Fastener

a technology of fasteners and sash handles, applied in the field of fasteners, can solve the problems of arms or wings losing tension, sagging or loose appearance of ribbons, medals or decorations, and inconvenient handling of devices, so as to eliminate sagging or loose appearan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

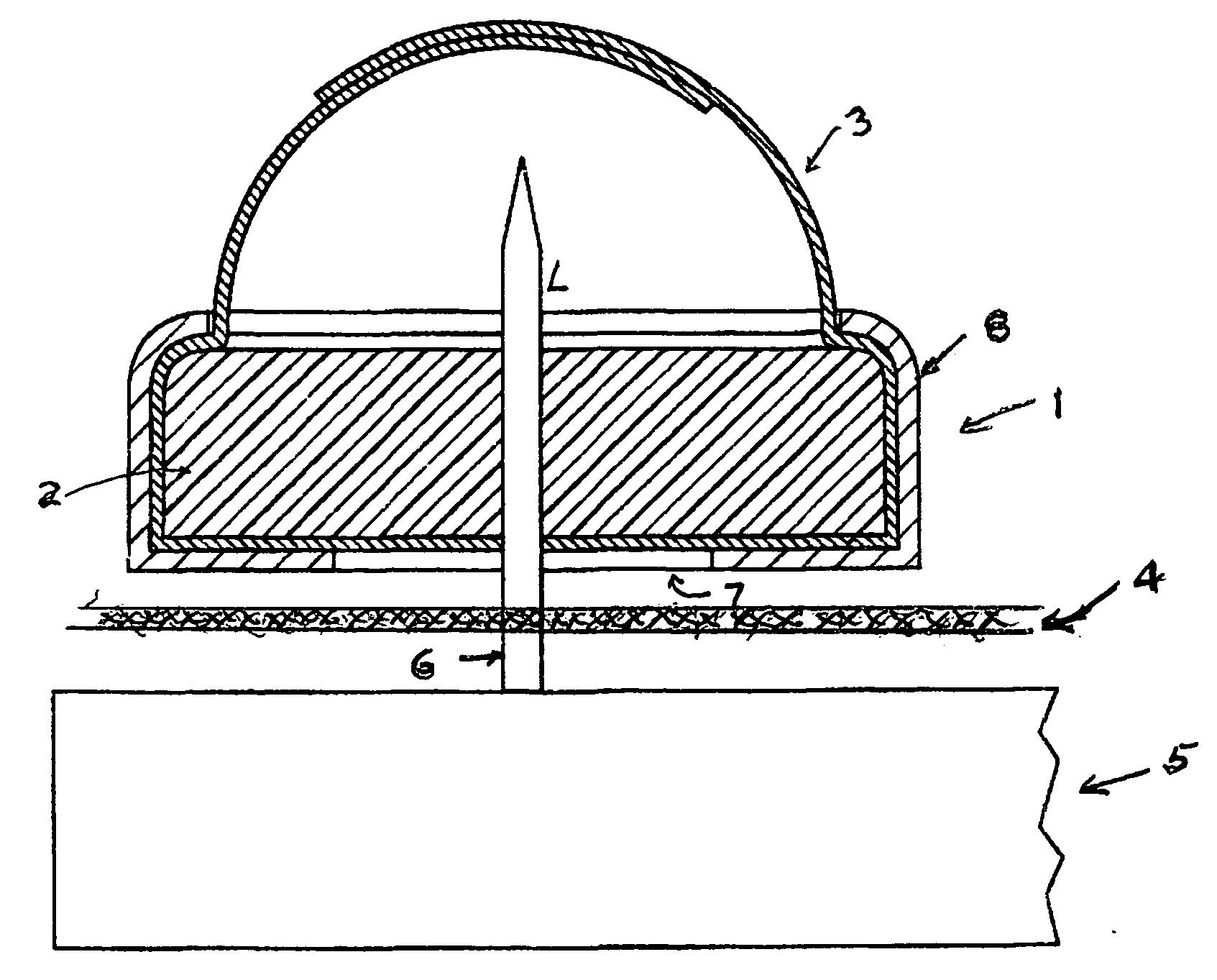

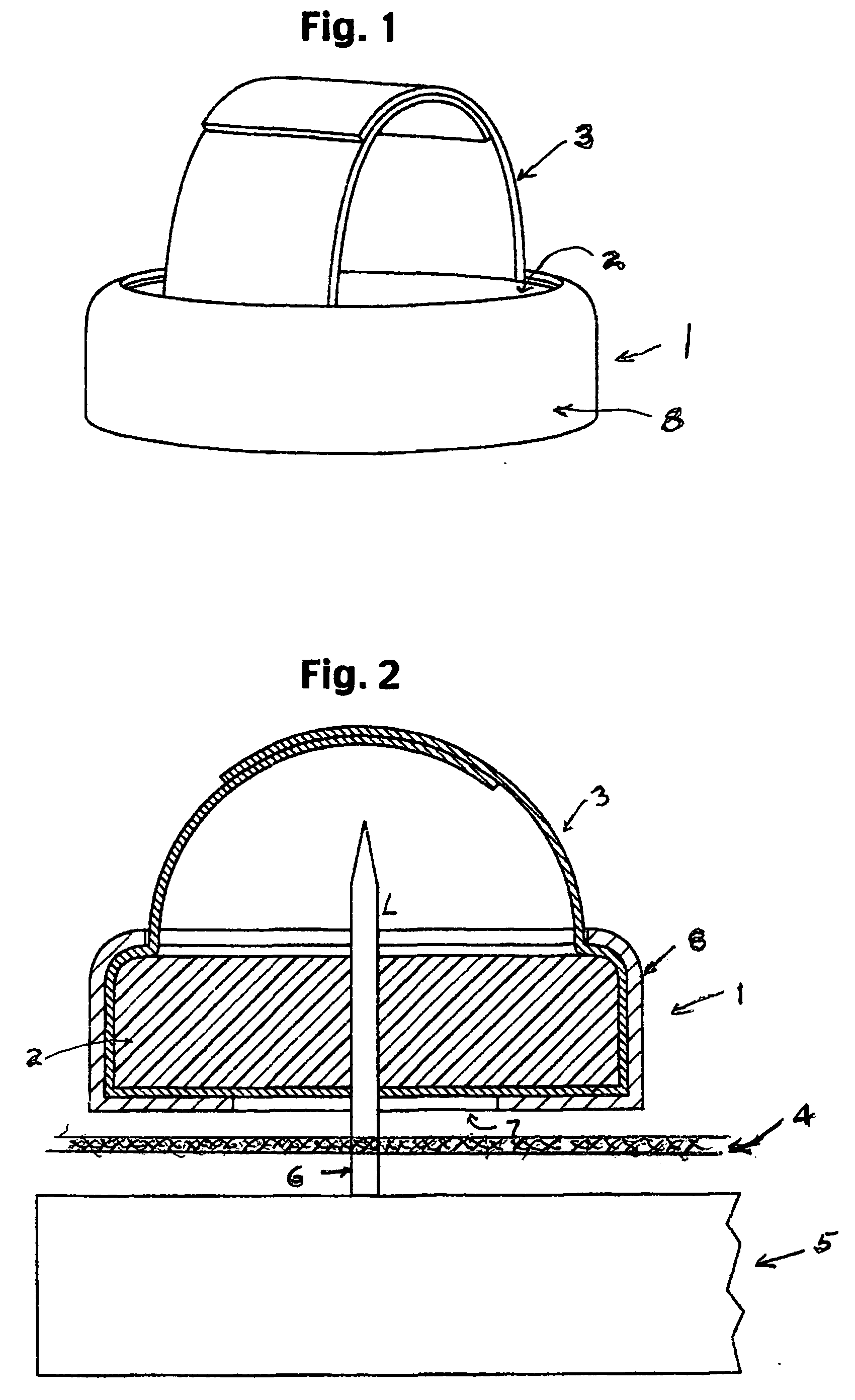

[0017] Referring to the drawings, a ribbon bar support, medal, or decoration 5 with a rearward projecting spike or pin 6 of a given length L fixed to the back surface of the decoration 5 for penetrating through any fabric layer 4. The decoration 5 is mounted on the outside surface of the uniform, or fabric layer, with the spike 6 pushed through the fabric layer 4 and the small opening 7 at bottom of fastener 1, and the polyurethane disc 2.

[0018] The spike 6 typically has a length L of about 0.25 inch. The decoration, medal, and / or insignia, may have one or more spikes.

[0019] In accordance with the invention, the improved ribbon bar, decoration, medal, etc., support assembly 1, includes a rated shore A 60 polyurethane disc 2, approximately 3 / 32 inch thick, ¼ inch diameter, enclosed in a brass ferrule-like shell receptacle. To prevent the spike or pin from penetrating the vinyl coated polyester back, a double layer of polyester protects the wearer, because there is little or no pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com