Method for producing low-sulfur molten iron in one step by smelting and reducing copper slag

A technology for low-sulfur molten iron and copper slag, applied in the fields of resources and environment, can solve the problems of complex treatment process, high sulfur content in molten iron, low iron recovery rate, etc., and achieve the effects of short process flow, lower sulfur content and lower investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

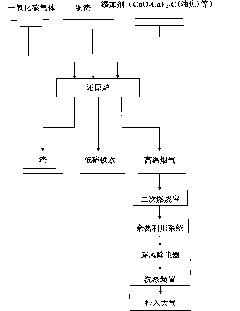

Image

Examples

Embodiment 1

[0034] When the iron reduction reaction in the molten copper slag in the reduction furnace is basically completed [the composition of the slag at this time is: CaO=33.708, SiO 2 =28.09, S=0.58, FeO=2.85 (mass percentage), molten pool temperature is 1630 ℃], the additive CaO-CaF 2 -C (oil coke) is ground to a particle size of about 0.6mm [CaO-CaF 2 -C (oil coke) is added in an amount to make the ternary alkalinity of the slag be 4.9, wherein CaF in the additive 2 The mass percent content of C (oil coke) is 9%, and the addition amount of C (oil coke) is 12% of the total mass of additive], joins in molten pool, and when it melts completely, injects carbon monoxide gas with spray gun deep molten pool to slag-iron interface place The reaction system is stirred to accelerate the desulfurization reaction, and the injection pressure of carbon monoxide gas is maintained at 1.2MPa. Under this condition, the carbon monoxide gas injection time is 30 minutes, and the spray gun is lifted ...

Embodiment 2

[0036] When the reduction reaction of iron in the molten copper slag in the reduction furnace is basically completed [at this time, the composition of the slag is: CaO=32.02, SiO 2 =29.39, S=0.62, FeO=2.74 (mass percentage), molten pool temperature is 1650 ℃], the additive CaO-CaF 2 Grind to a particle size of about 1mm (CaO-CaF 2 The amount added is to make the ternary alkalinity of the slag 5.2, and the CaF in the additive 2 The mass percentage content is 10%), put it into the molten pool, and when it is in a molten state, the spray gun is deep into the molten pool to spray carbon monoxide gas at the slag-iron interface to stir the reaction system, reduce the oxygen potential in the molten iron, and accelerate During the desulfurization reaction, the injection pressure of carbon monoxide gas was maintained at 1.32MPa. Under this condition, the carbon monoxide gas injection time is 35 minutes, and the spray gun is lifted out of the molten pool after the injection is stopped...

Embodiment 3

[0038] When the reduction reaction of iron in the molten copper slag in the reduction furnace is basically completed [at this time, the composition of the slag is: CaO=35.31, SiO 2 =26.34, S=0.54, FeO=2.73 (mass percentage), molten pool temperature is 1670 ℃], the additive CaO-BaO-CaF 2 Broken to a particle size of about 1.2mm (CaO-BaO-CaF 2 The amount of addition is enough to make the alkalinity of the slag 4.9, and the CaF in the additive 2 The mass percentage content of CaO and BaO is 10%, and the addition amount of CaO and BaO m CaO 、m BaO Satisfy the quality ratio ), into the molten pool, when it is in a molten state, the spray gun is deep into the molten pool to spray carbon monoxide gas at the slag-iron interface to stir the reaction system to accelerate the desulfurization reaction, and the injection pressure of carbon monoxide gas is maintained at 1.18MPa. Under this condition, the carbon monoxide gas injection time is 32 minutes, and the spray gun is lifted out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com