c/z purlin interchange production line

A production line and purlin technology, applied in belts/chains/gears, transmission boxes, mechanical equipment, etc., can solve the problems of time-consuming and labor-intensive processing, inability to guarantee accuracy, etc., and achieve the effect of convenient use, saving processing costs, and improving deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

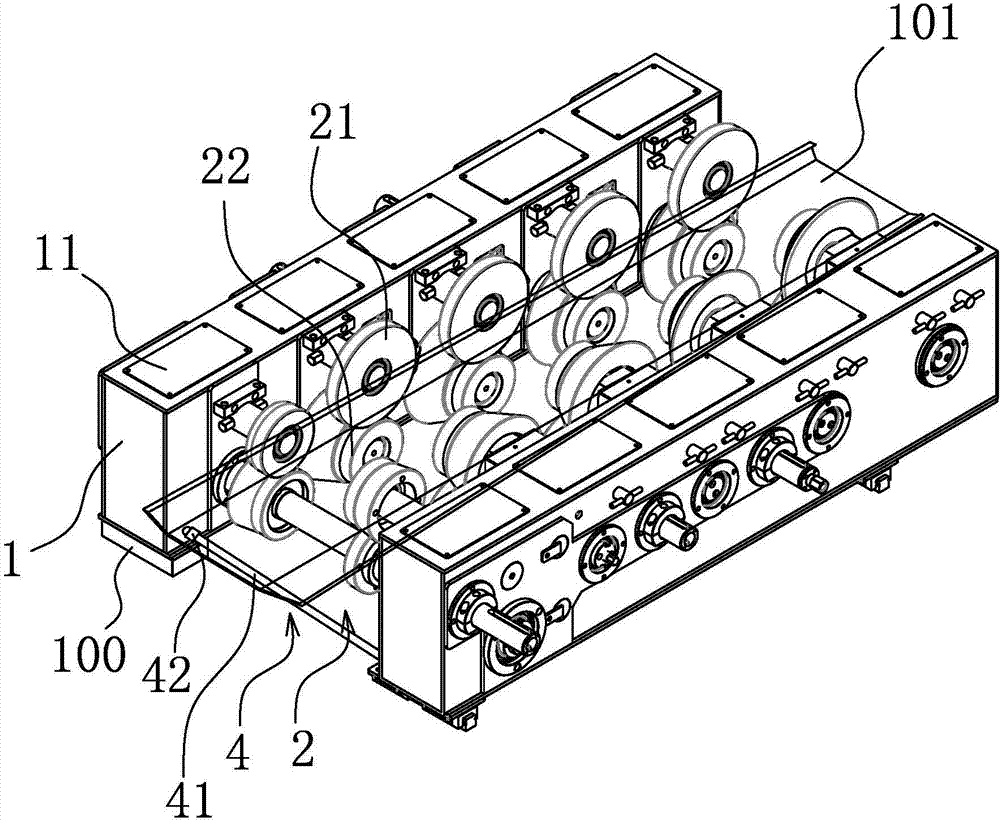

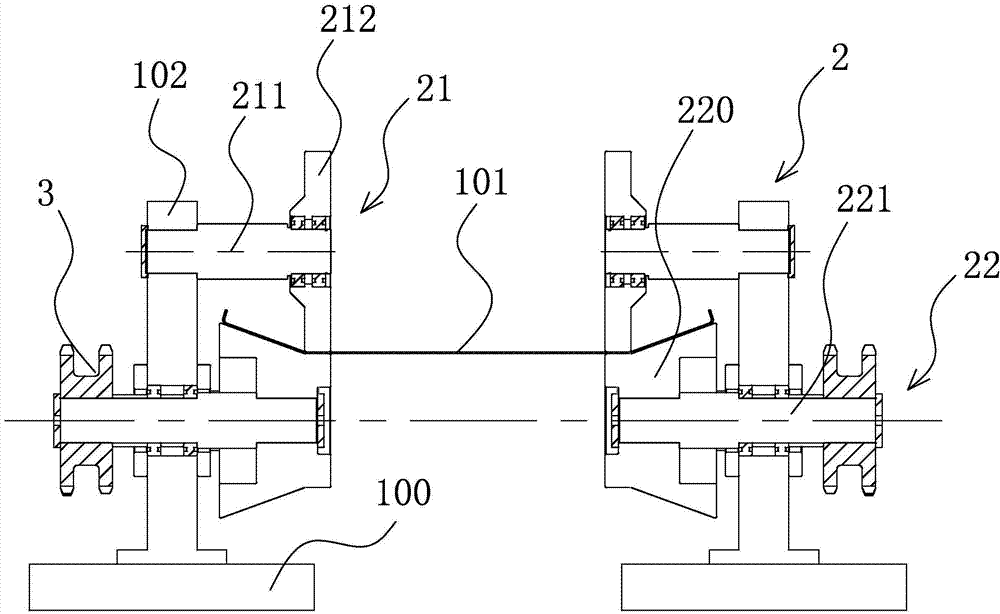

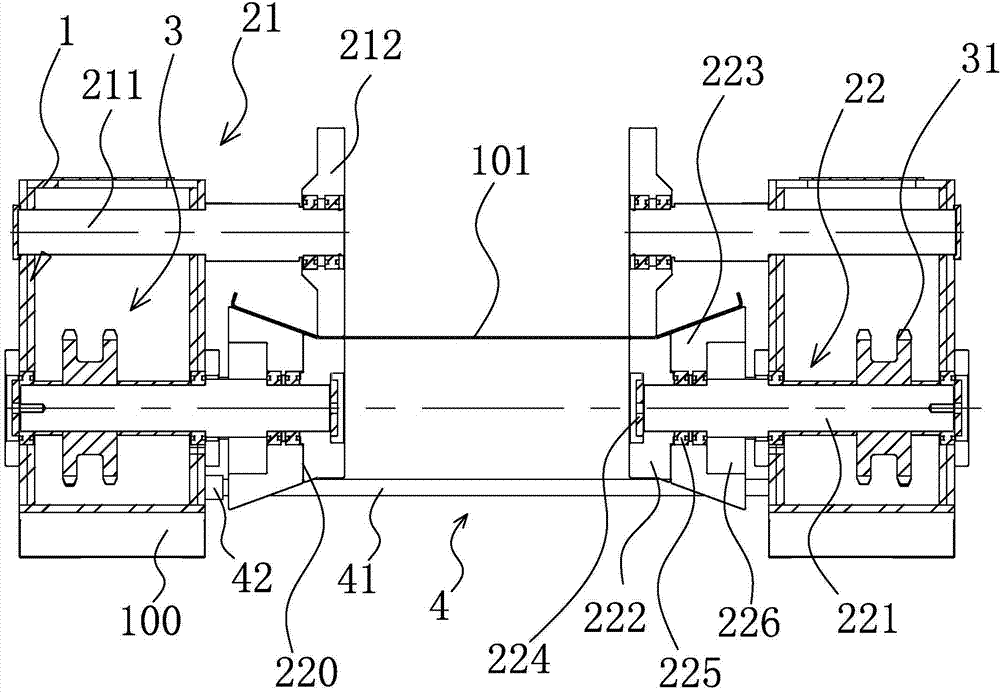

[0033] Such as figure 1 , Figure 3-5As shown, the present invention provides a C / Z purlin interchange production line, including a discharge device 1001, a feed leveling device 1002, a roll forming device 1003 and a receiving device 1004 connected in sequence, as a preferred solution , the roll forming device 1003 can also be divided into a small side roll forming mechanism 1031 and a large side roll forming mechanism 1032, the roll forming device 1003 includes a base 100, and the base 100 is oppositely arranged The two transmission boxes 1 and the distance between the two transmission boxes 1 can be adjusted on the machine base 100, which is convenient for replacing and producing purlins of different specifications. The transmission box 1 is a hollow structure surrounded by plates, and its shape can be various In this embodiment, the transmission box 1 is in the shape of a cuboid, and the side wall of the transmission box 1 is provided with several positioning hole structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com