Gold-plated bonding aluminum wire and preparation method thereof

A technology for bonding aluminum and aluminum wires, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve the problem of low tensile strength and heat resistance of bonded aluminum wires Poor surface cleanliness, reduced bonding strength, etc., to eliminate lead sagging and sagging, increase easy-to-clean features, and improve bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

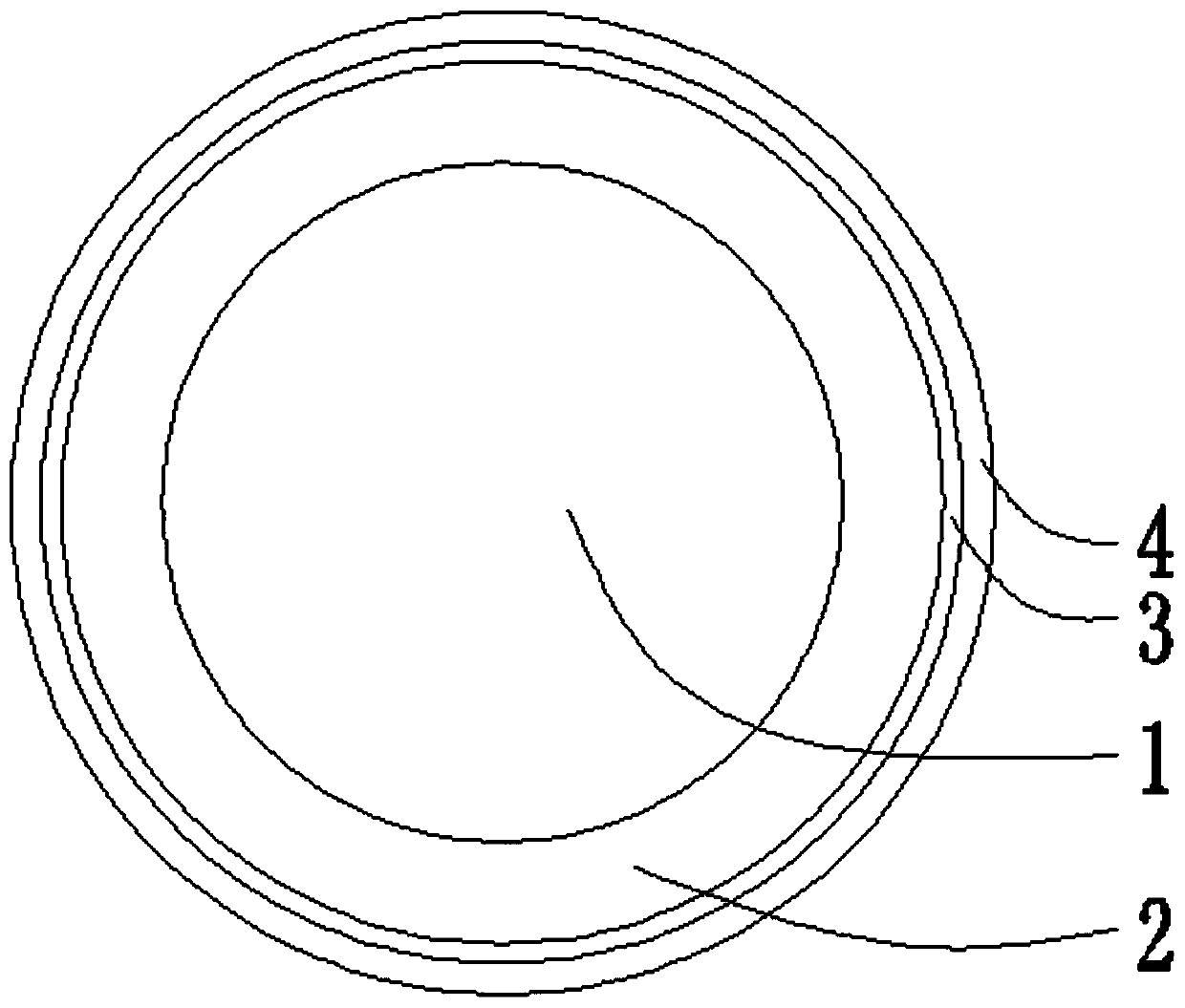

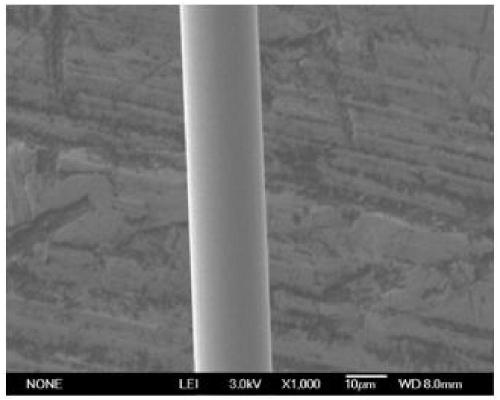

[0051] The present invention also provides a method for preparing gold-plated bonded aluminum wires, which realizes large-length drawing of gold-plated bonded aluminum wires by processing with a small area reduction rate and controlling the angle of the entrance zone, the length of the sizing zone and the angle of the exit zone of the mold. Eliminates the phenomenon that the gold-plated bonded aluminum wire is easy to break during the wire drawing process; at the same time, the gold-plated aluminum wire is processed with a mold with a small area reduction rate and optimized parameters to ensure that the surface of the gold-plated bonded aluminum wire has a good finish, effectively ensuring the bond bond strength during the bonding process.

[0052] The present invention provides a kind of preparation method of gold-plated bonding aluminum wire, and preparation method comprises the following steps:

[0053] S1. Weigh aluminum or aluminum-silicon alloy raw materials, place the r...

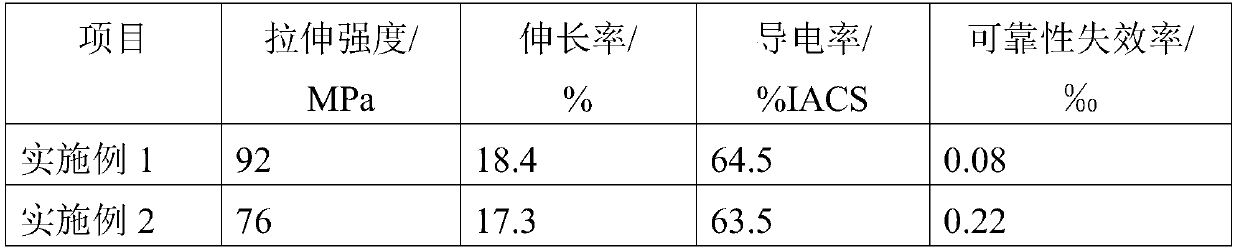

Embodiment 1

[0077] This embodiment provides a gold-plated aluminum bonding wire, which includes the following components in mass percentage, copper: 18%, nickel: 3%, gold: 5%, and the balance is aluminum: 74%.

[0078] The preparation method of gold-plated bonding aluminum wire in the present embodiment comprises the following steps:

[0079] S1. Take 74g of aluminum and place it in the crucible of the high-vacuum vertical-type intermediate frequency continuous casting machine. Vacuum the furnace of the high-vacuum vertical-type continuous casting machine. After the vacuum degree is higher than 2.0Pa, start to heat up, and the temperature rises to 380°C Finally, stop vacuuming and fill the high vacuum continuous casting machine with argon gas to a vacuum degree of 0.2MPa; then continue to heat up to 700°C, and fill the When the argon gas reaches 1.06 MPa, the traction mechanism is turned on for drawing casting, and the diameter of the obtained aluminum rod is 5 mm.

[0080] S2. Coat the ...

Embodiment 2

[0090] This embodiment provides a gold-plated aluminum bonding wire, which includes the following components in mass percentage, copper: 15%, nickel: 0.3%, gold: 1.2%, and the balance is aluminum: 83.5%.

[0091] The difference between the preparation method of the gold-plated aluminum bonding wire in this embodiment and the preparation method in Example 1 is that:

[0092] S1. Weigh 83.5g of aluminum to obtain an aluminum rod with a diameter of 6mm;

[0093] S2, the mass of coated copper foil is 15g;

[0094] S3, the area reduction rate in the drawing process is 12%, and drawn into a copper-clad aluminum wire with a diameter of 0.9mm;

[0095] S4, the mass of nickel plating is 0.3g, and the mass of gold plating is 1.2g;

[0096] S5, the area reduction rate in the micro-drawing process is 5%, and the micro-gold-plated aluminum wire with a diameter of 0.1 mm is obtained by drawing;

[0097] S6. The area reduction rate in the ultra-fine drawing process is 4%, and a gold-plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com