Aromatic hydrocarbon-rich wax oil hydrotreating method

A technology for hydrogenation and treatment of wax oil, which is applied in the fields of hydrogenation treatment process, hydrocarbon oil treatment, petroleum industry, etc., and can solve the problems of poor cracking performance, affecting the economic benefit of the device, and high aromatic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

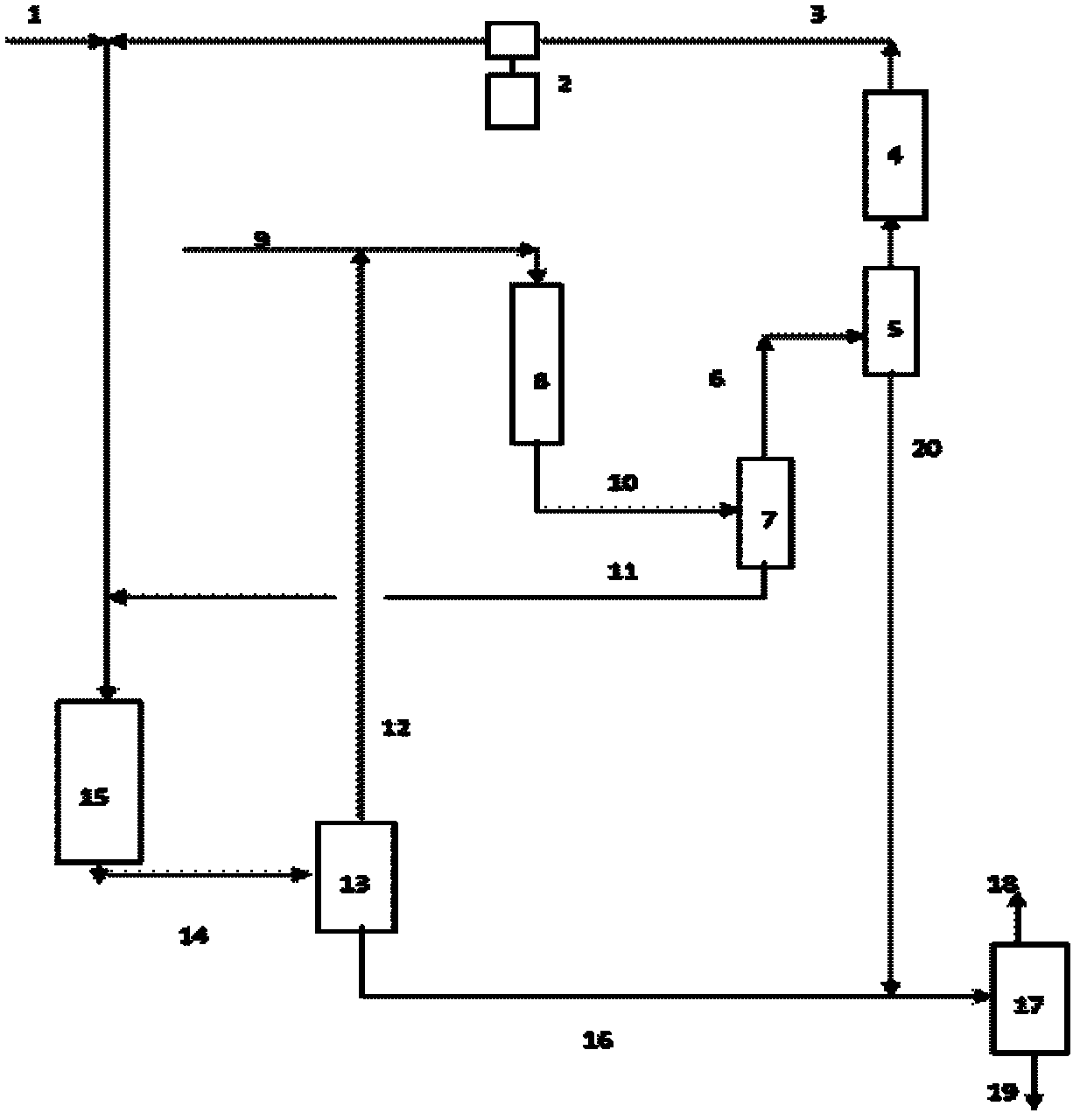

Method used

Image

Examples

Embodiment

[0020] The scheme and effect of the present invention are illustrated below by examples.

[0021] Table 1 Main Properties of Raw Oil

[0022] project

Venezuelan wax oil

Domestic mixed wax oil

Density(20℃) / g / ml

0.9660

0.9310

Distillation range, ℃

350~520

360~600

Sulfur content, wt%

3.3

3.1

Aromatic content, wt%

72

58

[0023] Table 2 Main Properties of Hydrotreating Catalysts

[0024] project

3936

MoO 3 , wt%

24.5

NiO, wt%

3.8

Specific surface, m2 / g

greater than 160

Pore volume, ml / g

0.33

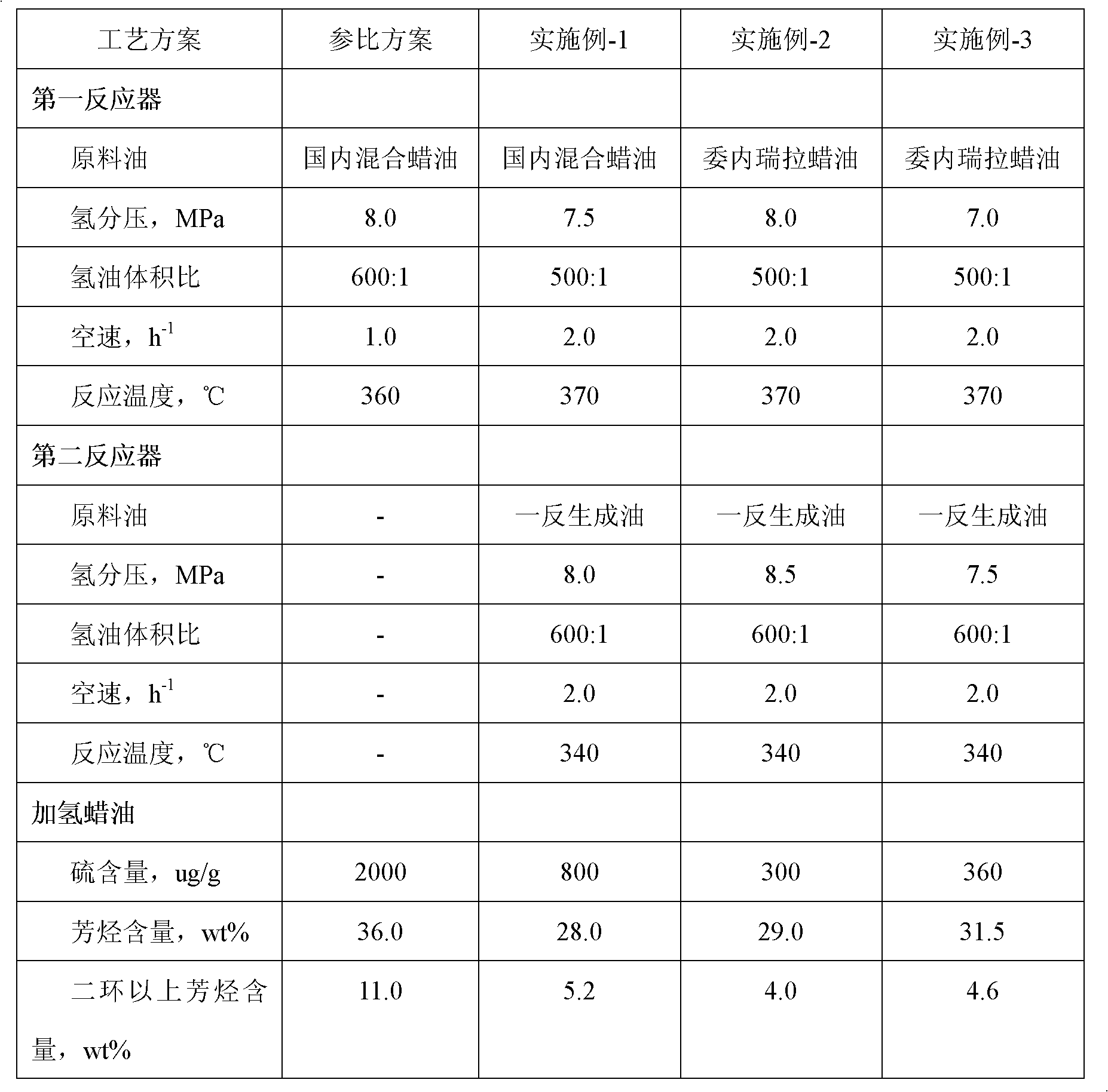

[0025] Table 3 embodiment process condition and reaction result

[0026]

[0027] It can be seen from the above examples that since the hydrogen sulfide content of the hydrogen in the second reactor is very low and the hydrogen partial pressure is relatively high, a sufficiently high desulfurization rate can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com