Torque wrench with very low reactive force to operator

A reaction force, torque wrench technology, applied in power tools, manufacturing tools, etc., can solve problems such as acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

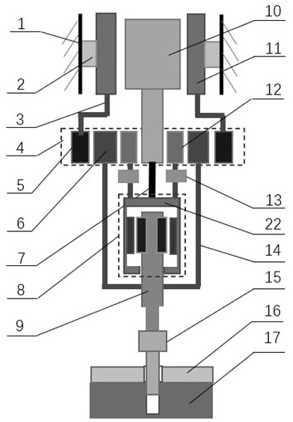

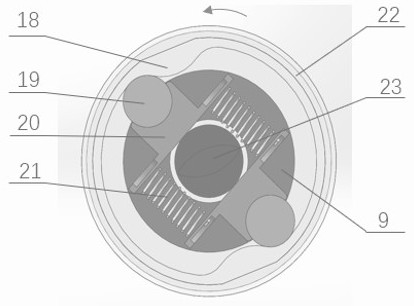

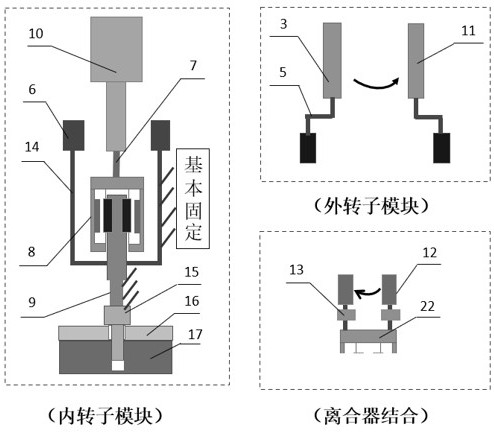

[0026] Such as figure 1 As shown, the present invention provides a torque wrench with extremely low reaction force to the operator, including a power assembly, a transmission assembly and an output assembly. The power assembly includes a torque wrench housing 1, a motor outer rotor 11 and a motor inner rotor 10 , The outer rotor 11 of the motor is assembled with the casing 1 through the bearing 2 . The transmission assembly includes a planetary gear train 4 and a clutch 13, wherein the planetary gear train 4 includes a ring gear 5, a planetary gear 6, a sun gear 12, and a planet carrier 14. The ring gear 4 is connected to the outer rotor 11 of the motor in the power pack through the connecting rod 3 Coaxial fixed connection, a through hole is machined in the center of the sun gear 12, the inner roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com