Resistor-based Ignition System for a Core Gun

a resistance-based ignition and core gun technology, applied in the field of resistor-based ignition systems for core guns, can solve the problems of b>hazardous to handle, negative safety issues with the current system, and b>hazardous to handle, and achieve the effect of eliminating safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

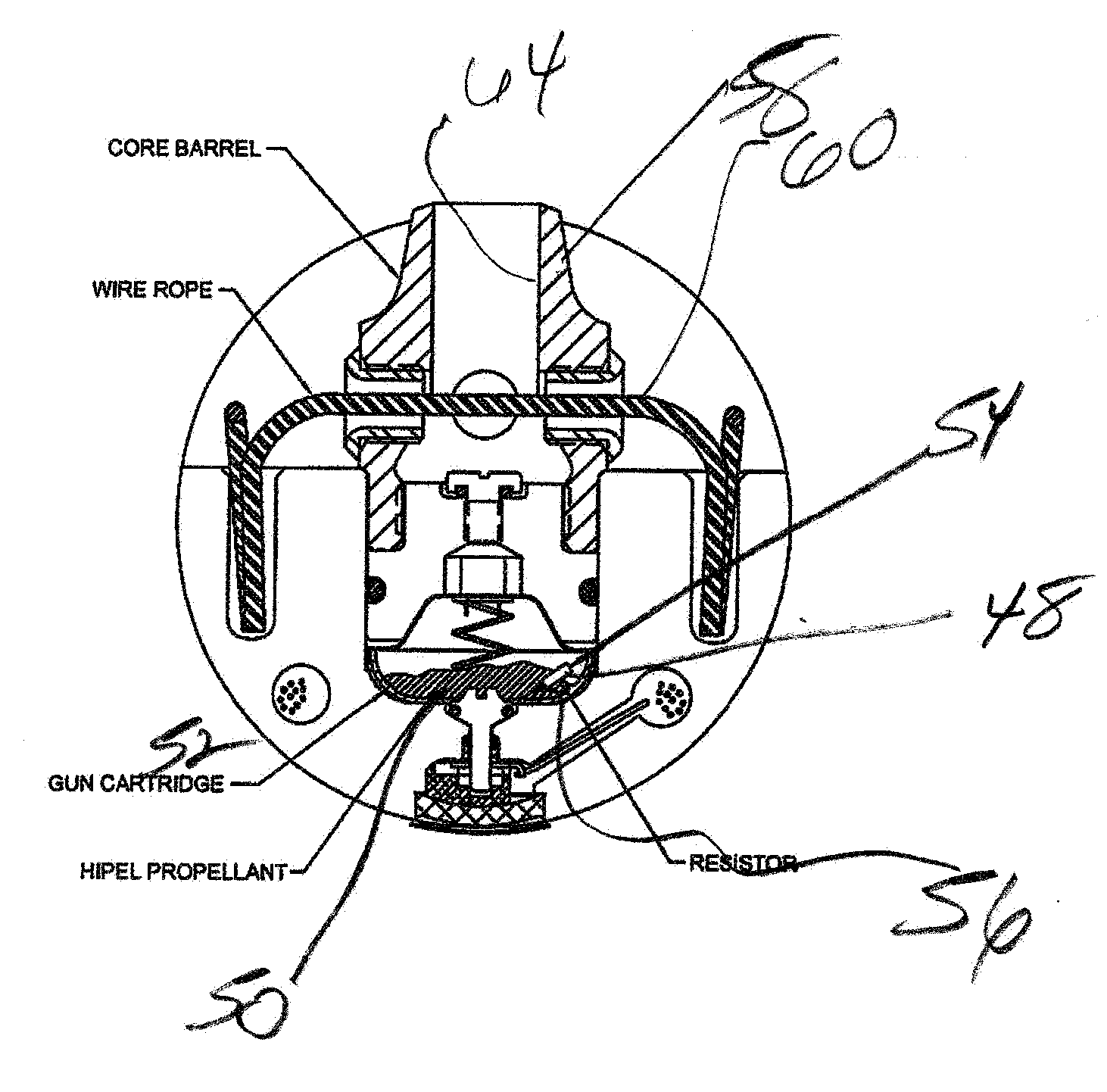

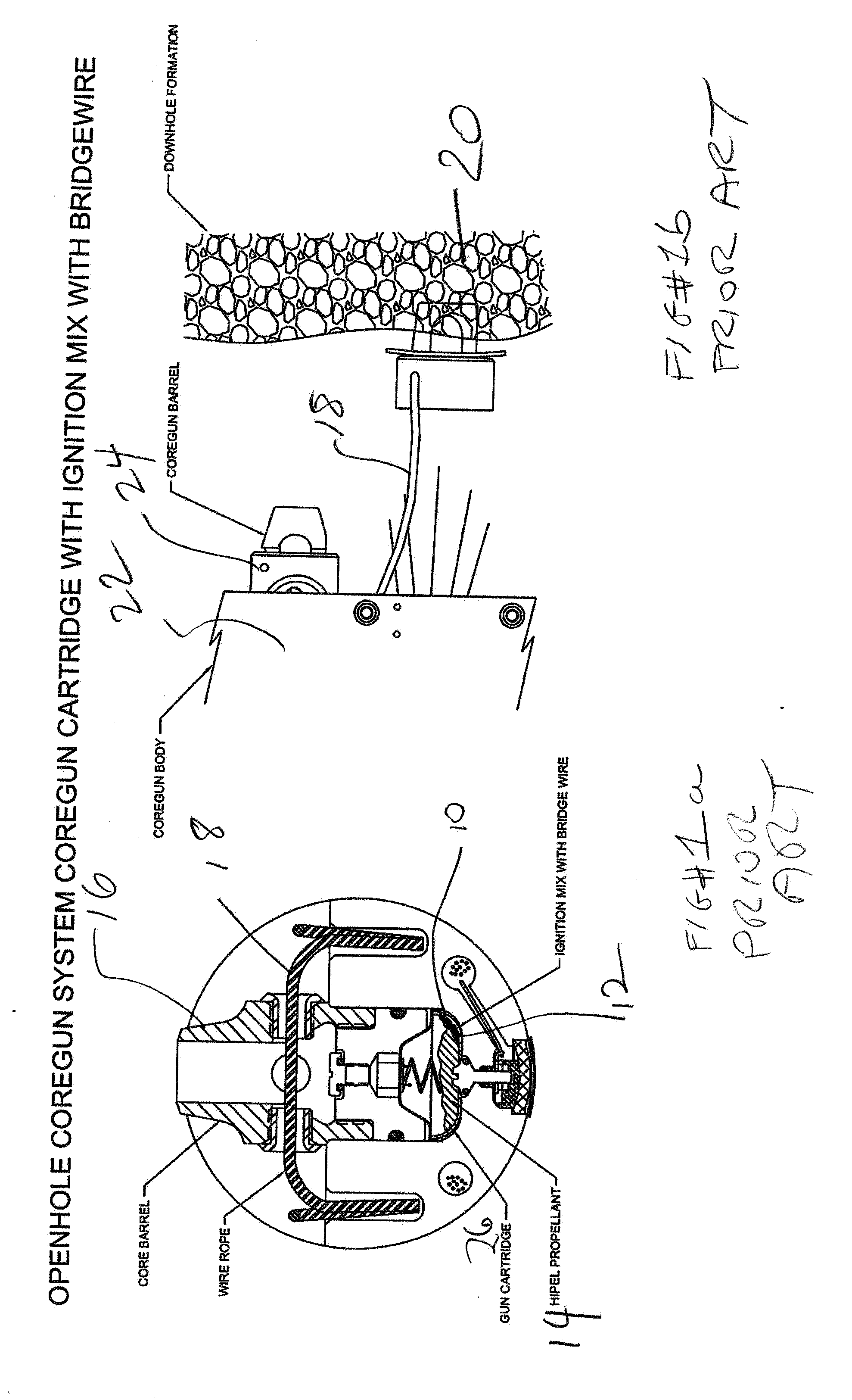

[0012]FIG. 3a shows a resistor 48 that when energized creates heat to burn the propellant 50 in the cartridge 52. The resistor is preferably under 50 ohms and is secured at opposed ends with welds 54 and 56. The barrel 58 is secured by the tether 60 that operates in the same manner as in FIG. 1a. Additional barrels such as 62 can be used in the core gun body 64. The core sample of the formation 66 is captured in the passage 64.

[0013]Those skilled in the art will appreciate that the elimination of the nichrome wire coated with the ignition mix that had been in persistent use in the past for years for core guns posed safety issues that caused fires and threatened personal injury for the assembly workers. The soldering process for attaching the wire also created reliability issues with the possibility that the barrel would not be propelled into the formation.

[0014]Now the core gun with a welded resistor of preferably under 50 ohms to set off the propellant to launch the barrel, the ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com