Method for modification by coupling hydrodesulfurization of FCC (Fluid Catalytic Cracking) gasoline and aromatization of liquefied petroleum gas

A gasoline hydrogenation and hydrodesulfurization technology, applied in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of difficult gasoline cleaning, lower gasoline octane number, high catalyzed gasoline sulfur and high olefin content , to achieve the effect of increasing the product octane number without loss, increasing gasoline yield, and high gasoline desulfurization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

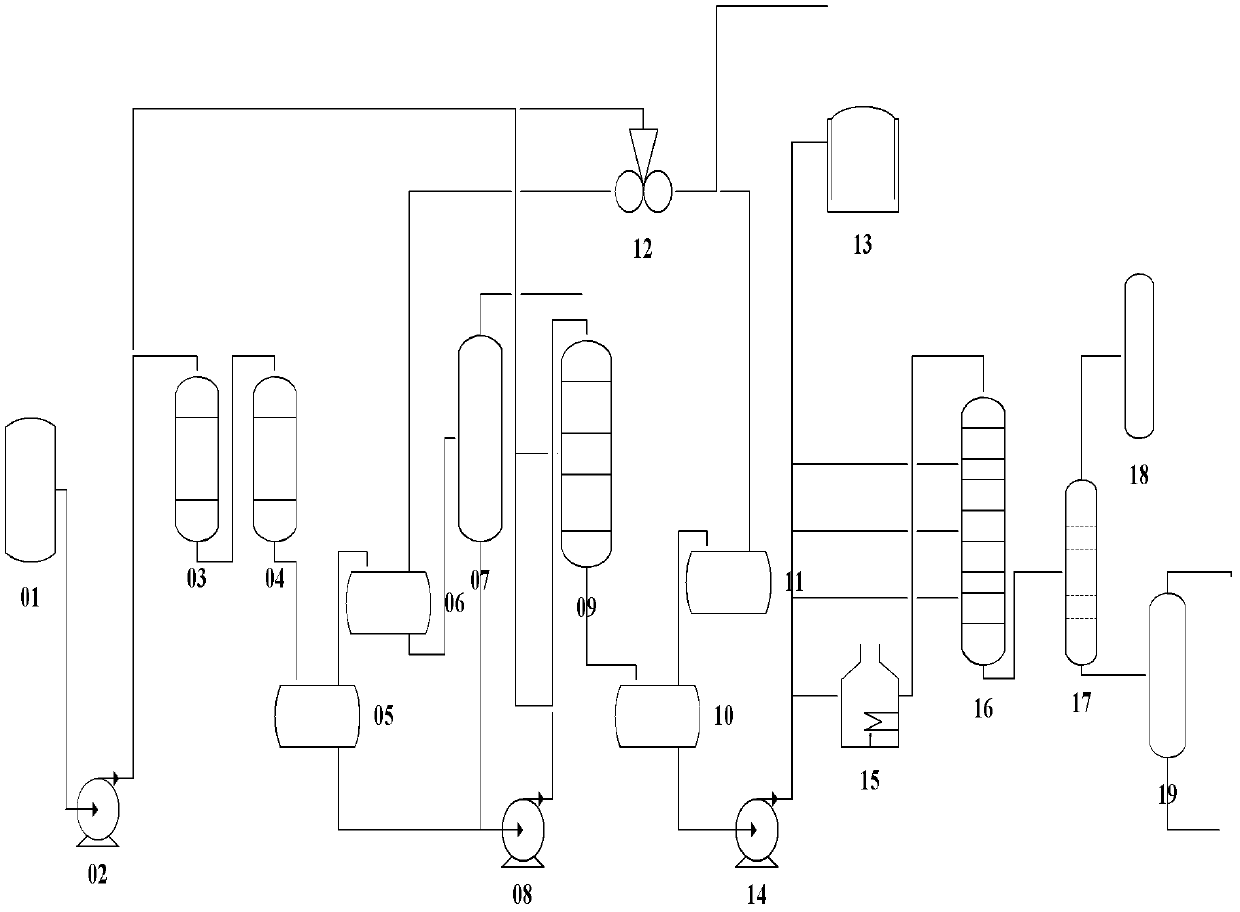

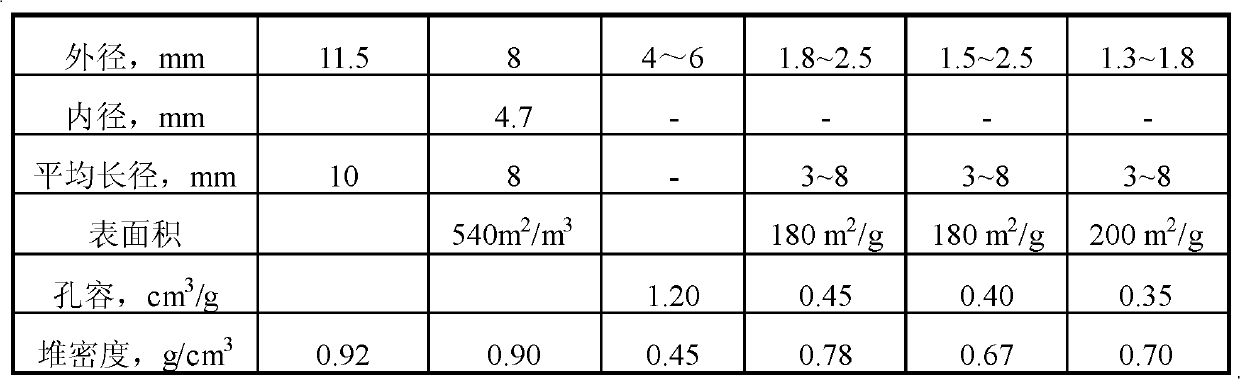

Method used

Image

Examples

Embodiment 1

[0028] Adopt the method provided by the present invention, take FCC gasoline 1 in Table 2 as raw material, first introduce whole cut FCC gasoline 1 into selective hydrogenation reactor and pre-desulfurization reactor to react, and the diolefins in the raw material are reduced from 1.5v% To below 0.5v%, the total sulfur content is reduced from 1250μg / g to 745μg / g, and the olefin saturation is less than 3%, and then the pre-desulfurized product enters the separator-fractionation tower combination device, with 75°C as the fractionation point, LCN:HCN The weight ratio is 40:60, the total sulfur of the fractionated LCN light component is 45.5 μg / g, the fractionated HCN heavy component has a total sulfur of 1405.2 μg / g, and the total sulfur of the HCN heavy component is reduced to 38.4 μg after hydrodesulfurization treatment / g, after reconciling with LCN light components, the total sulfur is 42.6μg / g, olefins are reduced from 38.5v% to 31.2v%, RON is reduced from 92.5 to 90.9, and t...

Embodiment 2

[0030] Using FCC gasoline 1 in Table 2 as the raw material, first introduce the full cut FCC gasoline 1 into the selective hydrogenation reactor and the pre-desulfurization reactor to reduce the dienes in the raw material from 1.5v% to below 0.5v%, and the total sulfur content Decrease from 1250μg / g to 685μg / g, olefin saturation is less than 5%, then the pre-desulfurization product enters the separator-fractionation tower combination device, with 80°C as the fractionation point, with LCN:HCN weight ratio of 45:55, fractionated out The total sulfur of the LCN light component is 42.8μg / g, the total sulfur of the HCN heavy component is 1326.5μg / g, and the total sulfur of the HCN heavy component is reduced to 44.5μg / g after hydrodesulfurization treatment, which is reconciled with the LCN light component The final total sulfur was 43.9 μg / g, olefins decreased from 38.5v% to 31.8v%, RON decreased from 92.5 to 91.0, and the loss was 1.5 units. The detailed data of reaction operating ...

Embodiment 3

[0032] Using the FCC gasoline 2 in Table 2 as the raw material, first introduce the full fraction FCC gasoline 2 into the selective hydrogenation reactor and the pre-desulfurization reactor, and reduce the diene content in the full fraction FCC gasoline 2 from 1.2v% to 0.45 after treatment. v%, the total sulfur content decreased from 412 μg / g to 281.4 μg / g, and the olefin saturation rate was less than 3%. Then the pre-desulfurization product is introduced into the separation-fractionation combined device, the fractionation point is selected as 75°C, the mass ratio of the fractionated LCN light component is 40%, the total sulfur content is 36.5 μg / g, and the mass ratio of the fractionated HCN heavy component is 60%. , the total sulfur content is 539.4μg / g, the total sulfur is reduced to 41.8μg / g after hydrogenation of heavy oil, and then the sulfur content is 39.4μg / g after reconciliation with LCN light components, and the olefin content is reduced from 39.4v% to 34.5v%, RON wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com