Electric operating mechanism for switchgear

A technology using electric control and switching equipment, applied in the field of electric control mechanism, can solve the problems of high cost, motor burnout, complex structure, etc., and achieve the effect of simple structure, small output angle error and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

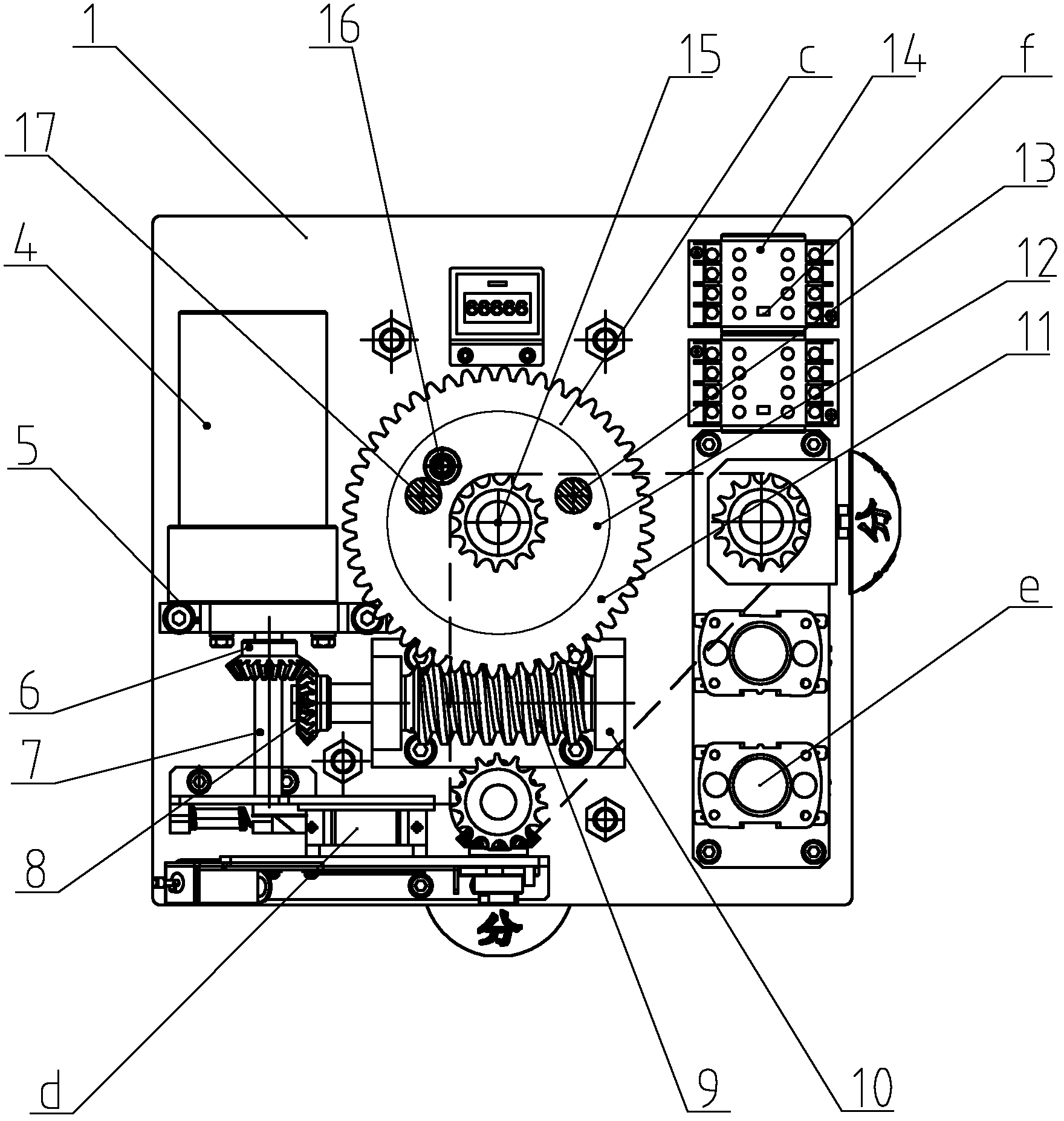

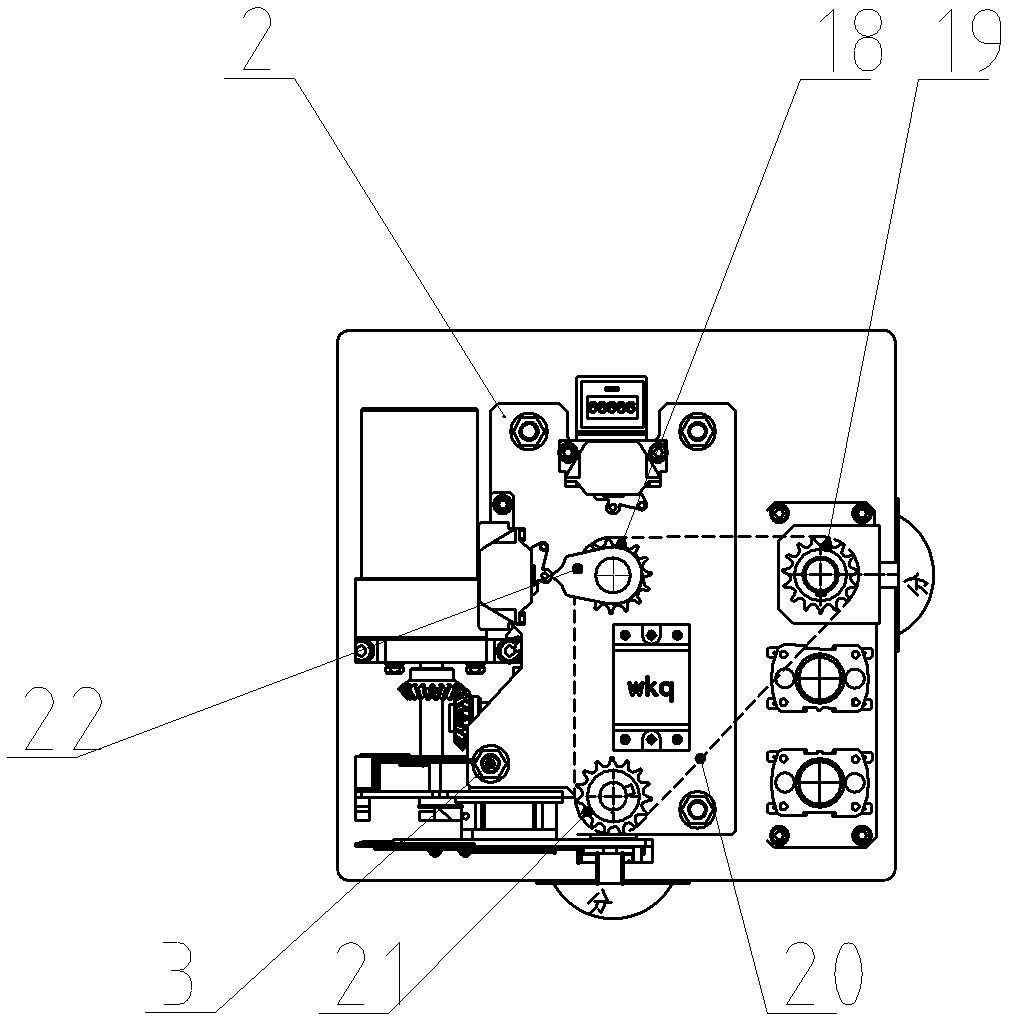

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0024] In this embodiment, the output shaft of the mechanism is steered, and the manual operation panel is set as the front view direction, and the output shaft is below the chassis, looking down from top to bottom: counterclockwise is divided, clockwise is closed; or vice versa.

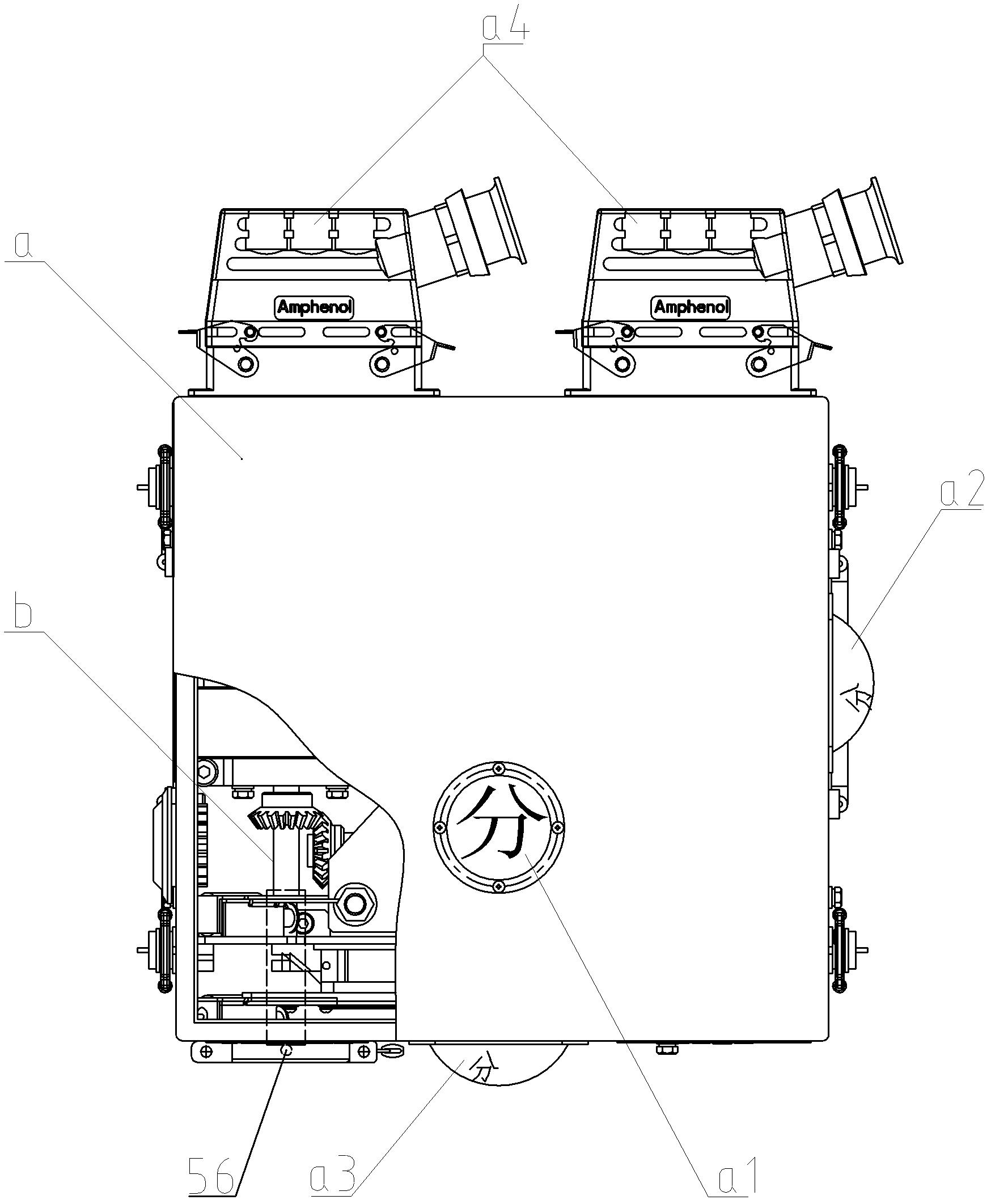

[0025] like Figure 1-Figure 9 As shown, the electric operating mechanism for switchgear is composed of a chassis a and a movement b. Element f, bottom plate 1 and upper splint 2.

[0026] Chassis a is connected by a8 box cover and a9 box body with buckle a10, and is fixed on the bottom plate 1 with screws. On the outer side, there are a1 on the top surface, a2 on the side surface, and a3 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com