Elastic fixing support structure for vertically installing non-segregated phase enclosed busbar

A vertical installation and elastic fixing technology, which is applied in the direction of fully enclosed busbar devices and anti-seismic equipment, can solve the problem that the impact of operating vibration on the enclosed busbar cannot be eliminated, and achieve the effect of eliminating the overall sagging of the busbar and eliminating the negative impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

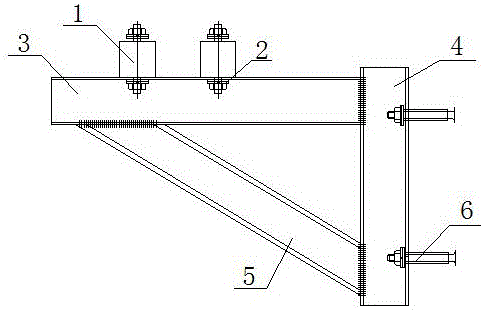

[0015] The present invention will now be described in further detail with reference to the drawings. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0016] Such as figure 1 As shown, a closed common box busbar of the present invention is vertically installed with an elastic fixing support structure, which is used to provide support for the busbar box body when the closed busbar is installed vertically, and fix it on the building body. The fixed support structure includes a transverse support The vertical support member, the longitudinal support member and the diagonal support member, the longitudinal support member is vertically fixed on the building body, the horizontal support member is fixed perpendicularly to the longitudinal support member, and the two ends of the diagonal support member are respectively connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com