Coating film transfer tool

a technology of coating film and transfer tool, which is applied in the direction of paper hanging, combustion air/fuel air treatment, and erasing devices, etc., can solve the problems of burdensome work for users, coating film cannot be transferred thereto, and the coating film transfer tool does not achieve the construction to bring a great deal, so as to achieve the effect of reducing sag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A description will be made below in detail of a coating film transfer tool according to the present invention with reference to the drawings while mentioning a preferred embodiment. (Summary of Entire Construction)

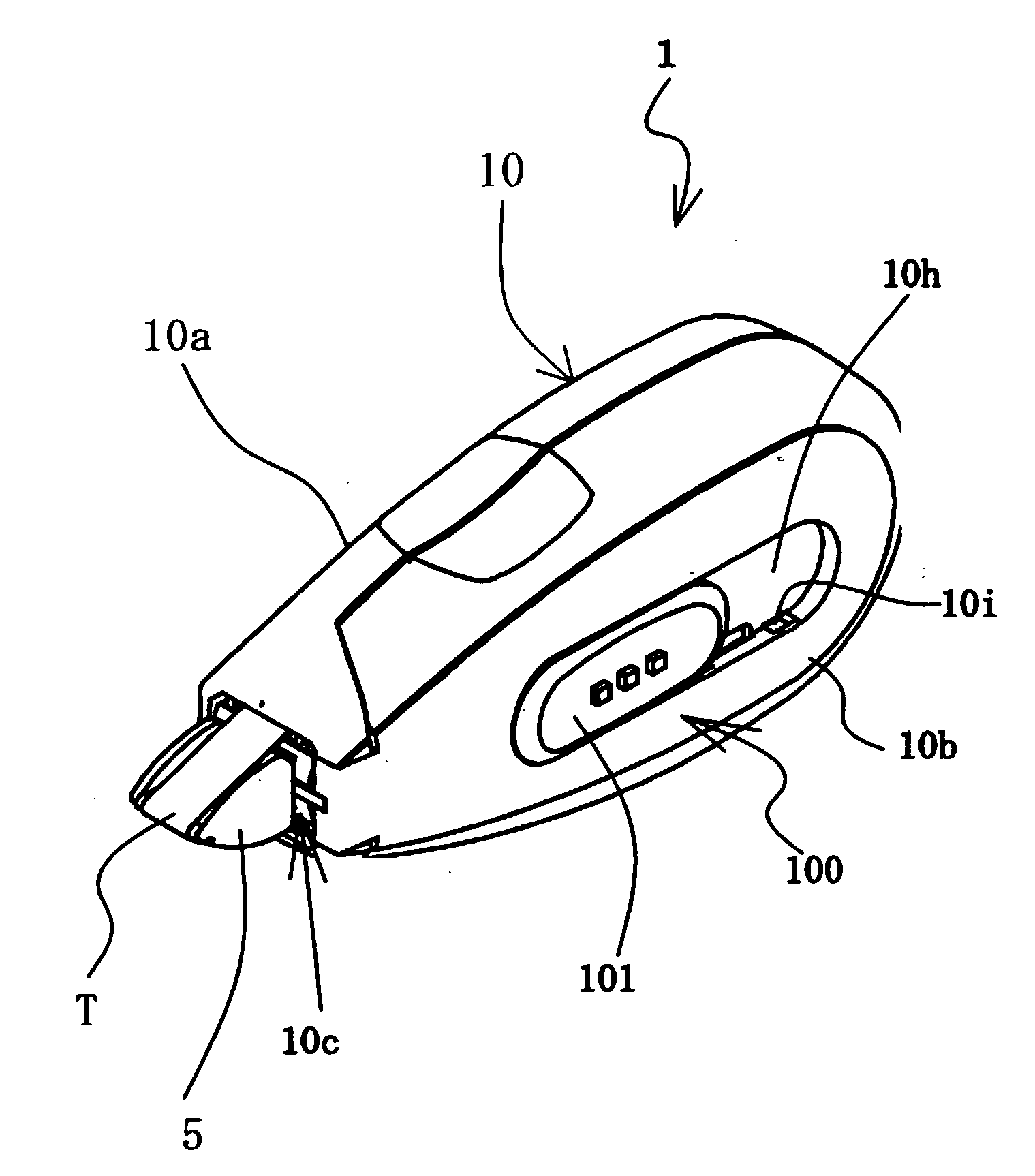

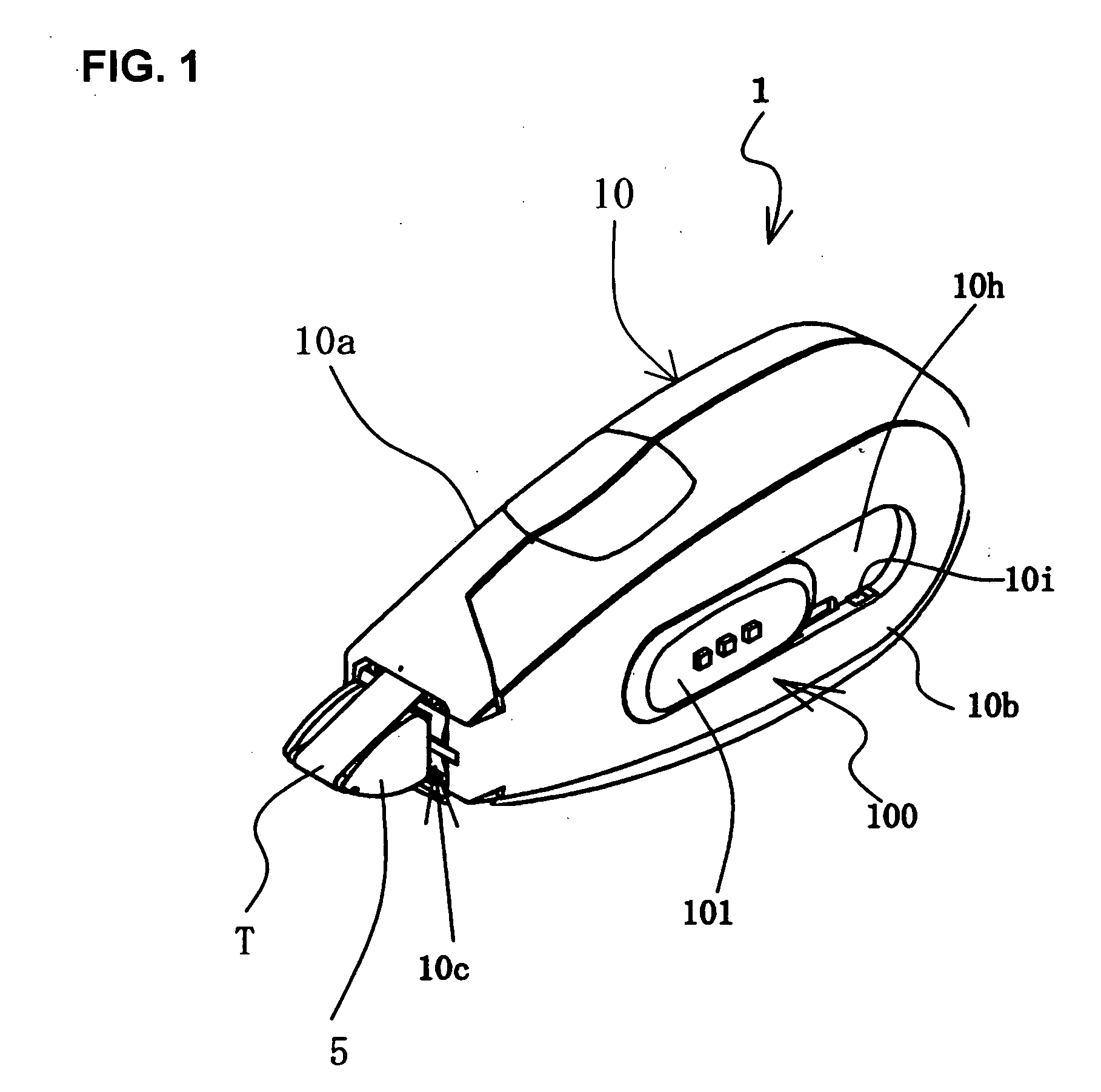

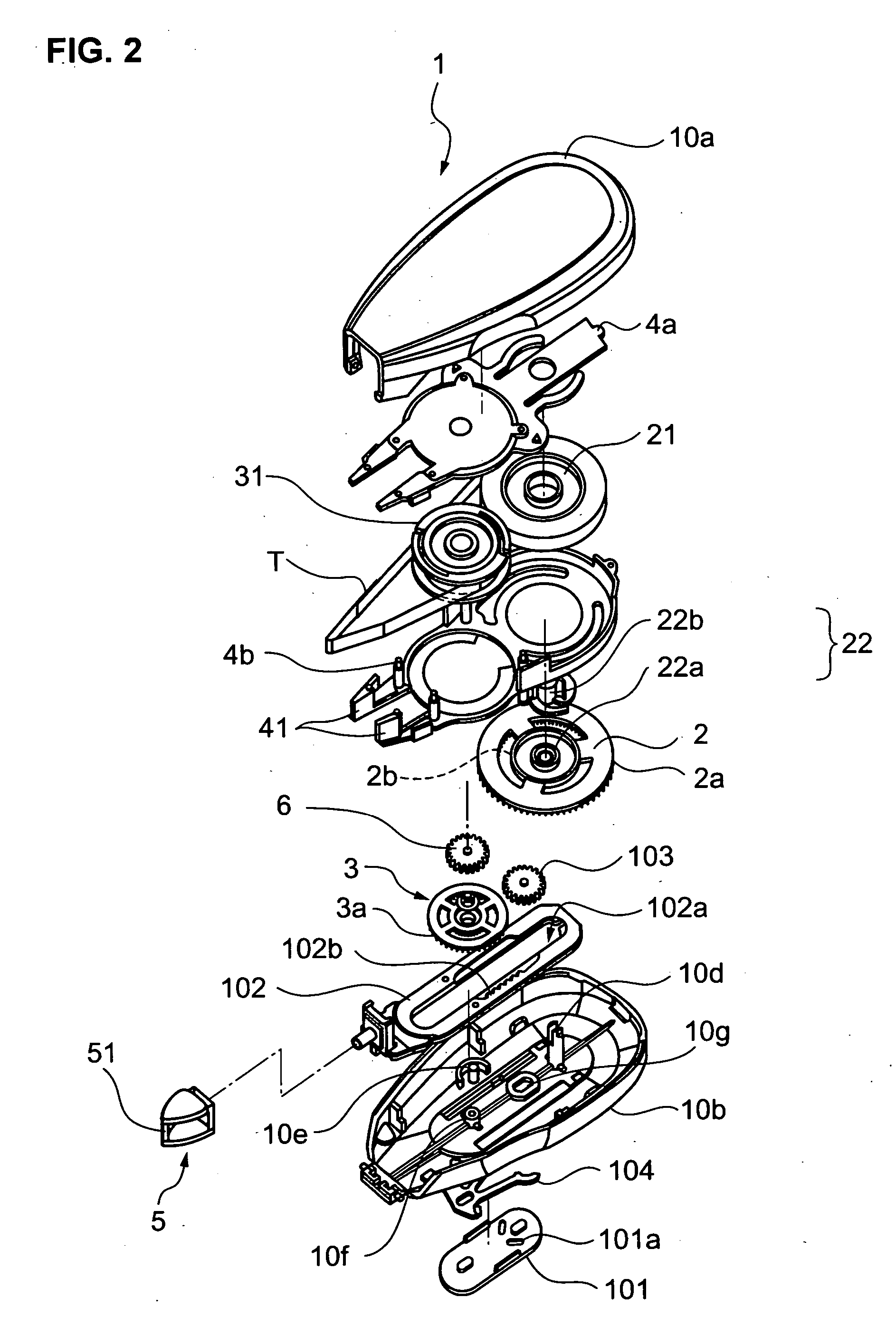

[0033]FIG. 1 is a perspective view showing an exterior of a construction of the coating film transfer tool according to an embodiment of the present invention. As shown in FIG. 1, a case upper portion 10a and a case lower portion 10b which function as a case 10 of a coating film transfer tool 1 of this embodiment are formed so as to be capable of being assembled with each other. A tape unit 4 is built in an inside of the case 10. The tape unit 4 is structured by winding a transfer tape T in which a transfer layer formed of a paste or the like is provided on a surface of a feeding tape. The feeding tape functions as a medium for feeding the transfer layer.

[0034] The coating film transfer tool according to the present invention comprises a transfer head 5 which tens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

| tensions | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com