Binary plug nozzle of turbofan engine with afterburning

A turbofan engine and afterburning technology, applied in the direction of machines/engines, jet propulsion devices, etc., can solve the problems of increased weight, increased flow resistance of the nozzle, and the influence of the aerodynamic performance of the nozzle, so as to achieve the reduction of metal solid radiation, mixed The effect of mixed enhancement and good thrust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is described further.

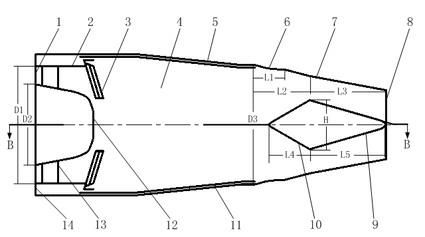

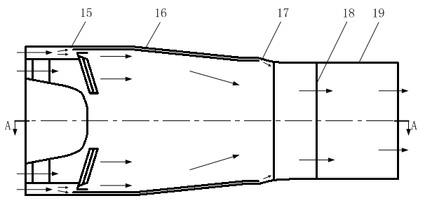

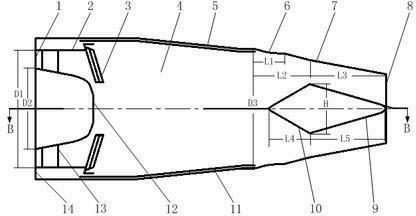

[0026] figure 1 with figure 2 The structural schematic diagrams of the A-A section and the B-B section of the binary plug nozzle are shown respectively. The front part of the nozzle has an outer channel 14 and an inner channel 1. A central cone 12 is installed in the inner channel through a support plate 13, and a flame stabilizer 3 is installed downstream of the central cone 12; the middle part of the nozzle is an afterburner; The rear portion is successively a transition section 6 and a convergent expansion section 7, and the convergent expansion section 7 is equipped with a plug cone. The plug cone is prismatic, including the front part 10 of the plug cone and the rear part 9 of the plug cone. The diameter of the defined connotation channel is D1, the diameter of the central cone is D2, the diameter of the entrance of the transition section is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com