Novel glue smearing gun

A glue gun, a new type of technology, applied in the field of tools for spraying or coating colloids, can solve the problems of uncontrollable glue output, short service life of the glue gun, complicated manufacturing process, etc., to achieve free control of glue output, printing The effect of high glue quality, uniform and continuous glue output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

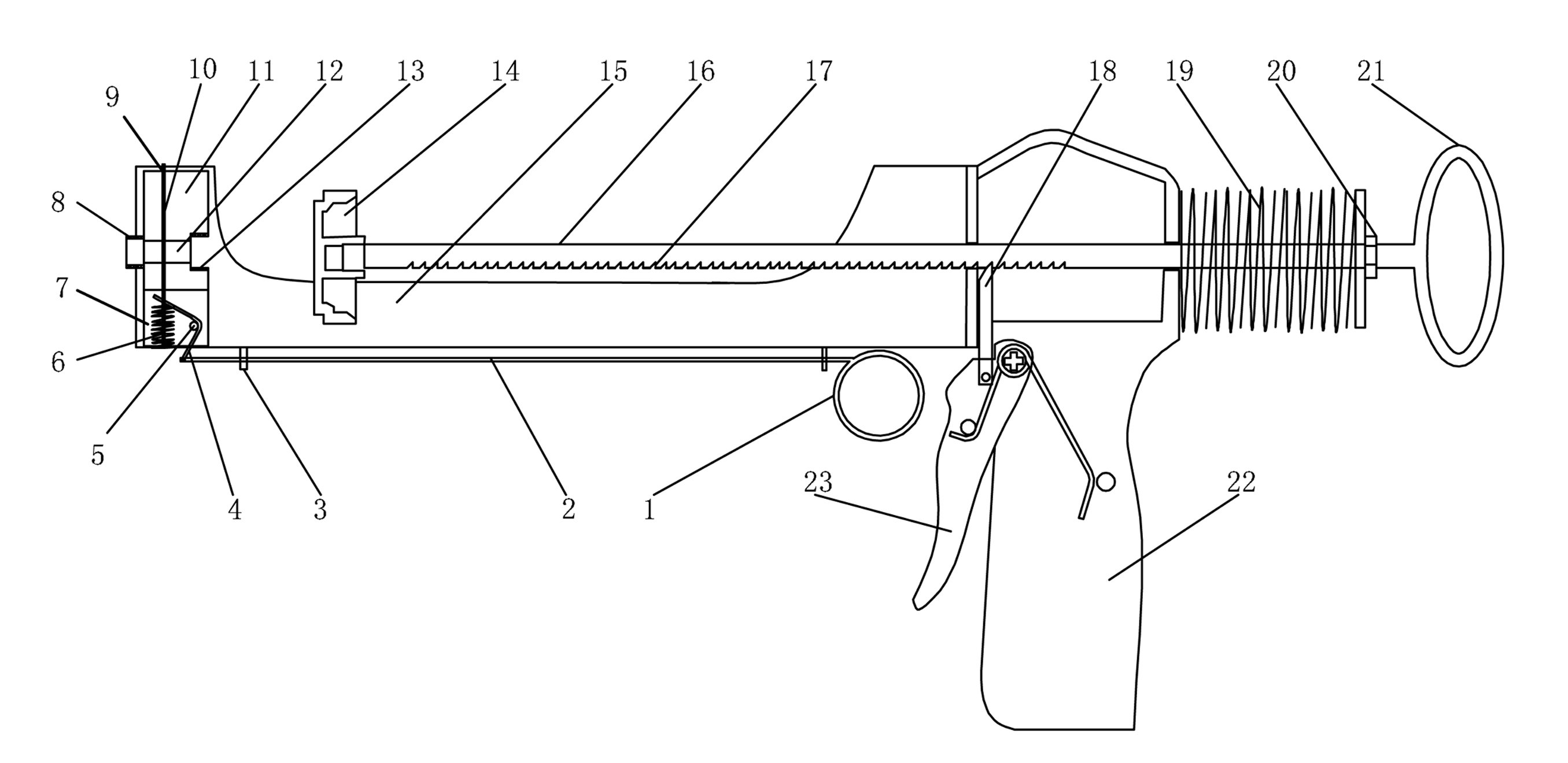

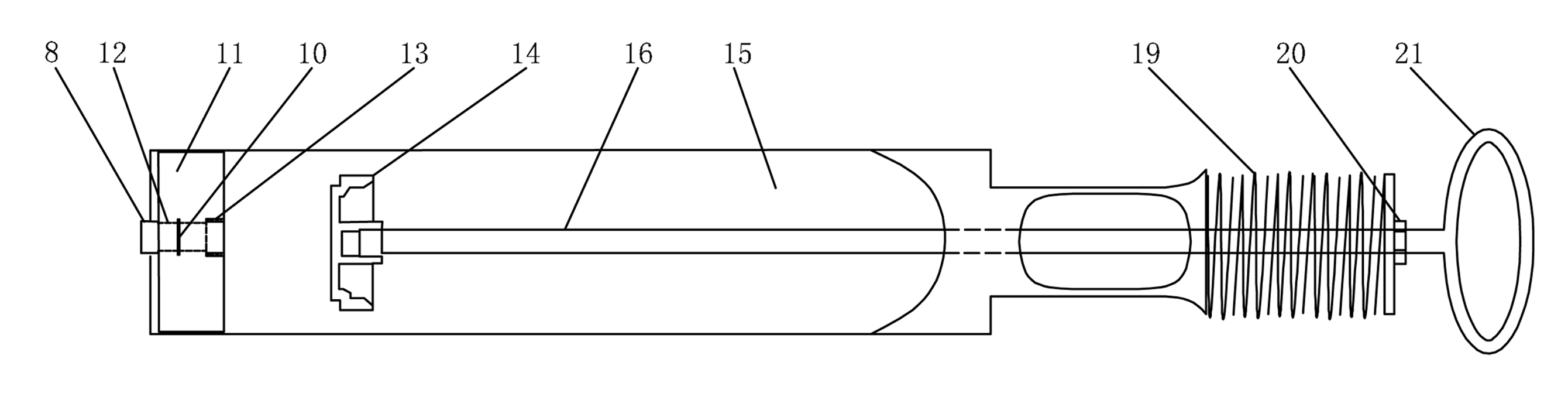

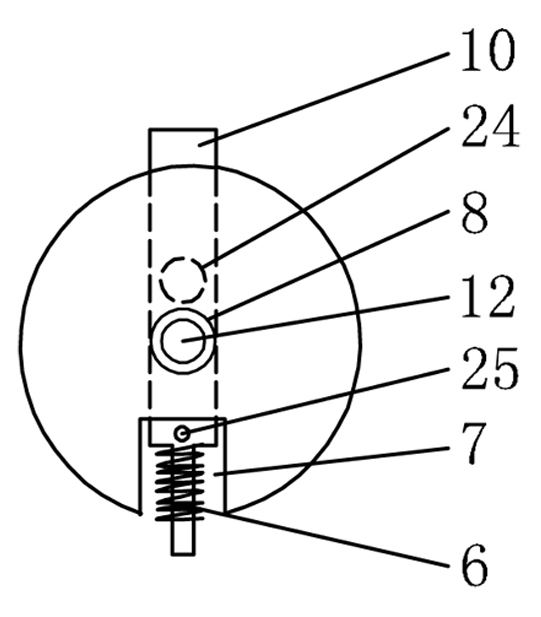

[0019] As shown in the figure: the invention forms a secondary control system by adding an opening and closing device for glue breaking at the front end and an automatic propulsion device at the rear end. The opening and closing device for cutting glue is composed of a switch block 11, a steel sheet for cutting glue 10, a return spring 6, a lever 4, and a pull rod 2. The switch block 11 is a cylinder with the same diameter as the gun groove 15, and the center of the switch block 11 is set The glue outlet channel 12, the inside of the glue outlet channel 12 is provided with the inner thread screw mouth 13 connected with the glue tank thread mouth, the outer wire screw mouth 8 connected with the glue nozzle is arranged on the outside, and the switch block 11 is perpendicular to the glue outlet channel 12. The rubber-breaking steel sheet jack 9, the bottom of the switch block 11 is provided with a groove 7, and a return spring 6 and a shift lever 4 are arranged in the groove 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com