Composite buffer material

A composite buffer and nanomaterial technology, applied in the field of packaging materials, can solve the problems of high consumption of natural resources and energy, increased demand for wood, and high manufacturing costs, reducing manufacturing process steps, increasing the number of cycles, and mechanical strength. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

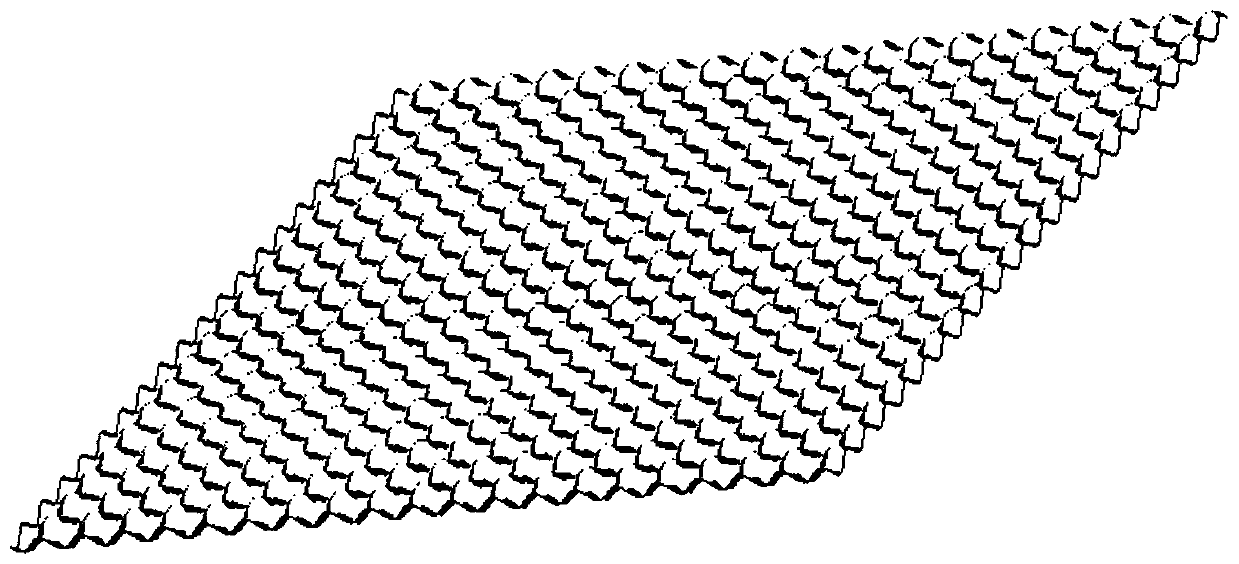

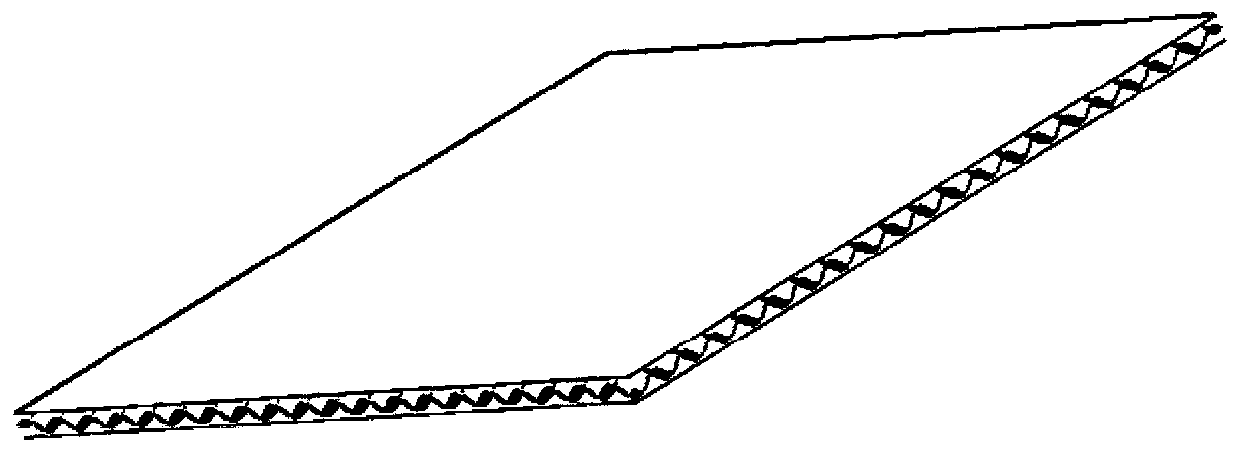

[0020] The material of the surface material is kraft paper, the material of the core material is polymaleic anhydride, and the corrugated angle between the two directions of the two-way stacked corrugated core material is 90 degrees, such as Figure 3-4 As shown, the corrugated cross-sectional shape in both directions is a sinusoidal function curve.

Embodiment 2

[0022] The material of the surface material is white cardboard, the material of the core material is polyethylene glycol, and the inside of the material of the core material is filled with nano-materials, and the nano-materials are nano-zinc oxide. The angle between corrugations in two directions of two-way superimposed corrugated core material is 45 degrees, and the cross-sectional shape of corrugations in two directions is a parabola.

Embodiment 3

[0024] The material of the surface material is plastic, the material of the core material is polyacrylamide, the material of the core material is filled with nanomaterials, the surface of the core material is coated with nanomaterials, and the nanomaterials are nano silicon carbide. The angle between the corrugations in the two directions of the two-way superimposed corrugated core material is 10 degrees, and the cross-sectional shape of the corrugations in the two directions is a hyperbola.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com