BGA (Ball Grid Array) ball mounting method based on infrared and hot air hybrid heating technology

A hot air and infrared technology, applied in the field of BGA ball planting, can solve the problem of low ball planting success rate, achieve high heating uniformity, high ball planting success rate, and large temperature controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

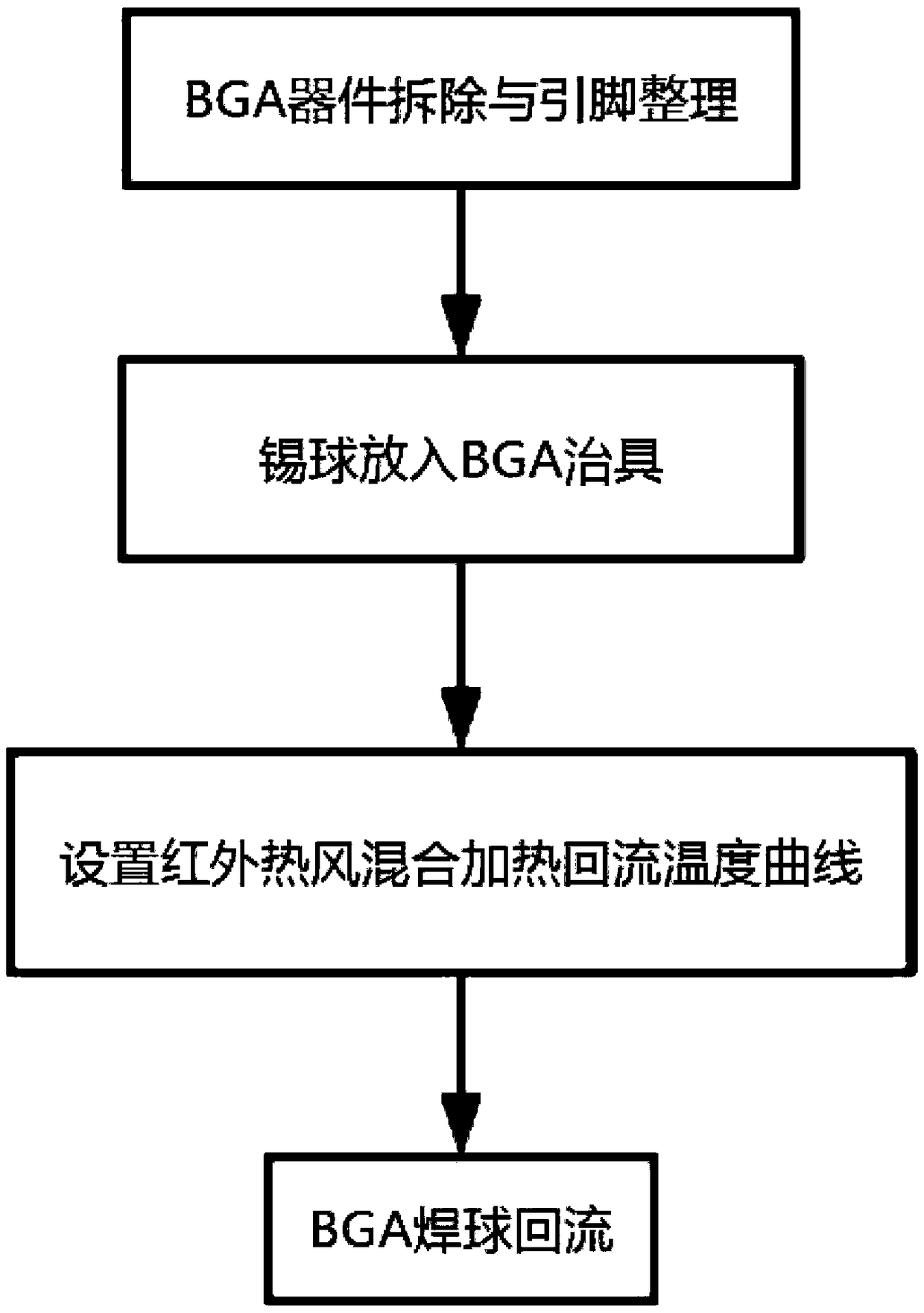

[0025] Such as figure 1 The flow chart of the method is shown:

[0026] A BGA ball planting method based on infrared and hot air mixed heating technology, comprising steps:

[0027] s1) BGA device removal and pin arrangement;

[0028] s2) Put the solder ball into the BGA fixture;

[0029] s3) setting the infrared hot air mixed heating and reflow temperature curve;

[0030] s4) BGA solder ball reflow.

[0031] Further, the step s1) uses a BGA desoldering station to complete the removal of the BGA device on the faulty circuit board, and completes the BGA device pin solder cleaning operation. The cleaning process cannot cause damage to the pad, otherwise the ball planting quality will be affected.

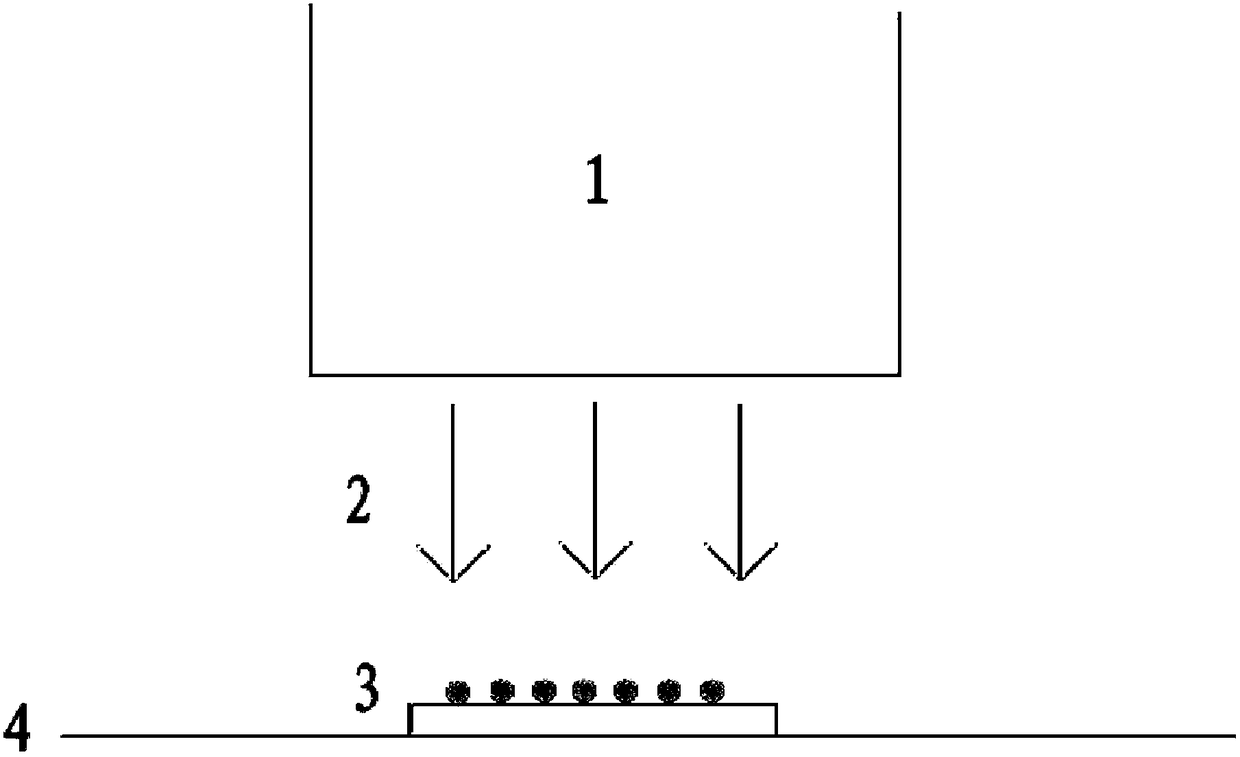

[0032] Further, the step s2) makes a special BGA ball planting jig according to the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com