Small-sized automatic hydraulic railway line tamping car

An automatic technology for railway lines, applied in the direction of roads, tracks, ballast layers, etc., can solve the problems of reducing the compaction effect of large compaction vehicles, large gaps in compactness, and large gaps in ballast compactness, so as to save manpower and traffic interference small, stability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

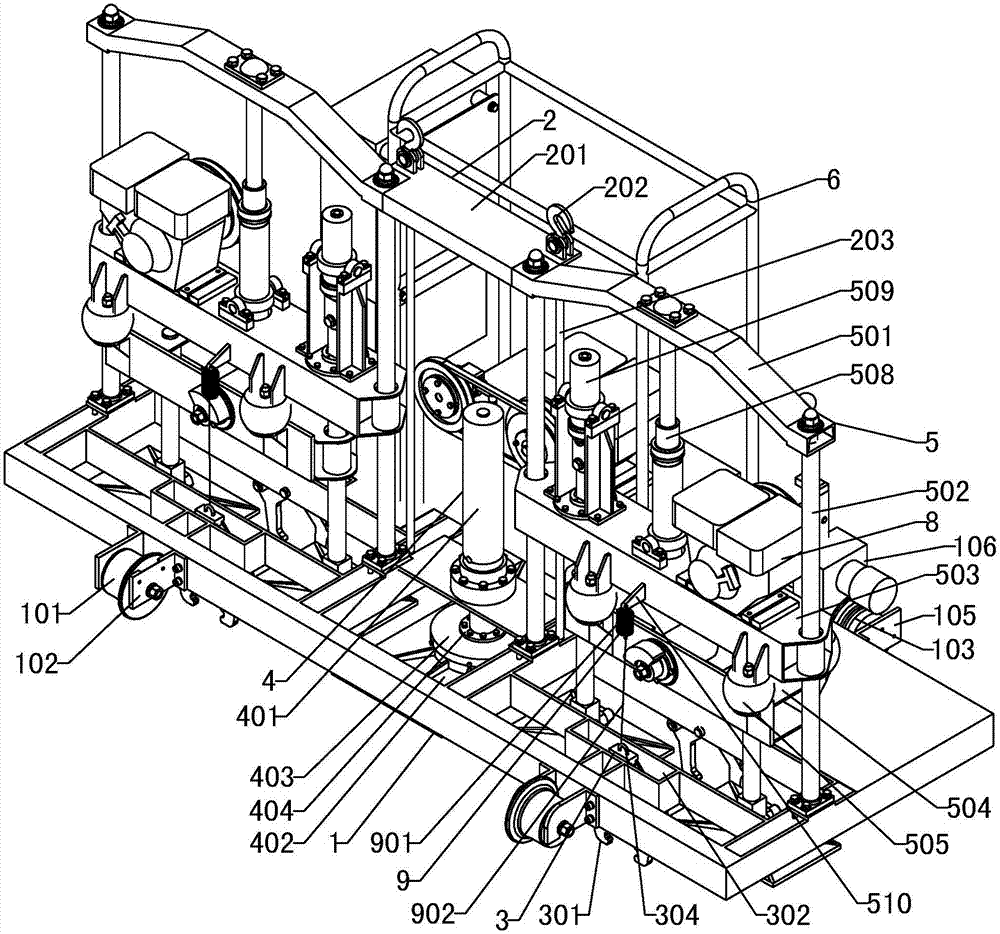

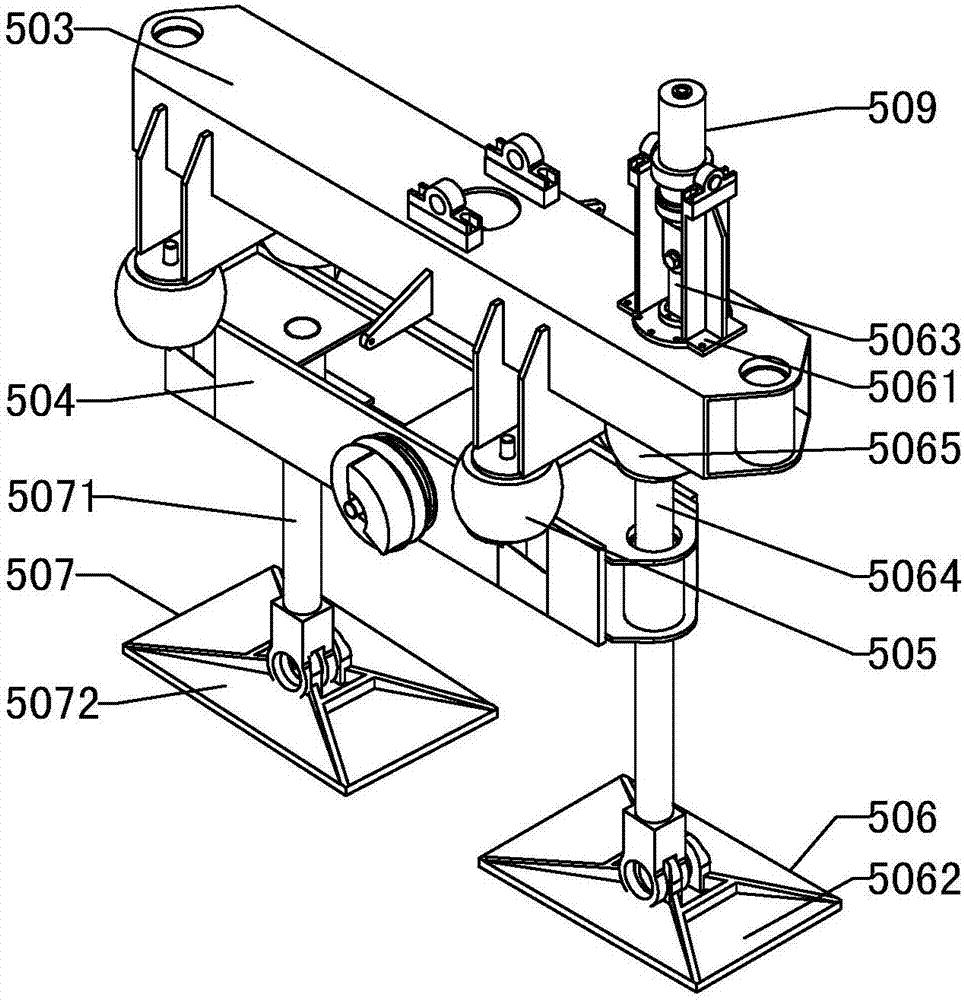

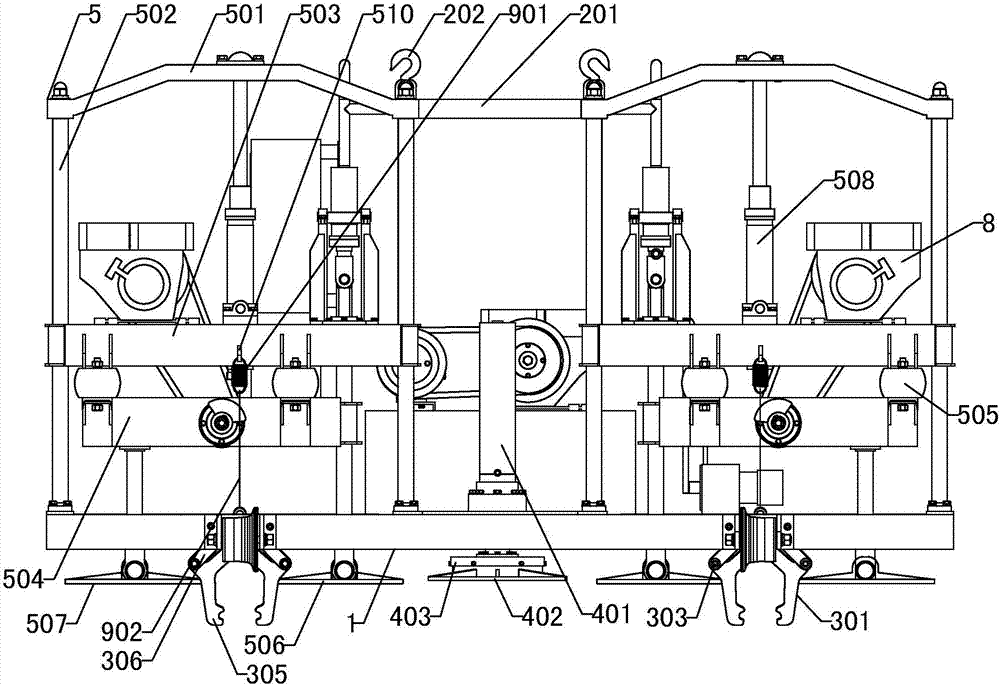

[0036] Figure 1~4 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~4 The present invention will be further described.

[0037] Refer to attached Figure 1~4 : Small-sized automatic hydraulic railway line tamping car, comprising a tamping mechanism 5 and a walking chassis 1, the longitudinal direction of the walking chassis 1 is the walking direction, and two groups of tamping mechanisms 5 arranged horizontally are arranged on the walking chassis 1, and two groups of tamping mechanisms 5 are arranged horizontally on the walking chassis 1. The lower part of the side is equipped with a walking mechanism that drives it to move, and the front side is equipped with a positioning sensor that detects the position of the compaction. The walking chassis 1 between the two groups of compacting mechanisms 5 is rotated and connected to the lower mechanism 4 that drives the whole machine to go up and down. A rail clamping mechanism 3 for cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com