Air compressor set capable of freezing and drying air inflow

A technology of air compressors and compressor units, which is applied in mechanical equipment, machines/engines, and liquid variable capacity machinery, etc. It can solve the problems of high maintenance rate of air compressors, compressor operation failures, high maintenance costs, etc., and achieve environmental protection performance Good, reliability improvement, energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

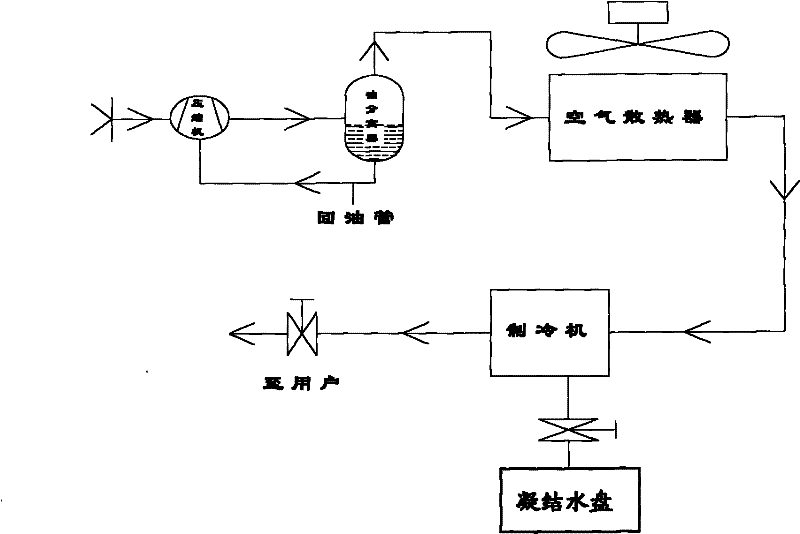

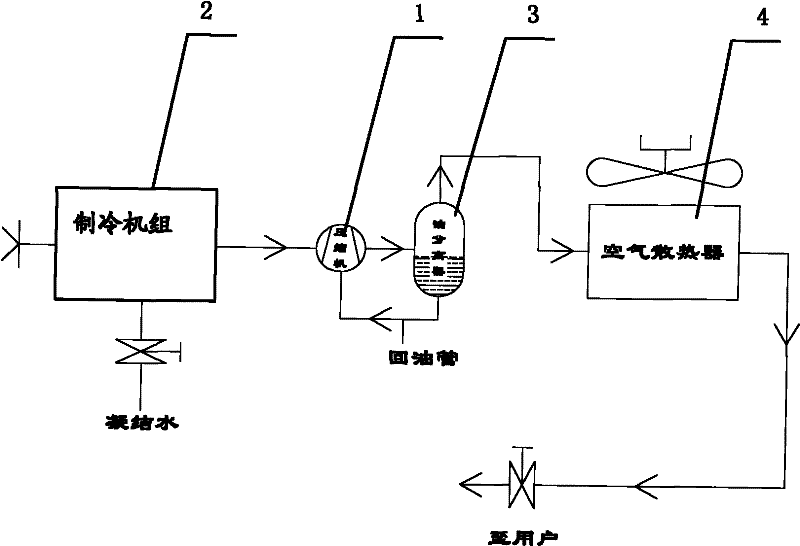

[0024] Such as figure 2 As shown, the intake freeze-drying air compressor unit of the present invention includes an air compressor 1, a refrigeration unit 2 is connected to the air inlet of the front end of the air compressor 1, and the compressed air outlet end of the air compressor 1 is sequentially connected to The oil separator 3 and the air radiator 4, the end of the air radiator 4 sends the dry compressed air to the user through the connecting pipe.

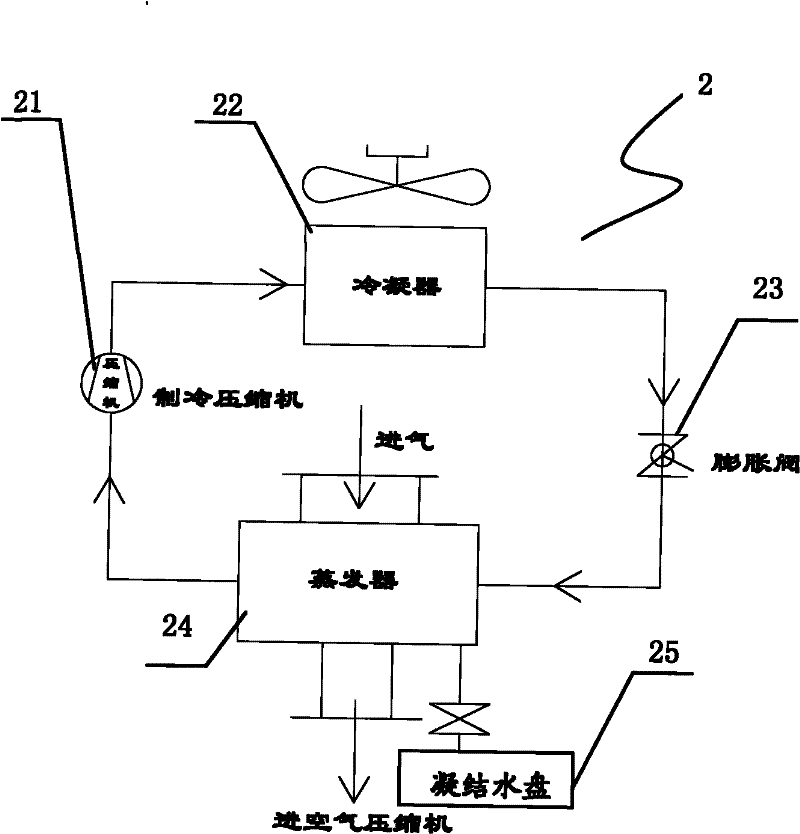

[0025] Such as image 3 As shown, in the present invention, the refrigerating unit 2 specifically includes a refrigerating compressor 21, a condenser 22, an expansion valve 23, and an evaporator 24 that are sequentially connected through connecting pipes, and a condensate pan 25 for collecting condensed water is provided below , in addition, in order to improve the dryness and drying efficiency of dry compressed air, the outlet of the dry compressed air of the evaporator is provided with a dry filter and a blower (not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com