Method for preparing black yarn through direct mixing of PET melt and special equipment of method

A melt and melt pipeline technology, applied in melt spinning, rayon manufacturing, textiles and paper making, etc., can solve the problems of insignificant viscosity reduction, melt viscosity reduction, complex process, etc., and achieve good quality stability, Stable quality and improved fiber spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 A kind of PET melt of the present invention directly mixes and prepares the method for black silk, comprises the steps:

[0030] Step 1. Introduce a melt with a viscosity of 0.63dl / g from the PET main melt pipeline, and mix in matting agent (49%) and dispersant (1%) according to the mass ratio to obtain a compound; mix in matting agent and dispersant in proportion , to obtain the mixture, the mass ratio of the melt: matting agent: dispersant is 1:0.49:0.01; the melt is PET, the matting agent is titanium dioxide, and the dispersant is titanic acid Ester coupling agent;

[0031] Step 2. The mixture obtained in step 1 is entered into a twin-screw extruder under negative pressure for low-speed (120rpm) initial mixing to form an initial mixing melt;

[0032] Step 3. The primary mixed melt coming out of the screw extruder is first blended by an ultrasonic dynamic mixer to obtain a mixed melt;

[0033] Step 4. The mixed melt is then input into the PET main melt ...

Embodiment 2

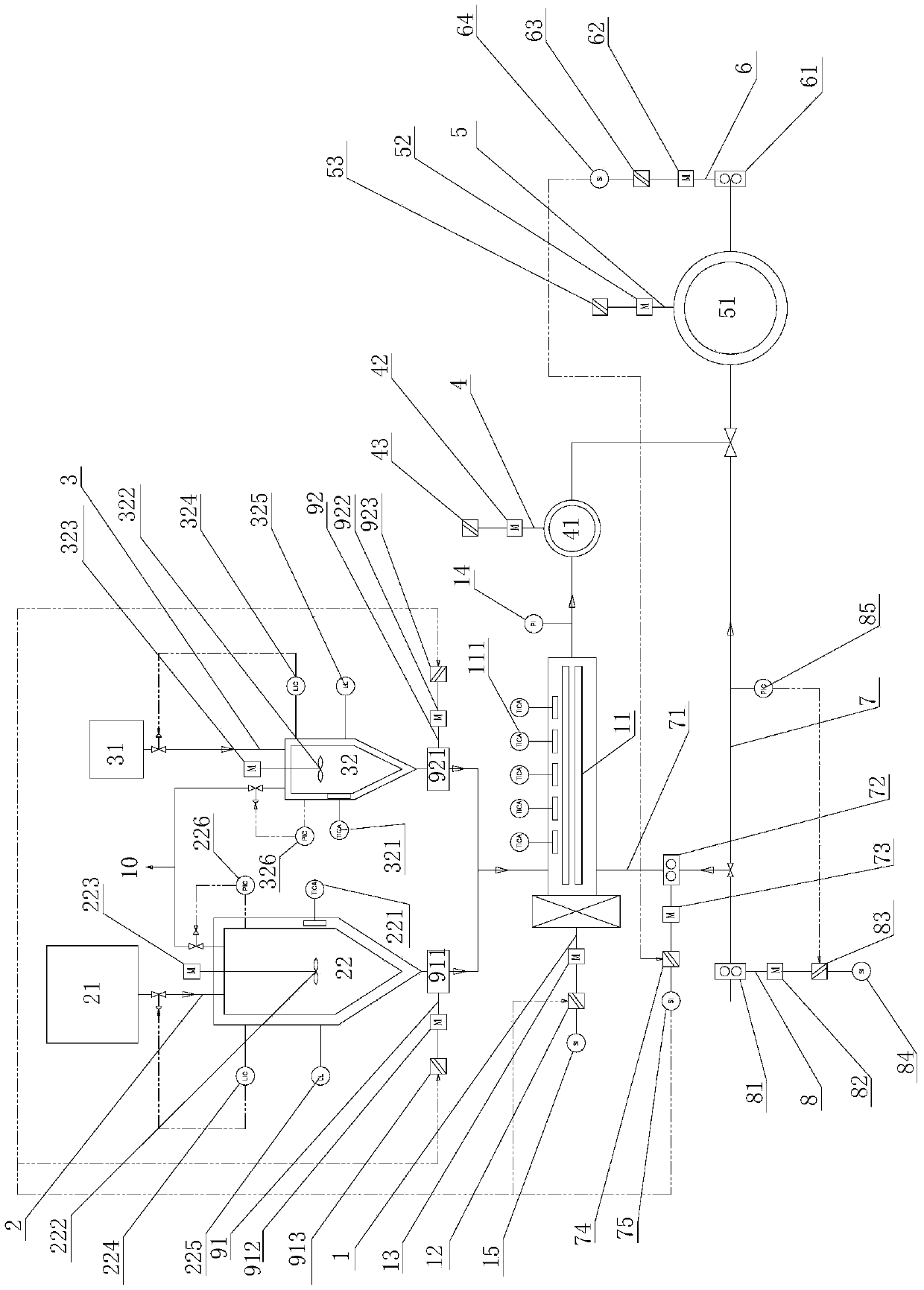

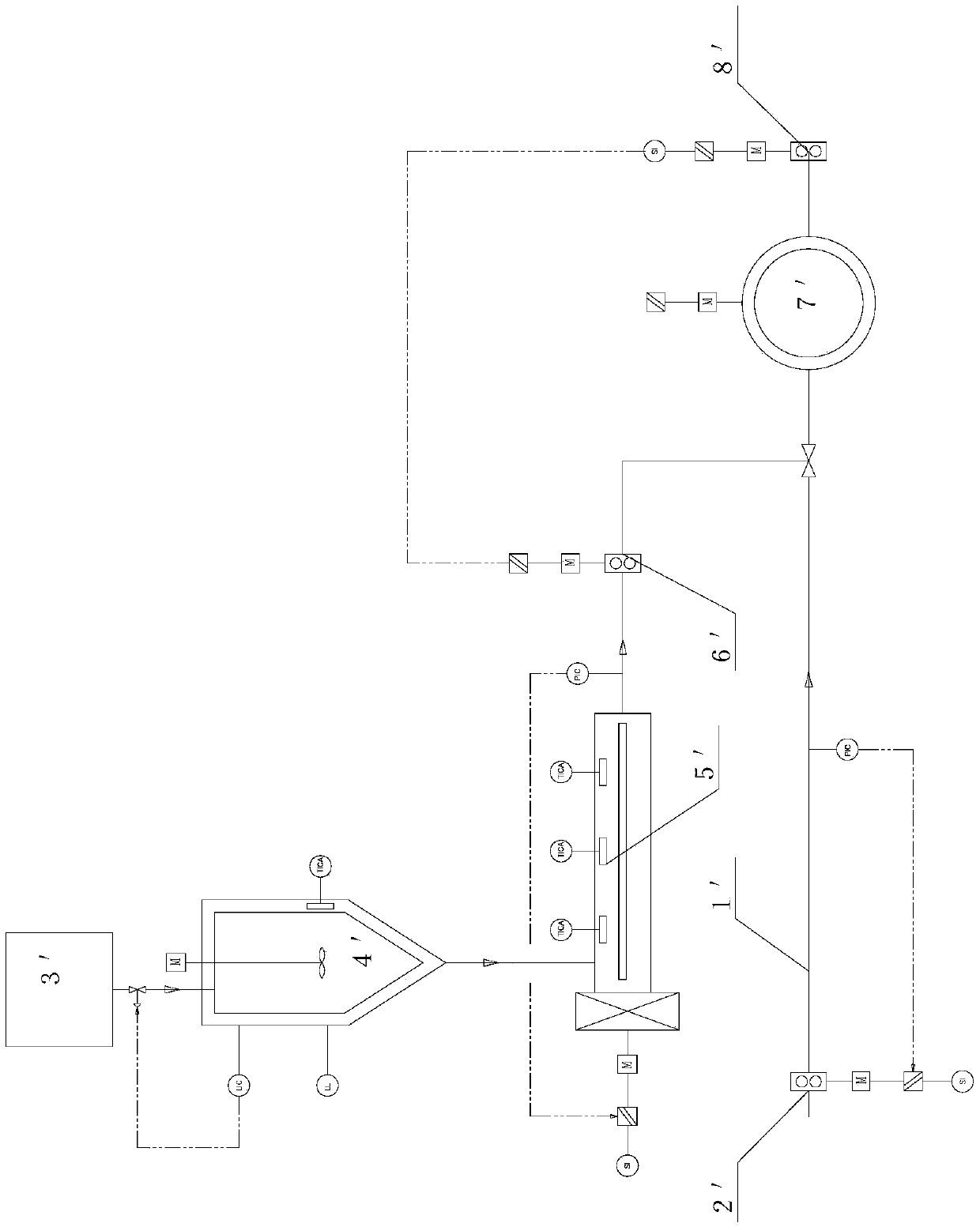

[0036] Example 2 The special equipment constructed by the method described in Example 1, including extruder assembly 1, auxiliary material bin assembly 2, dispersant bin assembly 3, ultrasonic dynamic mixing assembly 4, dynamic mixing assembly 5 , the spinning metering assembly 6 and the control box, the main melt pipeline 7 is connected to the discharge port of the discharge assembly 8, and the main melt pipeline 7 is connected with the extruder assembly through the branch melt pipeline 71 The first feeding port of 1 is communicated with the pipeline, the feeding port of the auxiliary material bin assembly 2 is configured with the first feeding assembly 91, and the feeding port of the dispersant bin assembly 3 is configured with the second feeding port. material assembly 92, and the discharge opening of the first feeding assembly 91 and the second feeding assembly 92 are all in communication with the second feed inlet pipeline of the extruder assembly 1, the extruder assembly ...

Embodiment 3

[0053] Example 3 Contrast of conventional masterbatch preparation and melt preparation masterbatch

[0054] 1. Cases of conventional masterbatch addition:

[0055] Black silk, output 48 tons / day:

[0056] Buy masterbatch (masterbatch concentration 30%), masterbatch viscosity 0.4dl / g, send into single-screw extruder after drying and melting, the screw extruder rotating speed controls outlet pressure. After metering, the masterbatch melt enters the main melt pipeline with an addition amount of 3% of the fiber, and is spun after being efficiently blended by a dynamic mixer, and the dynamic mixer speed is set at 35 rpm. The maintenance period is 3 months. The cost of black silk increases by 360 yuan / ton on the basis of white silk.

[0057] 2. Cases of direct addition of powder to prepare functional fibers:

[0058] Black silk, output 48 tons / day:

[0059] The melt with a viscosity of 0.62dl / g is introduced from the main melt pipeline, and the introduced melt is first metered by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com