Drum brake type parking brake device

A technology of drum brakes and parking brakes, applied in the direction of drum brakes, mechanically driven drum brakes, brake types, etc., to achieve the effect of simplifying the structure, promoting size and weight, and promoting light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

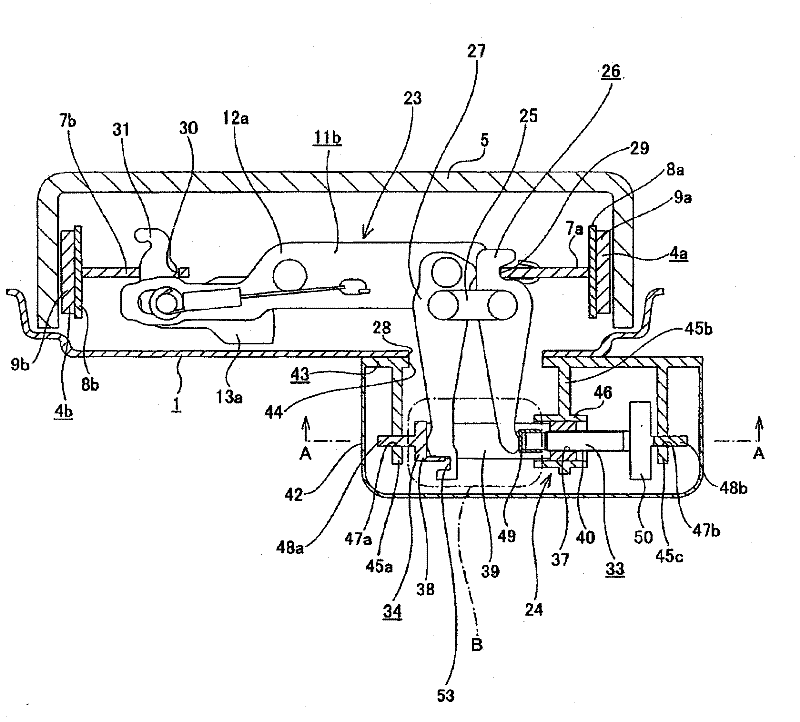

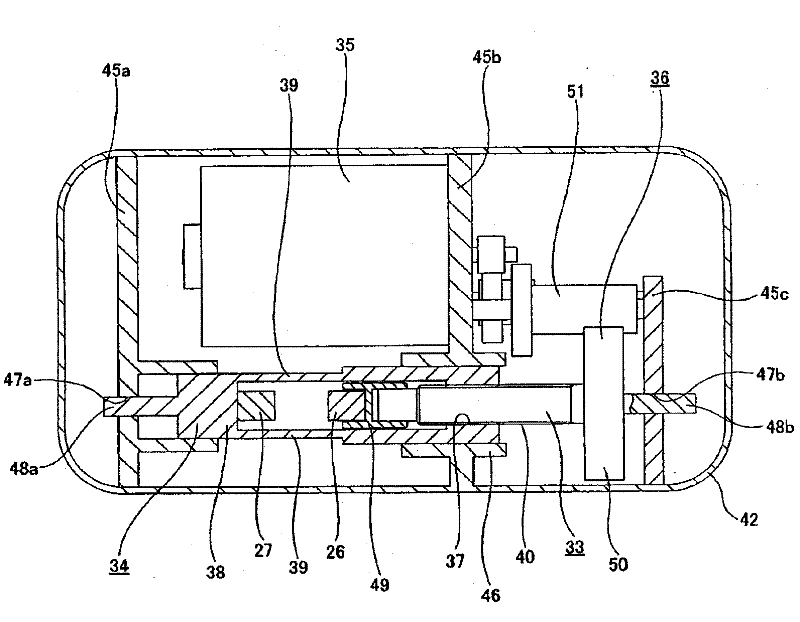

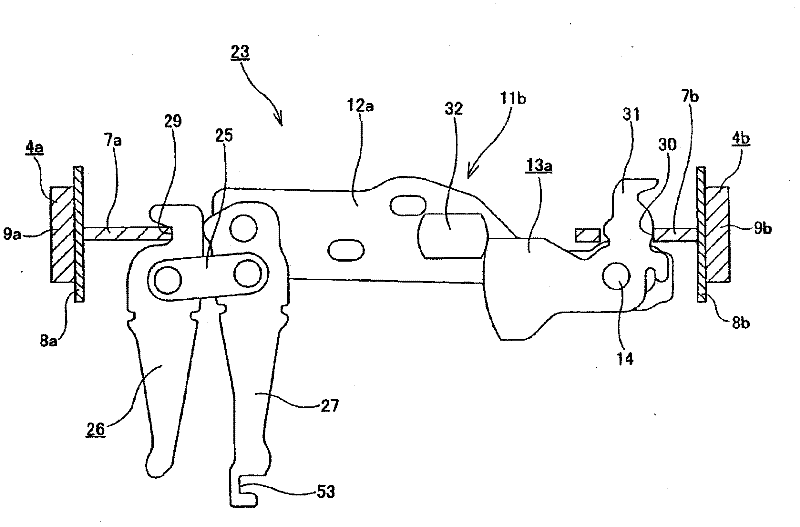

[0148] Figure 1 to Figure 5 The first example showing the embodiment of the present invention corresponds to the first to third, fifth and sixth inventions. In addition, the feature of the present invention including the present embodiment is the structure of the parking brake device used for the drum brake. In addition to the parking brake device, the structure and operation of the drum brake body are different from those mentioned above. Figure 15 to 20 The shown prior art structure is the same as the leader type drum brake widely known in the prior art, so illustrations and descriptions related to the same parts are omitted or simplified. Hereinafter, the characteristic part of the present invention will be mainly described.

[0149] An expansion and contraction device 23 for expanding and contracting the gap between the pair of brake shoes 4a and 4b is provided between the inner peripheral edges of the frame ribs 7a and 7b constituting the two brake shoes 4a and 4b, and Th...

no. 2 example

[0171] Image 6 9 shows a second example of the embodiment of the present invention, corresponding to the first, fourth and fifth inventions. In the case of this embodiment, the first and second pressing members that clamp and press the base end portions of the first and second expansion rods 26 and 27 from opposite sides are the cover 42a fixed to the back plate 1 and the support A threaded rod 54 is provided in the cover 42a so as to be swingable only in the axial direction. In addition, the threaded rod 54 is screwed into a threaded hole 56 provided in the middle portion of the reduction rotating member 55 rotatably supported in the cover 42a, such as a large reduction gear and a large reduction pulley. In addition, the speed reduction rotating member 55 is freely rotated and driven via the transmission belt 57 or the gear train by the motor constituting the driving source. In addition, the base end portions of the first and second expansion rods 26 and 27 are mutually supp...

no. 3 example

[0175] Picture 10 with Picture 11 The third example showing the embodiment of the present invention corresponds to the first to third, fifth and sixth inventions. In the case of this embodiment, compared with the case of the first embodiment of the foregoing embodiment, the female screw portion 37a is provided on the second pressing member 33a side, and the male screw portion 40a is provided on the first pressing member 34a side , And the two threaded portions 47a and 40a are screwed into each other. In addition, in order to clamp the base end portions of the first and second expansion rods 26a and 27a from opposite sides and enable the base end portions to be pressed by the two pressing members 33a and 34a, the two expansion rods 26a and The pressing target plate portions 64a and 64b are respectively provided in the side edge portions of the portion near the base end of 27a. The two pressing target plate portions 64a and 64b are directed by the metal plates constituting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com