture system comprises an access layer,an HTML single-page application module, a view module, a webpack module packer, a control module and a model layer. The method and the device are used for solving the problems that each page of an existing browser is time-consuming in requesting static resources, variable conflicts occur when js files are introduced, DOM element rendering is slow and performance is poor when the page is locally refreshed, and have the characteristic of improving the performance of a front-end architecture system.

Owner:北京三维天地科技股份有限公司

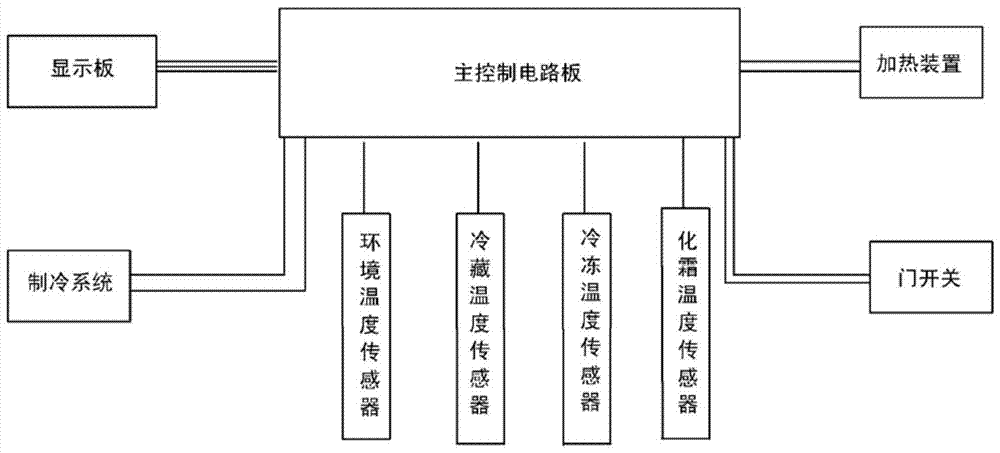

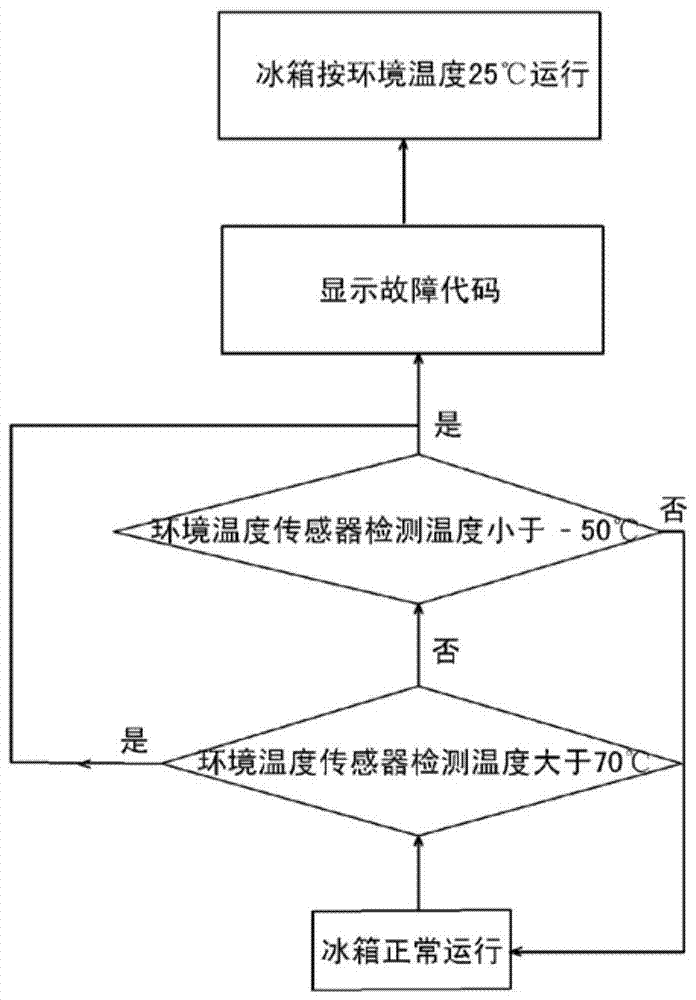

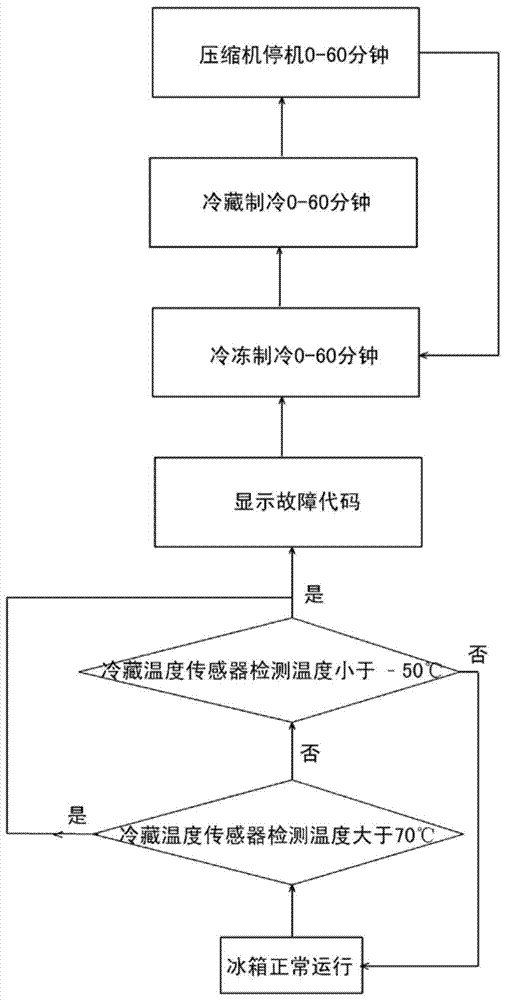

Faulty operation method of refrigerator and refrigerator thereof

ActiveCN104613730BGuaranteed uptimeImprove operational reliabilityDomestic cooling apparatusLighting and heating apparatusRefrigerator carDisplay board

Owner:CHANGHONG MEILING CO LTD

Method for determining location information of user terminal UE and network side equipment

ActiveCN102264095BSolve the unknowableGuaranteed service qualityWireless communicationTelecommunicationsResource utilization

The present invention relates to the field of communications. In order to solve the problem that the determination of UE location information depends on the establishment of an RRC connection, a method for determining UE location information and configuring parameters for the UE is provided, including: determining the path loss threshold PLTH for the UE to enter the cell edge; determining The grouping threshold matched with the PLTH is sent to each UE in the cell, which is used as a path loss comparison reference when the UE initiates a competitive random access. The UE determines to select a preamble in a different group when initiating a competitive random access according to the comparison result ; During the random access process initiated by the UE, obtain the random access method selected by the UE; when the selected random access method is contention random access, obtain the preamble selected during random access; according to the selected The group to which the preamble belongs determines the location information of the UE. The invention can reduce the overhead of air interface signaling caused by blindly configuring parameters when the RRC is not established, and further improves the utilization rate of system resources.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Browser front-end architecture system capable of being developed separately from rear-end architecture

ActiveCN111428168AReduce volumeImprove loading speedWebsite content managementSpecial data processing applicationsComputer architectureEngineering

The invention provides a browser front-end architecture system capable of being developed separately from a rear-end architecture. The browser front-end architecture system comprises an access layer,an HTML single-page application module, a view module, a webpack module packer, a control module and a model layer. The method and the device are used for solving the problems that each page of an existing browser is time-consuming in requesting static resources, variable conflicts occur when js files are introduced, DOM element rendering is slow and performance is poor when the page is locally refreshed, and have the characteristic of improving the performance of a front-end architecture system.

Owner:北京三维天地科技股份有限公司

Manganese zinc ferrite magnetic core with high pressure bearing performance

PendingCN114300248AImprove tightnessIncrease pressure typeInorganic material magnetismInductances/transformers/magnets manufactureSilicon oxideManganese oxide

The invention relates to the technical field of manganese zinc ferrite magnetic core manufacturing, in particular to a high-pressure-bearing manganese zinc ferrite magnetic core. The method mainly aims at solving the problems that due to the fact that the particle size difference is too large, gaps are formed in internal connection, the internal structure of the magnetic core is unstable, the pressure bearing degree of the magnetic core is affected, and due to the fact that the temperature of a setter plate is too high in the sintering process, the setter plate and zinc in manganese-zinc ferrite generate a replacement reaction, and the use performance of the magnetic core is reduced. According to the technical scheme, the composite material comprises the following raw materials in parts by mass: 45-60 mol of iron oxide, 12-18 mol of zinc oxide, 23-29 mol of manganese oxide, 2-8 mol of cobalt oxide, 1.8-4.8 mol of magnesium oxide, 16-19 mol of silicon oxide and 3-12 mol of calcium oxide. The raw materials are easy to obtain, preparation of the magnetic core is controlled from the raw materials, the problem that the internal structure of the magnetic core has a connection trend is solved, the tightness of the internal structure of the magnetic core is improved, the cushion layer is laid in the sintering process, the problem that the performance is indeed due to sintering is solved, the conductive stability is ensured, and the method is suitable for application and popularization.

Owner:ZHONGDE ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com