Patents

Literature

41results about How to "Eliminate sagging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

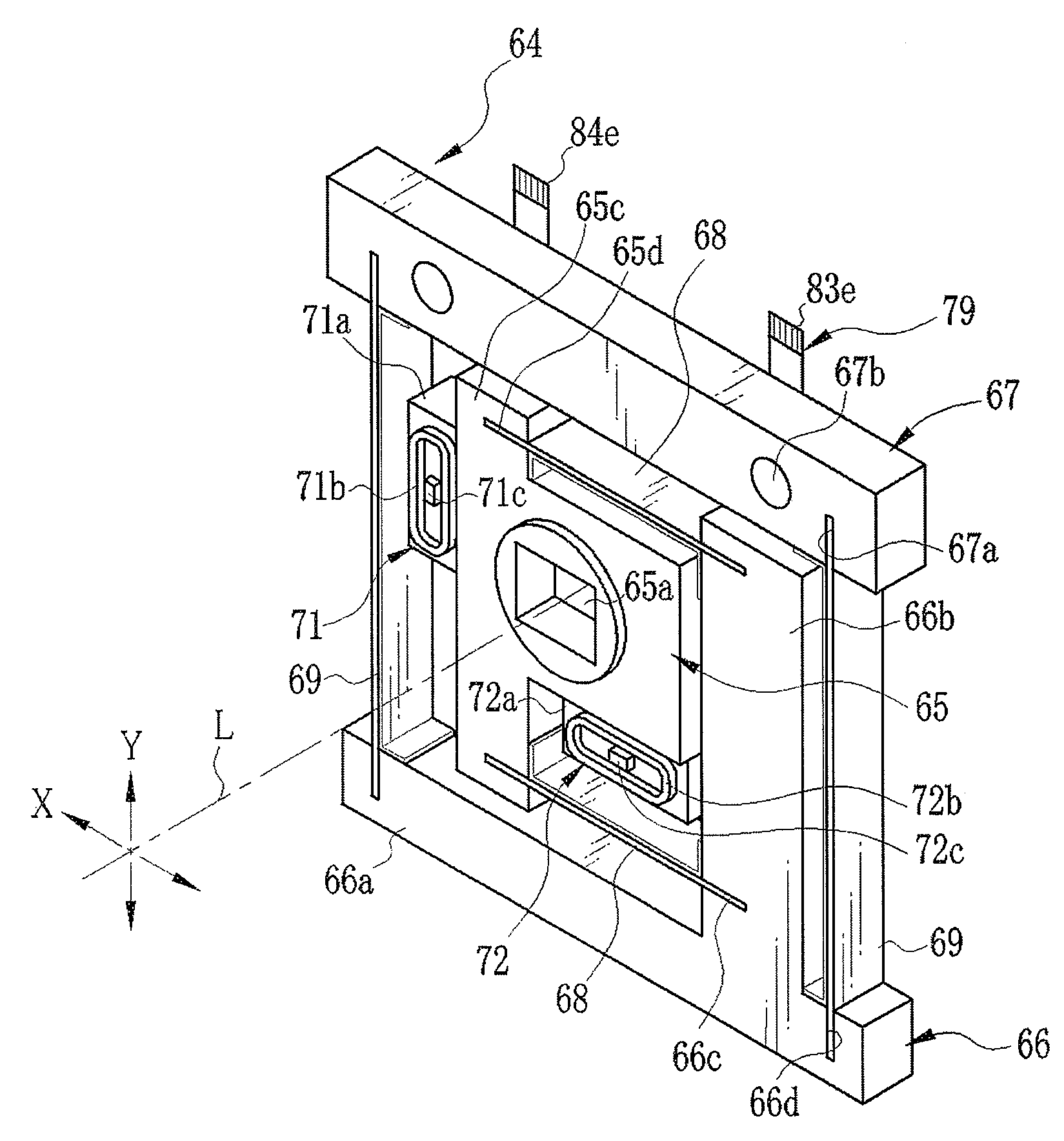

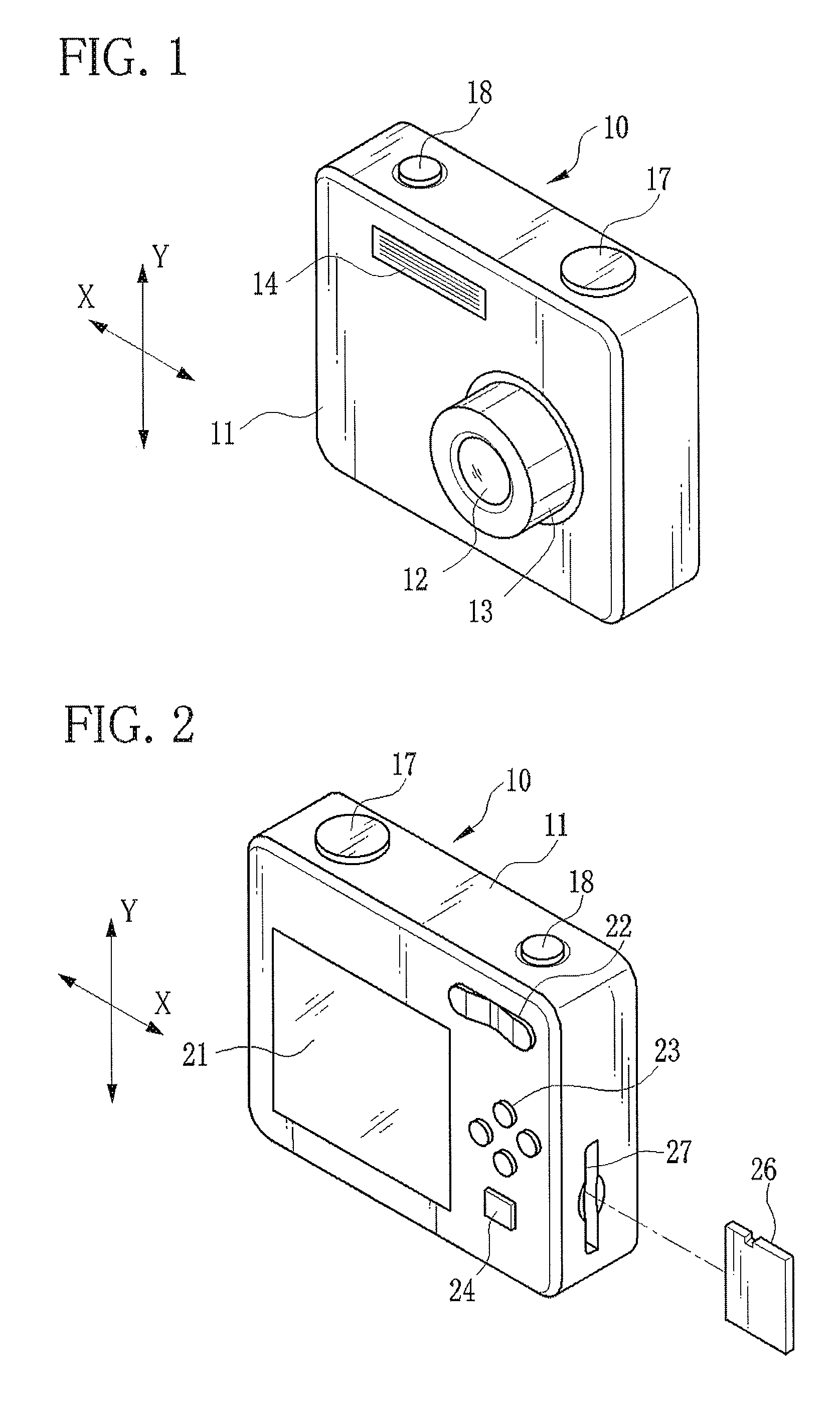

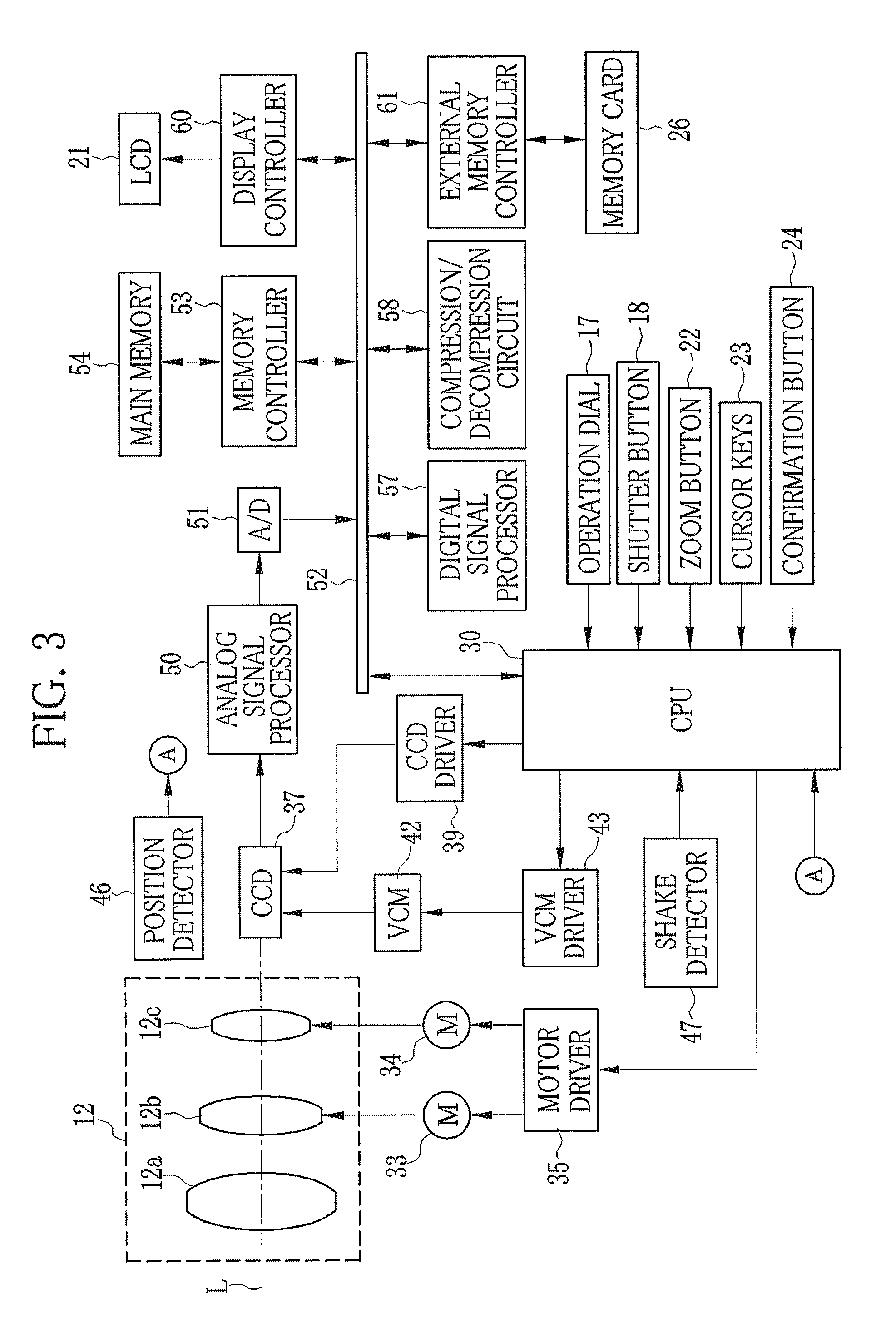

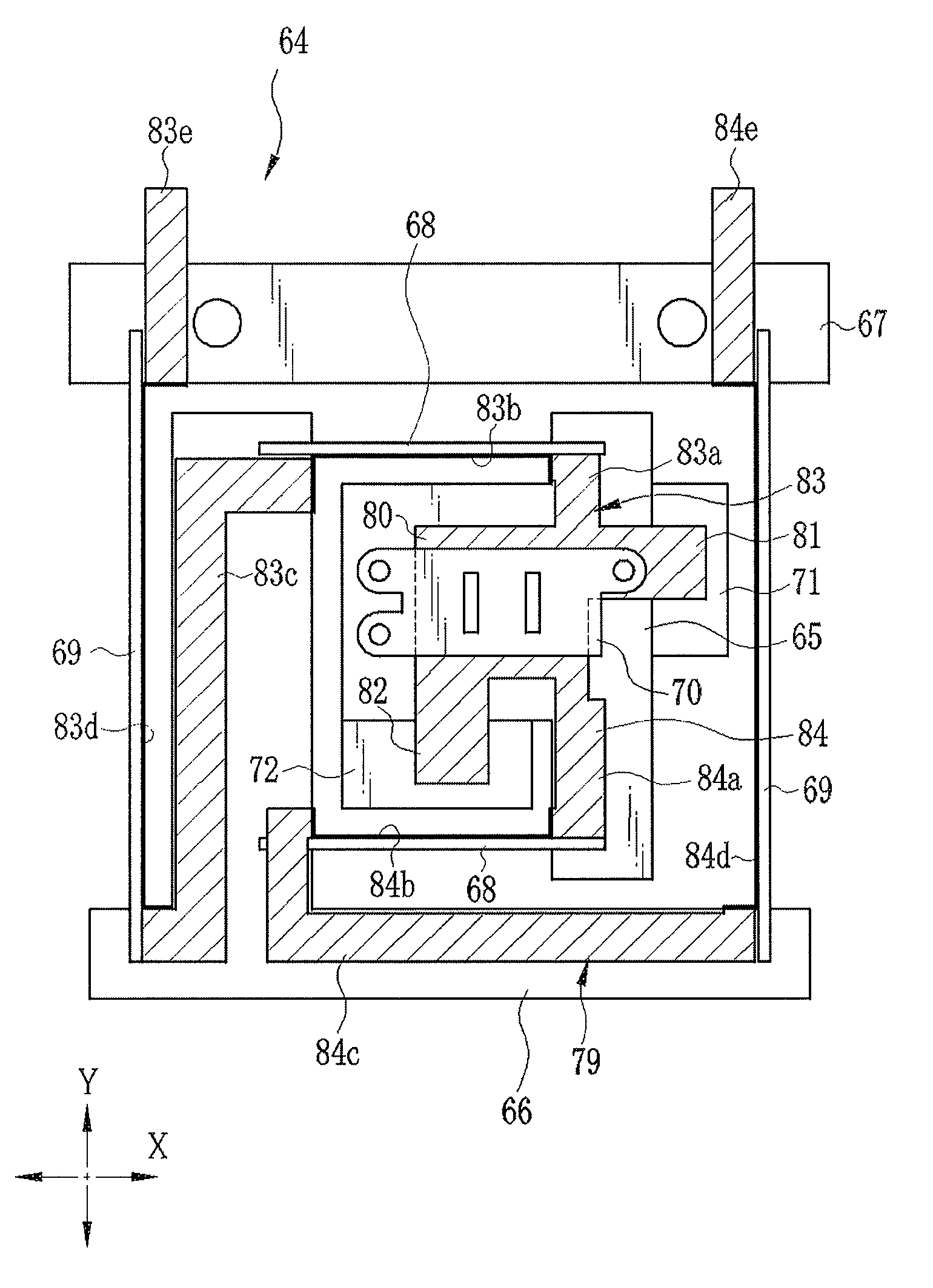

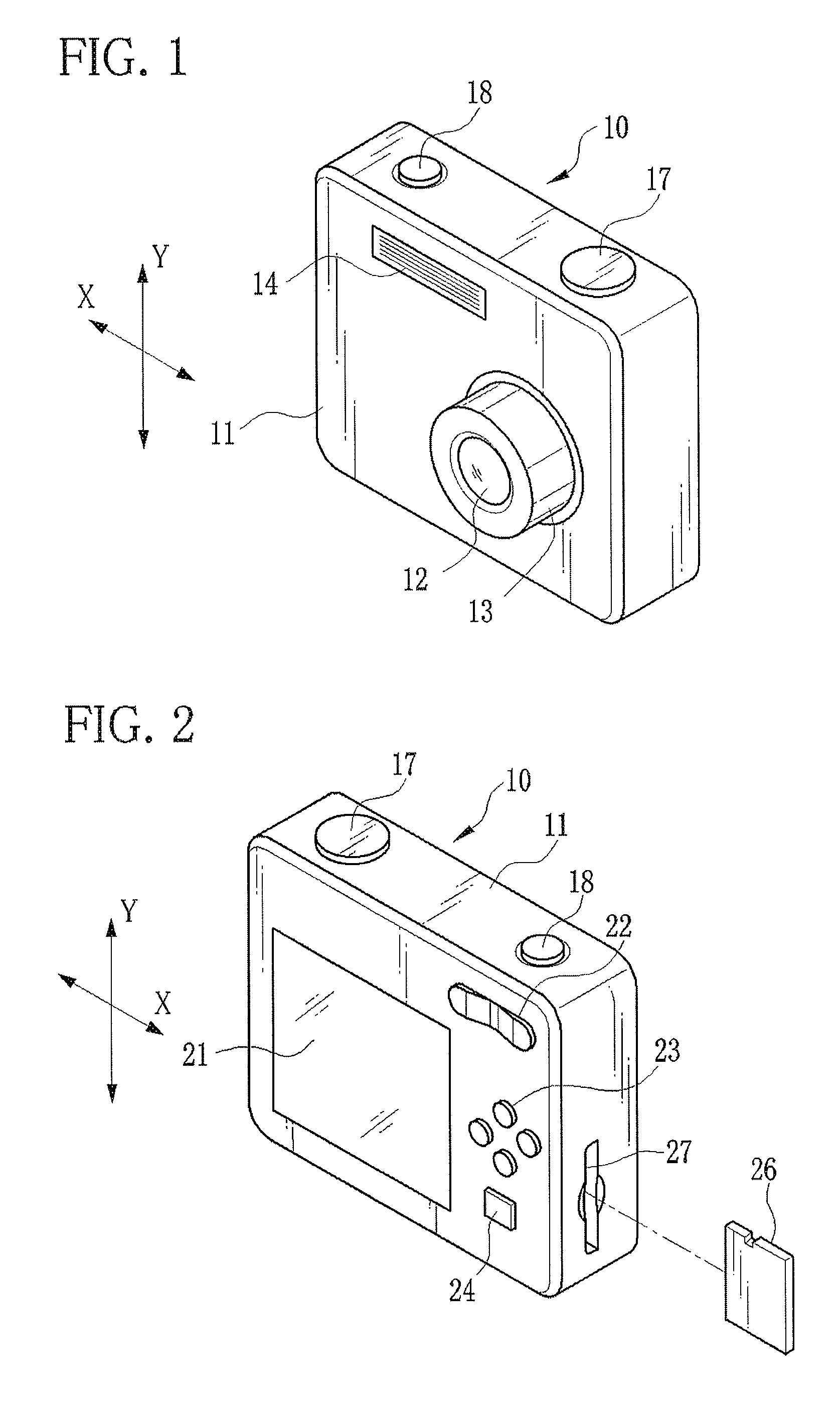

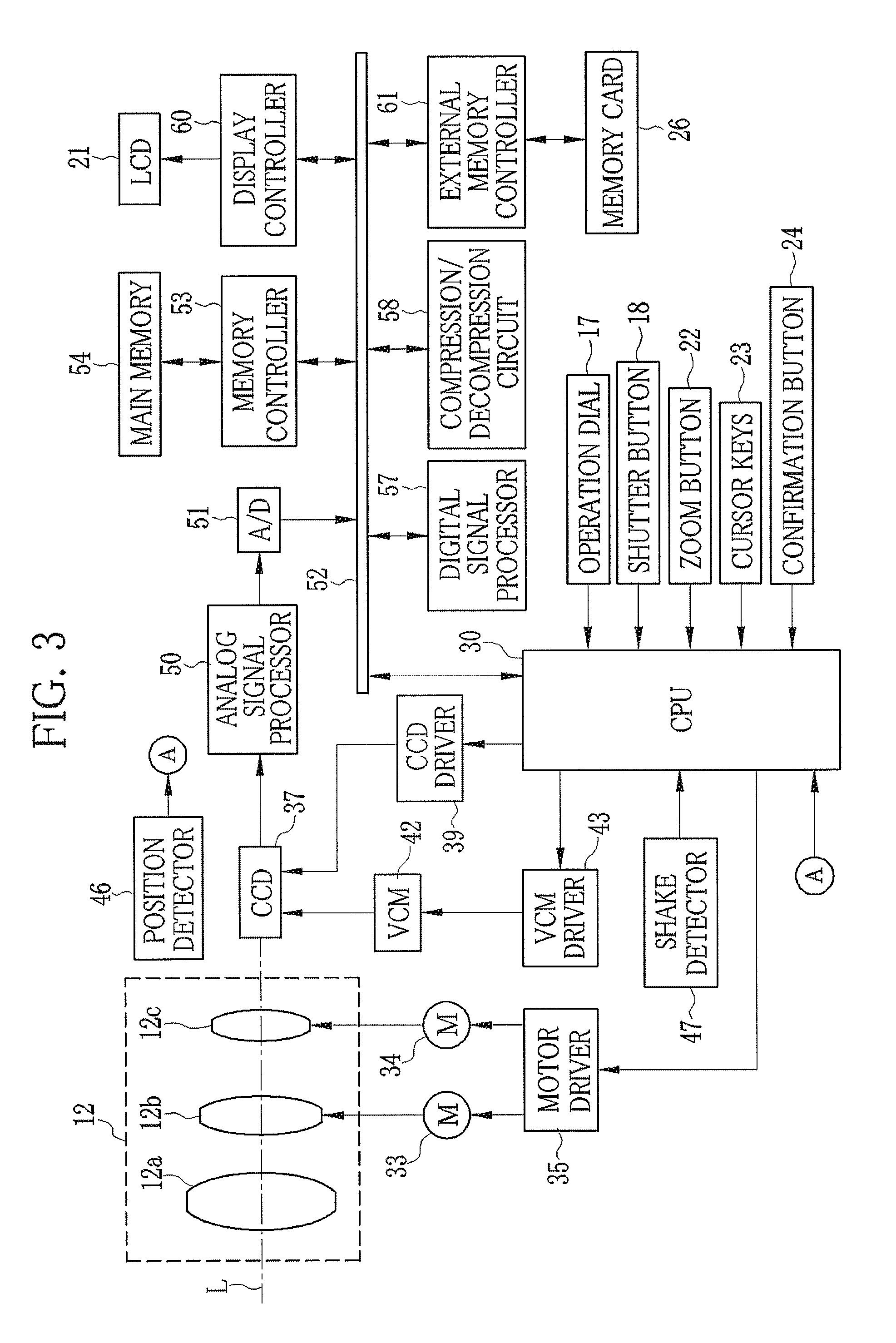

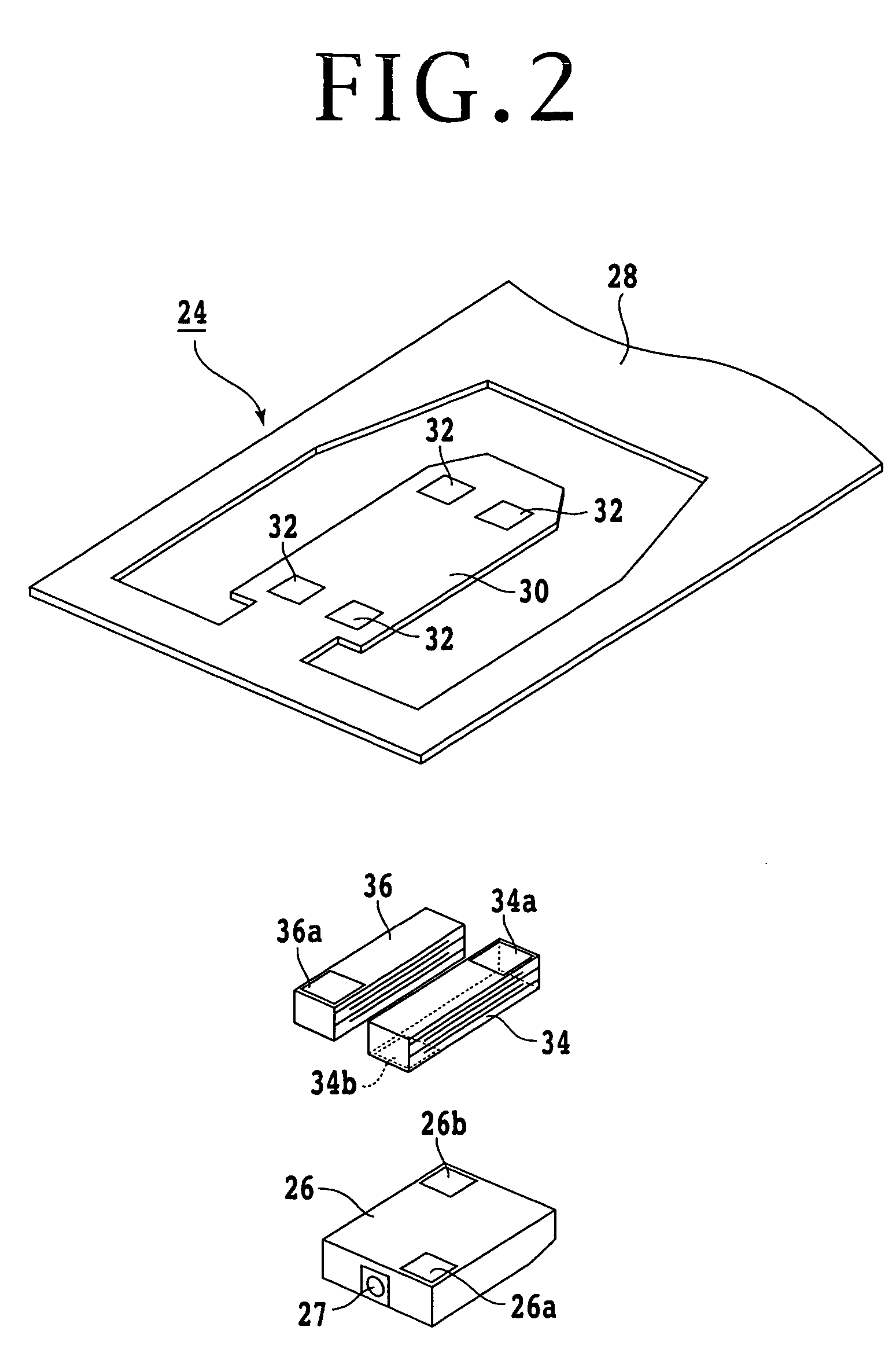

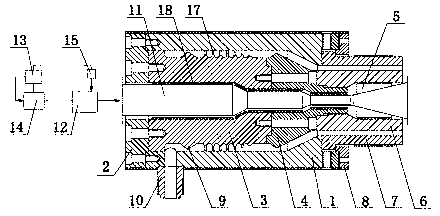

Image stabilizer and optical instrument therewith

ActiveUS20100165131A1Eliminate harmful effect of sagEliminate reaction forceTelevision system detailsPrintersHand heldEngineering

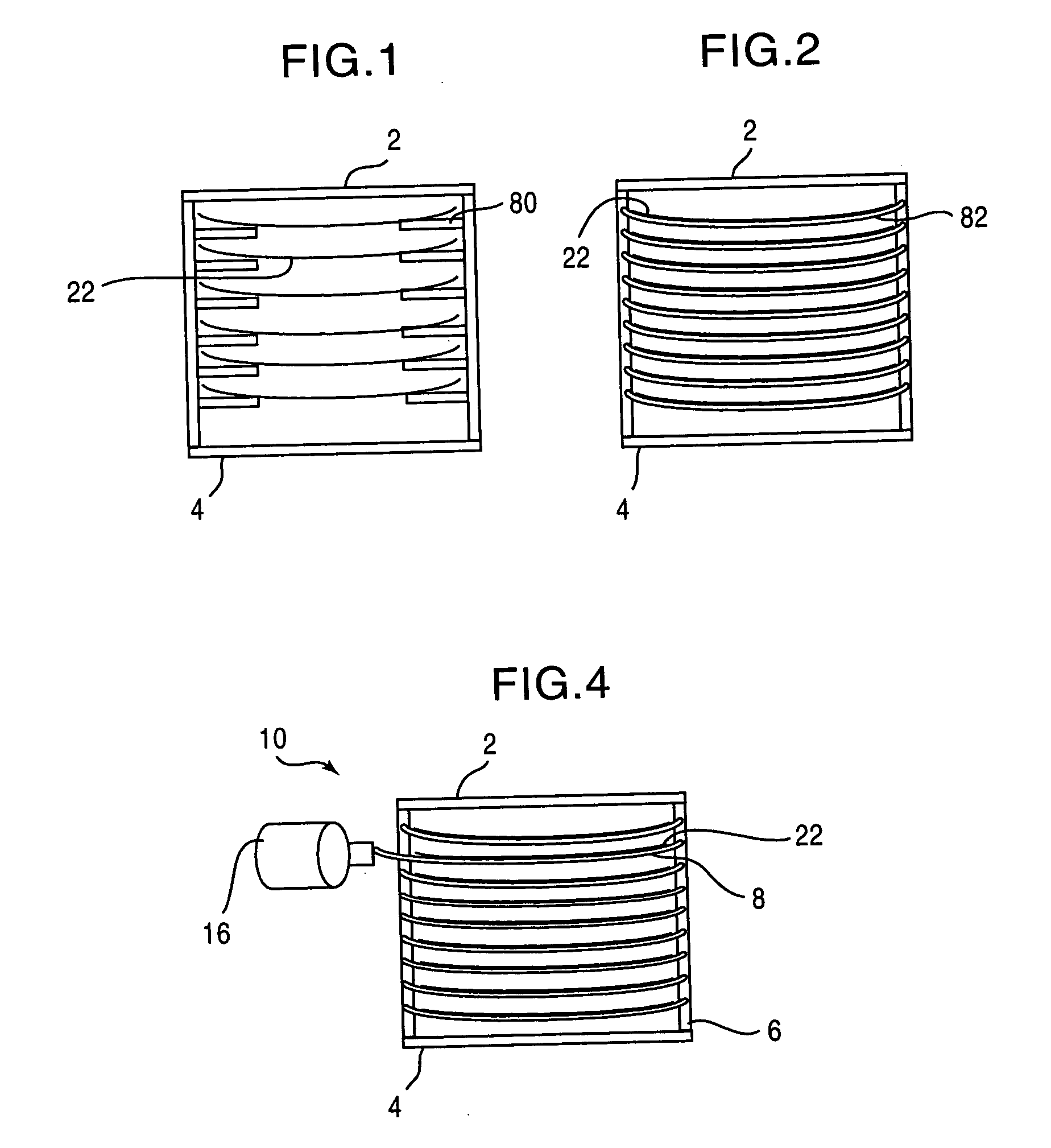

An image stabilizer has a base block, an inner frame for holding a CCD, an outer frame, a pair of horizontal leaf springs, a pair of vertical leaf springs, voice coil motors (VCMs) and a flexible printed circuit (FPC). Upon a shake of a digital still camera due to hand-held shooting, the VCMs shift the inner or outer frame while bending the horizontal or vertical leaf springs so that the CCD is shifted to counteract the camera shake. The FPC connected to the CCD and the VCMs is routed from the inner frame, through the horizontal leaf spring, the outer frame and the vertical leaf spring, and pulled out above the base block. The FPC is glued to the horizontal and vertical leaf springs, and elastically bent together with the horizontal and vertical leaf springs.

Owner:FUJIFILM CORP

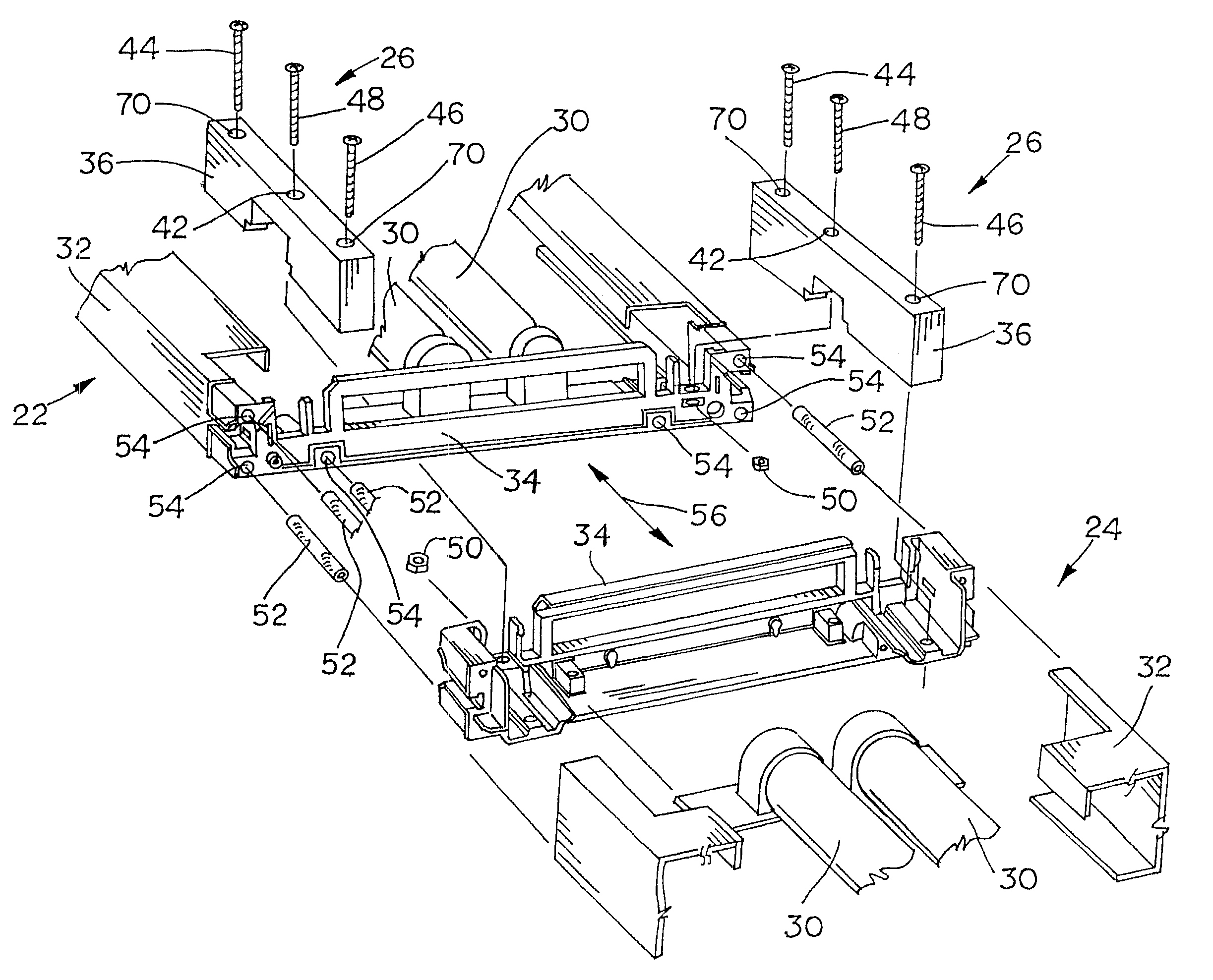

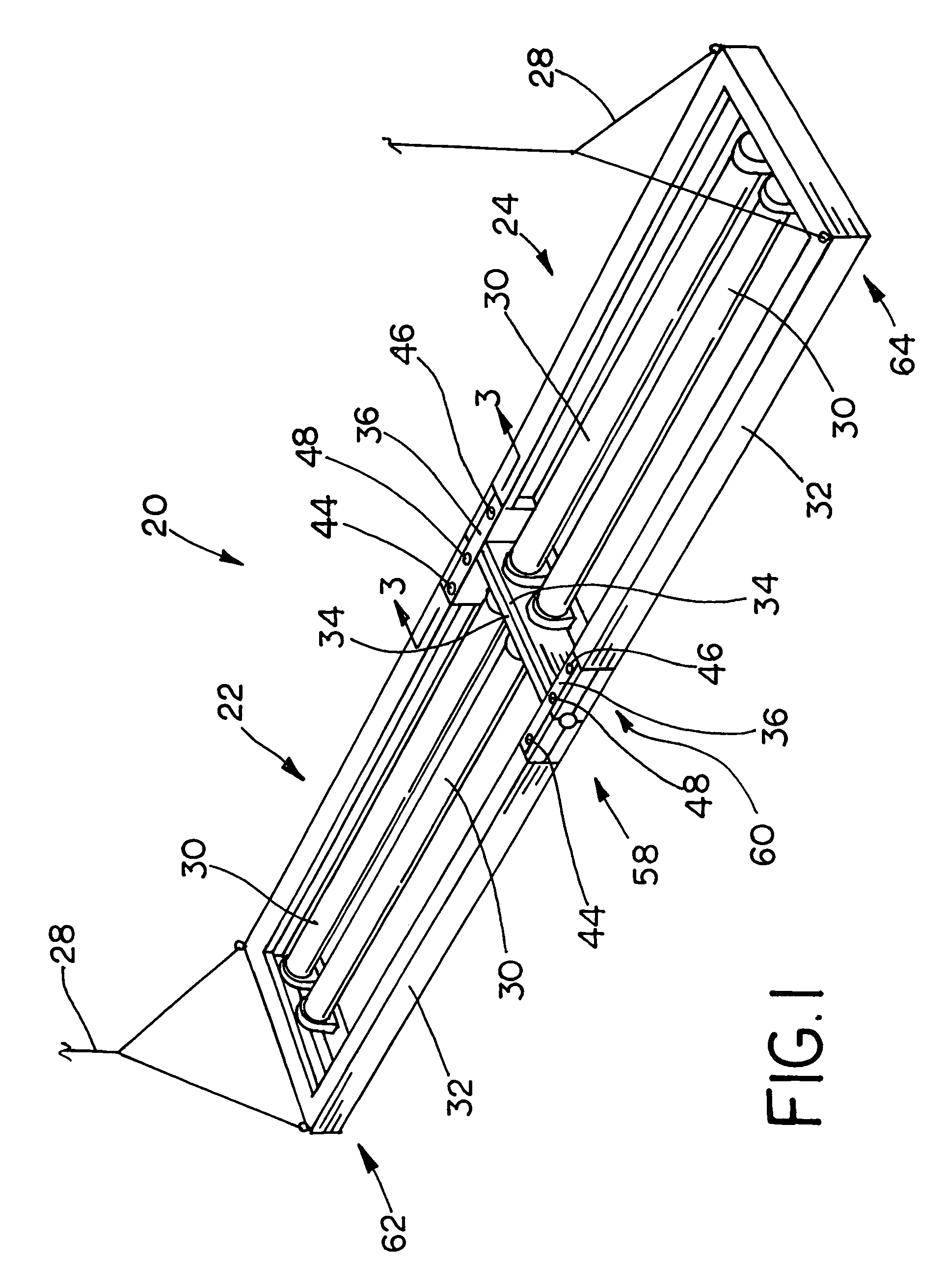

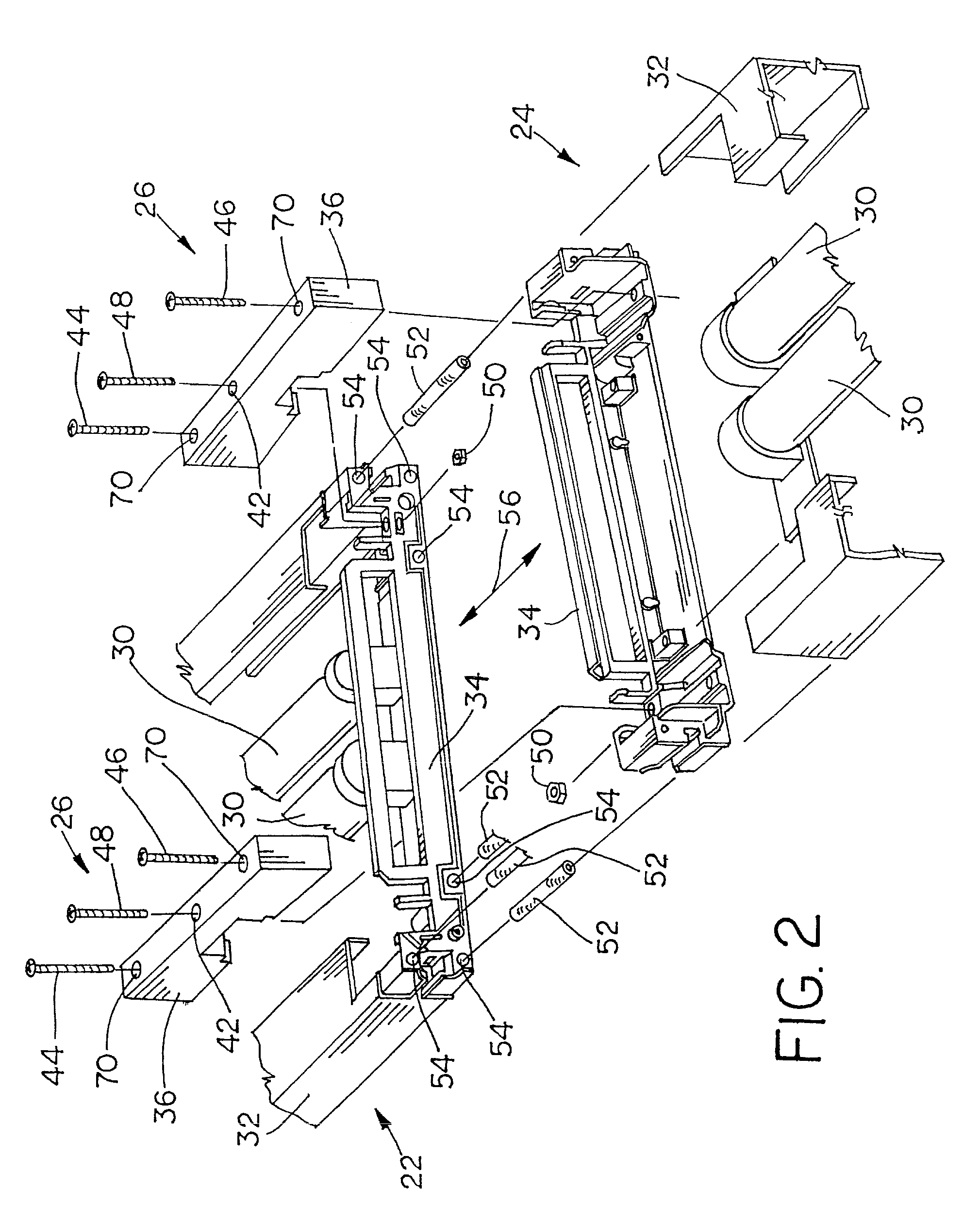

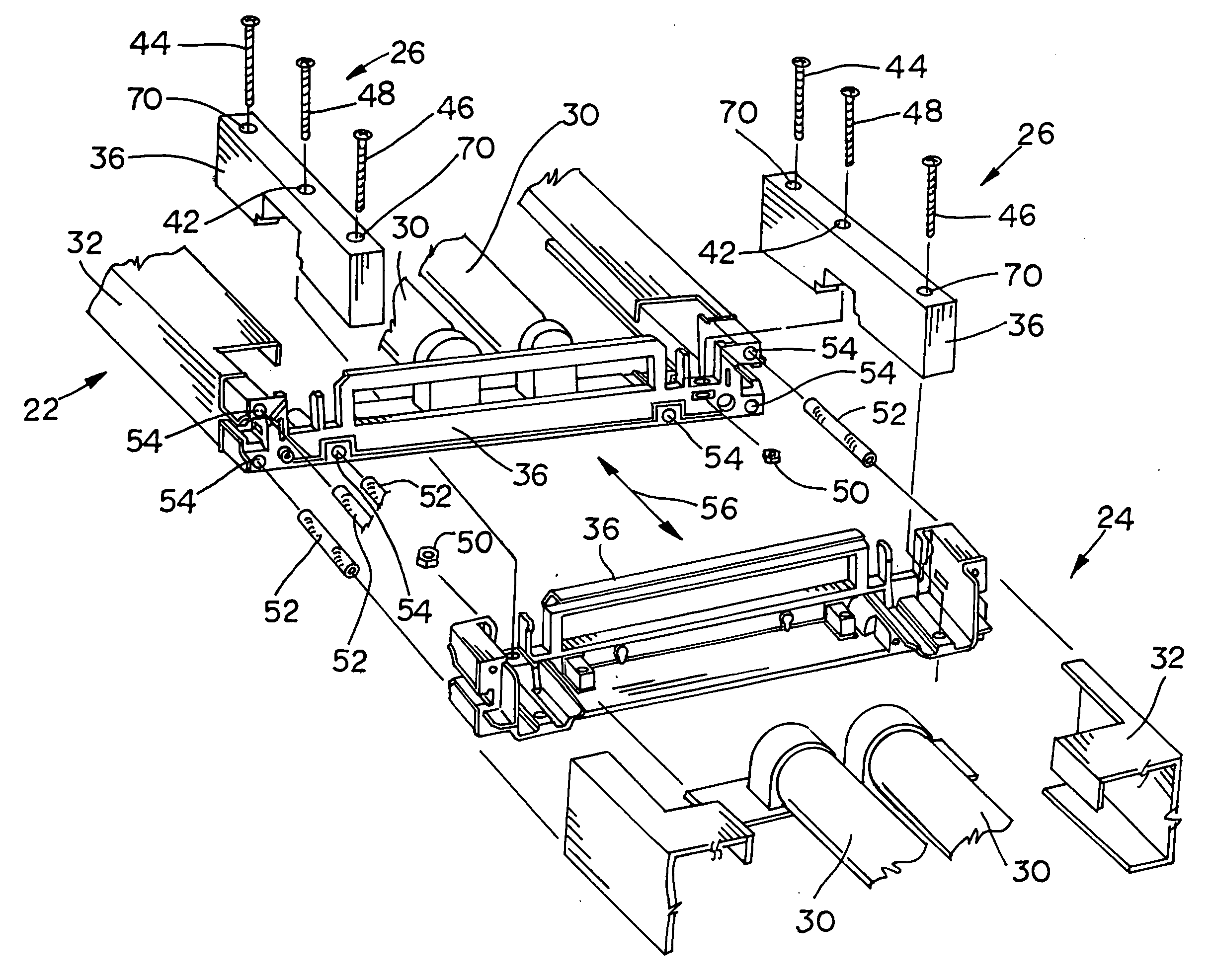

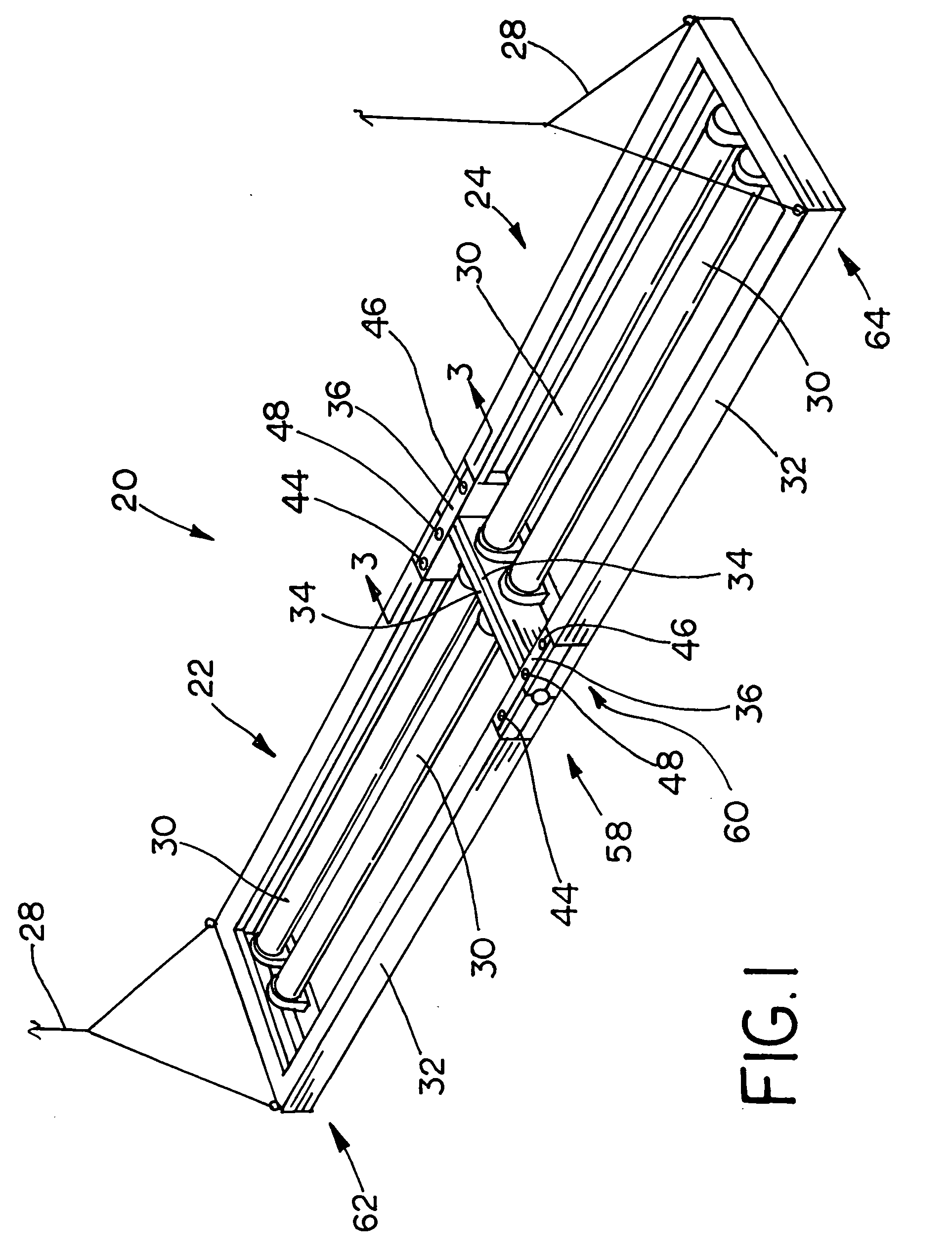

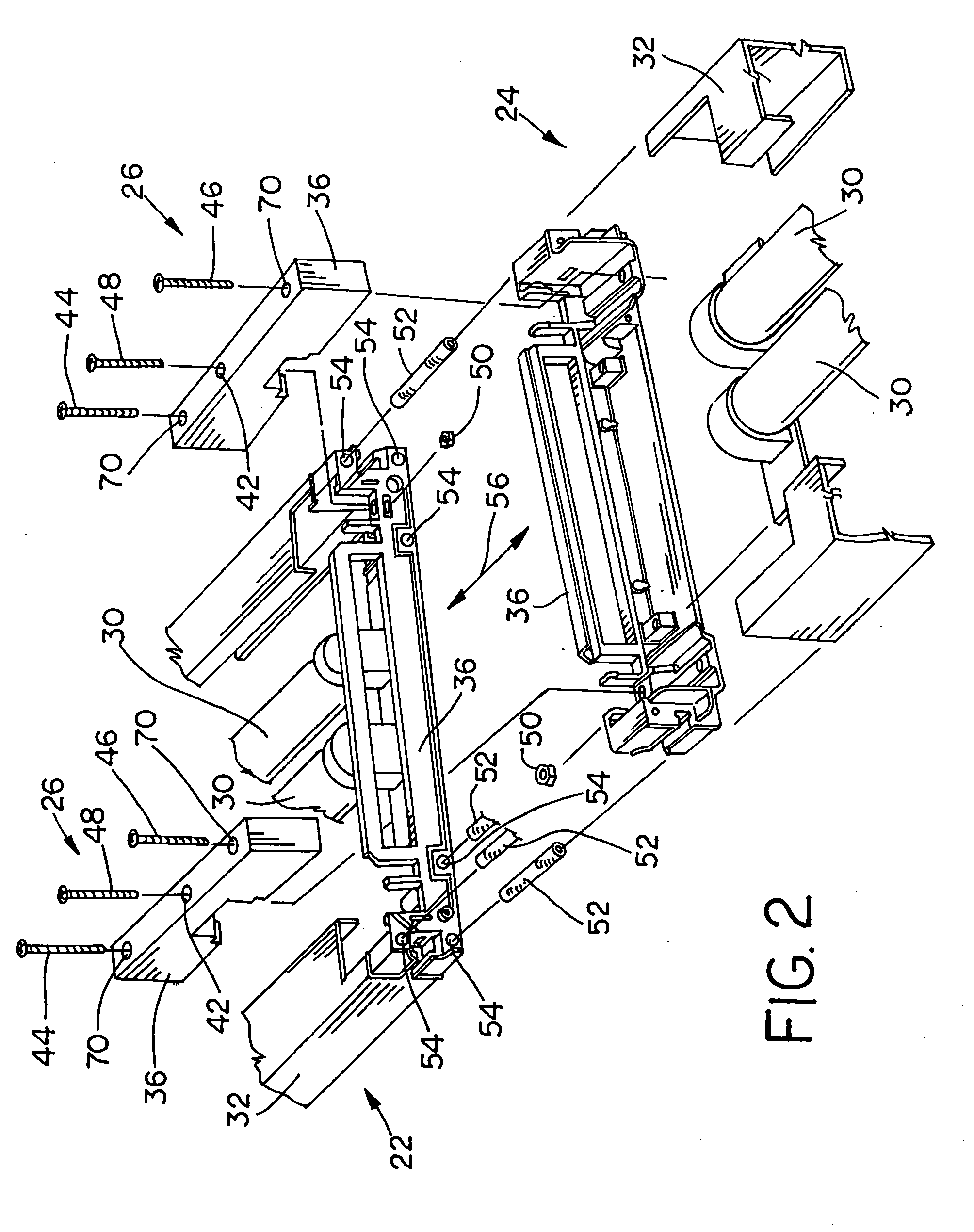

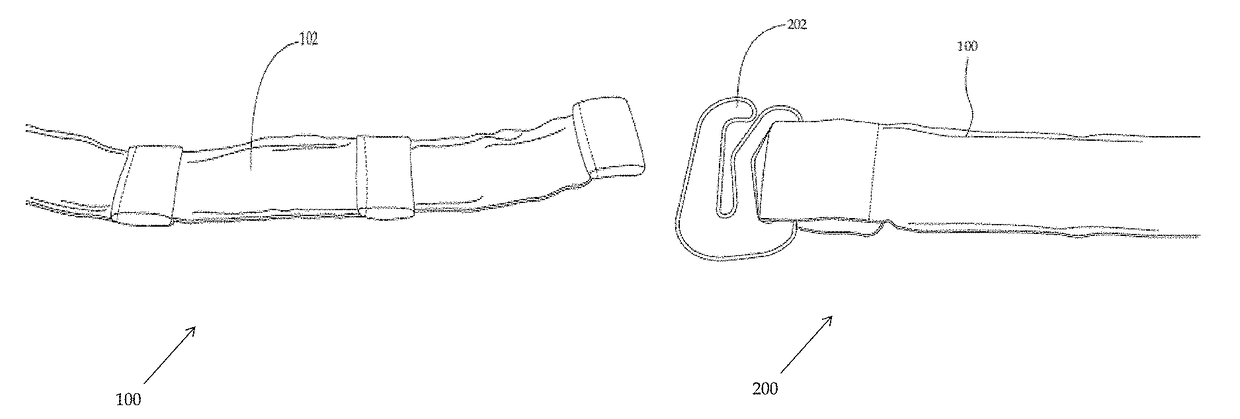

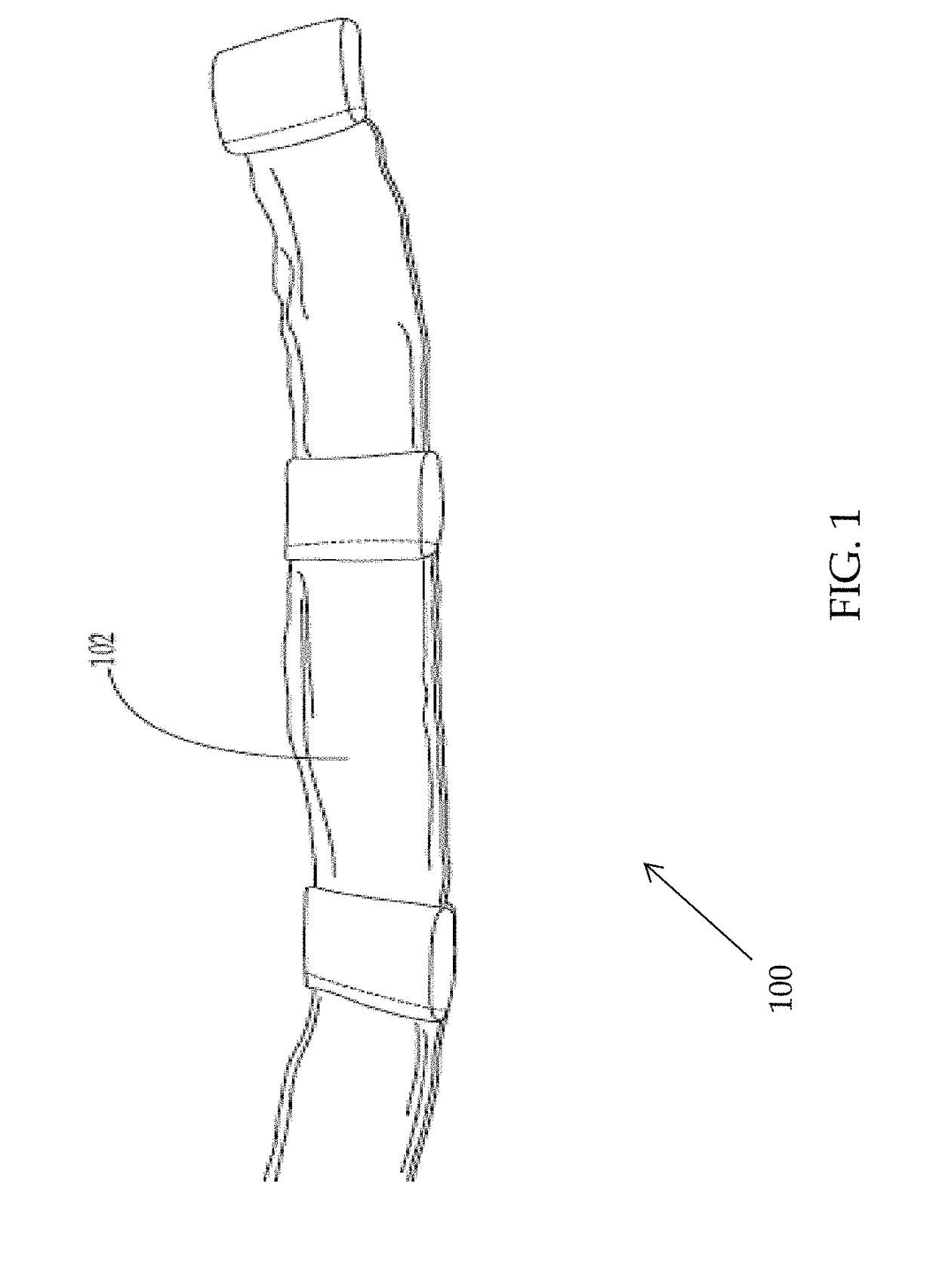

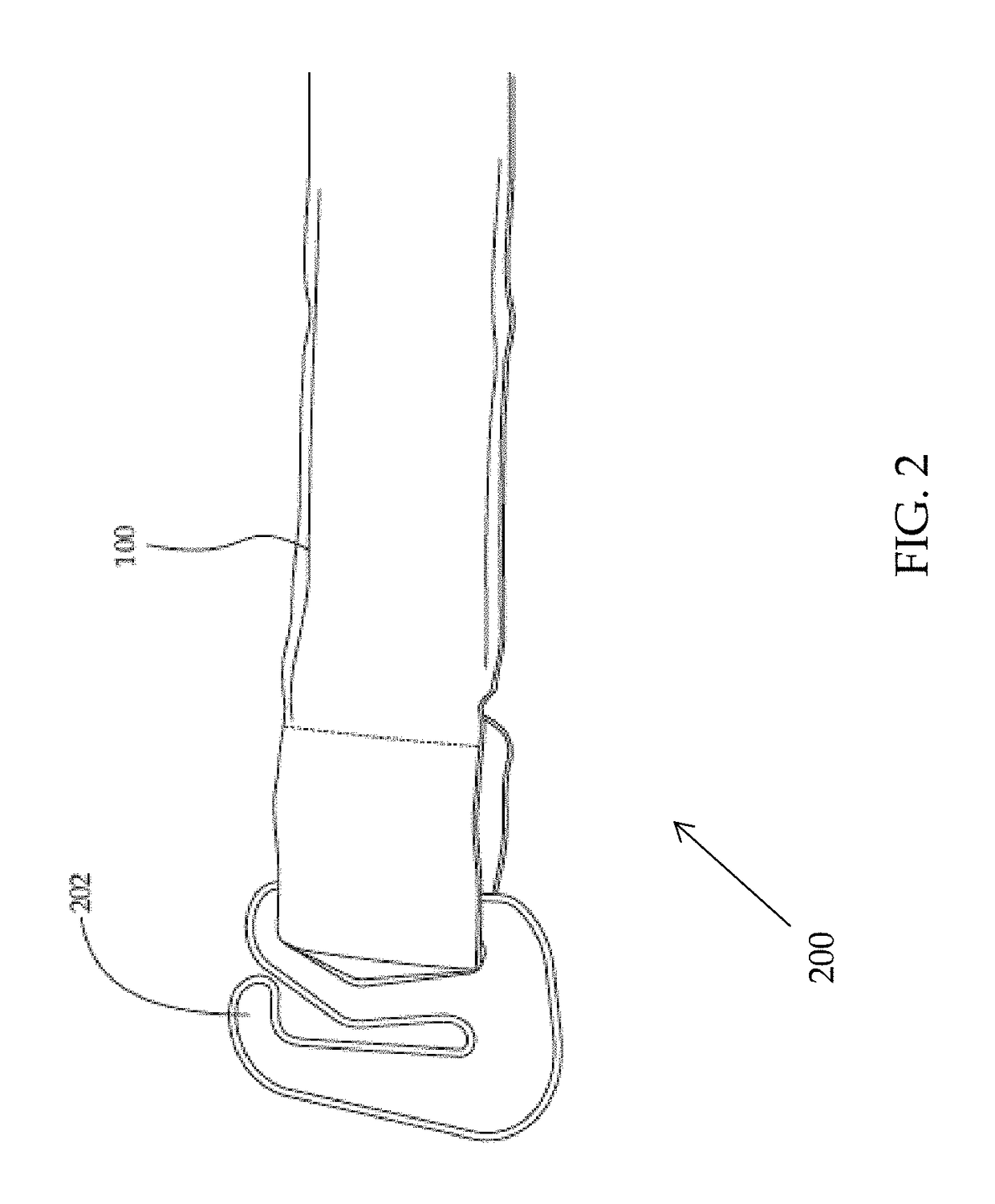

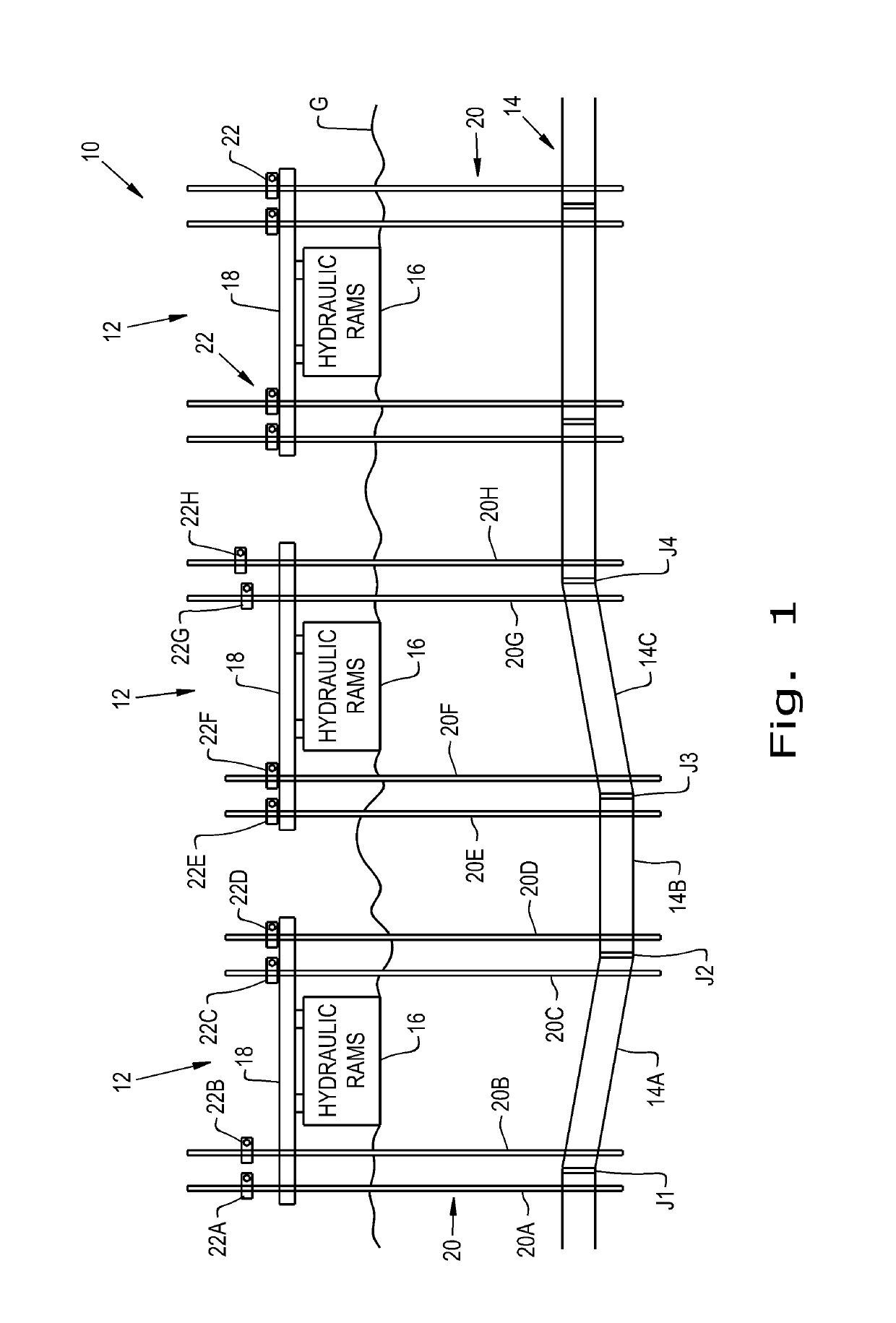

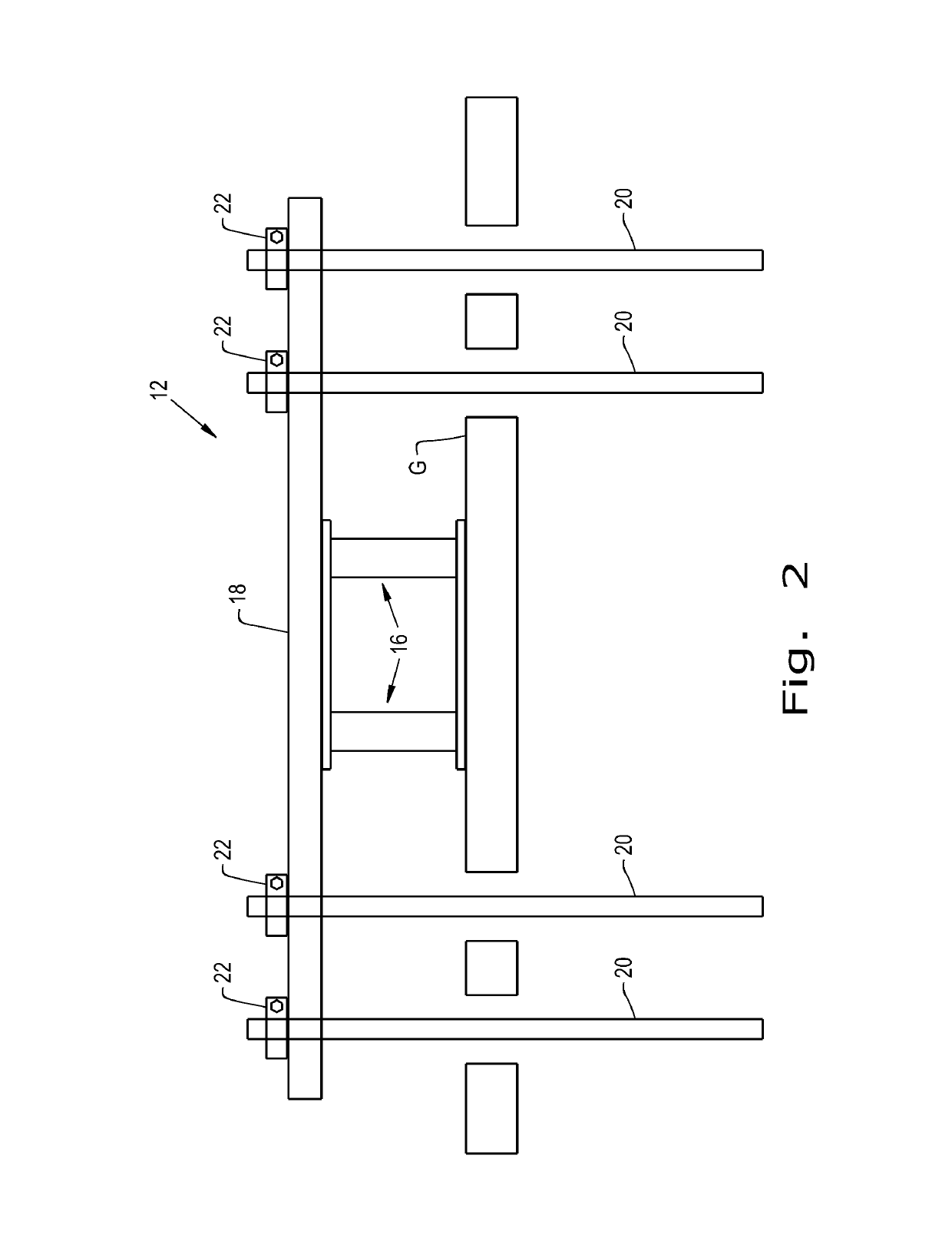

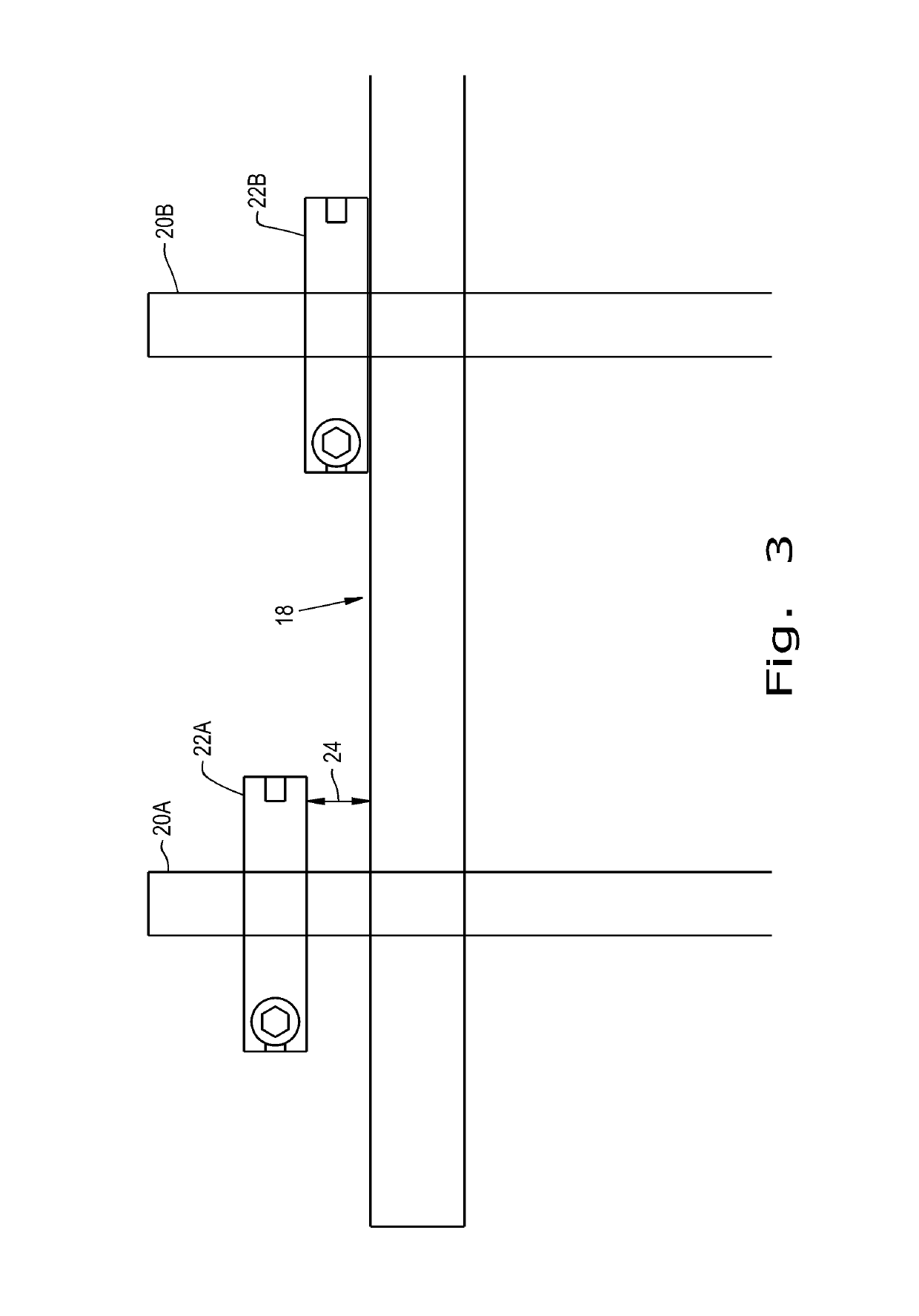

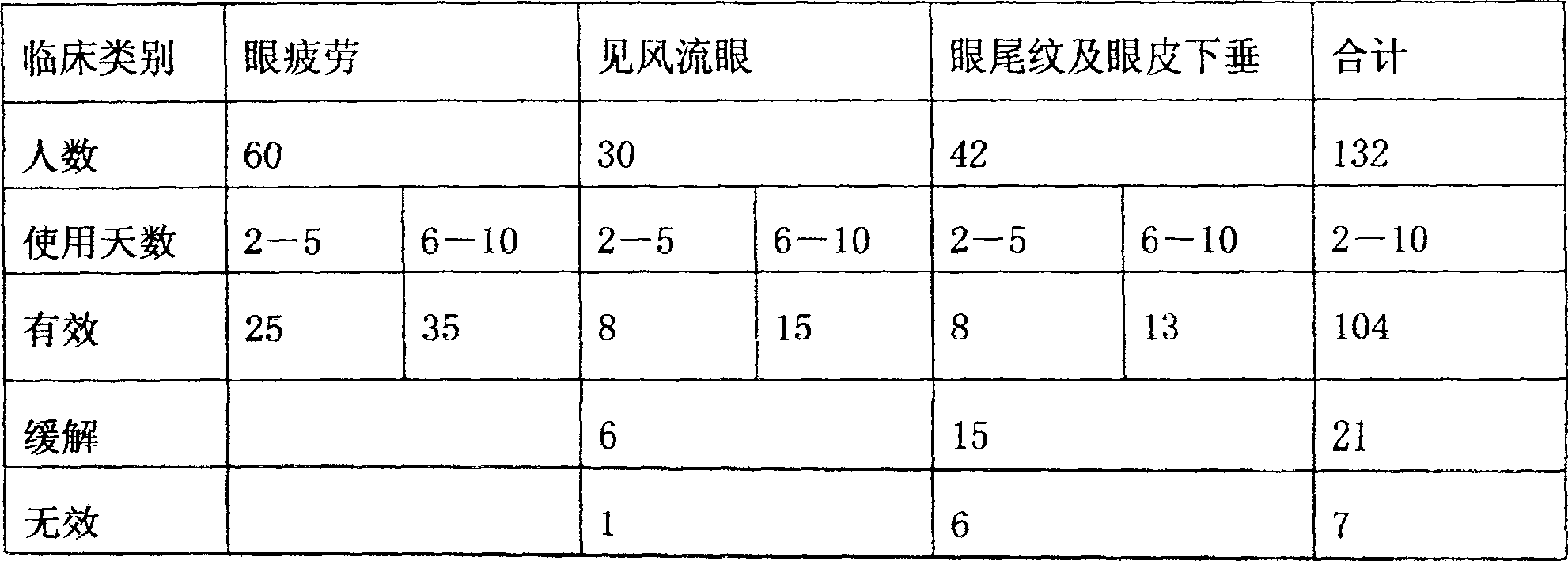

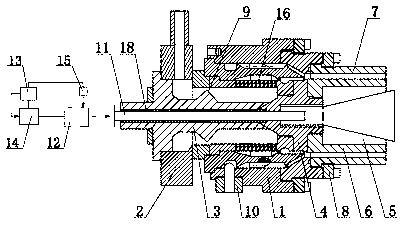

Method and apparatus for joining linear lighting fixtures to eliminate sag

InactiveUS7380957B2Safely hungEliminate saggingNon-electric lightingLighting support devicesEffect lightEngineering

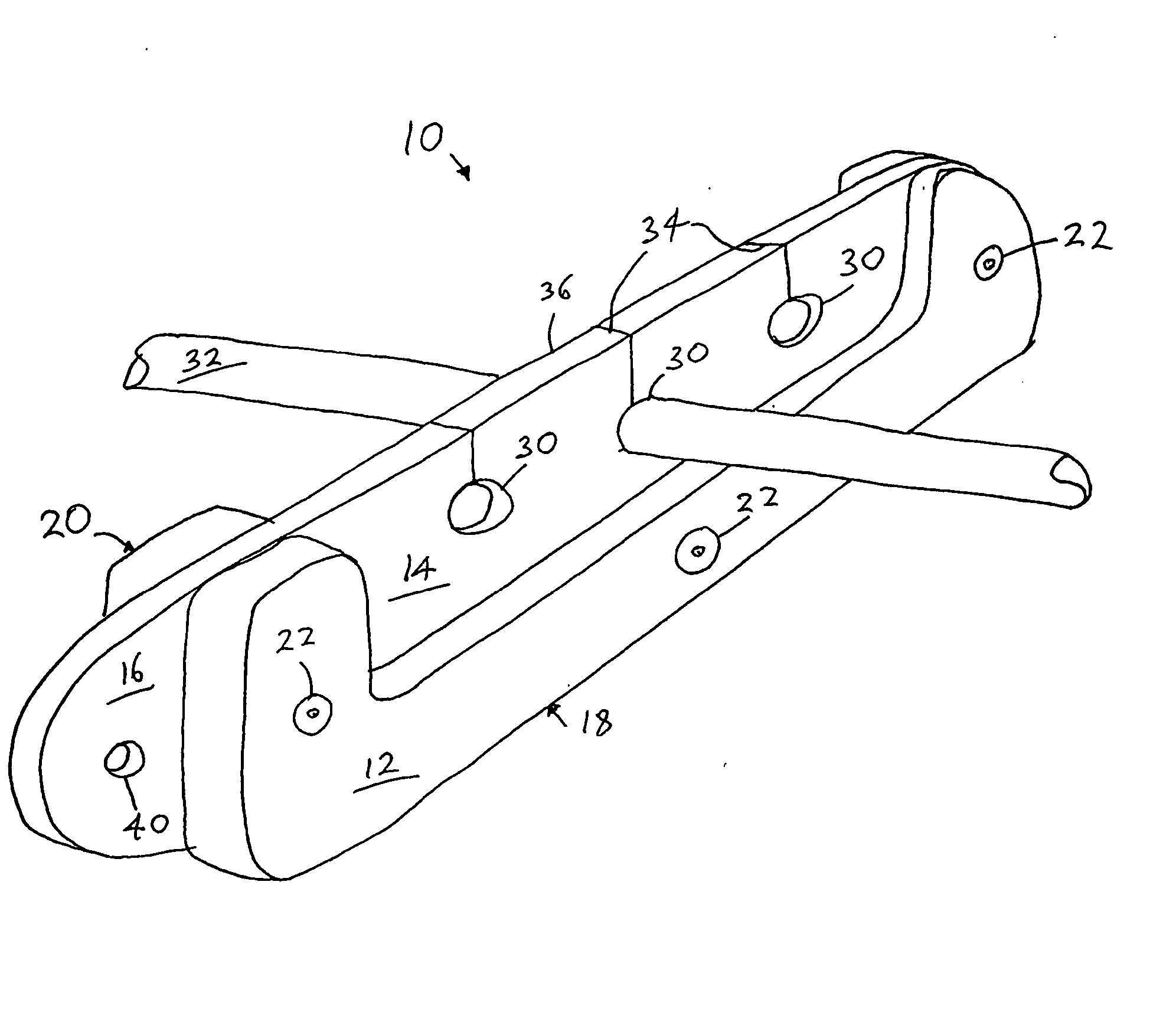

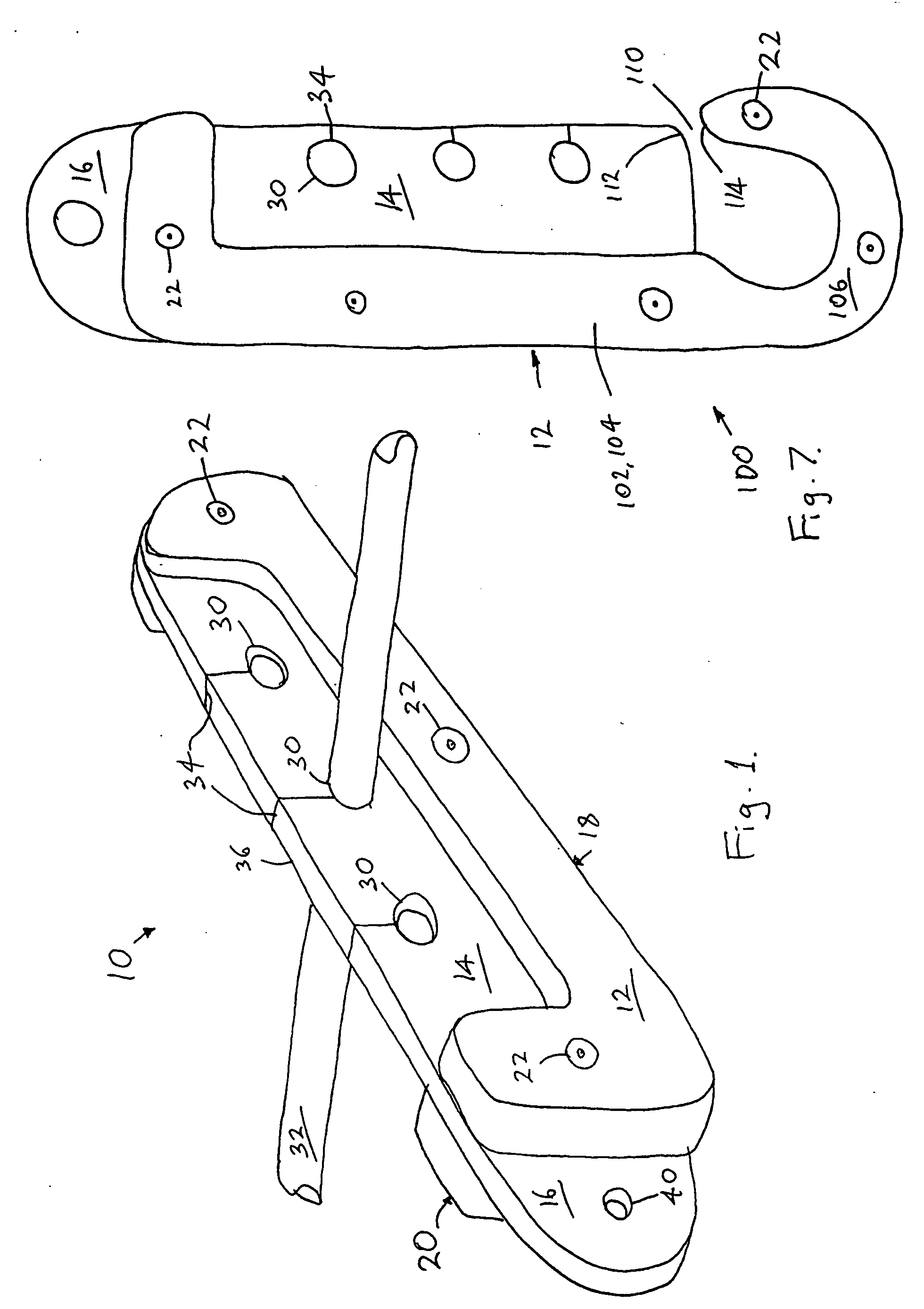

A joiner assembly for joining and supporting a first linear light fixture with a second linear light fixture. The joiner assembly includes a joiner bracket including first control surface connected to a second control surface and a draw fastener hole therebetween. The first control surface is configured for controlling a position of the first linear light fixture in a prestressed condition, and the second control surface is configured for controlling a position of the second linear light fixture in a prestressed condition. A draw fastener is connected to the draw fastener hole. A draw fastener constraint is connected to the draw fastener and configured for connection to at least one of the first linear light fixture and the second linear light fixture.

Owner:GROUP DEKKO

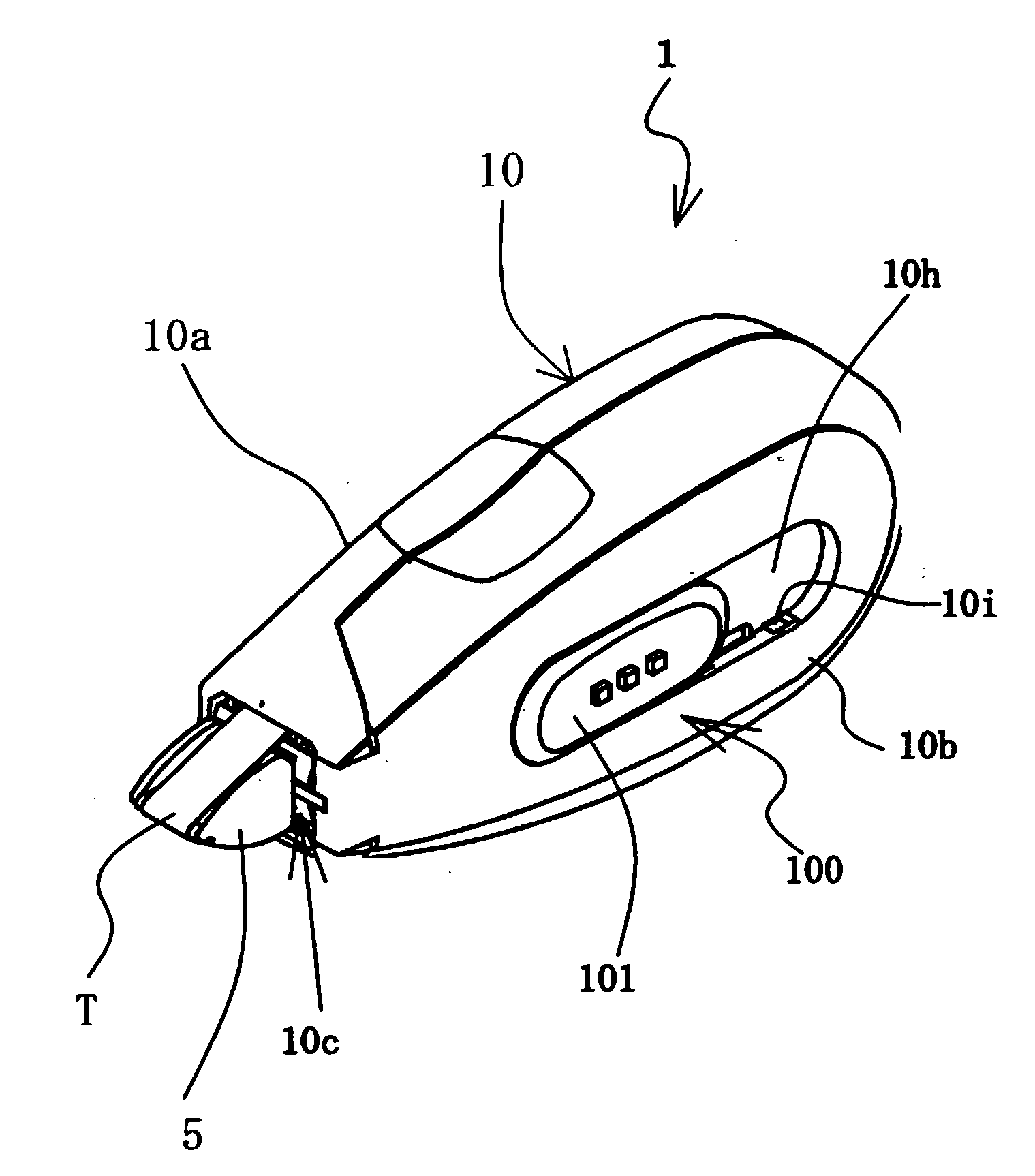

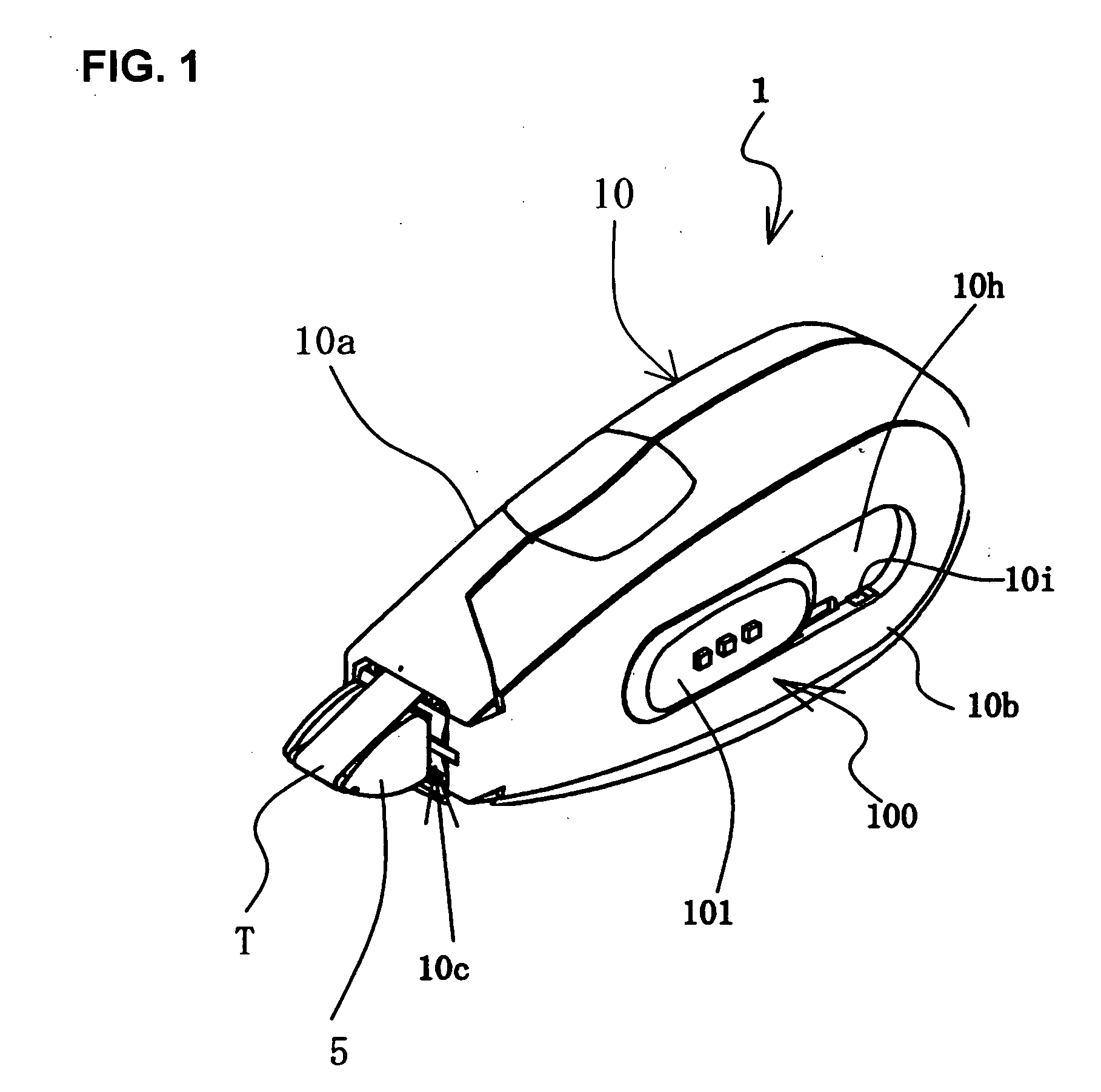

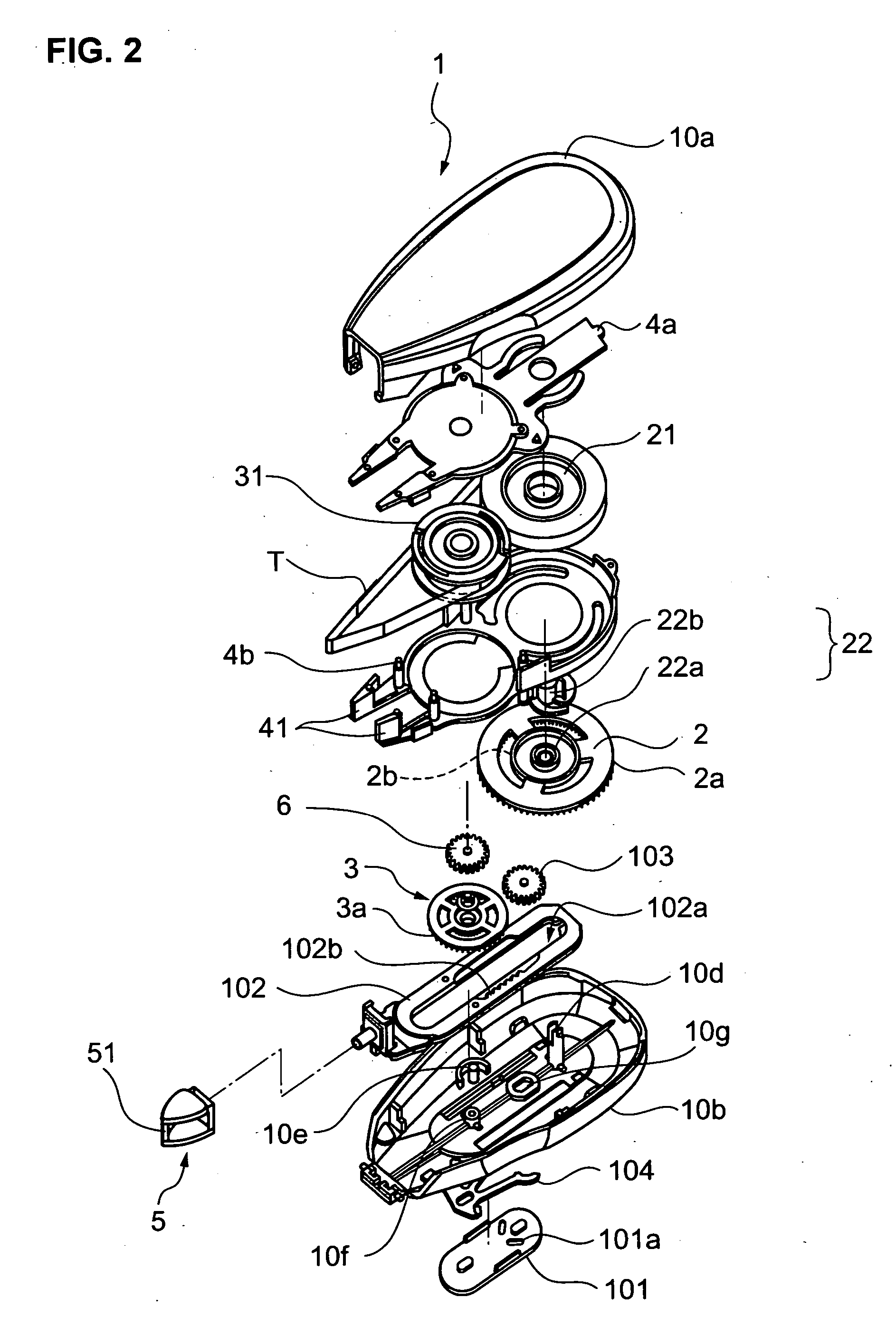

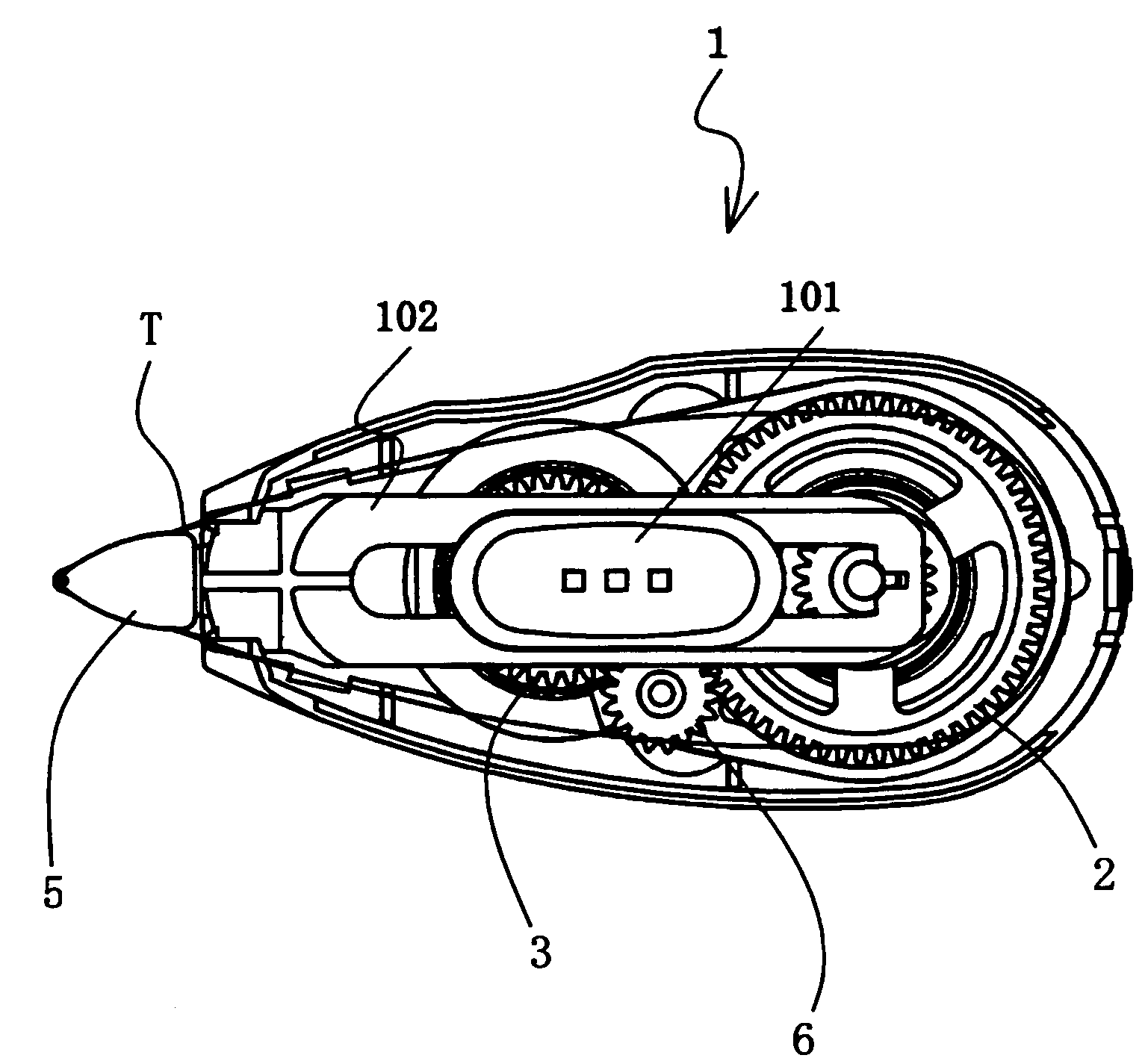

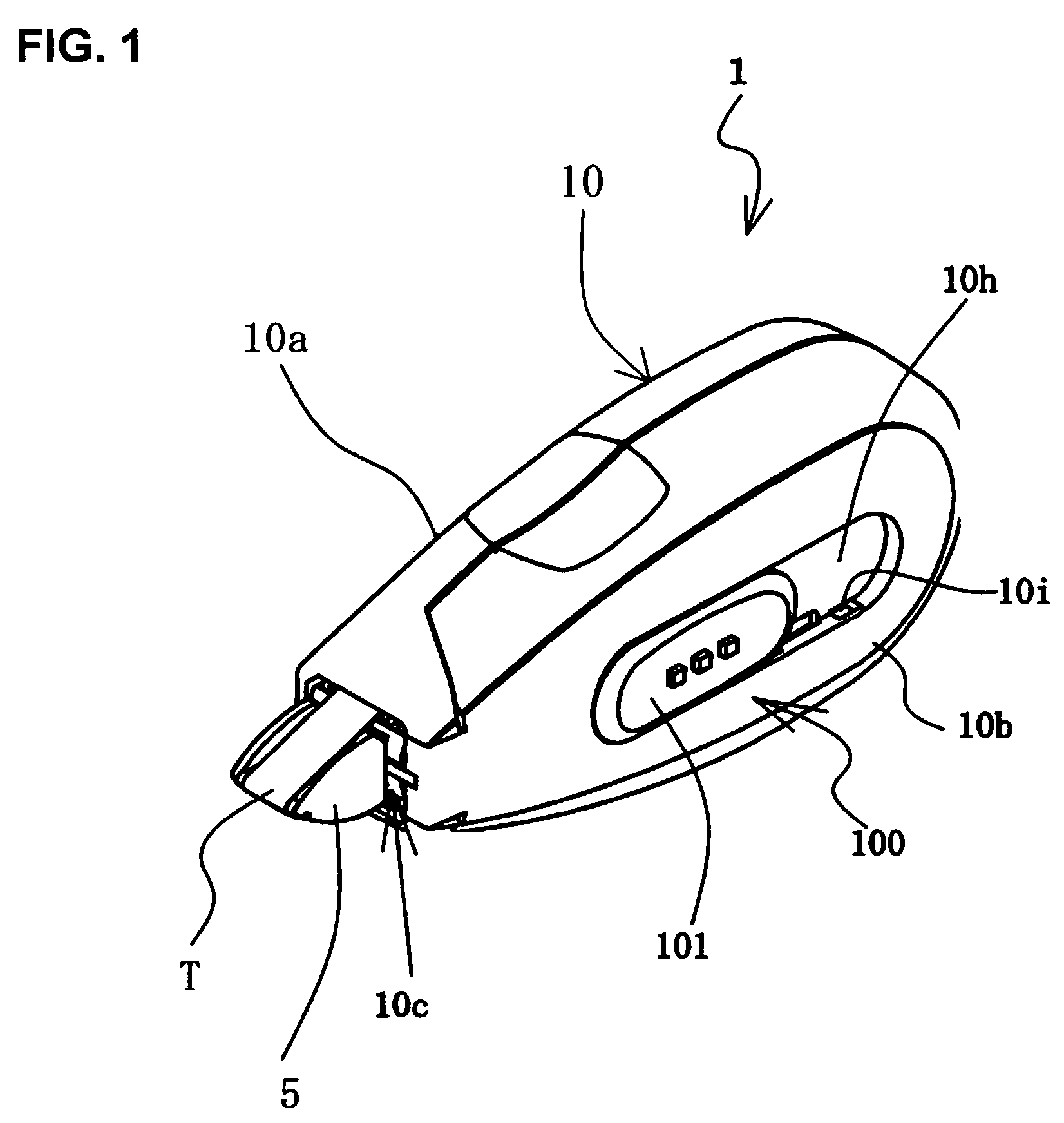

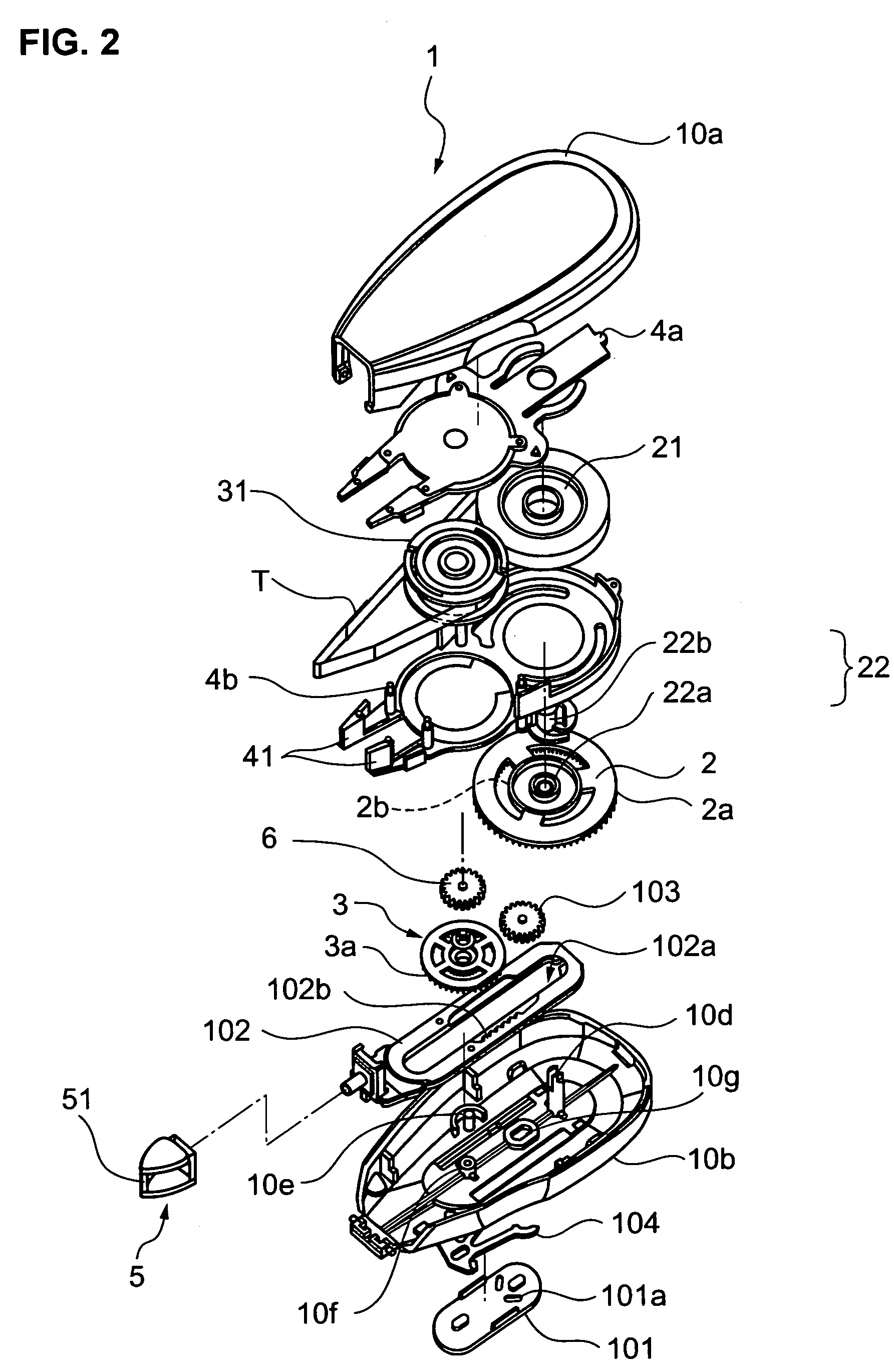

Coating film transfer tool

InactiveUS20070113987A1Eliminate saggingLiquid surface applicatorsFilament handlingBobbinEngineering

Provided is a coating film transfer tool capable of eliminating a sag when being used, while protecting the transfer tape when not being used. The coating film transfer tool includes: a slide mechanism which causes the transfer head to slide allowing the transfer head to contact with the transfer tape and to protrude from the case in order to perform the transfer, and / or accommodate the transfer head into the case; and a slip mechanism which, when a sliding operation to cause the transfer head to protrude is performed by the slide mechanism, releases interlocking between the supply bobbin and the supply reel, and, when the supply bobbin rotates in the direction of winding up the transfer tape by running of the transfer tape at a time of the transfer, rotates the supply reel and the supply bobbin in interlocking with each other, the slip mechanism being interposed between the supply bobbin and the supply reel, in which, when a sliding operation to accommodate the transfer head is performed by the slide mechanism, the slide mechanism is engaged with the supply reel, and rotates the supply reel reversely.

Owner:PLUS STATIONARY CORP

Method and apparatus for joining linear lighting fixtures to eliminate sag

InactiveUS20060158877A1Safely hungEliminate saggingNon-electric lightingLighting support devicesEffect lightEngineering

A joiner assembly for joining and supporting a first linear light fixture with a second linear light fixture. The joiner assembly includes a joiner bracket including first control surface connected to a second control surface and a draw fastener hole therebetween. The first control surface is configured for controlling a position of the first linear light fixture in a prestressed condition, and the second control surface is configured for controlling a position of the second linear light fixture in a prestressed condition. A draw fastener is connected to the draw fastener hole. A draw fastener constraint is connected to the draw fastener and configured for connection to at least one of the first linear light fixture and the second linear light fixture.

Owner:GROUP DEKKO

Image stabilizer and optical instrument therewith

ActiveUS8208031B2Eliminate saggingImage is often very smallTelevision system detailsPrintersEngineeringOptical instrument

An image stabilizer has a base block, an inner frame for holding a CCD, an outer frame, a pair of horizontal leaf springs, a pair of vertical leaf springs, voice coil motors (VCMs) and a flexible printed circuit (FPC). Upon a shake of a digital still camera due to hand-held shooting, the VCMs shift the inner or outer frame while bending the horizontal or vertical leaf springs so that the CCD is shifted to counteract the camera shake. The FPC connected to the CCD and the VCMs is routed from the inner frame, through the horizontal leaf spring, the outer frame and the vertical leaf spring, and pulled out above the base block. The FPC is glued to the horizontal and vertical leaf springs, and elastically bent together with the horizontal and vertical leaf springs.

Owner:FUJIFILM CORP

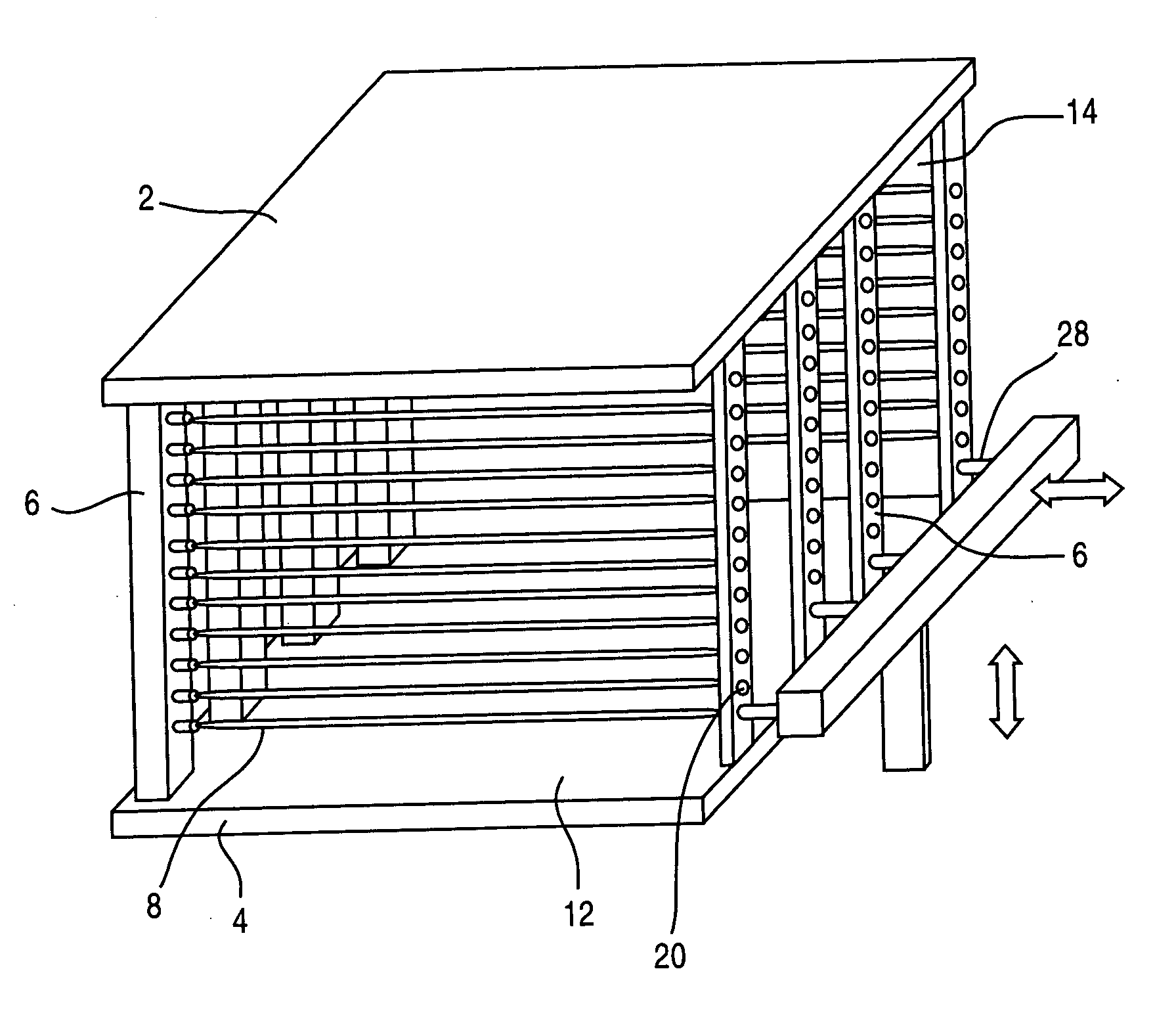

Substrate transportation device (wire)

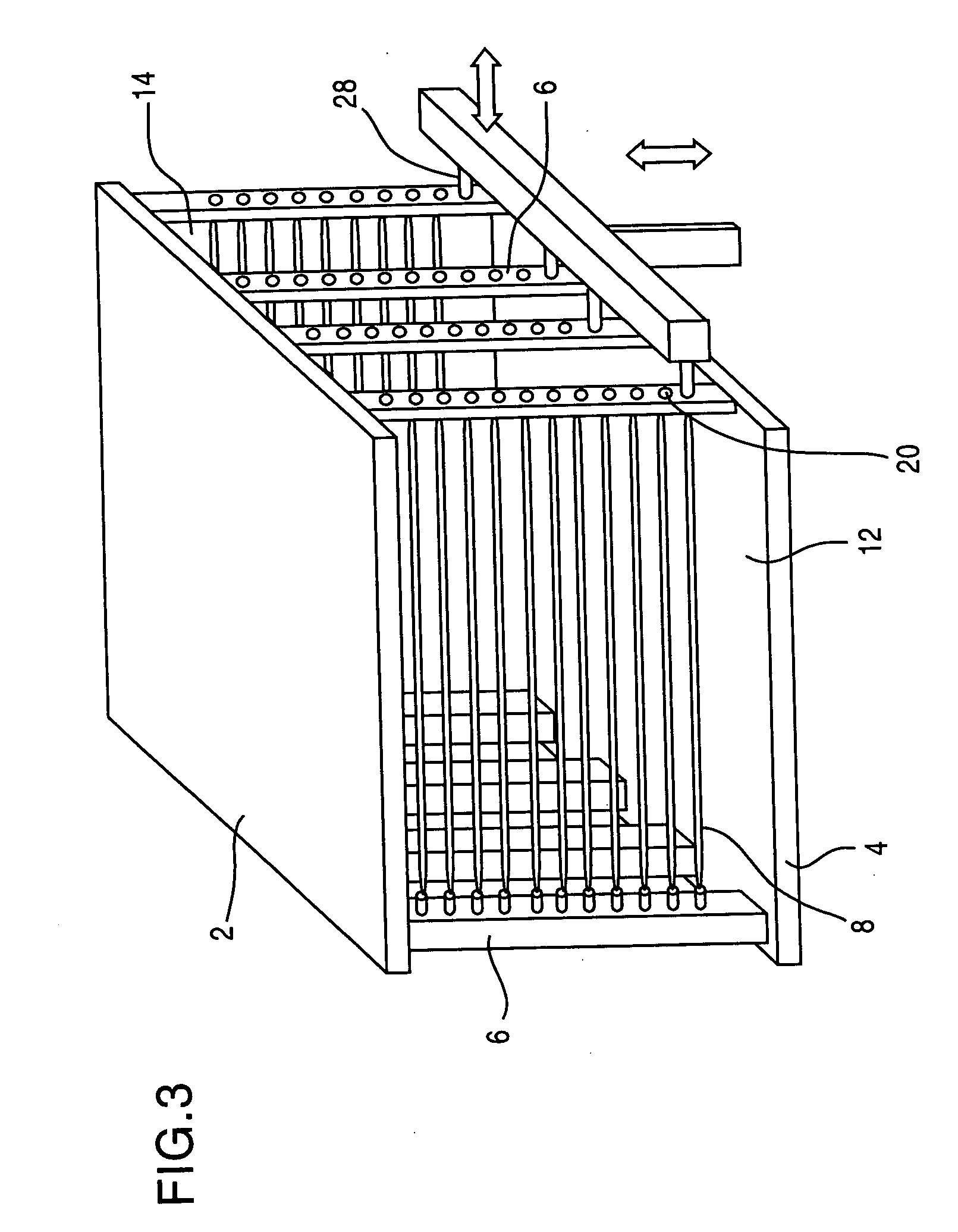

InactiveUS20060182556A1High strengthEliminate saggingConveyorsSemiconductor/solid-state device manufacturingWire rodEngineering

A substrate transportation device includes a housing formed of an upper surface, a lower surface, and opposing sidewalls. The housing has a rear opening through which the substrate enters the housing and a front opening through which the substrate exit the housing. A plurality supporting members are disposed within the housing and operatively connected to the opposing sidewalls which can be formed as a plurality of columns. A motor and motor shaft transmit a rotational force to an axle system, which transmits rotational force to the supporting members to transfer the substrate into or out of the housing randomly.

Owner:AU OPTRONICS CORP

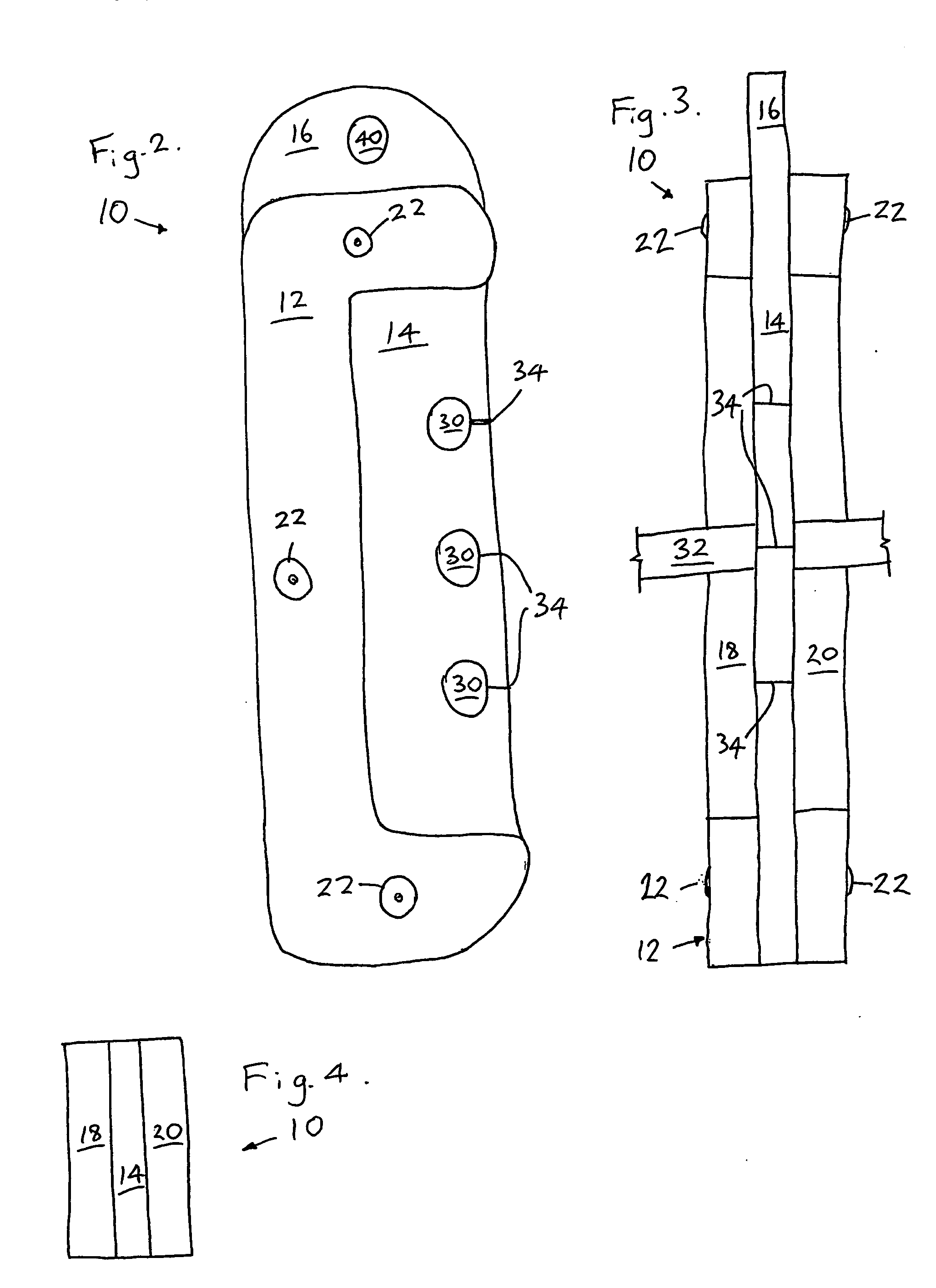

Cord retainer

InactiveUS20050172459A1Control displacementEliminate saggingSnap fastenersPipe supportsEngineeringPneumatic Hose

A cord retainer (10, 100, 140, 160) for retaining cords such as electrical power leads (32) and pneumatic hoses in an elevated position above the ground or floor. The cord retainer (10, 100, 140, 160) has a flexible web (14, 146, 168) with holes (30, 148) dimensioned to receive a cord (32) and substantially retained it against longitudinal movement with respect to the web (14, 146, 168) to the extent that the cord (32) is substantially prevented from sliding longitudinally in the hole (30, 148) under the force of its own weight or during normal installation of the cord (32), in two spaced apart cord retainers (10, 100, 140, 160). A series of frames 170, 180 and 190 are also provided for attaching the cord retainer (10, 100, 140, 160) structures on building and construction sites.

Owner:RYAN MARTIN RODNEY +2

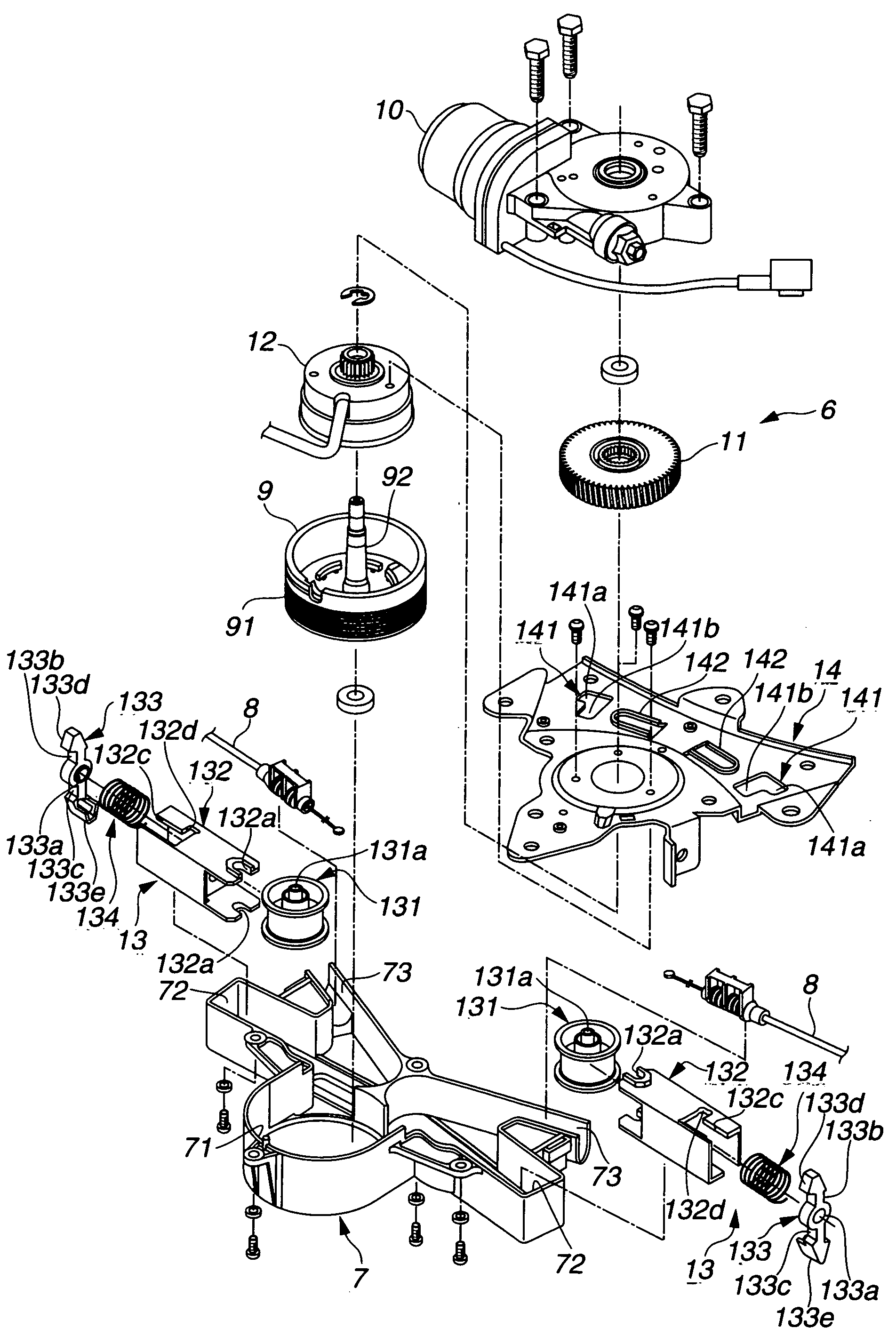

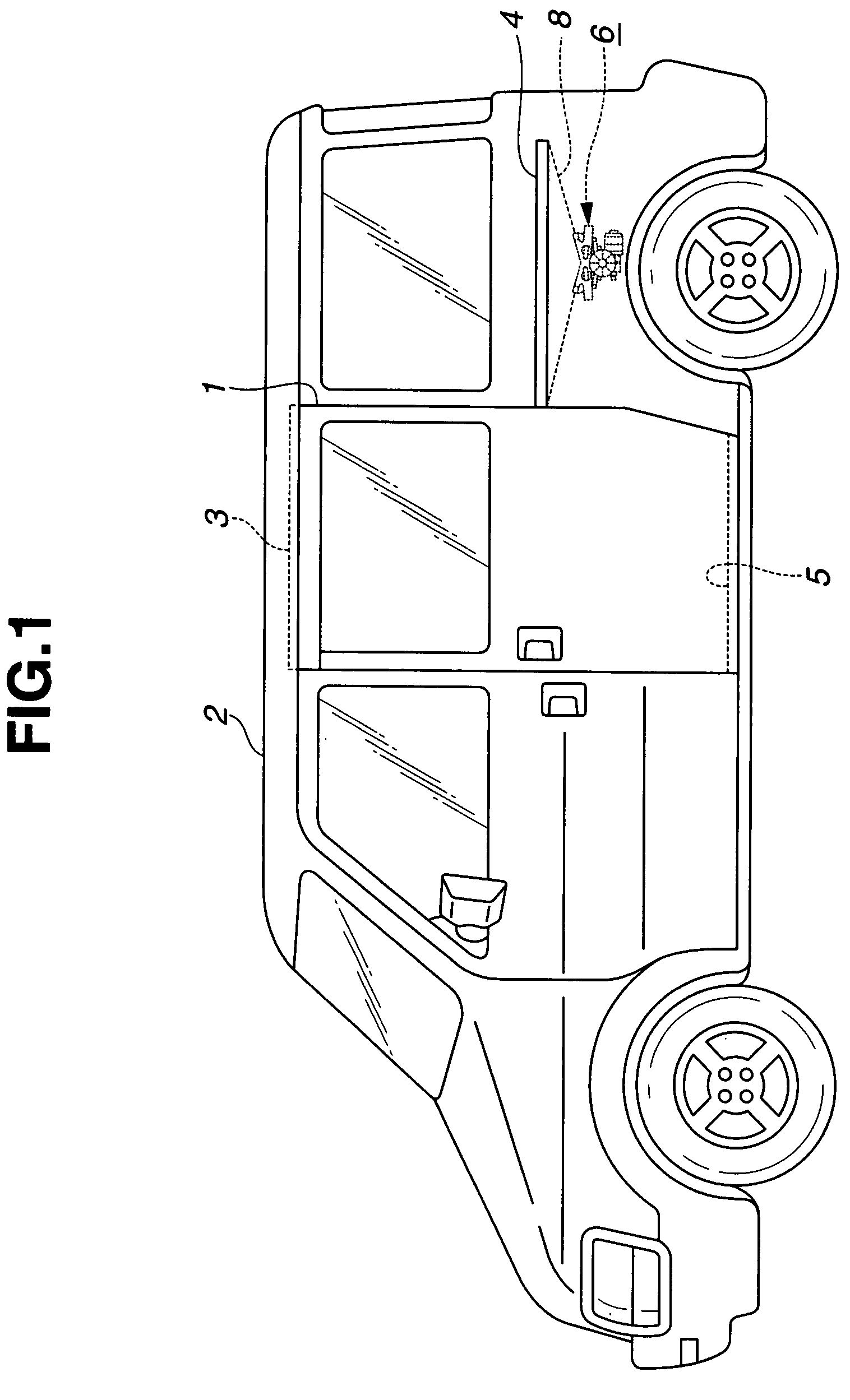

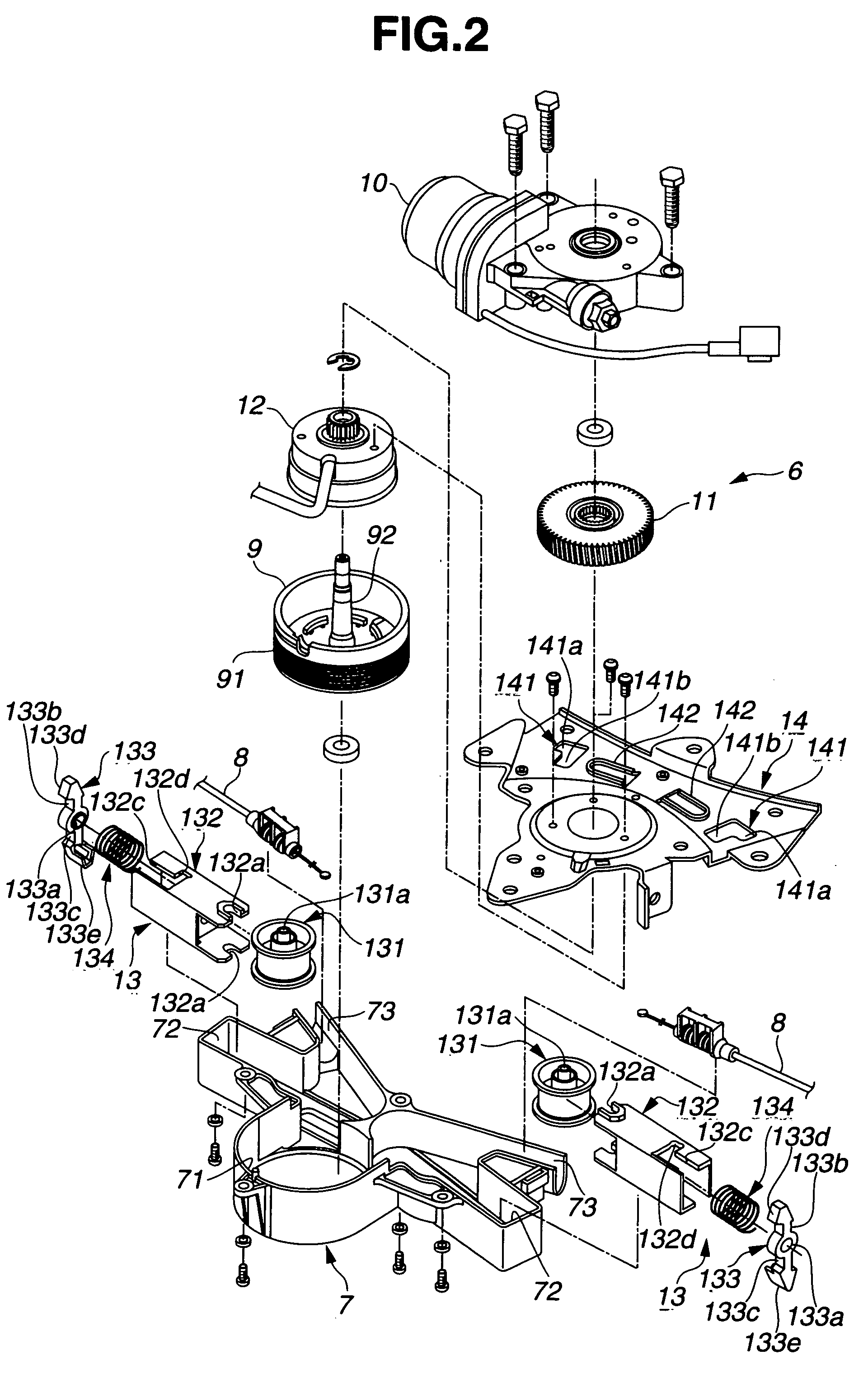

Drive apparatus for sliding member

InactiveUS7774985B2Small sizeEliminate saggingMan-operated mechanismPower-operated mechanismEngineeringElectric motor

Owner:MITSUI KINZOKU ACT

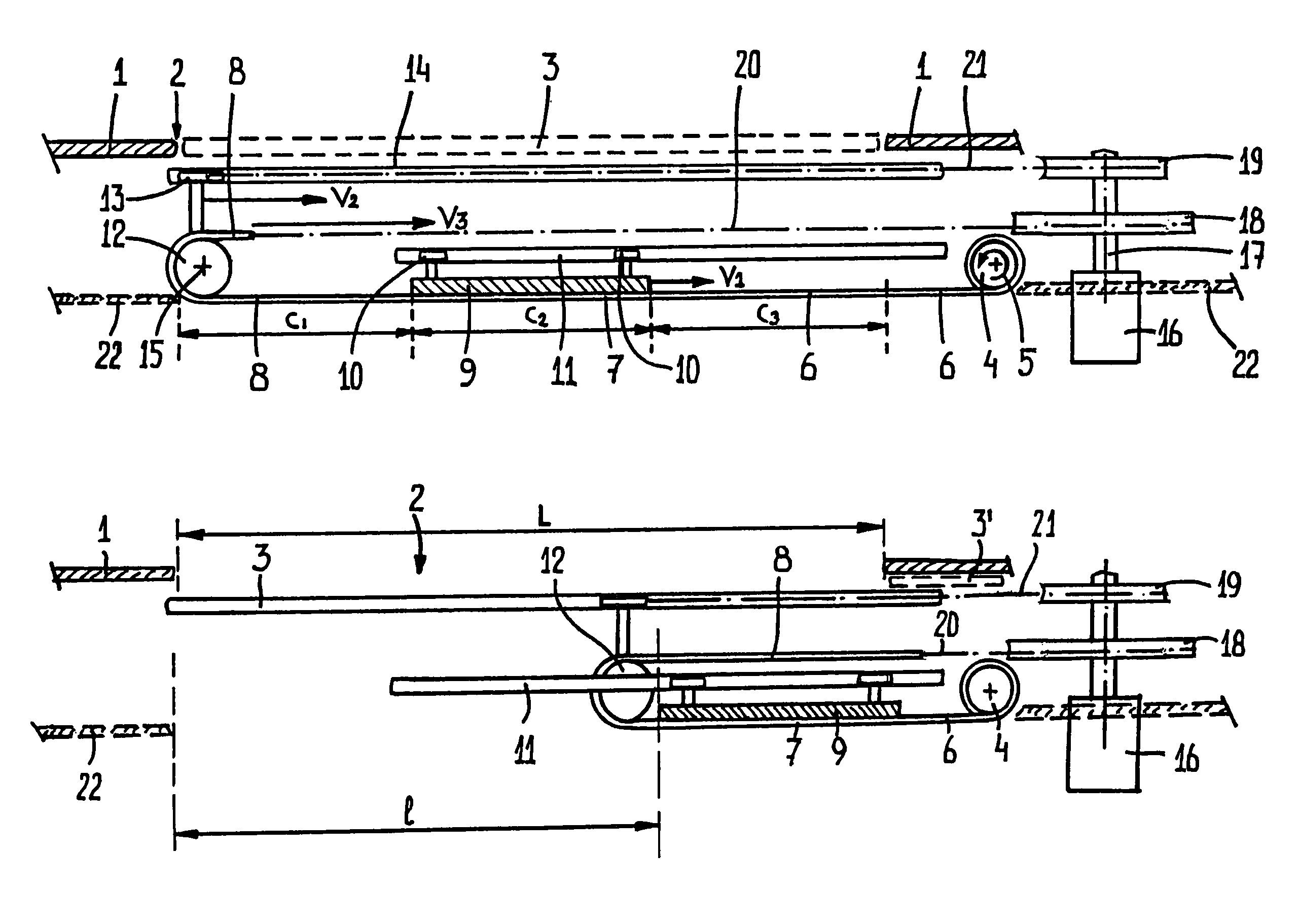

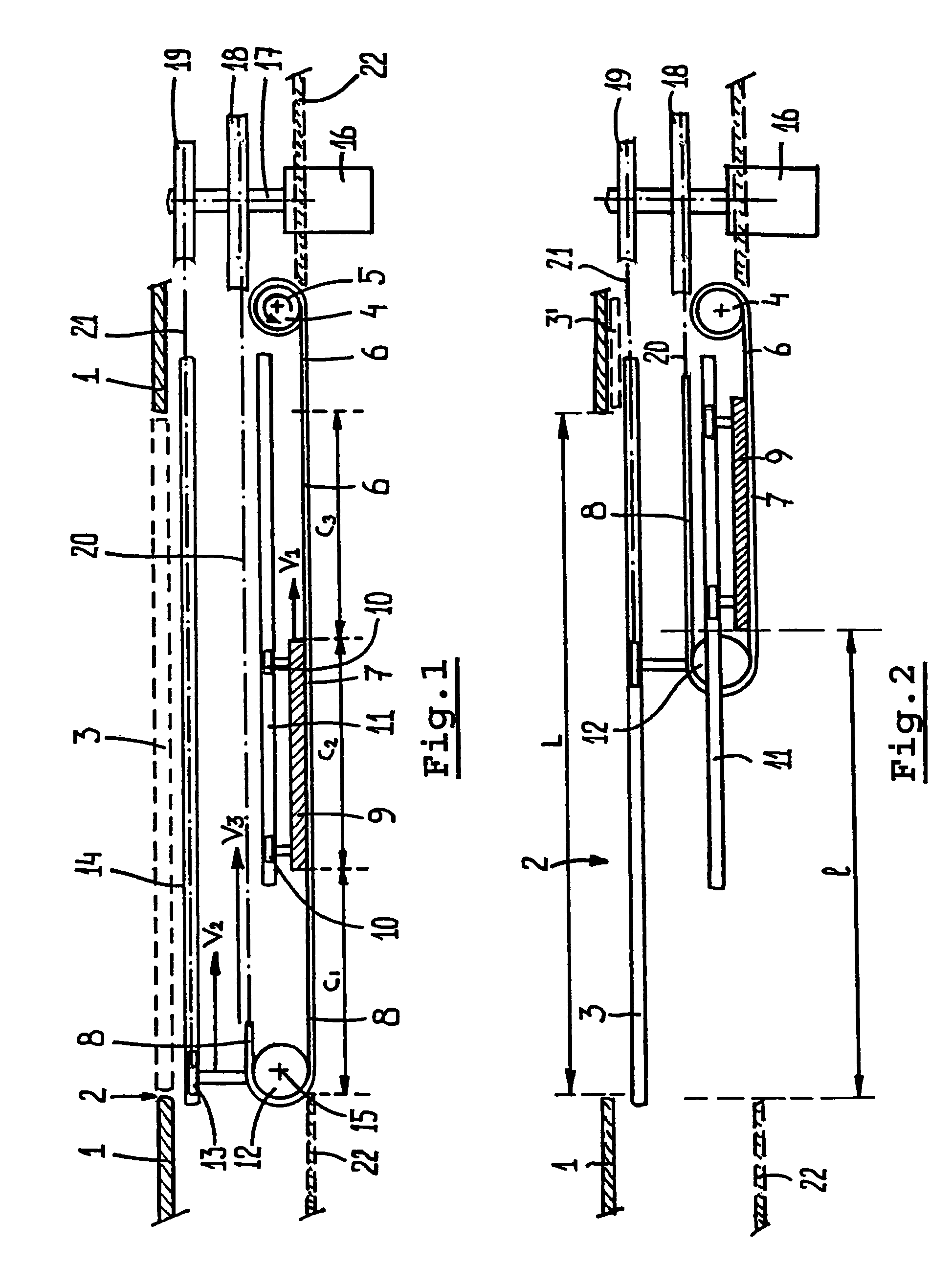

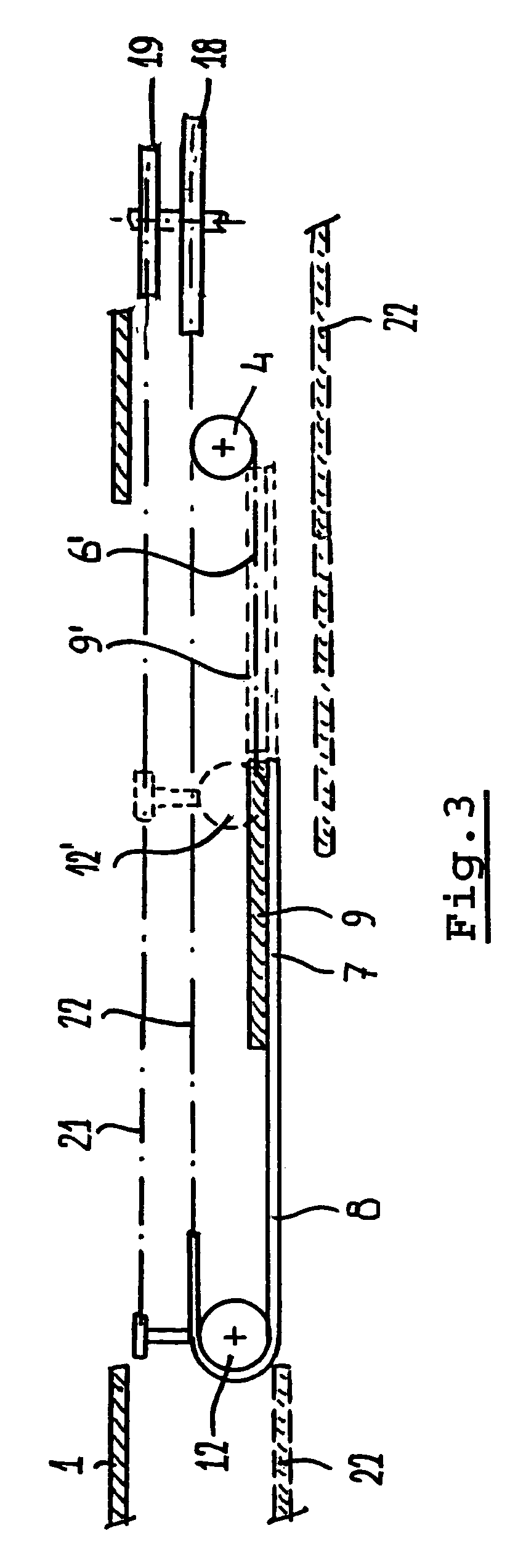

Assembly for covering an opening

InactiveUS7287811B2Eliminate saggingPleasant esthetical appearance without any seamsScreensDoor/window protective devicesEngineeringConductor Coil

An assembly for covering an opening comprises a movable cover having a first flexible cover part that can be wound on or off a winding tube, a second rigid cover part attached to the first cover part at the end of latter remote from the winding tube and a third flexible cover part attached to the second cover part at the end of latter remote from the first cover part, wherein the free end of the third cover part extends around a reversing member which is movable by a first driving member, which free end is connected to a second driving member, and wherein the ratio between the winding velocity V1 of the winding tube, and thus the first and second cover parts, the driving velocity V2 of the first driving member and the driving velocity V3 of the second driving member is such, that V1+V3=2 V2, whereas V3>V2>V1>0.

Owner:INALFA ROOF SYST GROUP

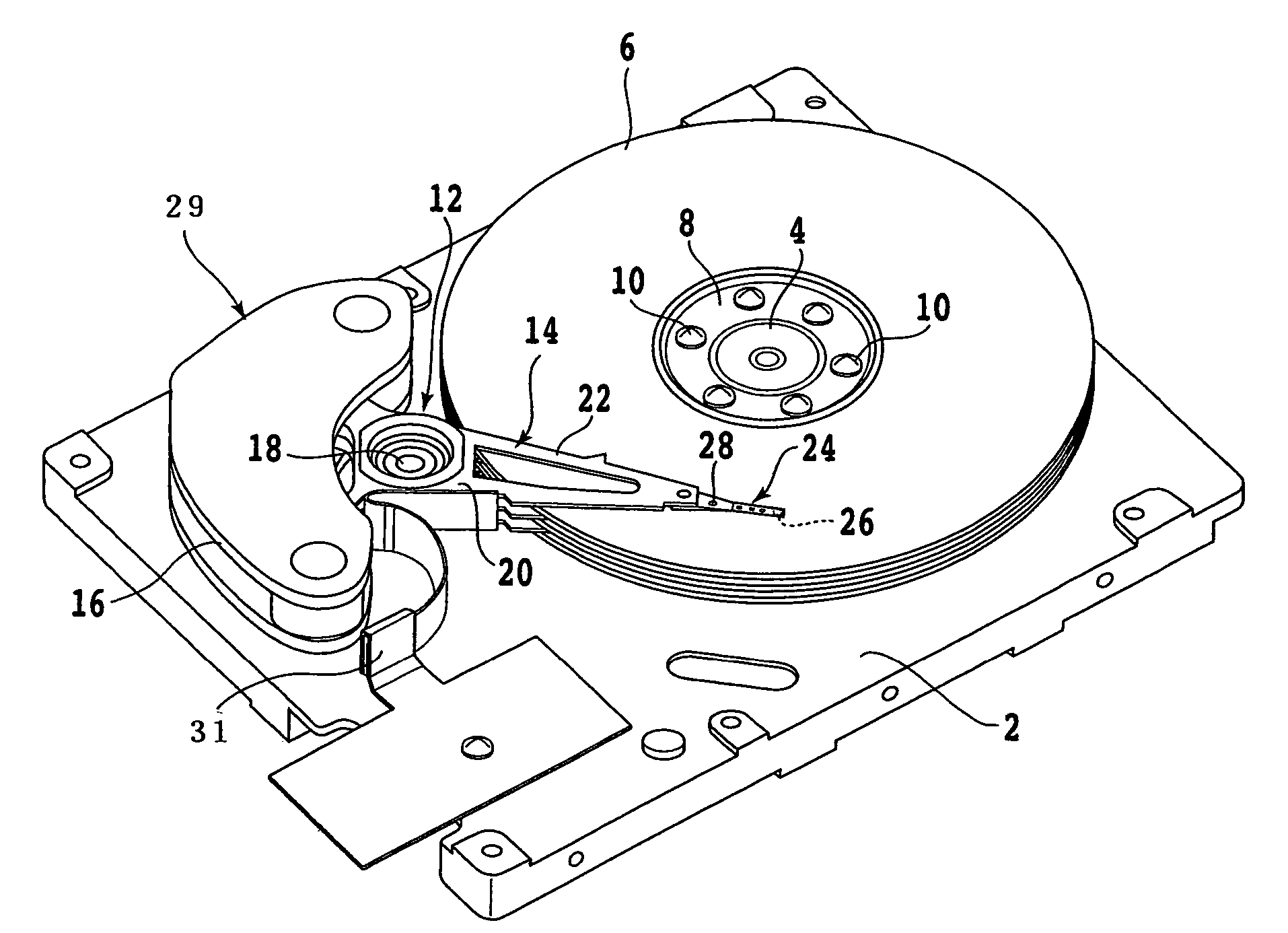

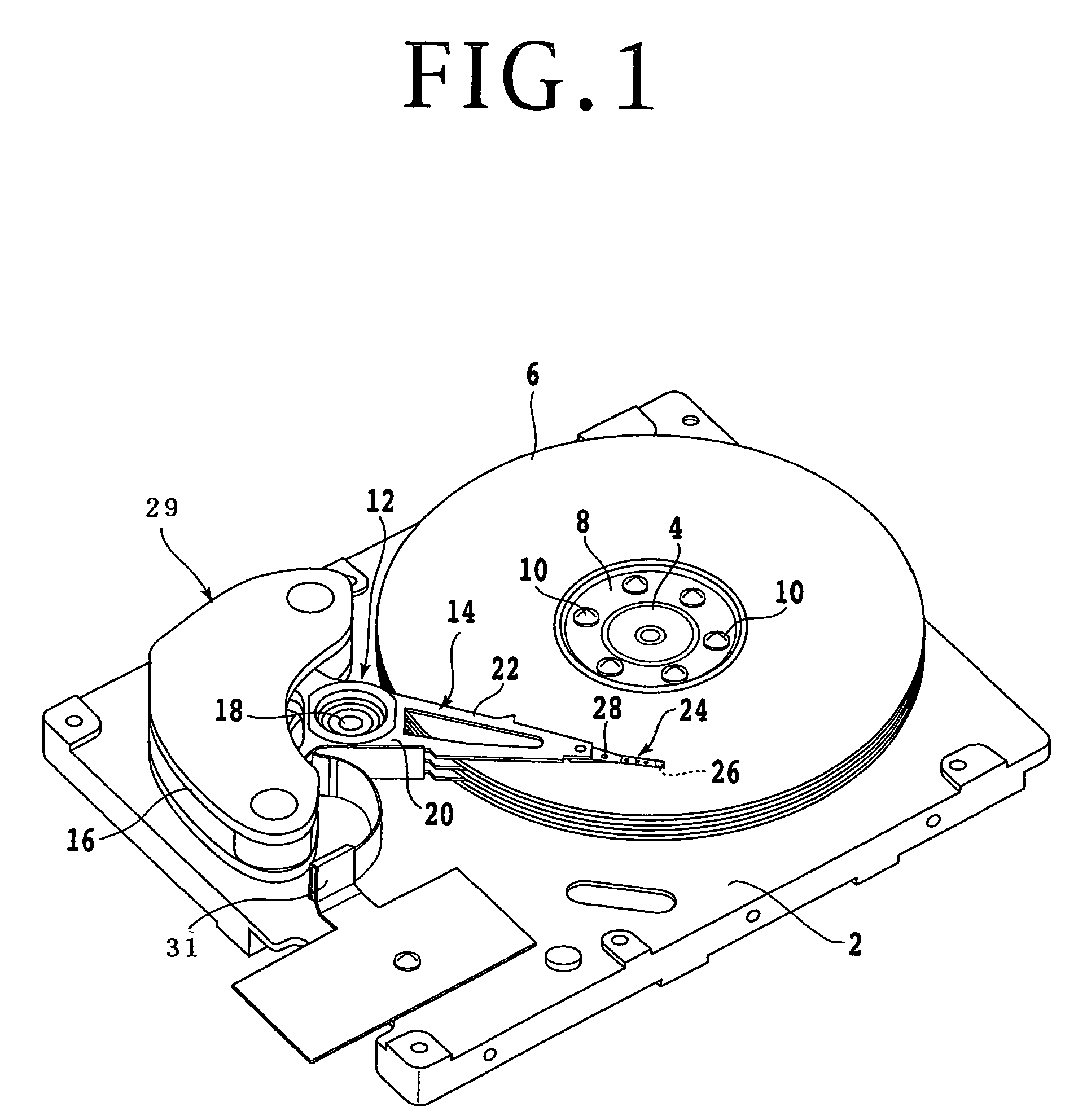

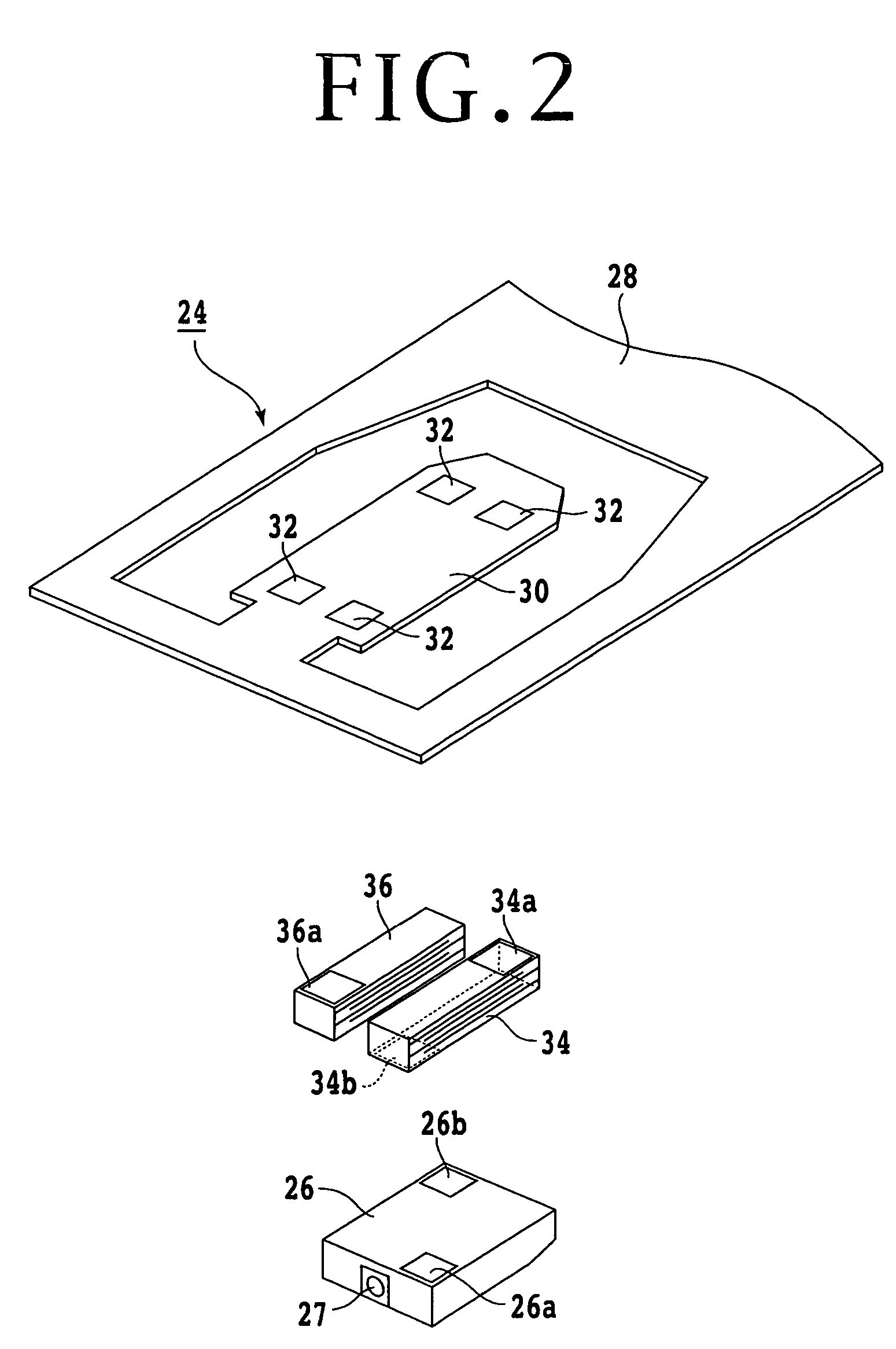

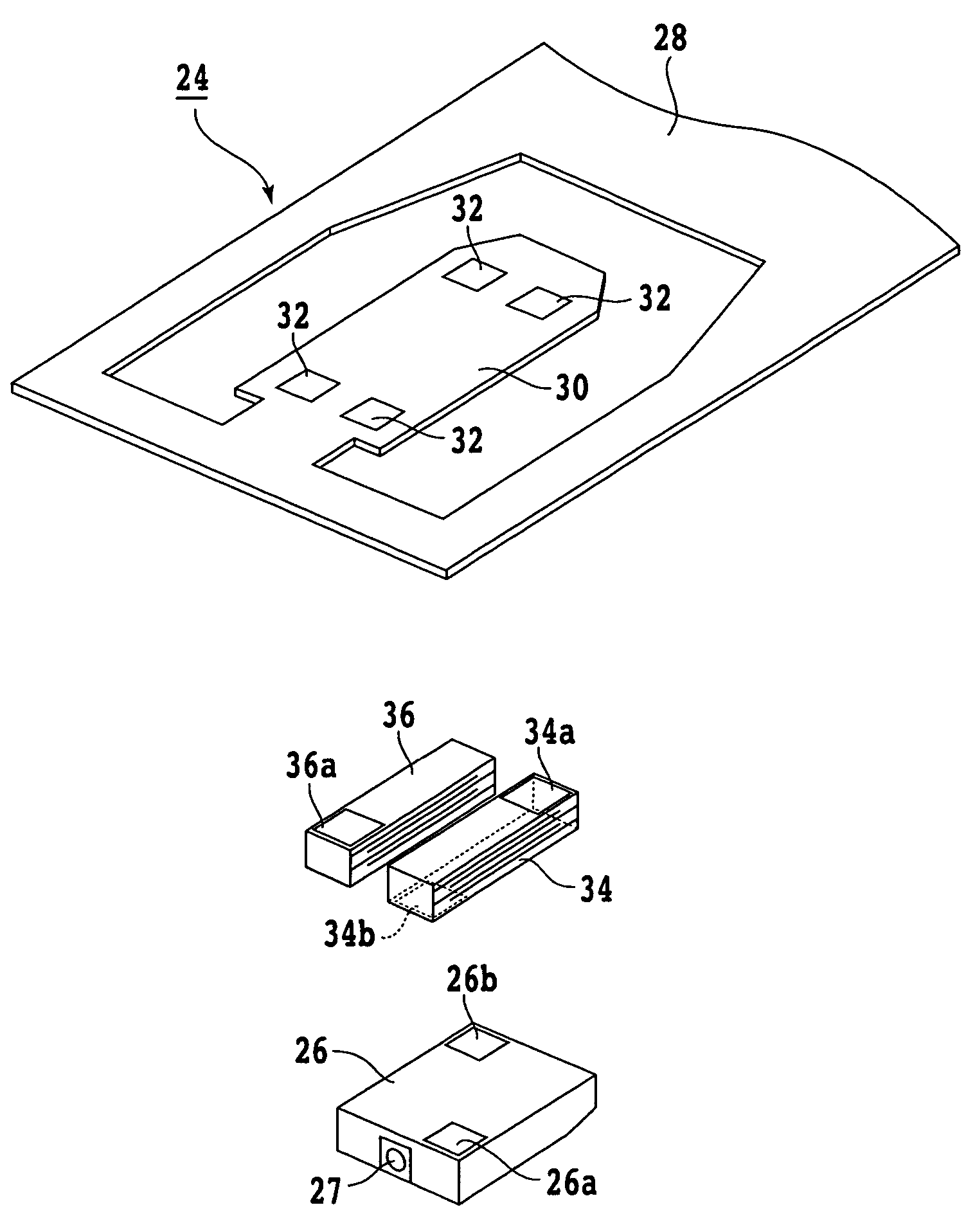

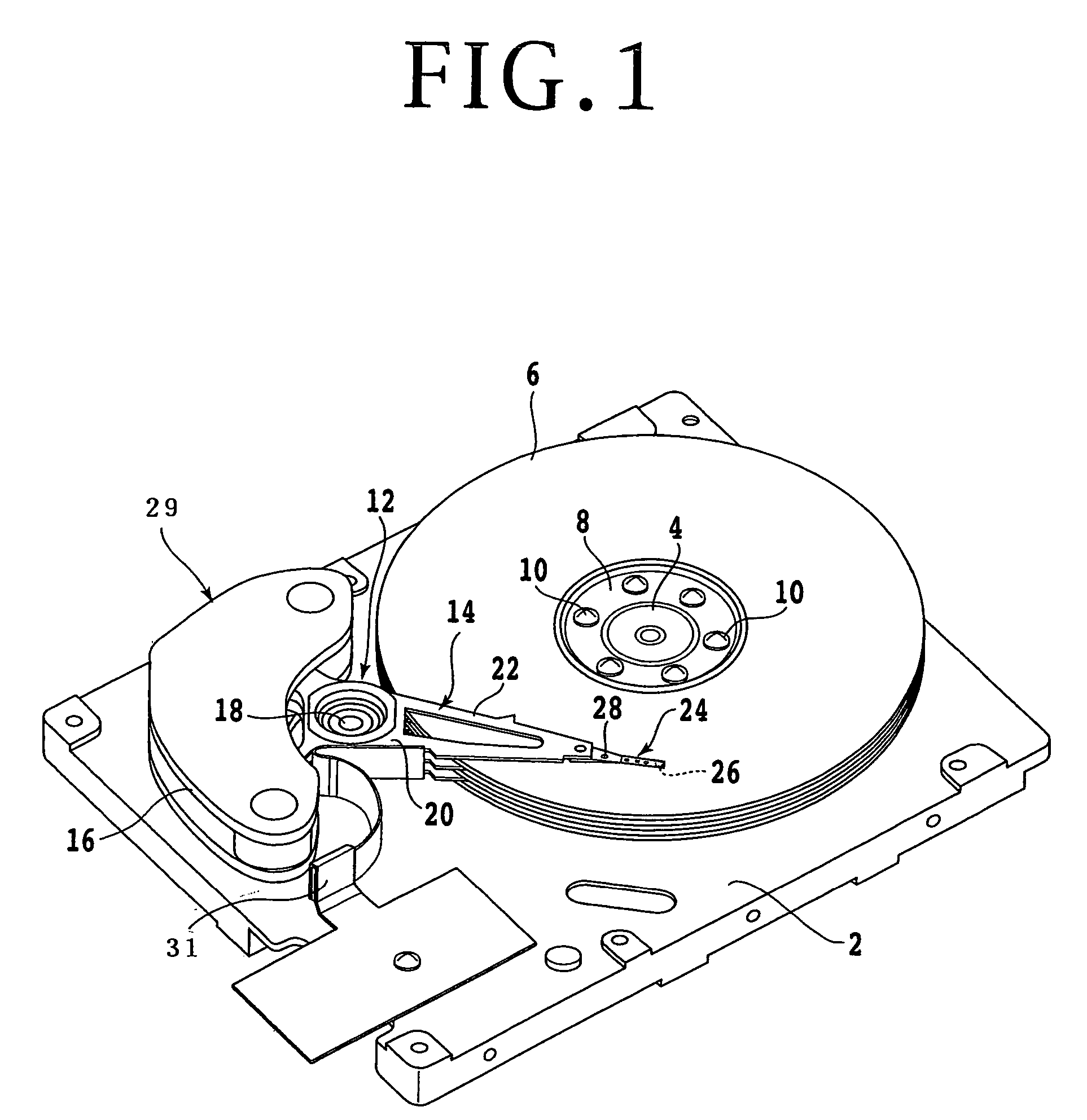

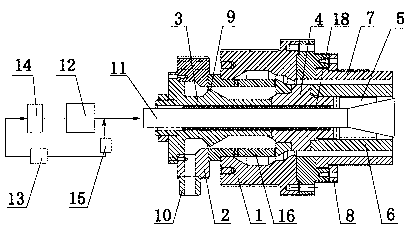

Piezoelectric actuator and head assembly using the piezoelectric actuator

InactiveUS7242132B2Eliminate saggingImprove electrical reliabilityTrack finding/aligningElectrical connection between head and armElectrical conductorPiezoelectric actuators

A head assembly includes a suspension having a gimbal, a flexible printed wiring sheet having a plurality of conductor patterns and adhered to the suspension, first and second piezoelectric actuators mounted on the gimbal, and a head slider mounted on the first and second piezoelectric actuators. The first and second piezoelectric actuators are adhered to the gimbal at end portion adhesion portions symmetrical with respect to the center of pivotal motion thereof and are adhered to the head slider at end portion adhesion portions on the opposite side disposed symmetrically with respect to the center of pivotal motion similarly. Consequently, when a voltage is applied to the first and second piezoelectric actuators through the flexible printed wiring sheet, a couple of forces can be generated which vary the posture of the head slider only in one direction around the center of pivotal motion.

Owner:FUJITSU LTD

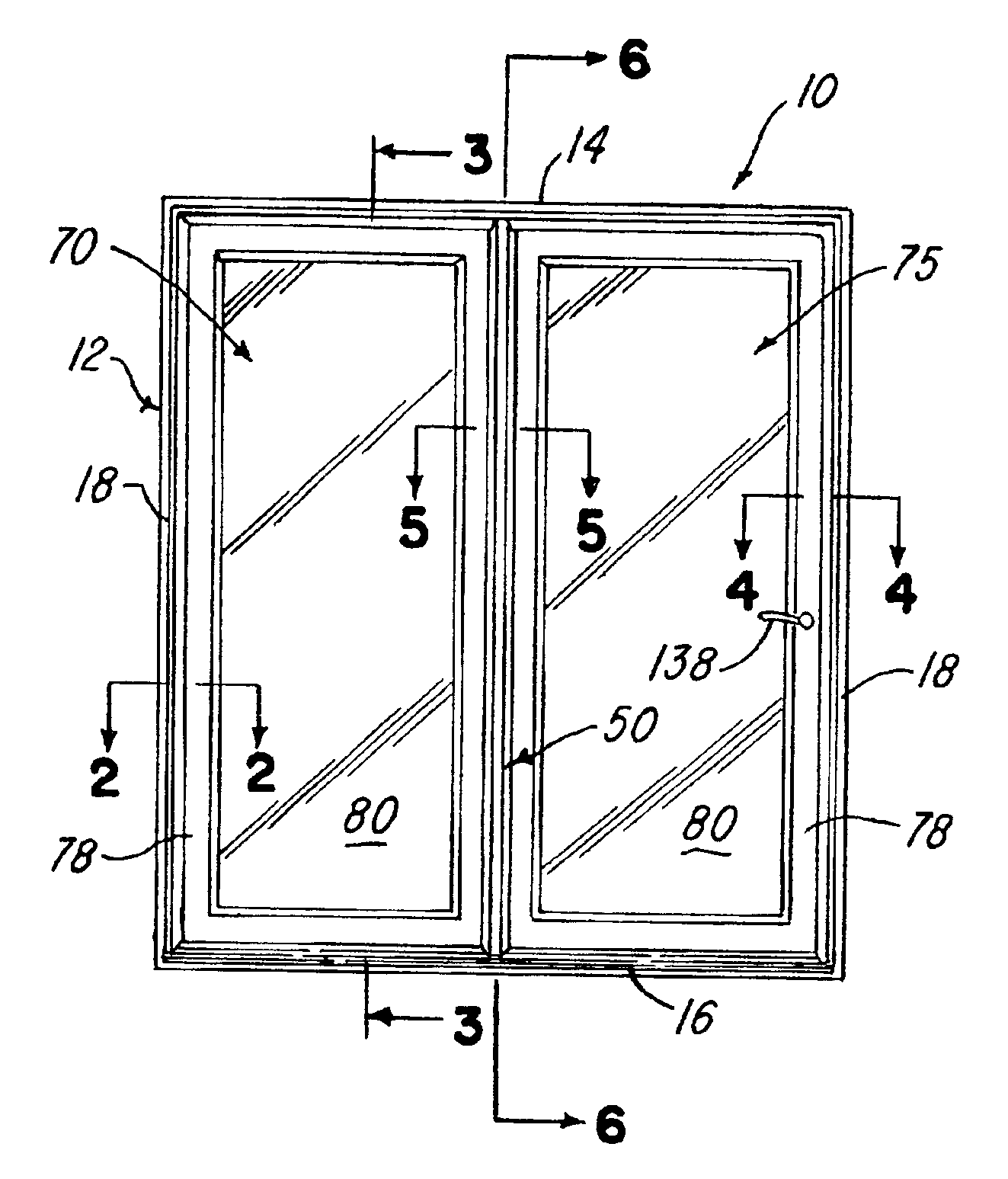

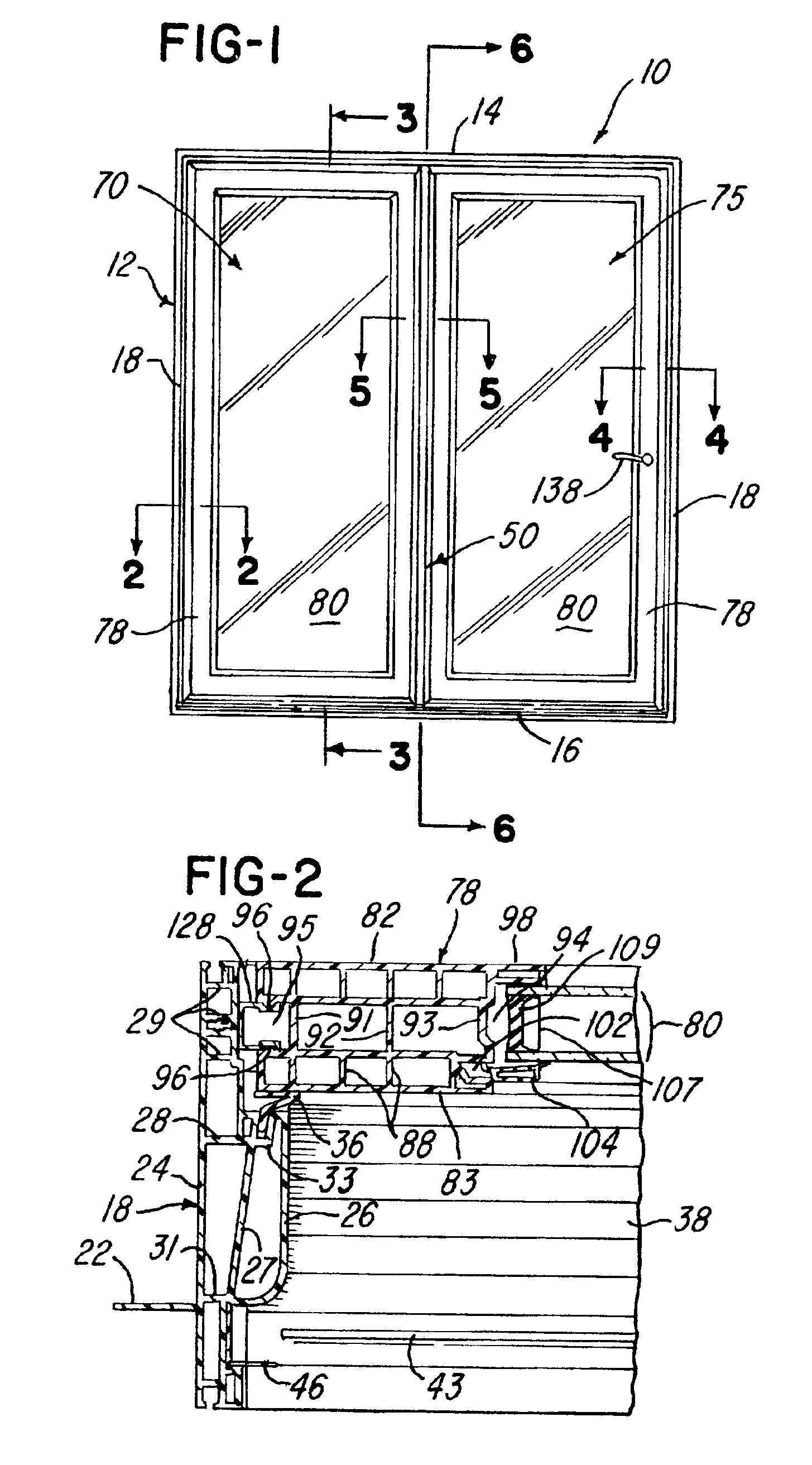

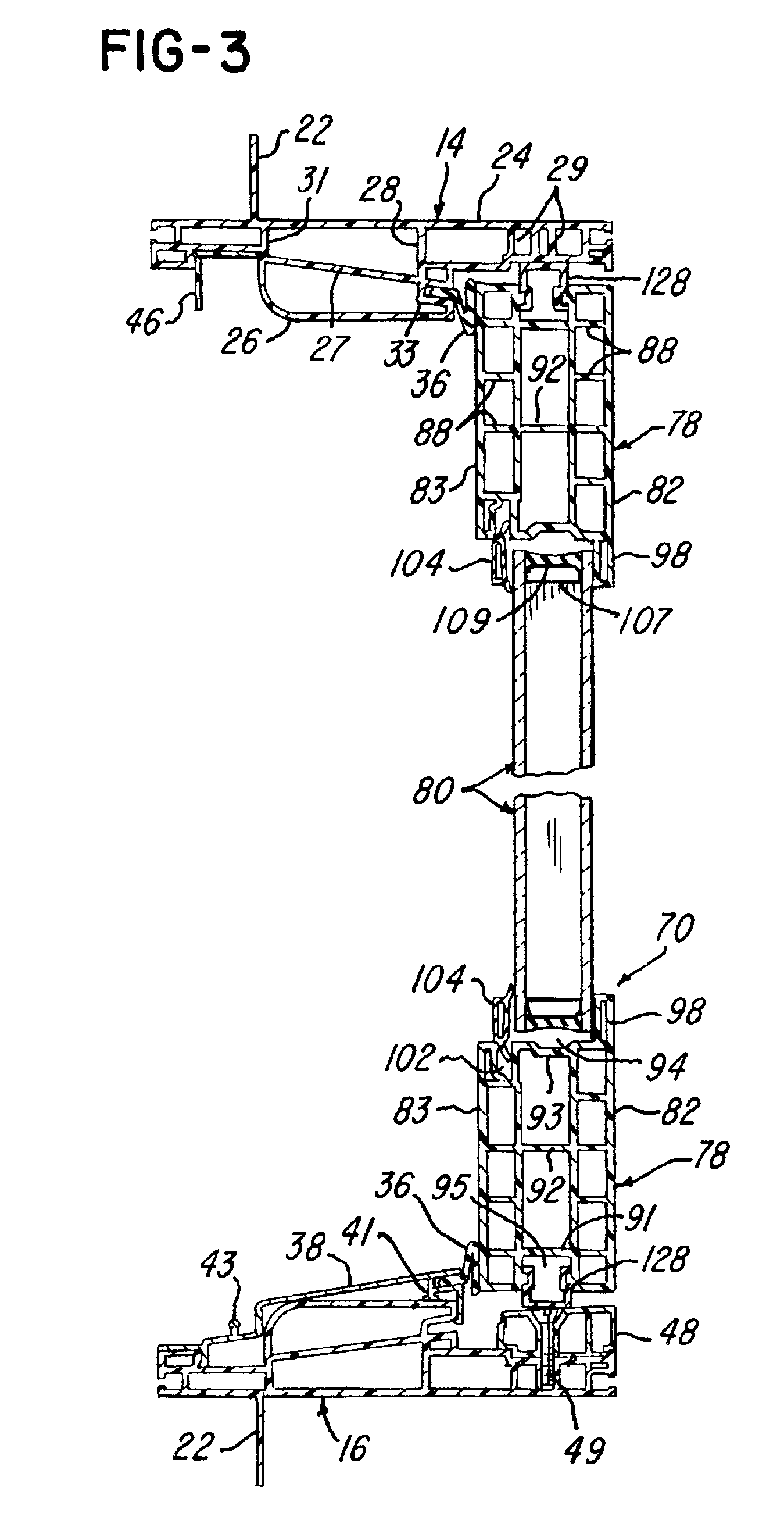

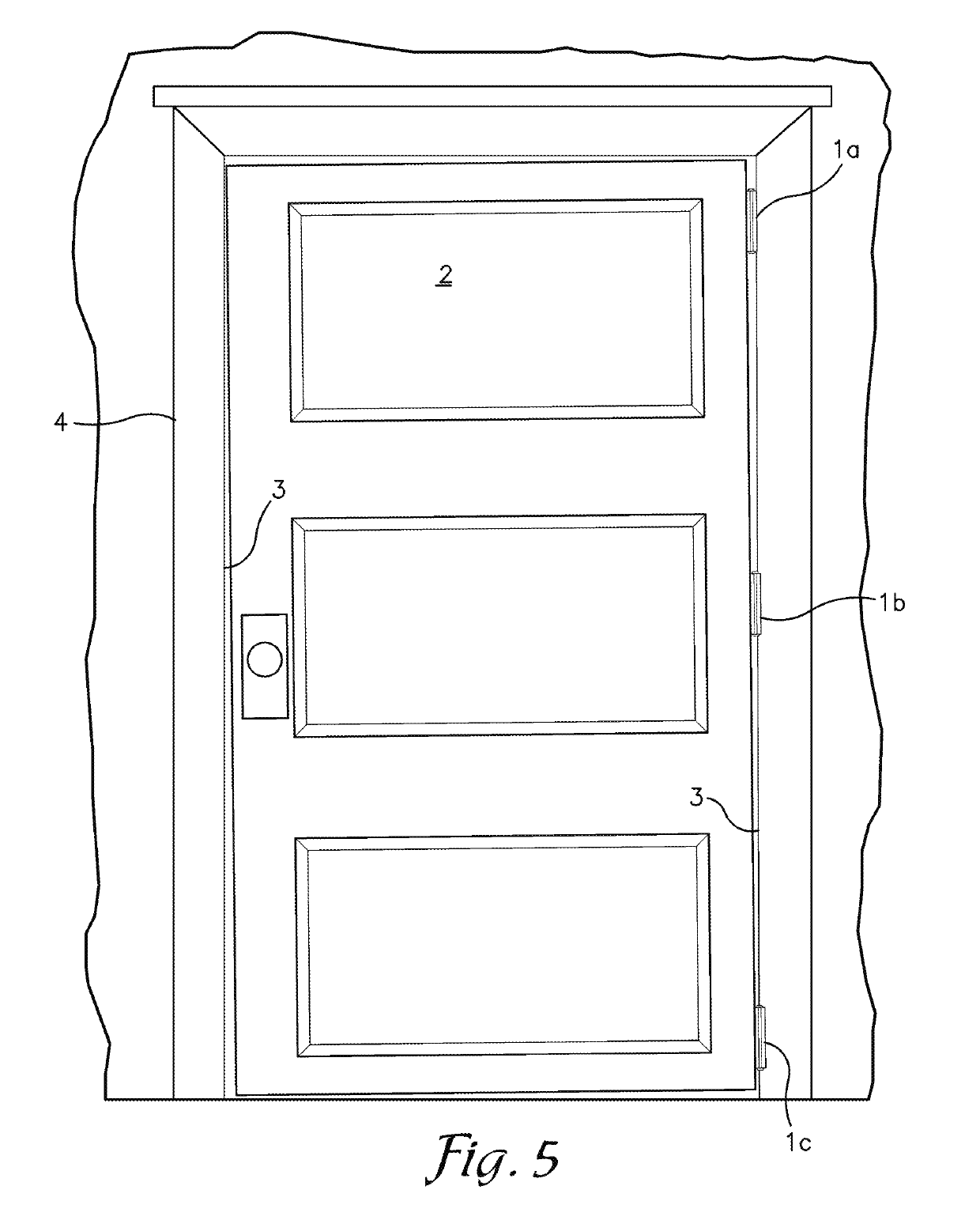

Patio door assembly with extruded plastics components

InactiveUS6968657B2Eliminate saggingEliminate warpingCorner/edge jointsCurtain suspension devicesPlastic materialsEngineering

Sections of extruded rigid plastics material form a rectangular main frame including a pair of vertical jamb members, a top head member and a bottom sill member connected by welded mitered corners. An extruded plastic astragal member is spaced between the jamb members and has laterally projecting stop portions and internal walls which are rigidly connected by long screws to the head and sill members. A fixed door panel and a pivotal door panel have extruded plastic rectangular frames with welded mitered corner joints and which surround corresponding glazing panels. A continuous gear hinge has an inactive leaf secured to the astragal member and a slightly shorter active leaf. The door panel frames have internal walls which cooperate with the welded corner joints to maintain each frame flat, and long screws positively connect the leaves of the gear hinge to the pivotal door panel frame and the astragal member.

Owner:DECEUNINCK NORTH AMERICA

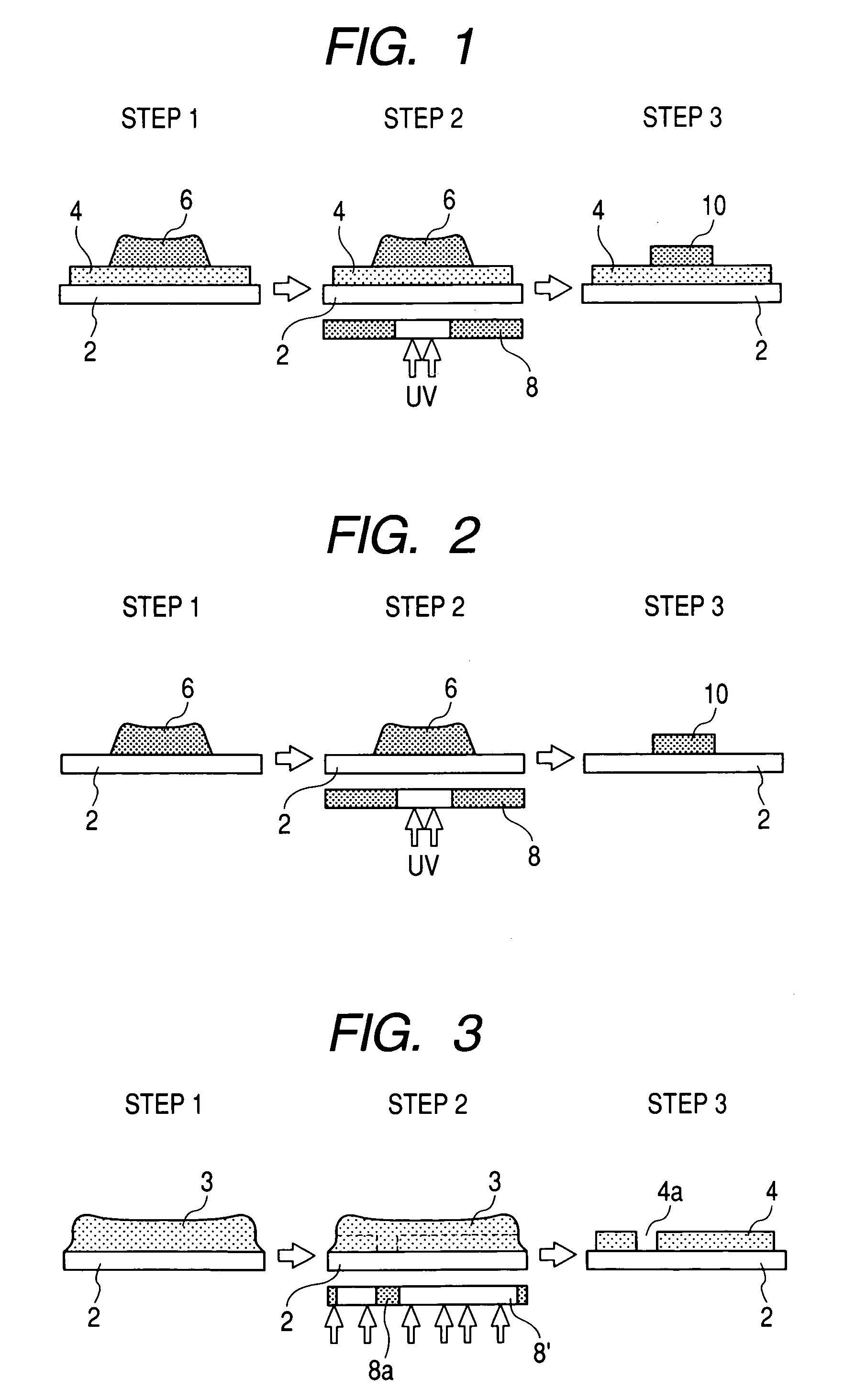

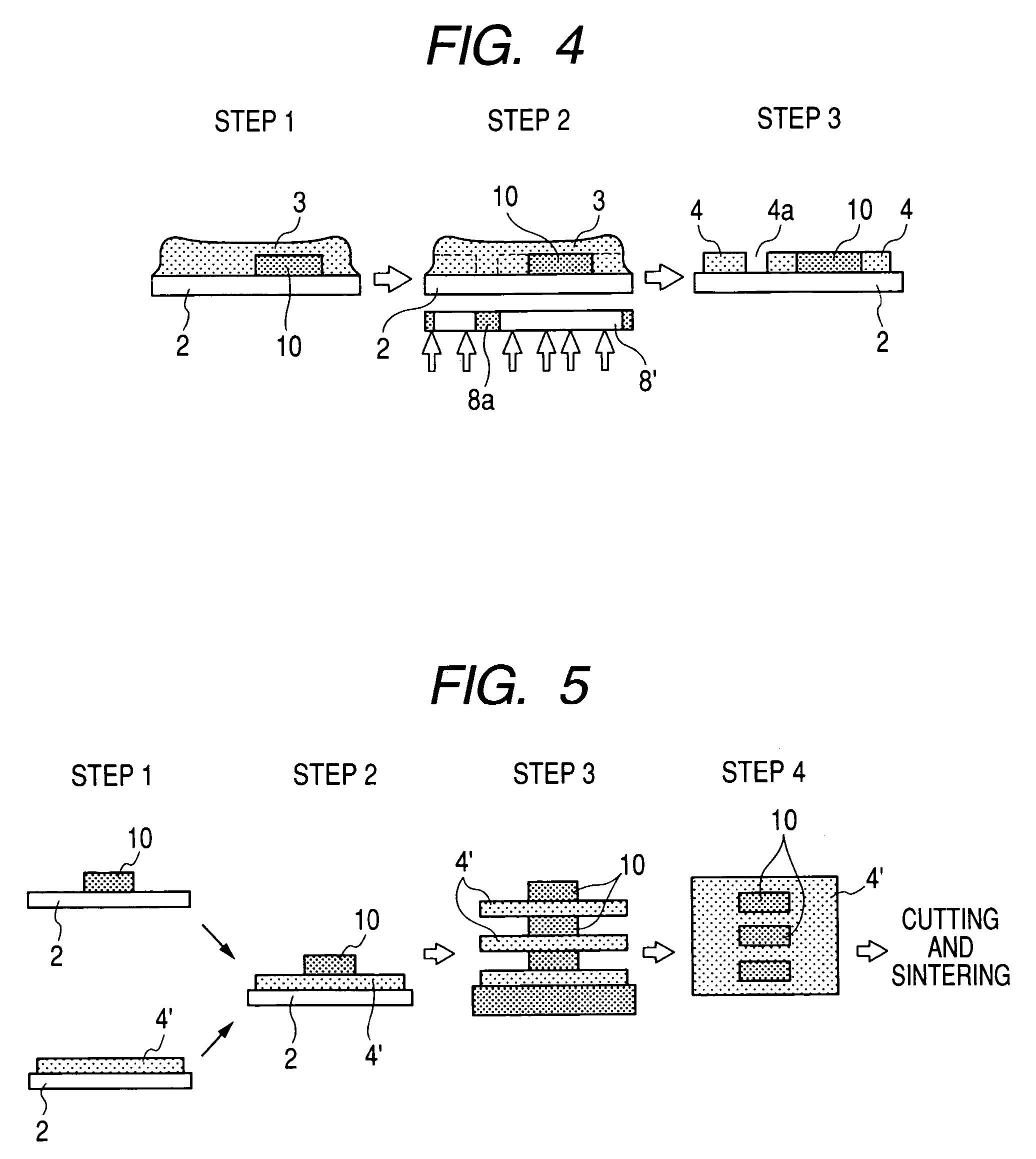

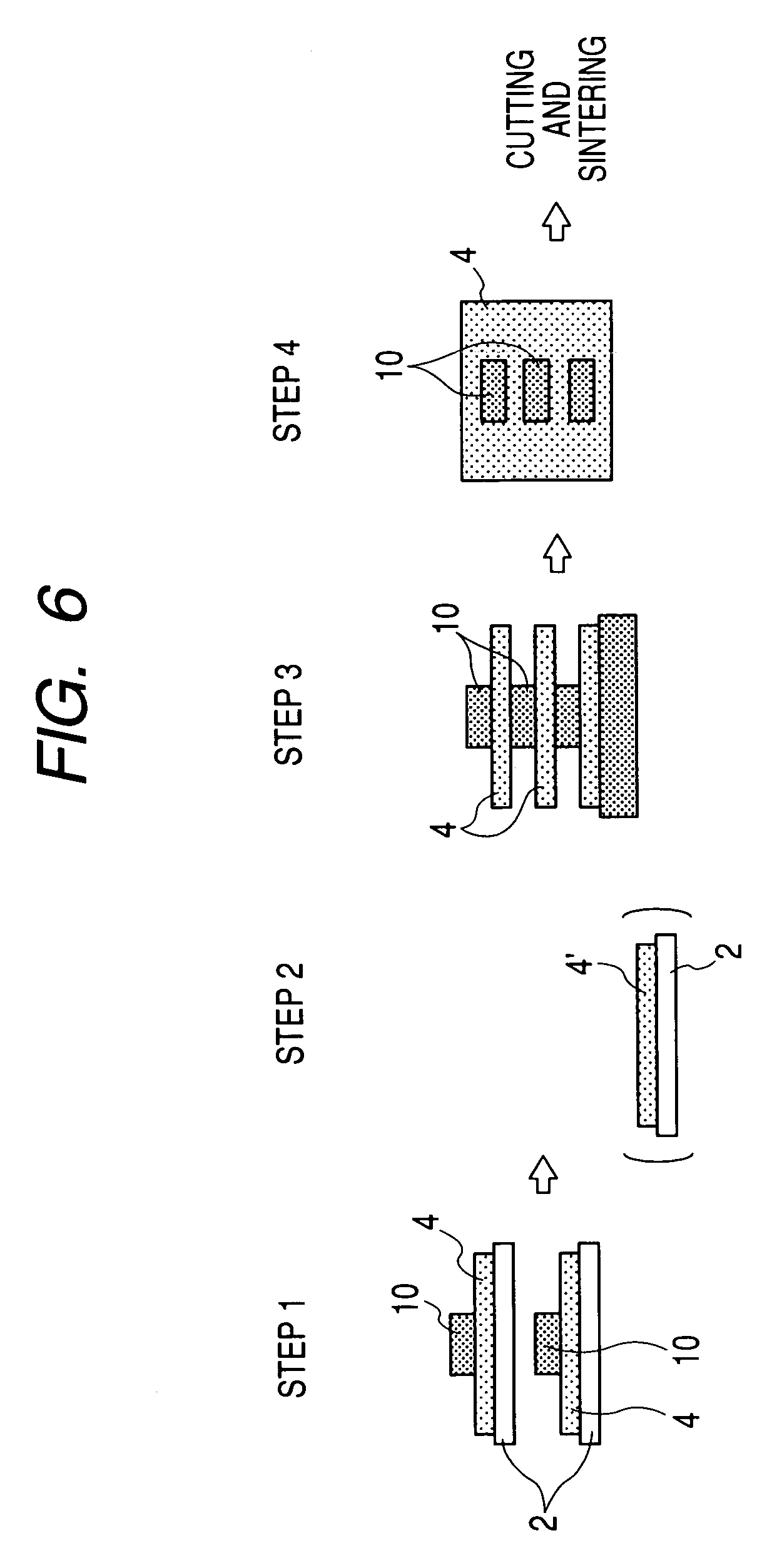

Method for manufacturing ceramic green sheet and method for manufacturing electronic part using that ceramic green sheet

InactiveUS7387870B2Reduce variation in electric characteristicExcellent electrical propertiesPhotomechanical apparatusSemiconductor/solid-state device manufacturingElectronMaterials science

The invention relates to a so-called ceramic green sheet used for manufacturing multilayer ceramic electronic parts. The invention is intended to improve accuracy in shape of an electrode or other element formed on the sheet, accuracy in its position and uniformity in its thickness. In a process according to the invention, a layer made of a photosensitive material including a powder having a desired electric characteristic is formed on a light transmissive base member. A mask having a desired pattern is disposed on the back side of the base member and the photosensitive material is exposed from the back side of the base member through the mask. Then the photosensitive layer after the exposure is subjected to development.

Owner:TDK CORPARATION

Apparatus and method for window treatment management

ActiveUS9763530B2Uniform and symmetrical lookEliminate saggingCurtain rodsTreatment managementEngineering

Embodiments of the present disclosure provide an apparatus and method for window treatment management. The apparatus may include a material strip and a pulling device. The material strip may include a hook threaded onto at least one end of the material strip and a plurality of loops stitched longitudinally onto the material strip. The pulling device may be utilized for pulling the material strip through the hook from a first end opening of a rod pocket of a window element to a second end opening thereof. Herein, the hook may be connected to one of the loops to create a securing loop around the window element when the material strip is exposed at the second end opening.

Owner:CACCAVO LAURIE ANN +2

Coating film transfer tool

A coating film transfer tool capable of eliminating a sag when being used, while protecting the transfer tape when not being used. The coating film transfer tool includes: a slide mechanism which causes the transfer head to slide allowing the transfer head to contact with the transfer tape and to protrude from the case in order to perform the transfer, and / or accommodate the transfer head into the case; and a slip mechanism which, when a sliding operation to cause the transfer head to protrude is performed by the slide mechanism, releases interlocking between the supply bobbin and the supply reel, and, when the supply bobbin rotates in the direction of winding up the transfer tape by running of the transfer tape at a time of the transfer, rotates the supply reel and the supply bobbin in interlocking with each other, the slip mechanism being interposed between the supply bobbin and the supply reel, in which, when a sliding operation to accommodate the transfer head is performed by the side mechanism, the slide mechanism is engaged with the supply reel, and rotates the supply reel in reverse.

Owner:PLUS STATIONARY CORP

Piezoelectric actuator and head assembly using the piezoelectric actuator

InactiveUS20050168107A1Eliminate saggingImprove electrical reliabilityTrack finding/aligningElectrical connection between head and armElectrical conductorPiezoelectric actuators

A head assembly includes a suspension having a gimbal, a flexible printed wiring sheet having a plurality of conductor patterns and adhered to the suspension, first and second piezoelectric actuators mounted on the gimbal, and a head slider mounted on the first and second piezoelectric actuators. The first and second piezoelectric actuators are adhered to the gimbal at end portion adhesion portions symmetrical with respect to the center of pivotal motion thereof and are adhered to the head slider at end portion adhesion portions on the opposite side disposed symmetrically with respect to the center of pivotal motion similarly. Consequently, when a voltage is applied to the first and second piezoelectric actuators through the flexible printed wiring sheet, a couple of forces can be generated which vary the posture of the head slider only in one direction around the center of pivotal motion.

Owner:FUJITSU LTD

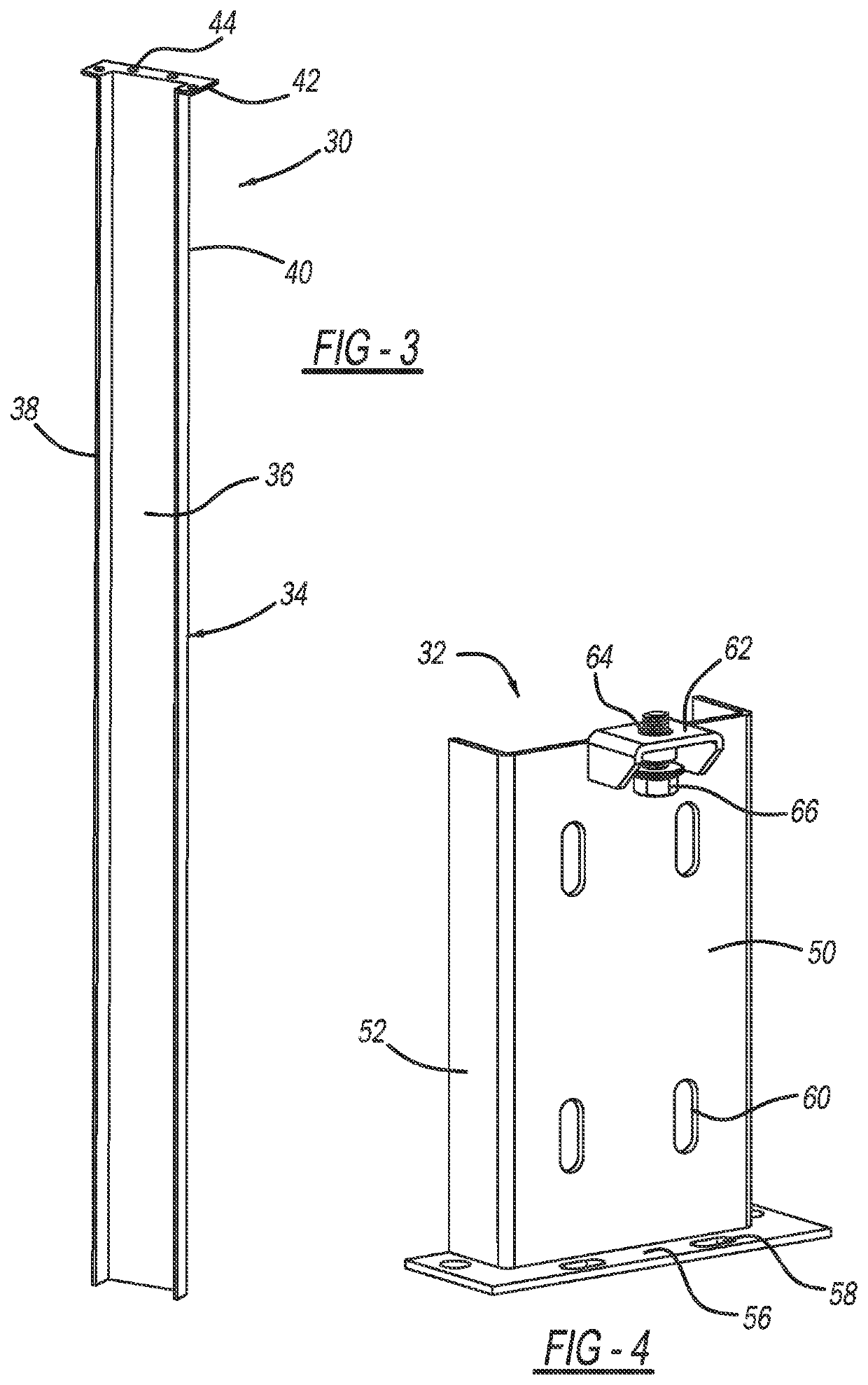

Health product improving acuity of vision and making method thereof

InactiveCN1919066APromote absorptionEliminate saggingAlcoholic beverage preparationFood preparationGinger RhizomeHealth food

The invention relates to a health food with function of improving acuity of vision, as well as the process for preparation. The raw materials of the product include ginkgo leaves, fresh ginger, dried orange peel, meat, star aniseed, pricklyash peel, Chinese green onion stalk, bee honey, soy sauce, yellow rice wine, edible vinegar, table salt and medical ethanol. The health product is the nutrient solution extracted from each raw materials through boiling.

Owner:于炳文

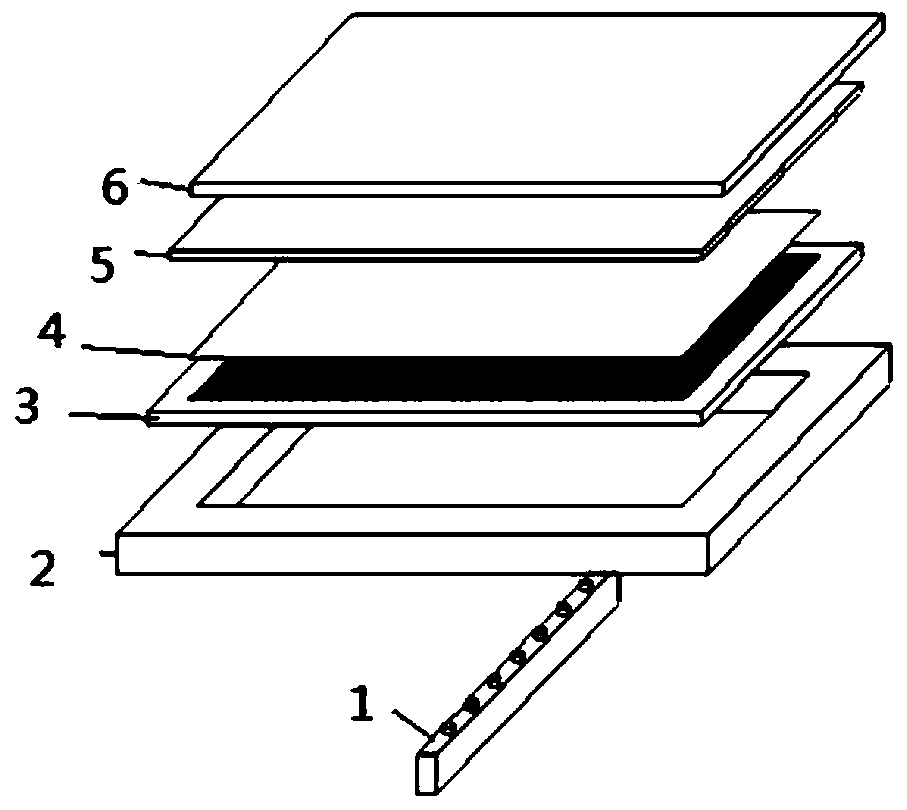

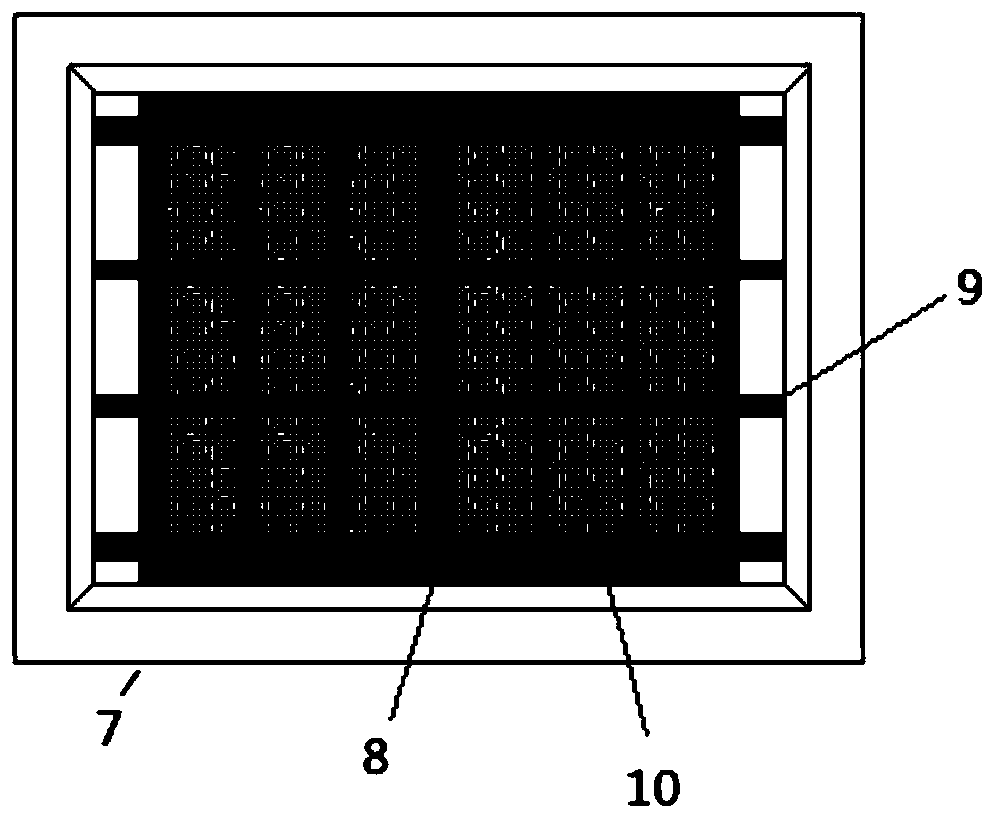

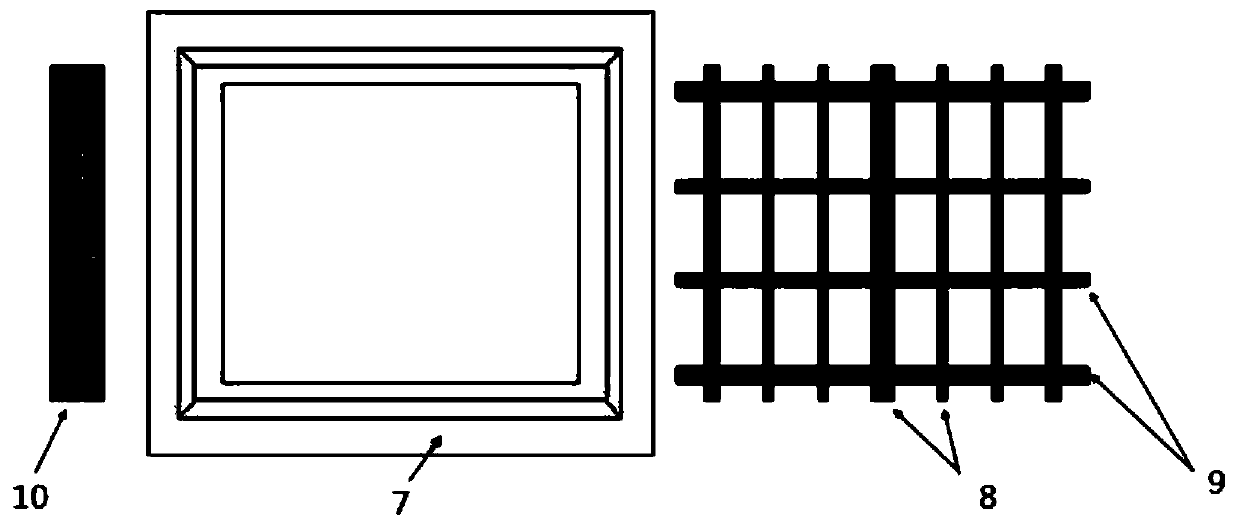

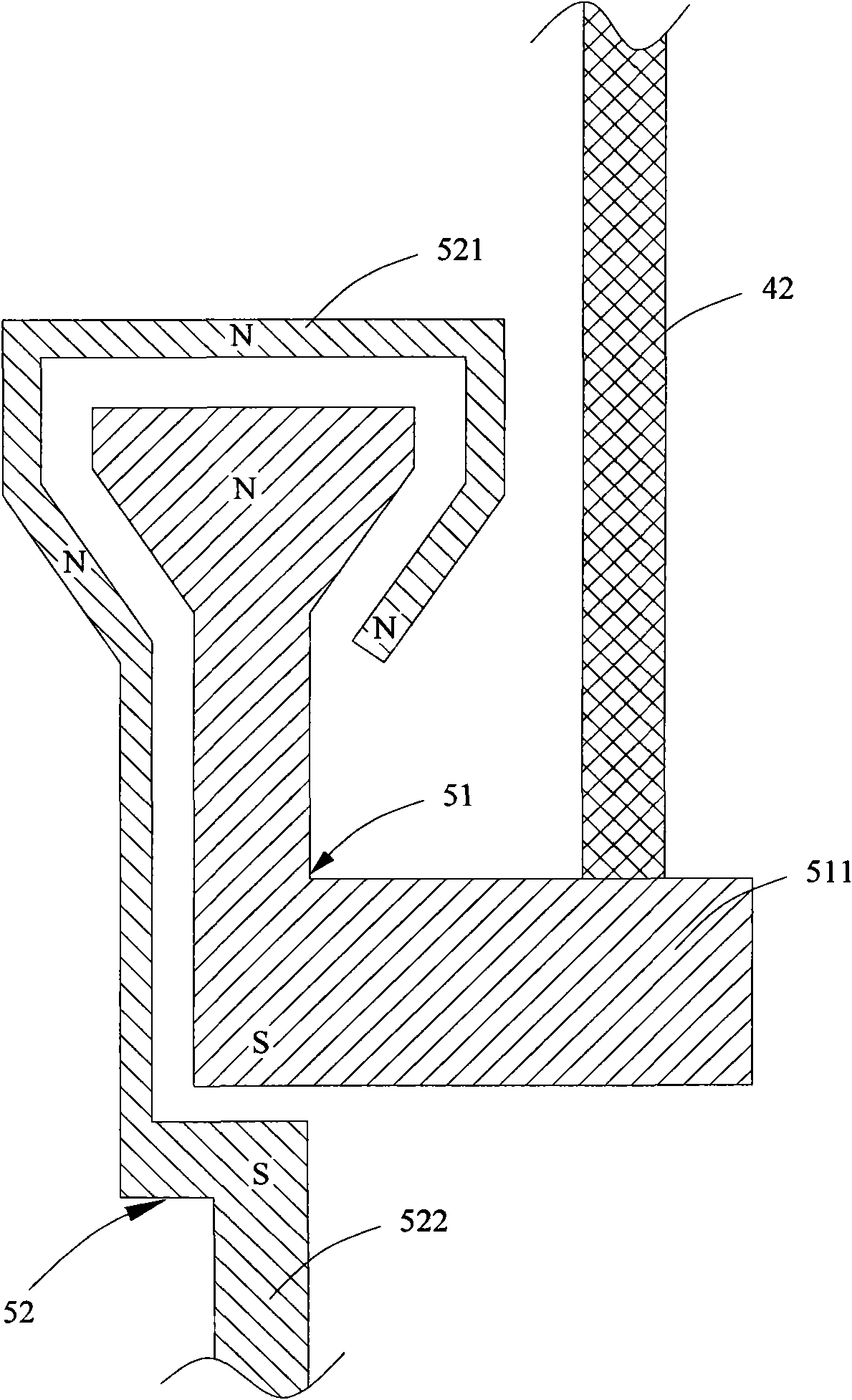

Mask plate

PendingCN110735108AEliminate saggingOvercome the wrinkle problemVacuum evaporation coatingSputtering coatingMechanical engineeringPhysics

The invention relates to the technical field of display and discloses a mask plate. The mask plate comprises a frame. The frame is provided with an open area which is a ladder hole. A supporting partand a mask are fixedly connected in the end which is large in opening of the ladder hole. The supporting part and the mask are fixedly connected to the frame, separately. The mask is supported on thesupporting part which is used for eliminating droop of the mask, so that the problem of overcoming droop by way of increasing tension is solved in a net towing process by the mask. Therefore, the netcan be towed with relatively small tension. Along with reduction of tension, the problem of wrinkles of the mask caused by large tension is overcome. The welding difficulty of the mask welded to the frame is also reduced correspondingly, so that the net towing precision is improved and the problem of mixed color of evaporation as a result of poor net towing precision is overcome.

Owner:BOE TECH GRP CO LTD +1

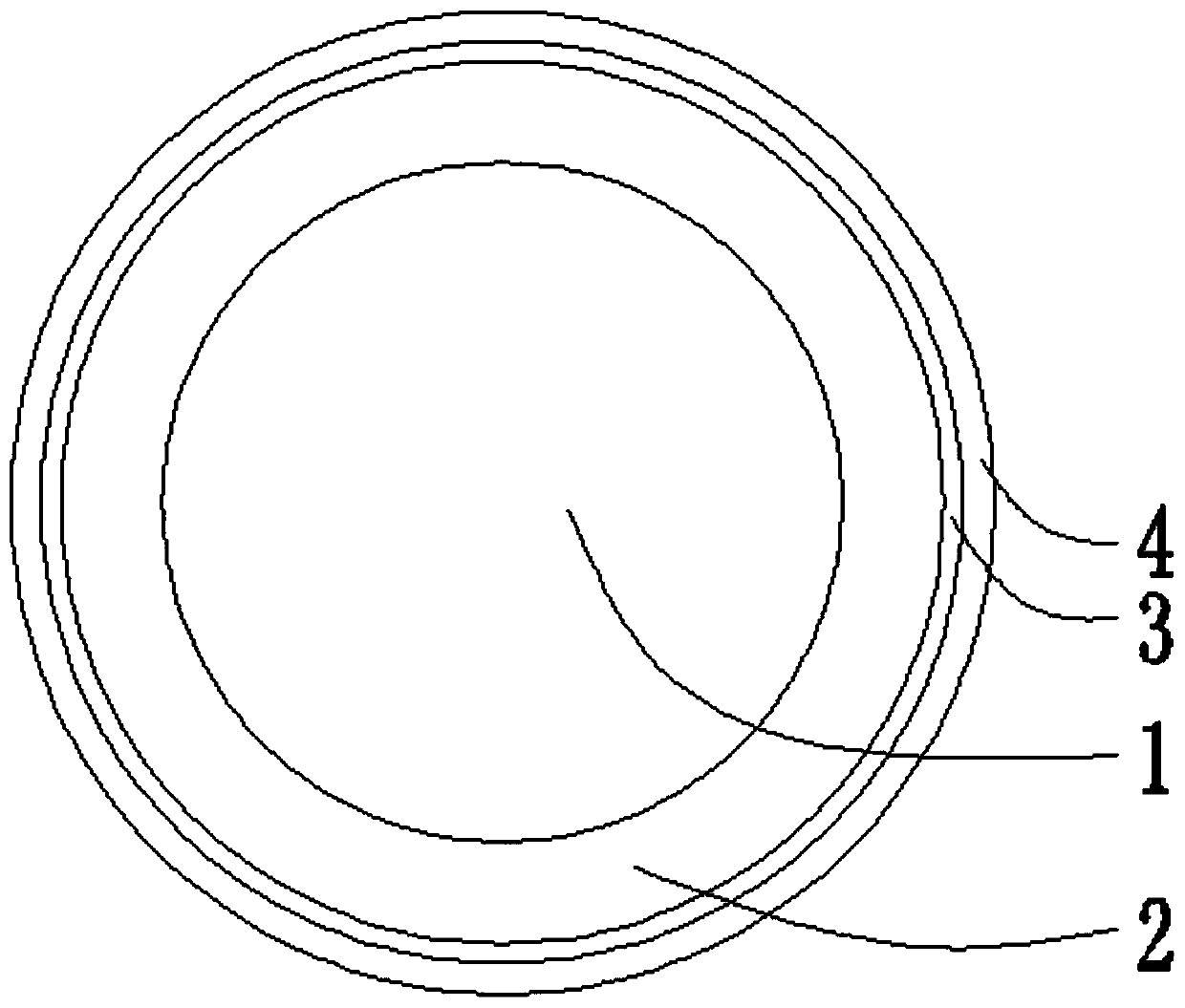

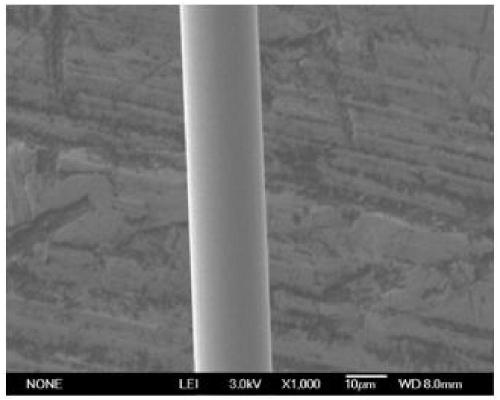

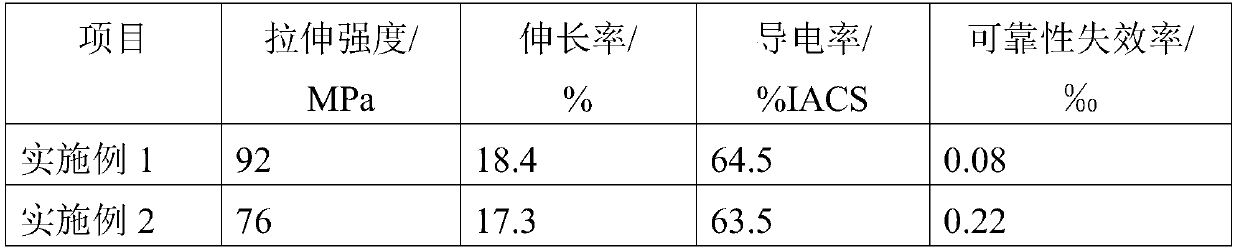

Gold-plated bonding aluminum wire and preparation method thereof

ActiveCN111326491AHigh strengthImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesSilicon alloyBonding process

The invention provides a gold-plated bonding aluminum wire and a preparation method thereof. The gold-plated bonding aluminum wire comprises the following components in percentage by mass: 15%-20% ofcopper, 0.3%-5% of nickel or 0.3%-6.5% of silver, 1.2%-7.5% of gold and the balance of aluminum or aluminum-silicon alloy. The preparation method comprises the steps of preparing an aluminum rod or analuminum-silicon alloy rod, coating copper, performing drawing, performing nickel plating or silver plating, performing gold plating, and finally performing fine drawing, ultra-fine drawing and heattreatment to prepare the gold-plated bonding aluminum wire. The gold-plated bonding aluminum wire has the characteristics of high strength and high reliability, application of an IGBT device is met, large-length drawing of the gold-plated bonding aluminum wire is achieved by adopting small area reduction rate machining and controlling the angle of an inlet area, the length of a sizing area and theangle of an outlet area of a die, and the phenomenon that the gold-plated bonding aluminum wire is prone to breakage in the wire drawing process is eliminated; and meanwhile, the surface of the gold-plated bonding aluminum wire is ensured to have good smoothness, and the bonding strength in the bonding process is effectively ensured.

Owner:ZHEJIANG TONY ELECTRONICS CO LTD

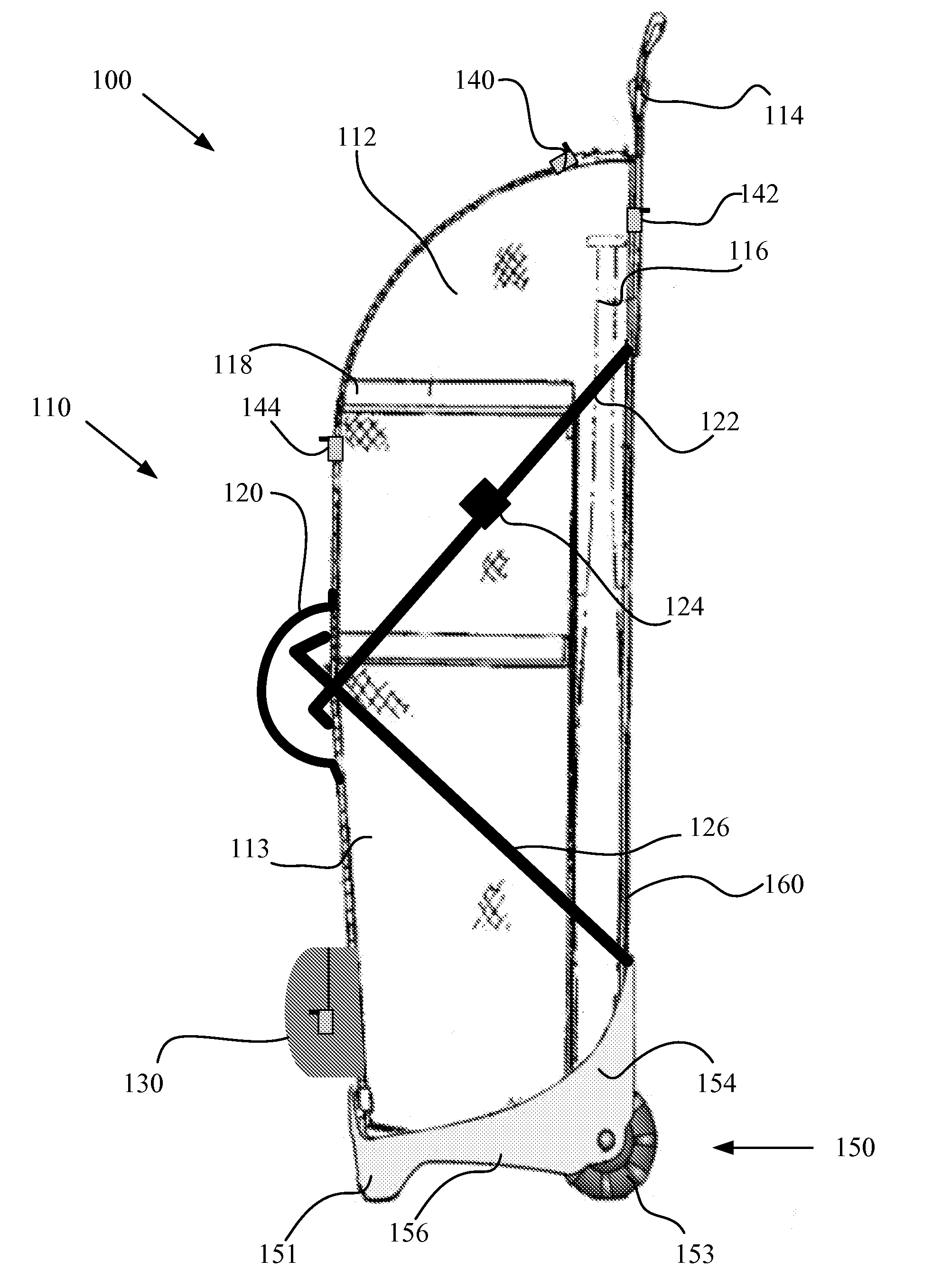

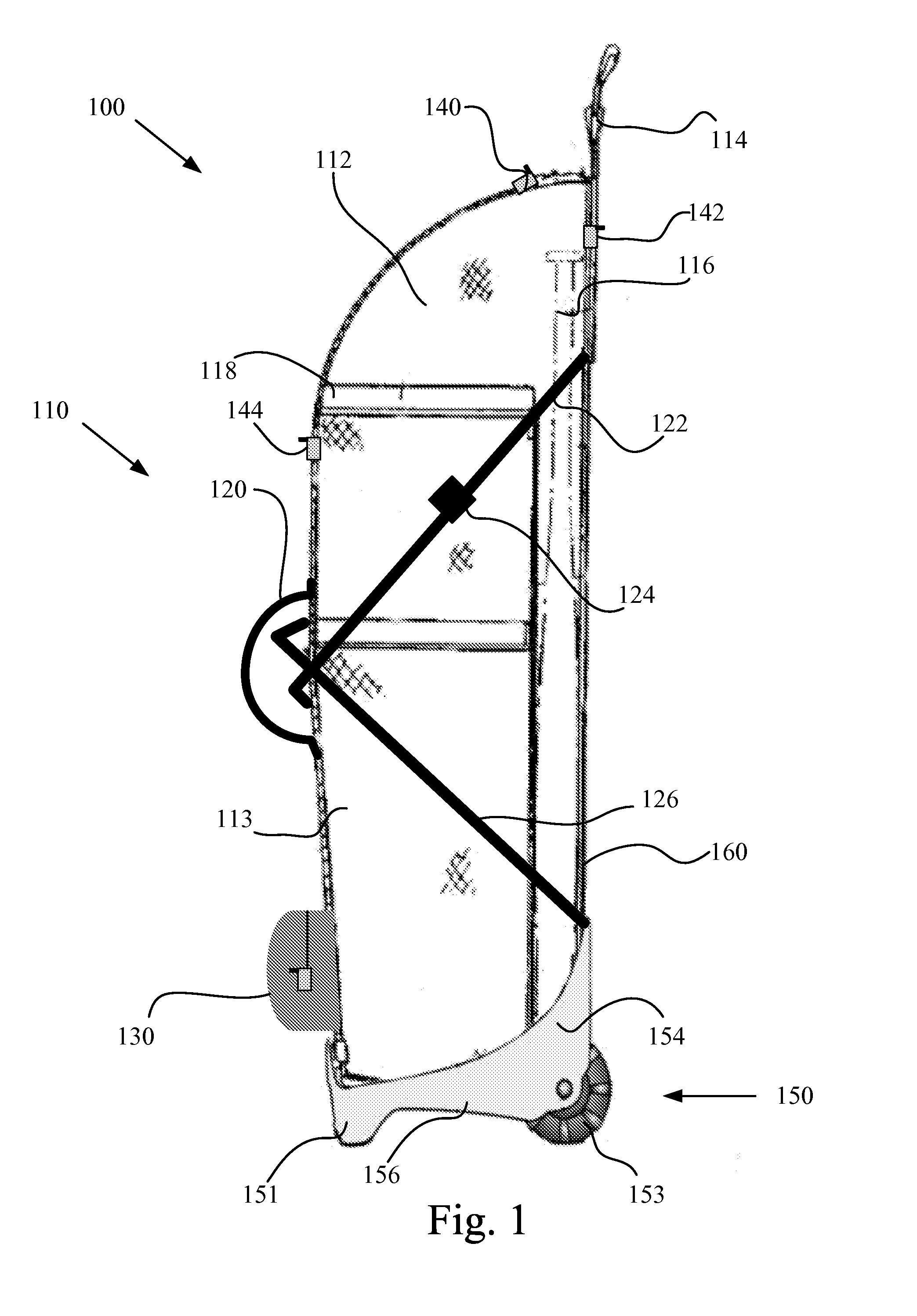

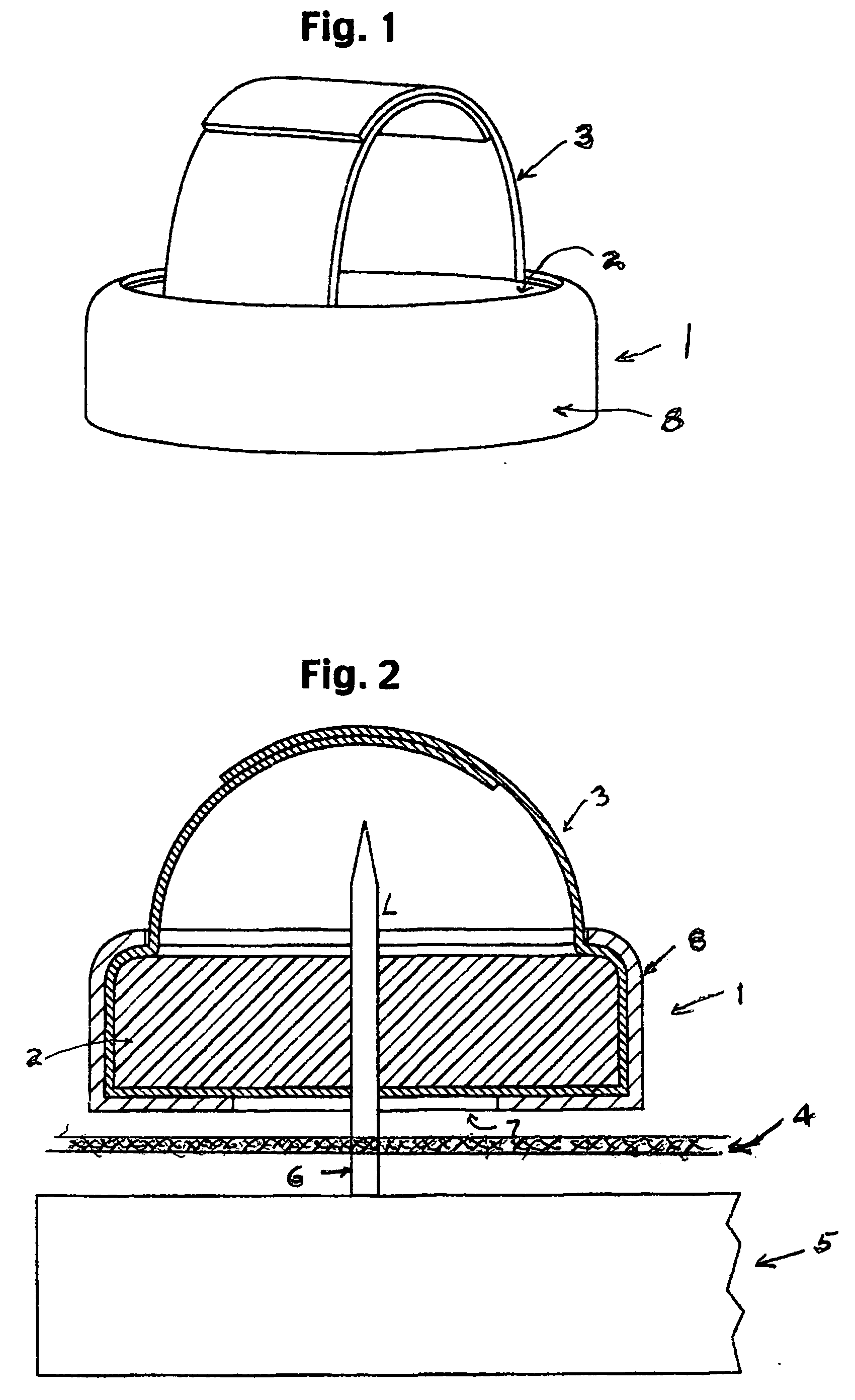

Wheeled bag and support chassis

ActiveUS20150076778A1Improve performanceIncreased durabilityCarriage/perambulator with single axisHand carts with one axisEngineeringRolling chassis

This invention relates generally to an arched one-piece wheeled support chassis fixedly attached to a bag or container. The main body of the wheeled support chassis is arched or curved inwards from back to front and upwards from bottom to top. The curvilinear architecture of the wheeled support chassis provides for substantial strength and rigidity to support a bag or container and its contents while allowing the wheeled support chassis to be both thin and lightweight.

Owner:WILSON SPORTING GOODS

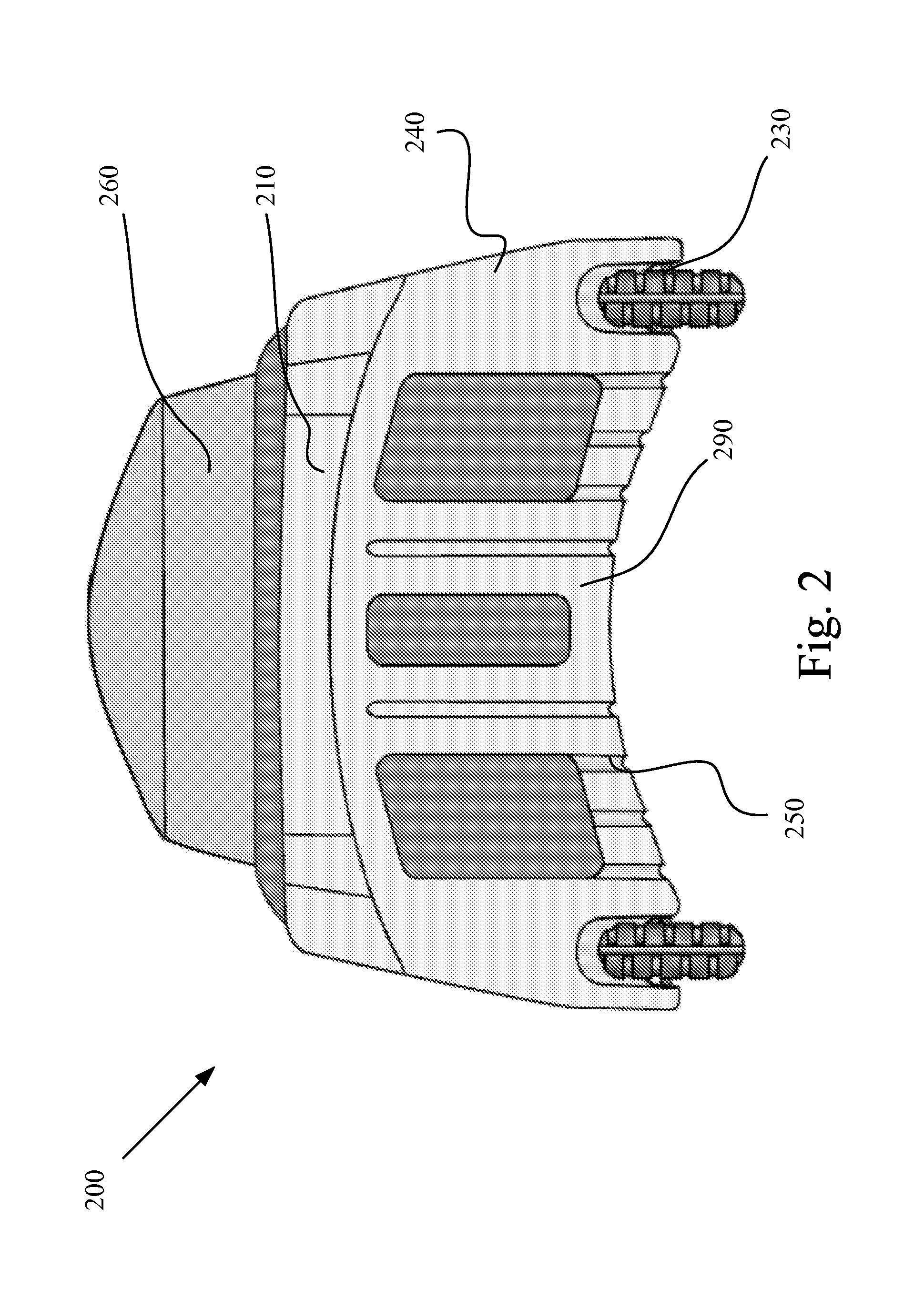

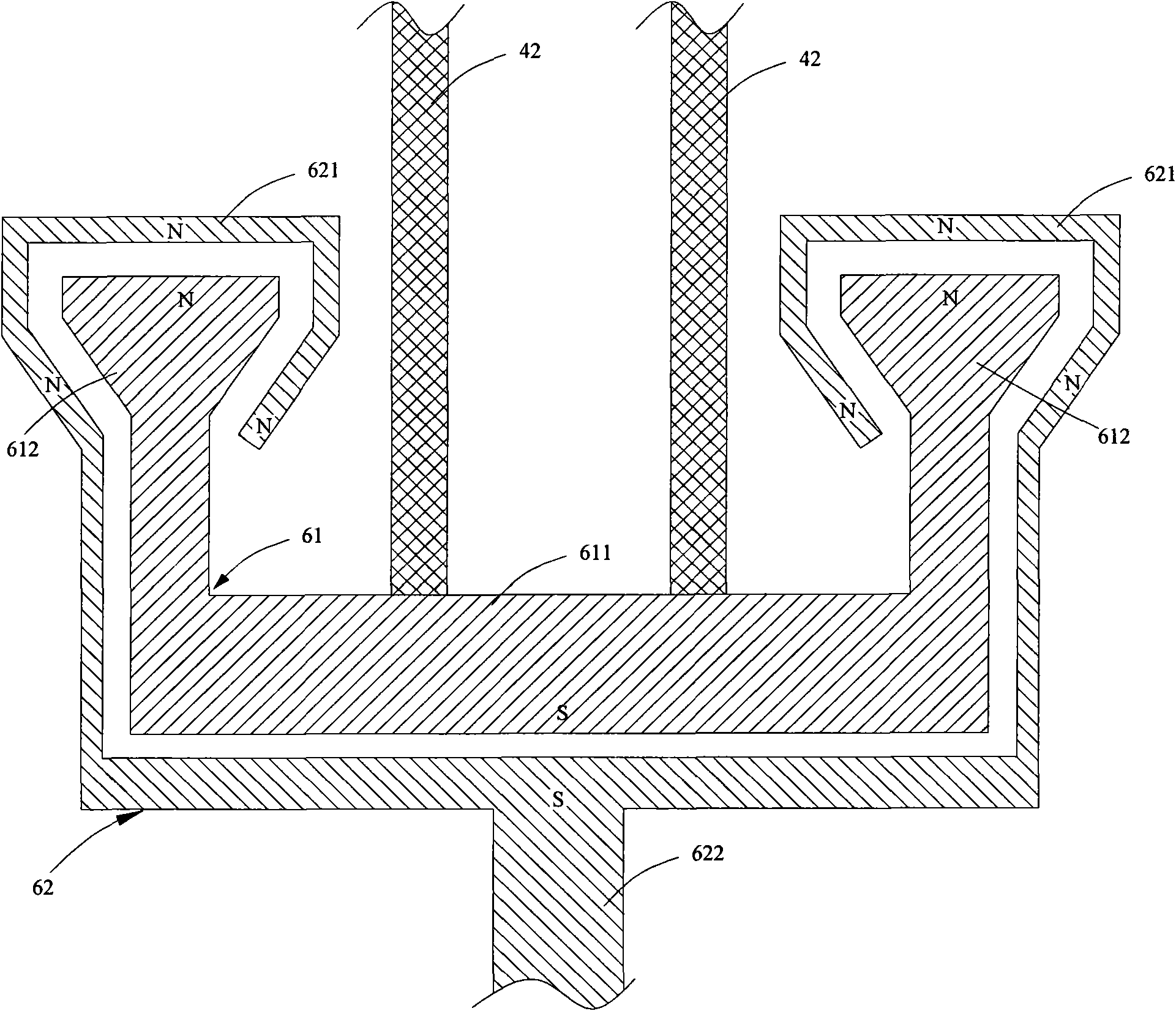

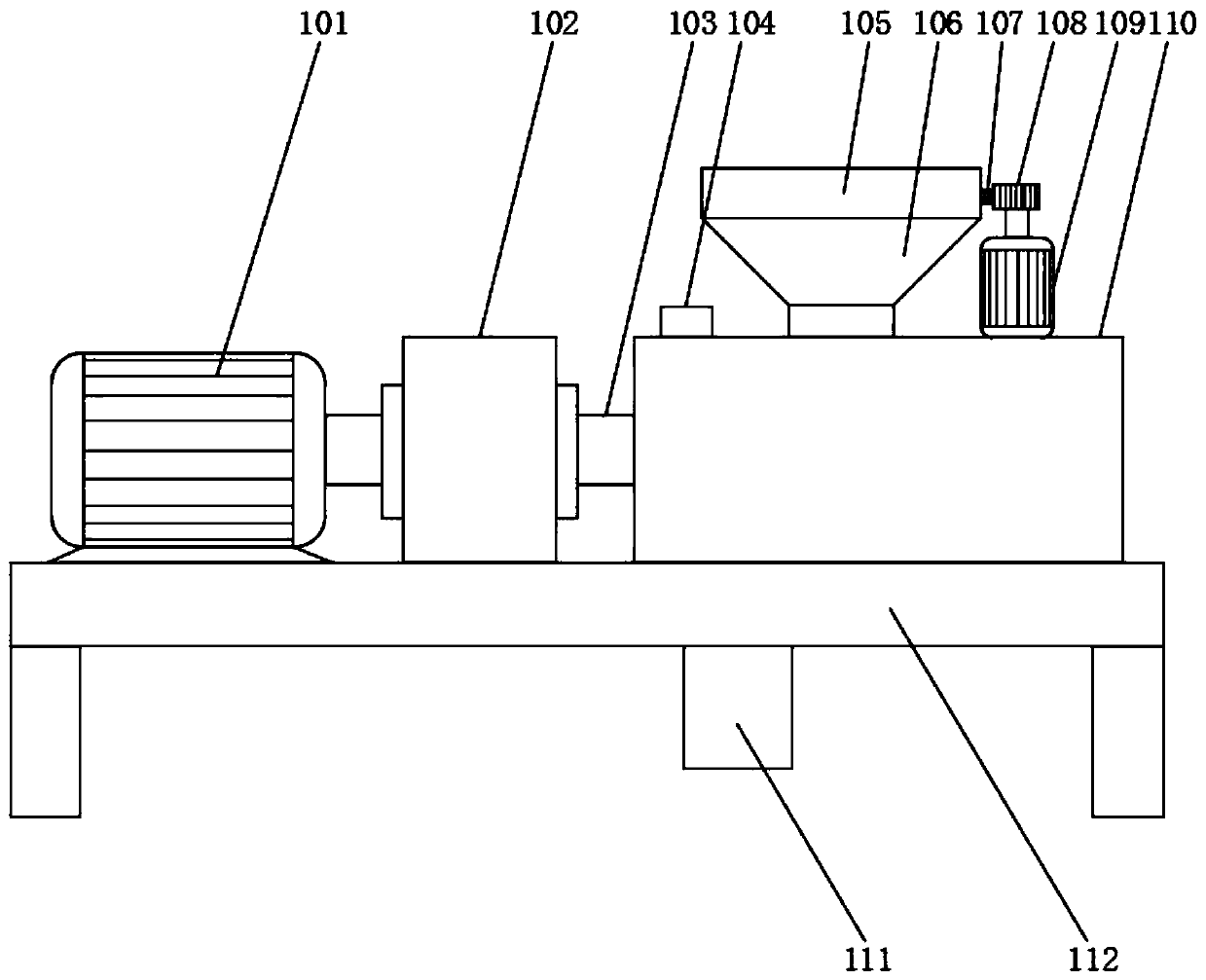

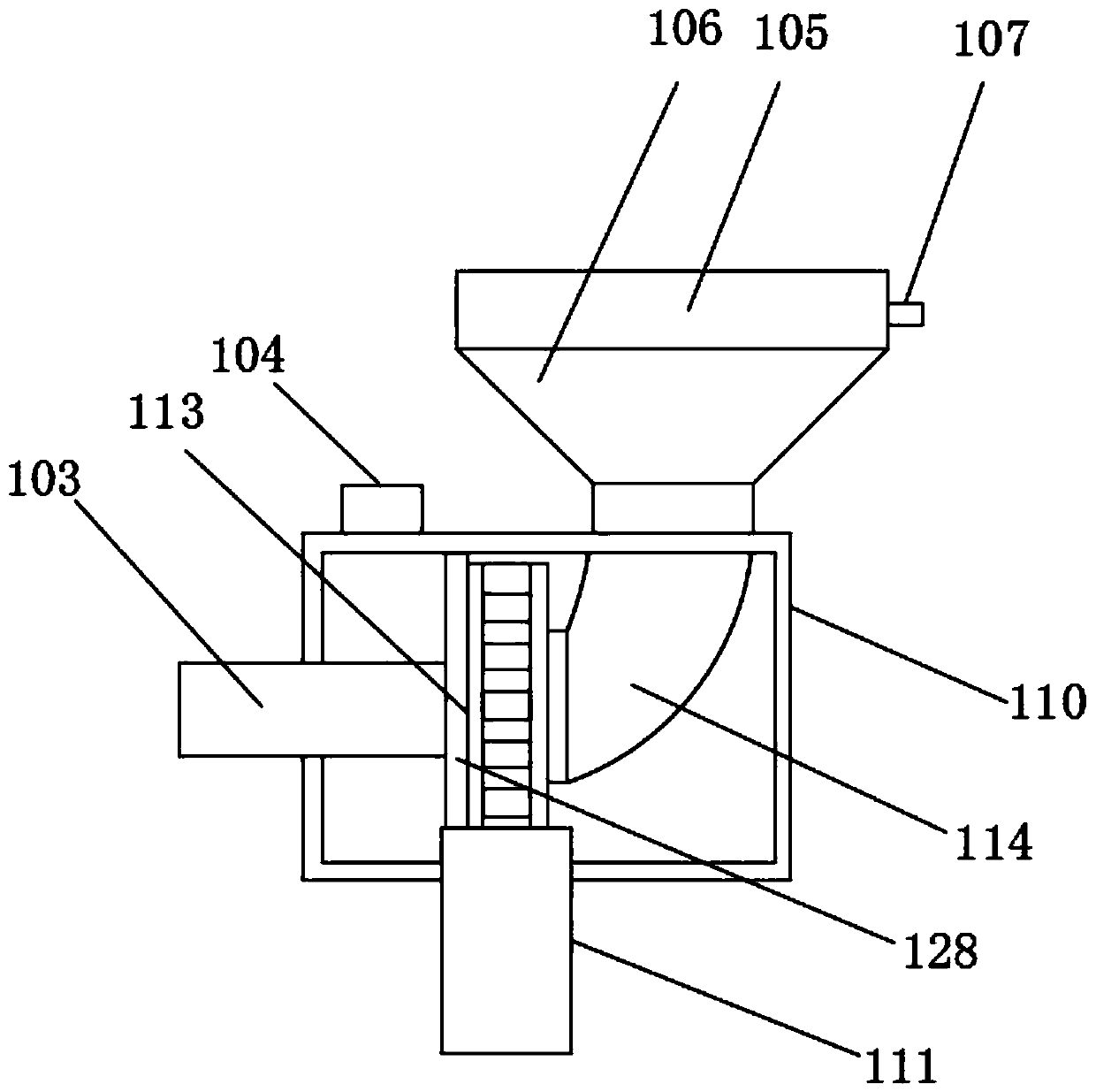

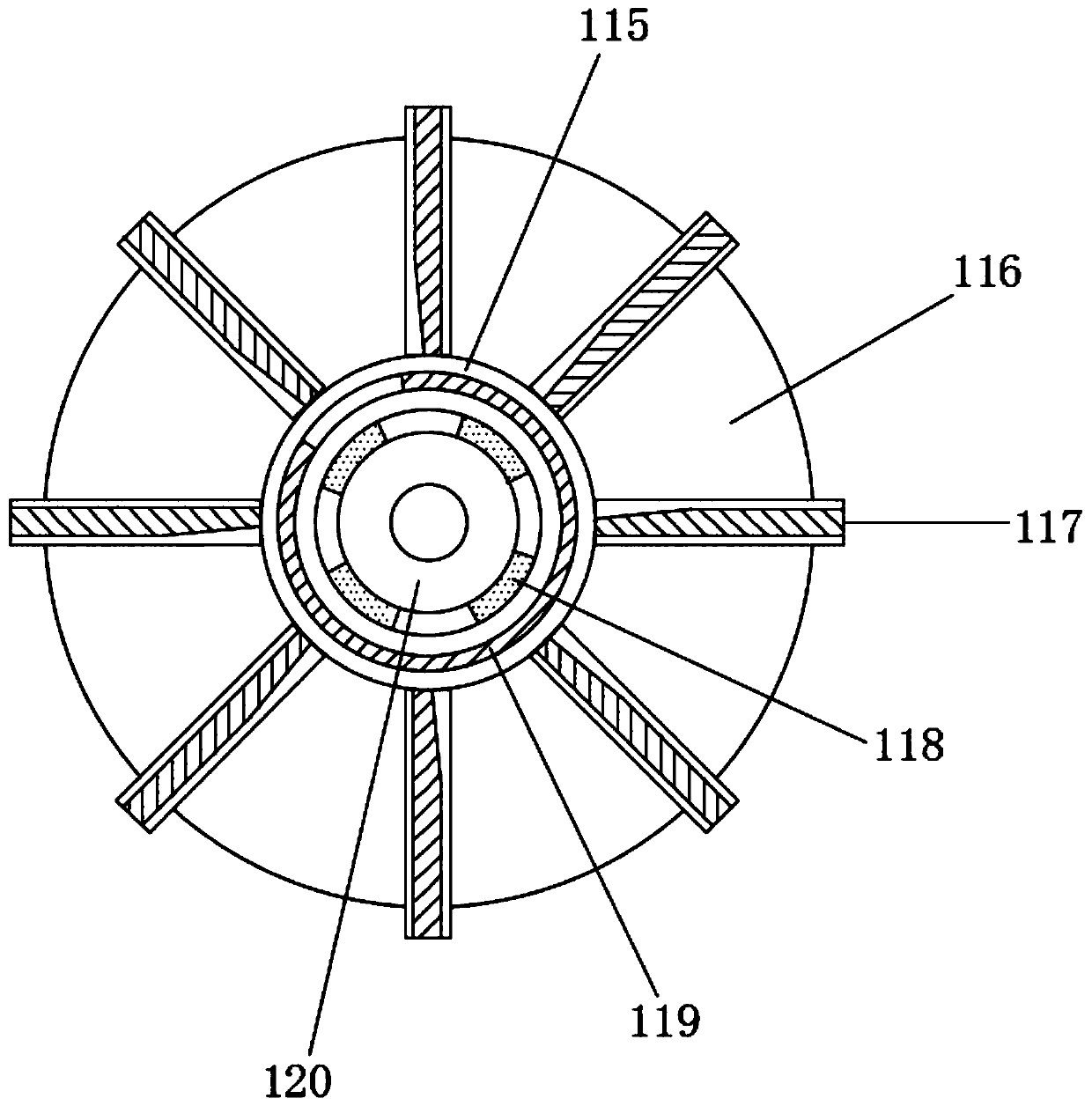

Magnetic suspension type chain sail wind machine

InactiveCN101592125AReduce resistanceImprove efficiencyMachines/enginesWind energy generationFriction reductionWinding machine

The invention relates to a magnetic suspension type chain sail wind machine, which comprises at least two separated tower frames, chain sail frames, closed chain cables, and a plurality of chain sails, wherein each chain sail frame is arranged on each tower frame; the closed chain cables are connected with the adjacent chain sail frames; the chain sails are arranged on the closed chain cables and provided with windward angles; each tower frame is also provided with a supporting component and a horizontal suspending device which is supported by the supporting component and horizontally arranged; the horizontal suspending device ensures that the closed chain cables keep horizontal. The closed chain cables can be suspended or supported by adding the horizontal suspending device to eliminate sagging and the like brought by the gravity of the chain sails and ensure that the closed chain cables are kept on the same horizontal plane so as to reduce the resistance in the process of operating the closed chain cables. The horizontal suspending device forms an air gap to reduce friction and improve the efficiency of the magnetic suspension type chain sail wind machine.

Owner:李世展 +2

Wear-resistant antiskid polyurethane solid tire and preparation method thereof

InactiveCN111169226AExtended service lifeImprove wear resistanceNon-inflatable tyresSpecial tyresAdhesive cementPolymer science

The invention discloses a wear-resistant antiskid polyurethane solid tire and a preparation method thereof. The polyurethane solid tire is prepared from a metal rim and a polyurethane layer, by addingisophorone diisocyanate into polyurethane, the structure of a reaction monomer is changed, and the content of a soft segment in a polyurethane molecular chain is increased, so that a solid tire is not easy to harden at low temperature, good flexibility is kept, the antiskid effect is improved, and the wear resistance is improved; according to the preparation method, a shot blasting device is usedfor carrying out surface treatment on the metal rim, high-speed shot blasting sand is blasted by the shot blasting device to impact the surface of the metal rim, the surface roughness of the metal rim is increased, polyurethane is poured after shot blasting is finished and an adhesive is coated, and the compactness between a polyurethane layer and the metal rim is improved; the shot blasting device separates shot blasting sand according to different particle sizes, damage to the device caused by large-size particles is avoided, and the situation that the quality of the solid tire is reduced due to large particle size difference is avoided.

Owner:CHUZHOU YULIN POLYURETHANE

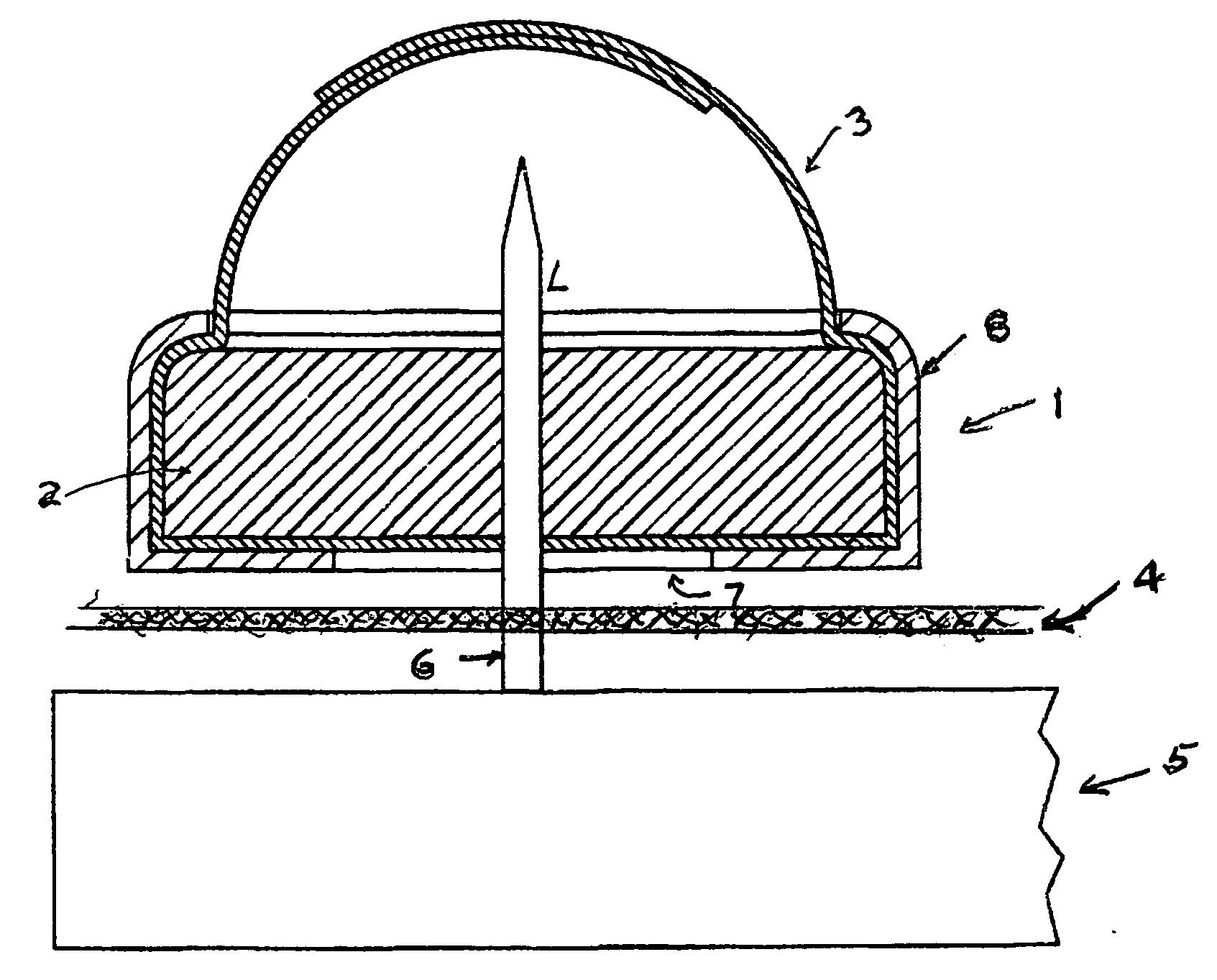

Buried pipe lifting device and method

ActiveUS10408375B2Obviating utilityEliminate saggingPipe laying and repairLifting devicesEngineeringIndustrial engineering

A method for in situ relocation of an underground utility including the steps of inserting, extending, raising and continuing to raise. The inserting step is carried out by the inserting of at least one lifting member down into the ground alongside the underground utility. The extending step extends a lifting bracket from the at least one lifting member. The raising step raises the lifting member causing the lifting bracket to engage a portion of the underground utility. The continuing step continues to raise the lifting member until the underground utility reaches a predetermined position.

Owner:THE TROUT GROUP INC

Fastener

Decorations, badges, insignia, etc., worn on clothing, are held by pins or nail-like projections of various lengths which penetrate the fabric. The decoration is usually held in place by sliding some sort of holding device onto said pin or nail-like projection. Because of the design of the holding device, if the pin is extraordinarily long, or the fabric it is placed upon is thin, the decoration will not lay flush to the fabric. In addition, most fasteners, after a short period of time, lose their holding ability. Subsequently, both the fastener and the decoration are lost. This invention eliminates both problems by holding the decoration flush to the fabric, and not readily wearing out.

Owner:THORN ALVIN E

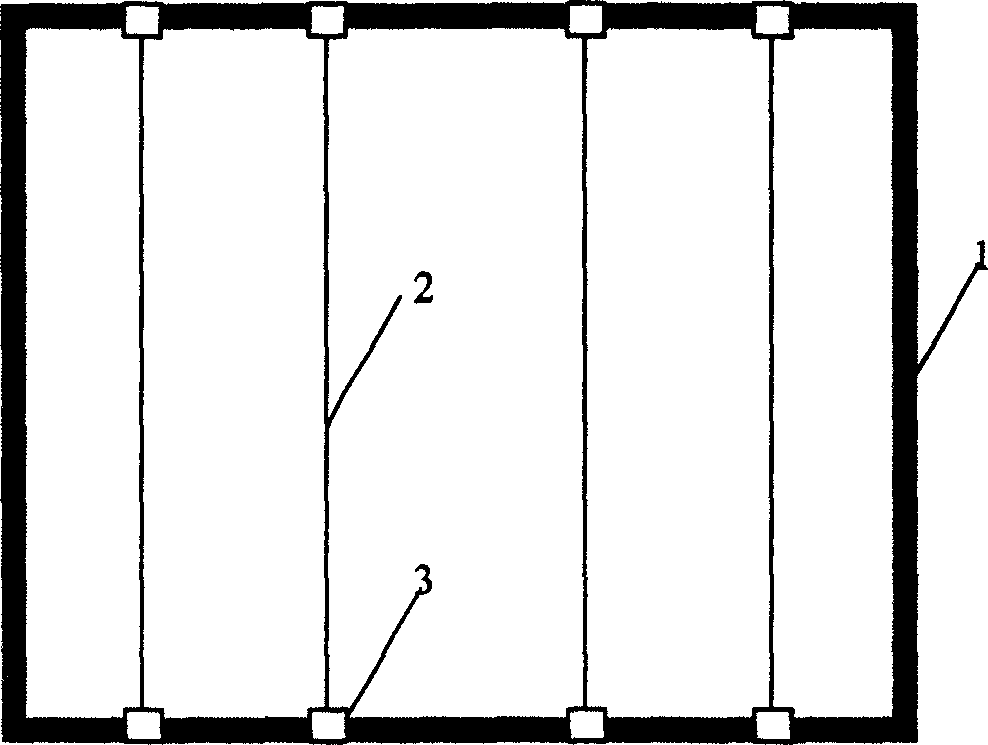

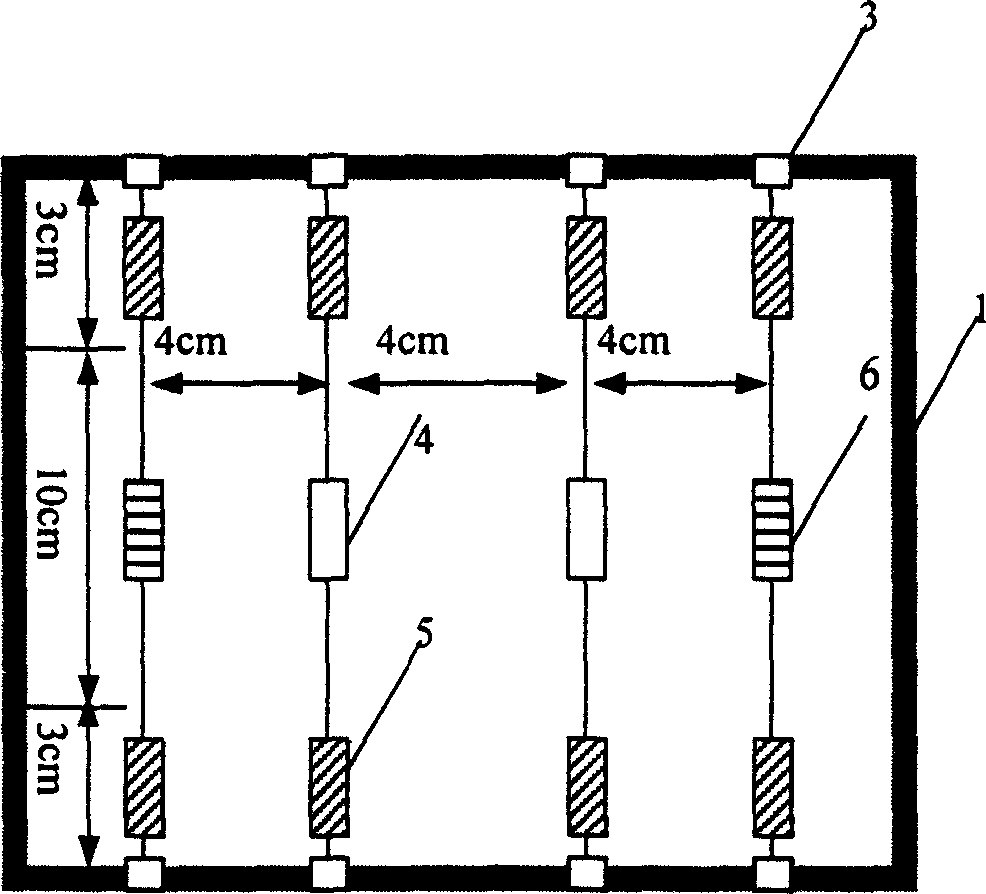

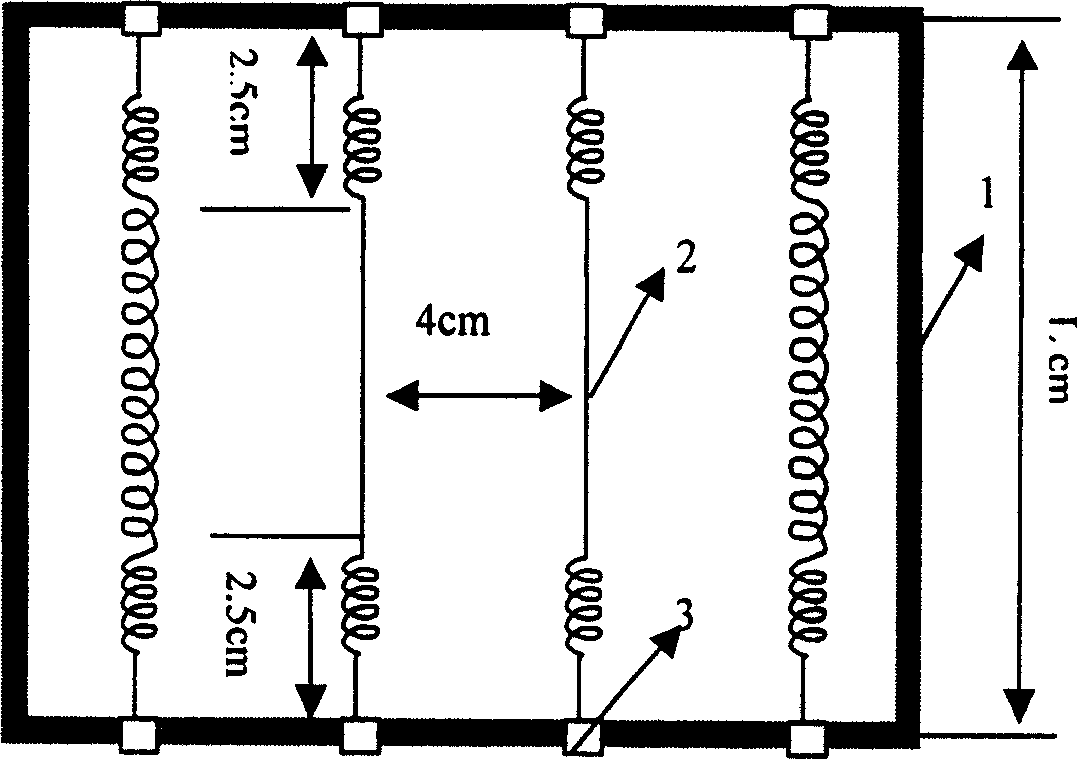

Non-linear hot wire structure used for preparing large area uniform thin film

InactiveCN1603463AUniform areaAvoid oversizingChemical vapor deposition coatingMaterials preparationField uniformity

The invention involves a kind to use in to prepare the big area even thin film the hot filament structure, belongs to the material preparation area of technology. The structure including hot filament frame, multi- roots hot filament and hot filament insulated rail joint; The hot filament insulated rail joint fixes on a hot filament two relative frame, this hot filament two reasons and the hot filament insulated rail joint are connected; Its characteristic lies in, various hot filament uses the non-uniform spring shape the hot filament, turn / cm is bigger than the hot filament intermediate region in the hot filament beginnings and ends region turn / cm. The invention involves the hot filament structure, through enhanced the vertex hot filament temperature to solve well has limited the big area application the kernel Si boundary cold end effect, enhanced the hot filament longitudinal of hot field uniformity, avoided the dependence increase hot filament length enhancing the hot filament which the hot filament direction uniformity caused to be curving and the cavity body oversized question, obviously increased ratio of F the even hot field area and hot filament structure area, effectively realized the big area even thin film deposition, had simply, the practical convenience characteristic.

Owner:GD SOLAR +2

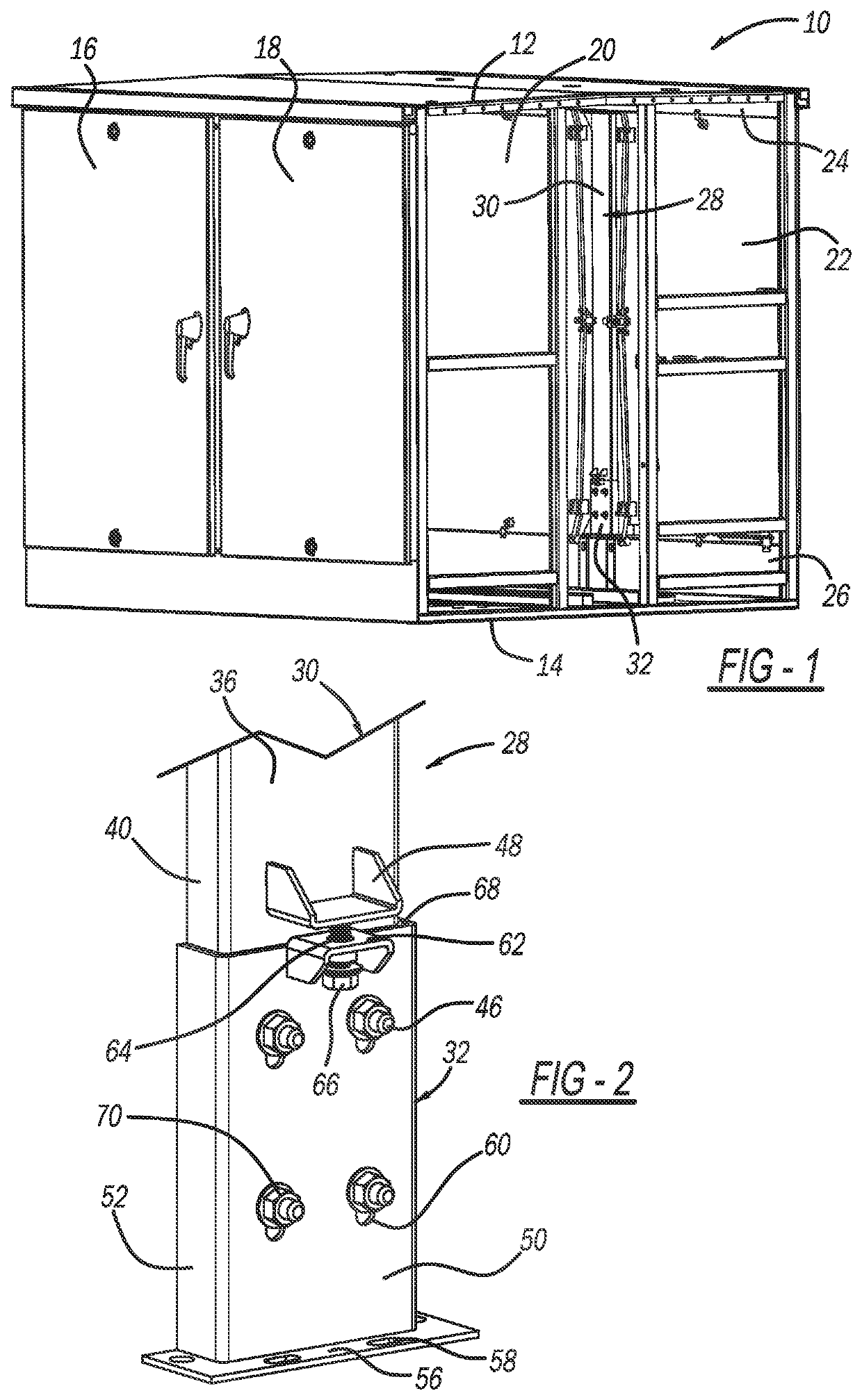

Adjustible center post for multi-door enclosures

ActiveUS20220104619A1Eliminate saggingIncrease the lengthSubstation/switching arrangement casingsVariable dimension cabinetsJackscrewScrew thread

A center post assembly for eliminating sagging of a roof panel in a cabinet, where doors of the cabinet latch to the post assembly. The post assembly includes a base portion and a post portion, where one of the base portion or the post portion includes a plurality of slots and the other one of the base portion or the slot portion includes a plurality of threaded studs. The base portion further includes a first bracket and a jackscrew threaded into a threaded opening in the first bracket and the post portion further includes a second bracket, where the jackscrew engages the second bracket so that rotation of the jackscrew causes the second bracket to move relative to the first bracket so that the studs slide in the slots and increase the length of the post assembly to remove the sag.

Owner:S&C ELECTRIC

Health product improving acuity of vision and making method thereof

InactiveCN100521975CPromote absorptionEliminate saggingAlcoholic beverage preparationFood preparationBees honeyNutrient solution

The invention relates to a health food with function of improving acuity of vision, as well as the process for preparation. The raw materials of the product include ginkgo leaves, fresh ginger, dried orange peel, meat, star aniseed, pricklyash peel, Chinese green onion stalk, bee honey, soy sauce, yellow rice wine, edible vinegar, table salt and medical ethanol. The health product is the nutrient solution extracted from each raw materials through boiling.

Owner:于炳文

Mould for simultaneously cooling inner and outer pipe walls of plastic pipe during molding

The invention relates to a mould for simultaneously cooling the inner and the outer pipe walls of a plastic pipe during molding, belonging to the technical field of accessory devices of a plastic pipe production line. The mould comprises a mould body, a core mould, a core mould base, a mouth mould, a neck mould and the like. The mould body is internally provided with the core mould and the core mould seat, and the core mould is provided with a strainer sleeve or a spiral body; and the left end of the mould body is provided with the neck mould, the right end of the mould body is provided with the core mould and the mouth mould, a blowing guide pipe is arranged in the centers of the core mould and the core mould base, the left side of the blowing guide pipe is provided with a fan, a fan frequency converter and an industrial control computer. When the mould for simultaneously cooling the inner and the outer pipe walls of the plastic pipe during molding is molded, melt flows through a shunt runner and are superposed layer by layer, and thus, not only are the melt and a lateral incipientfusion phenomenon improved through an elliptic structure of a distribution barrier, but also the inner pipe wall and the outer pipe wall are synchronously cooled by using the fan to blow natural wind onto the inner wall of a plastic pipe blank via the blowing guide pipe. Therefore, the problem that the outer wall of the plastic pipe always has internal stress and incipientfusion when water cooling is adopted in the prior art is solved, and the stress cracking resistance and the shock resistance of the plastic pipe are improved.

Owner:宜昌宜硕塑业有限公司

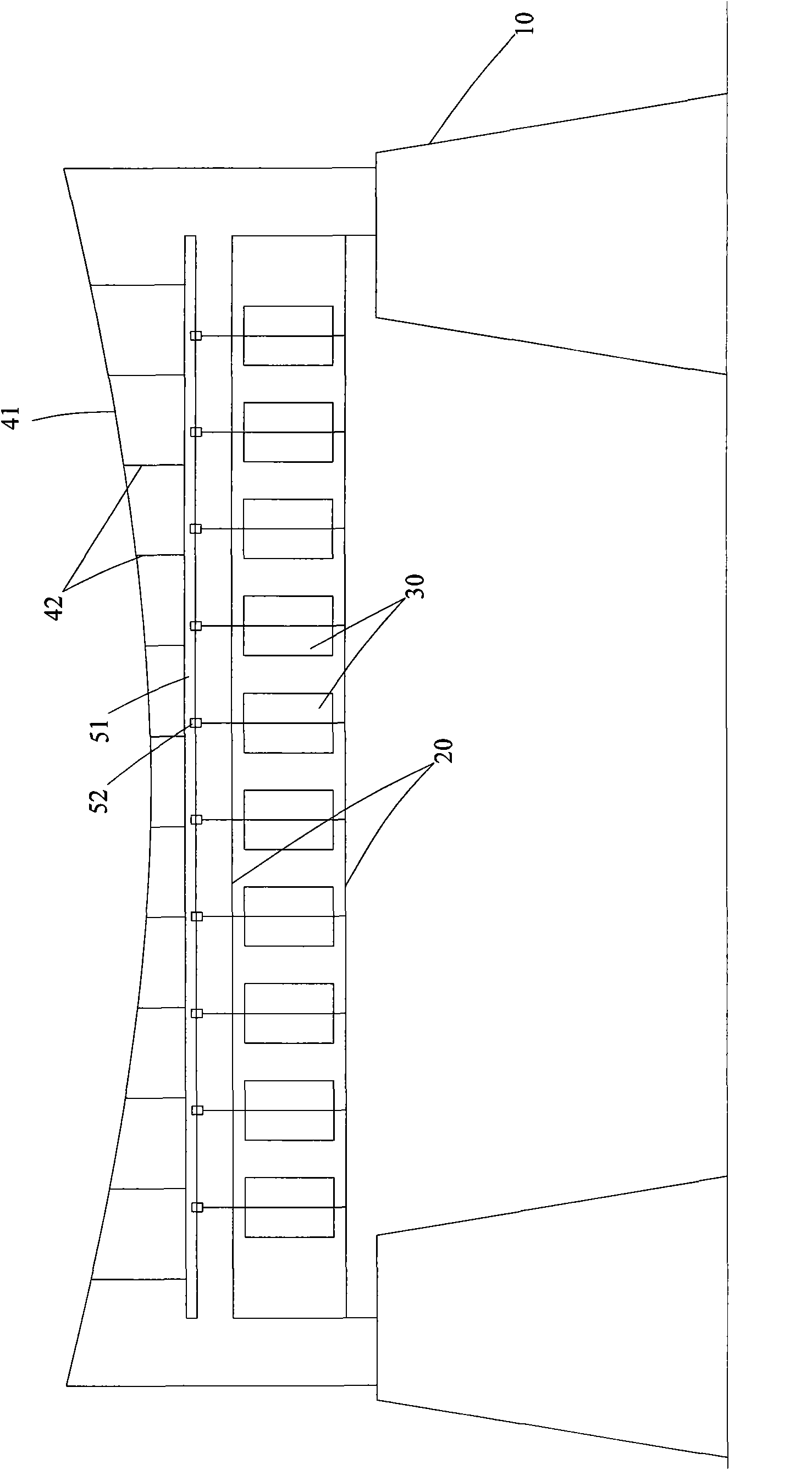

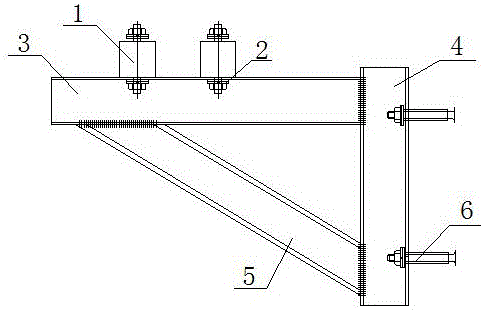

Elastic fixing support structure for vertically installing non-segregated phase enclosed busbar

InactiveCN106129933AEliminates saggingEliminate negative effectsTotally enclosed bus-bar installationsAnti-seismic devicesBusbarStructural engineering

The invention relates to an elastic fixing support structure for vertically installing a non-segregated phase enclosed busbar. The structure comprises a horizontal support member, a longitudinal support member and an angled support member, wherein the longitudinal support member is vertically fixed on a building; the horizontal support member and the longitudinal support member are vertically fixed; the two ends of the angled support member are respectively fixed with the longitudinal support member and the horizontal support member; the horizontal support member, the longitudinal support member and the angled support member are arranged in a triangle; a busbar chamber is fixed on the surface of the horizontal support member; two elastic rubber bases are fixed on the surface of the horizontal support member and are arranged between the busbar chamber and the horizontal support member. The structure has the effect of effectively eliminating the phenomenon of overall drooping of the busbar caused due to downward gravity while bearing the overall weight of the non-segregated phase busbar and can also delay vibration during operation, thus effectively eliminating the negative effects of vibration during operation on the enclosed busbar.

Owner:江苏瑞欧宝电气股份有限公司

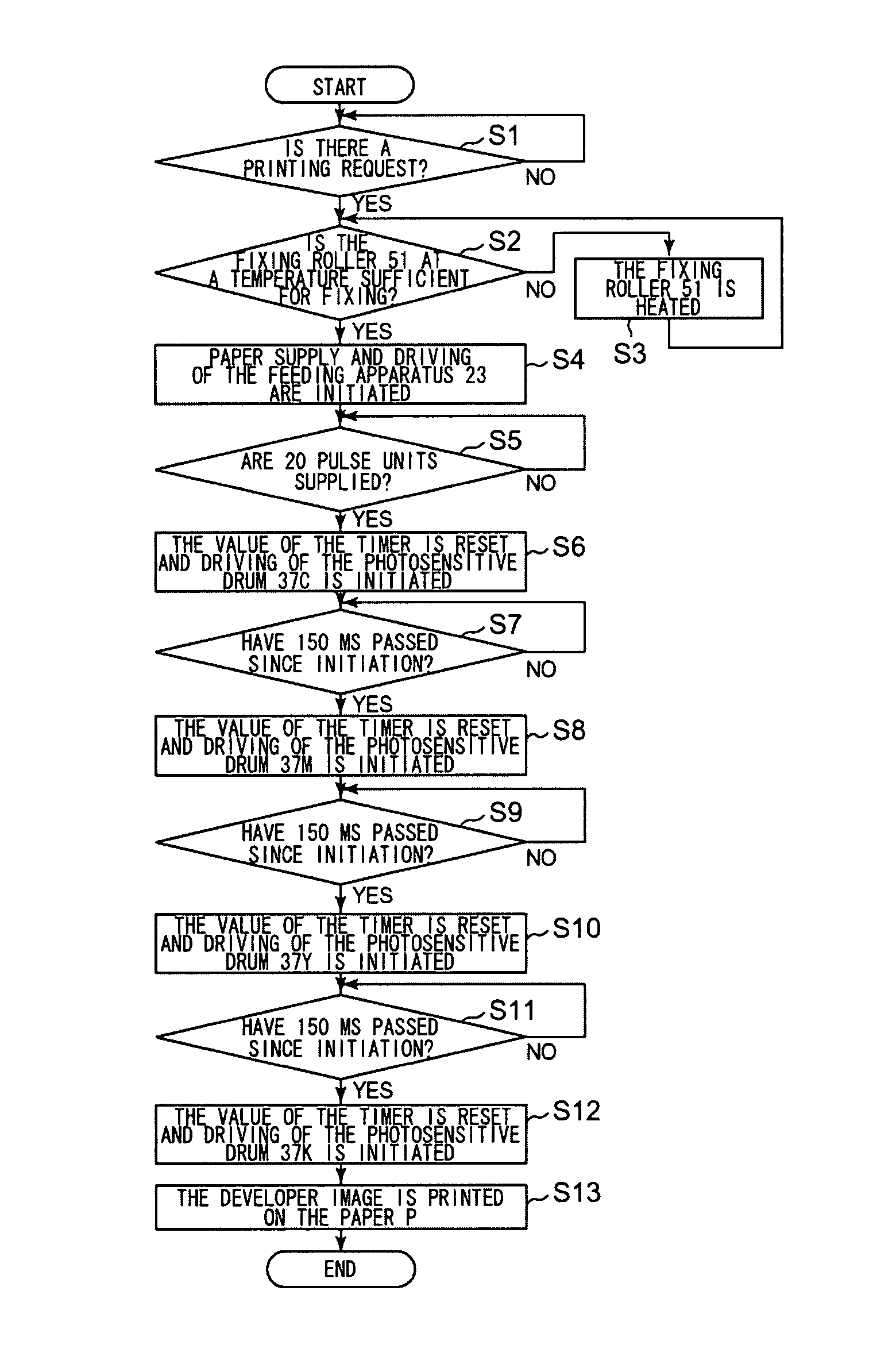

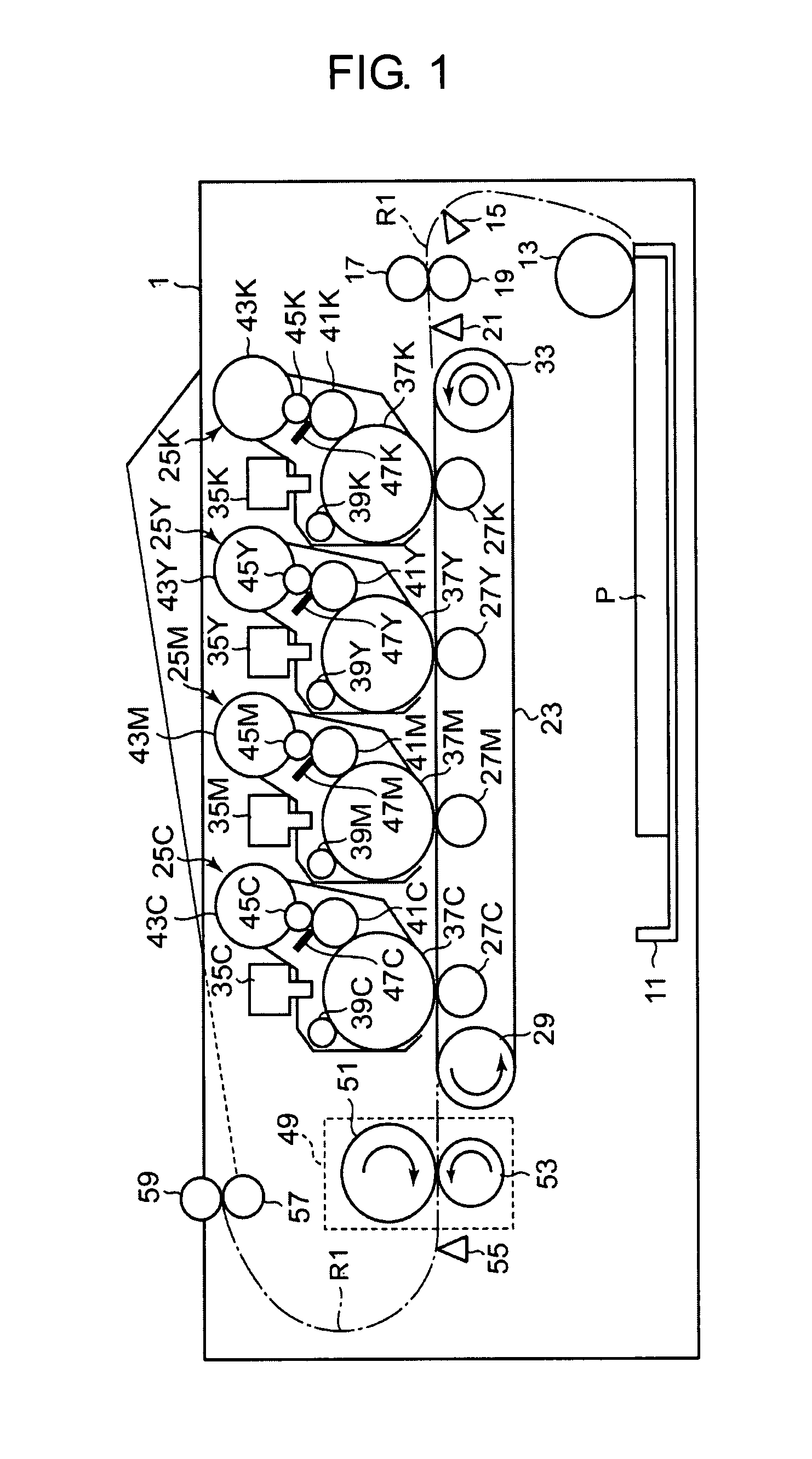

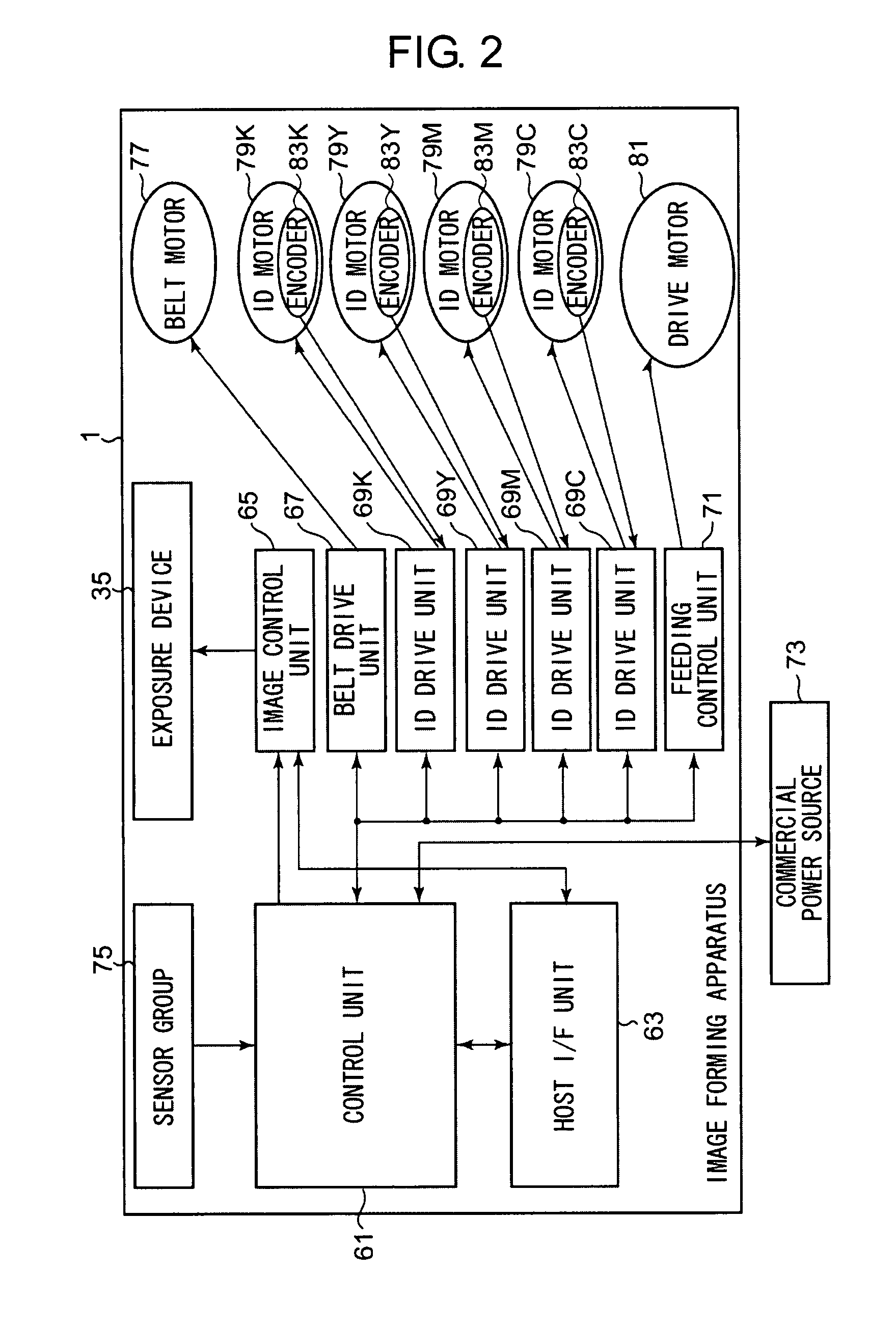

Image forming apparatus

ActiveUS8228523B2Eliminate saggingQuality improvementDigitally marking record carriersDigital computer detailsImage formationEngineering

An image forming apparatus in which multiple image forming units for forming a developer image arranged along a prescribed medium feeding path are disposed in a manner to contact and face a belt component, the image forming apparatus includes an image formation driving unit for driving said multiple image forming units; a belt component driving unit for driving said belt component; and a drive control unit for supplying a drive command to said belt component driving unit and said image formation driving unit, said drive control unit sequentially initiating the driving of said image forming units from said image forming unit located downstream in the medium feeding path, after initiating the driving of said belt component drive unit.

Owner:OKI ELECTRIC IND CO LTD

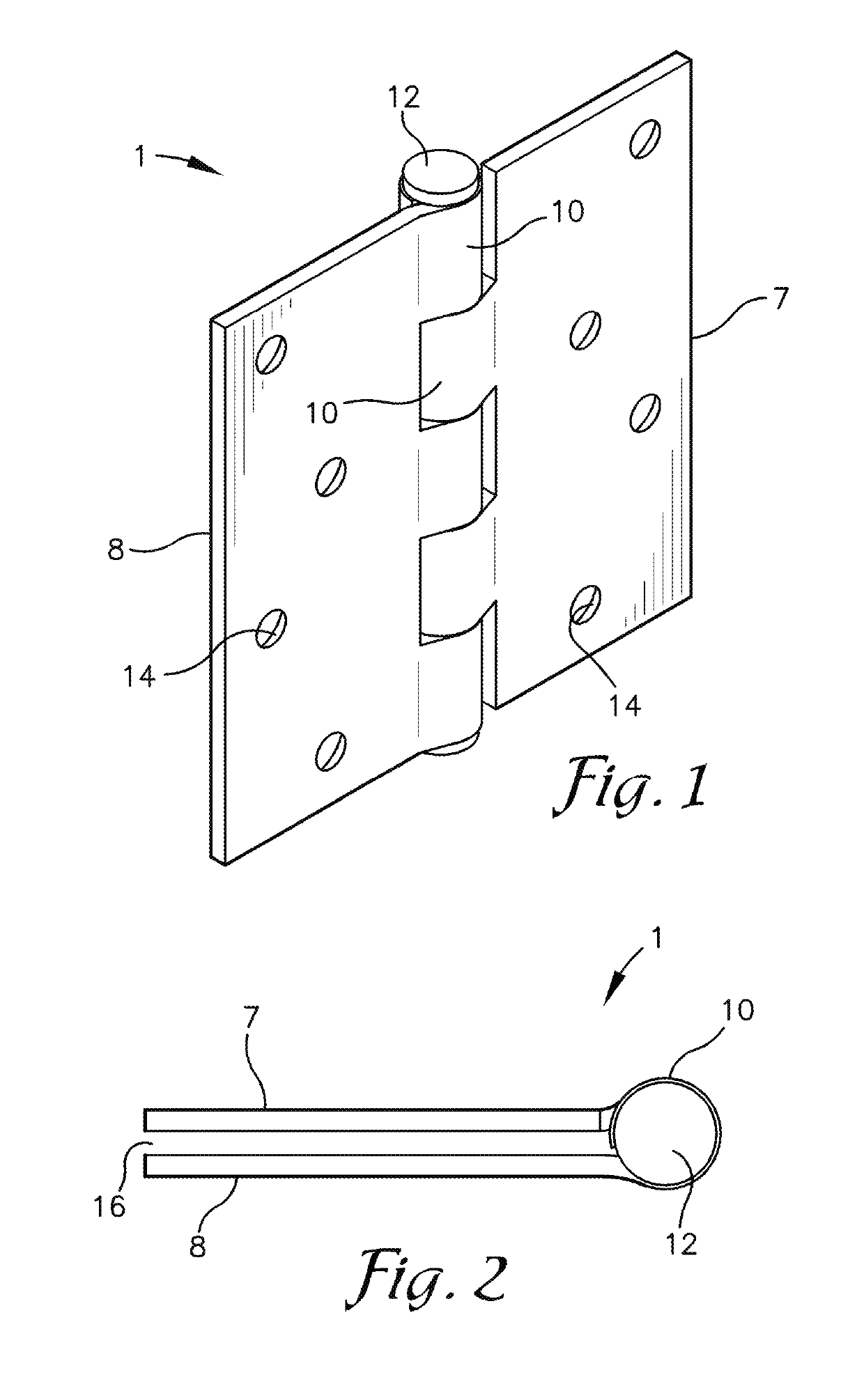

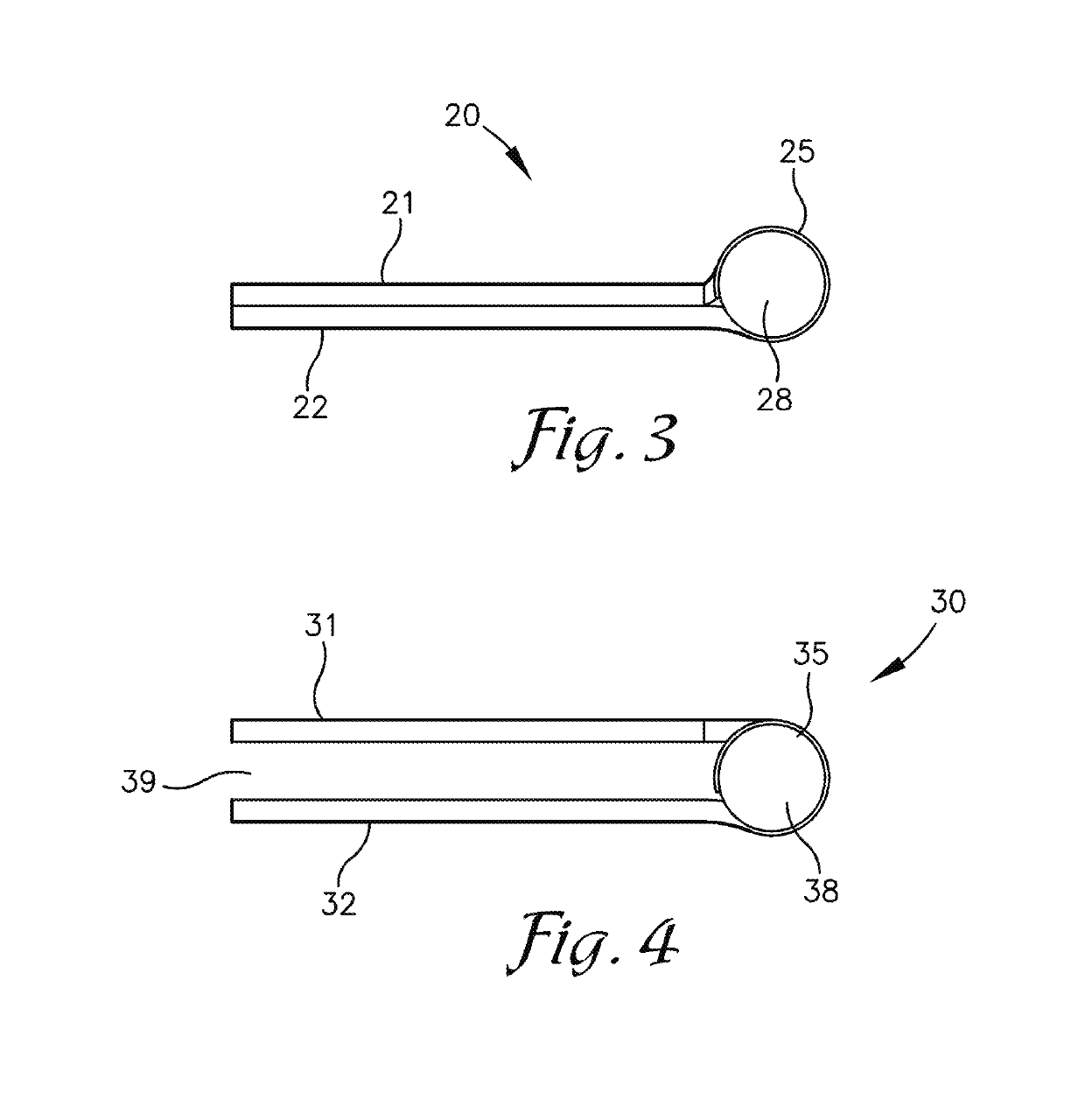

Door hinges and method for rehanging a door to realign the door in relation to a door jamb

ActiveUS10246916B1Eliminate any saggingChange in widthDoors/windowsWing accessoriesEngineeringMechanical engineering

A kit for use in rehanging a sagging door connected to a door jamb included a plurality of replacement hinges having different sized gaps between the leaves of the hinges when pivoted to extend in parallel, juxtaposed alignment, including gaps that are larger and smaller than the gaps of the conventional hinges originally used to hang the door. The smaller gap replacement hinge may have no gap between the hinge leaves when pivoted to parallel and juxtaposed alignment. The kit may include multiple reduced gap hinges with varying sized gaps and multiple enlarged gap hinges with varying sized gaps. To rehang the sagging door, the original, top hinge is replaced with a reduced gap hinge and the original, bottom hinge may be replaced with an enlarged gap hinge.

Owner:KESSLER TYLER L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com