Linear Motor Assembly And Machine Tool With Linear Motor Assembly

A linear motor and coil device technology, applied in the field of machine tools, can solve the problems of large machine tool structure space requirements, high equipment technology costs, etc., and achieve the effects of cost saving and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

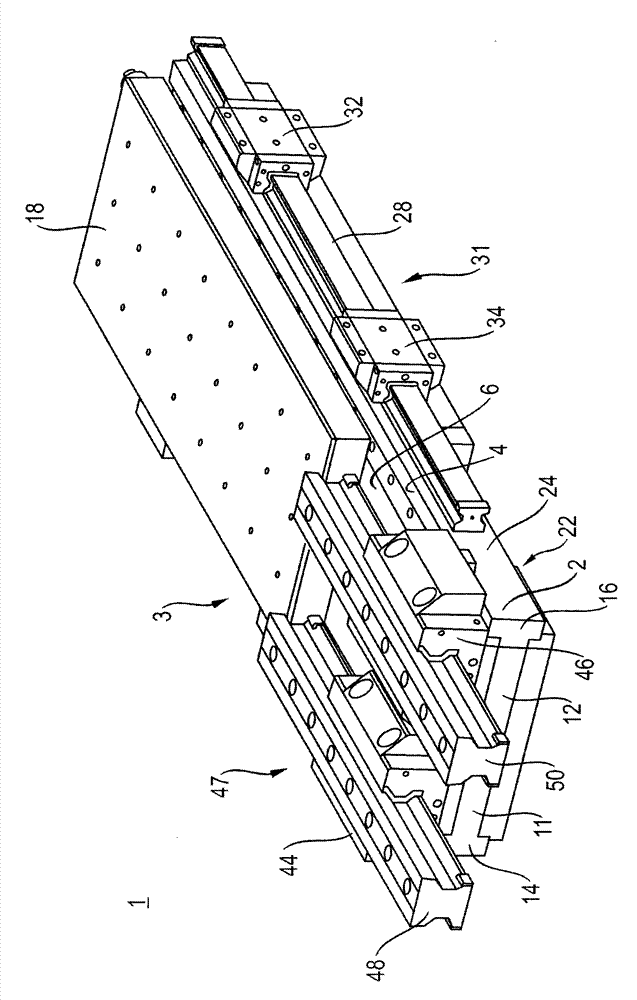

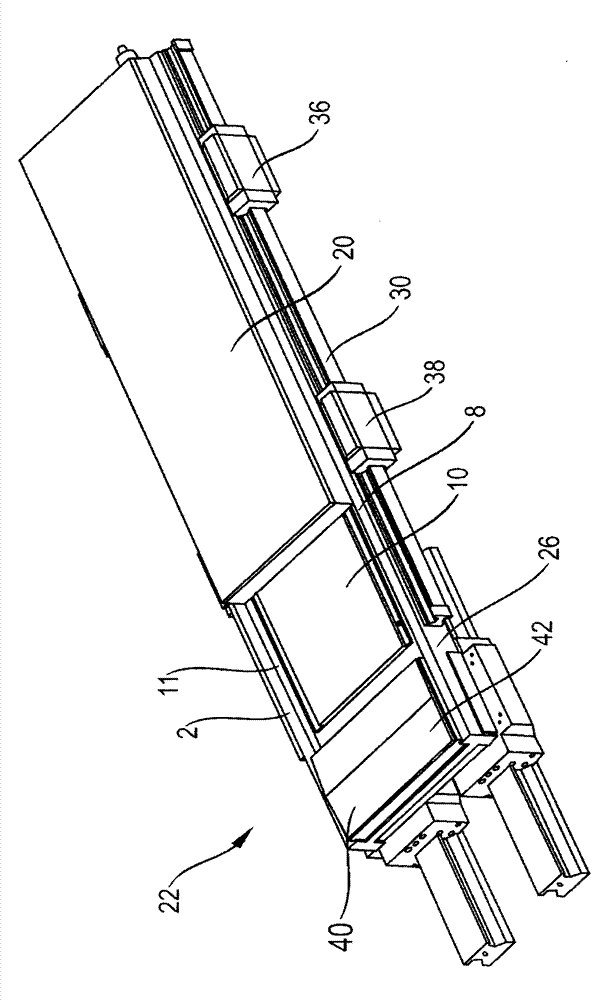

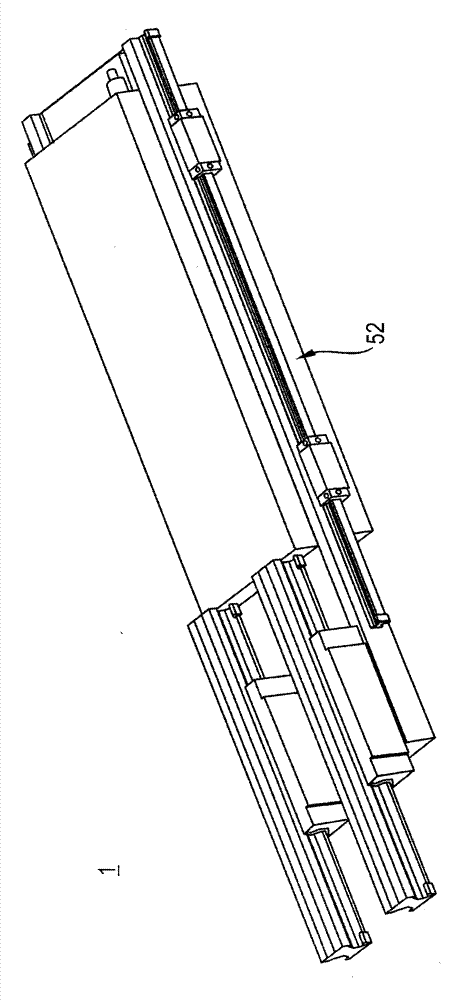

[0068] according to figure 1 A linear motor arrangement 1 for a nibbling machine is shown, extending approximately in the horizontal direction, with a linear motor 3 . The linear motor arrangement has a slide carriage 2 on the upper slide carriage side of which a secondary unit in the form of a magnetic arrangement is arranged. On the side 8 of the lower sliding bracket of the sliding bracket according to figure 2 A further secondary unit in the form of a magnetic device 10 is provided. according to figure 1 , the sliding bracket 2 has, viewed in cross section, a support plate 11 with an H-shaped profile, which has a connecting web 12 and two side webs 14 and 16 . The magnetic devices 6 and 10 are each located on a connection web 12 and thus arranged between webs 14 and 16 . The magnetic devices 6 and 10 each have an approximately plate-shaped housing, which is preferably screwed to the slide carrier 2 . A primary unit in the form of a coil arrangement 18 is arranged opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com