Patents

Literature

37results about How to "Control component" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

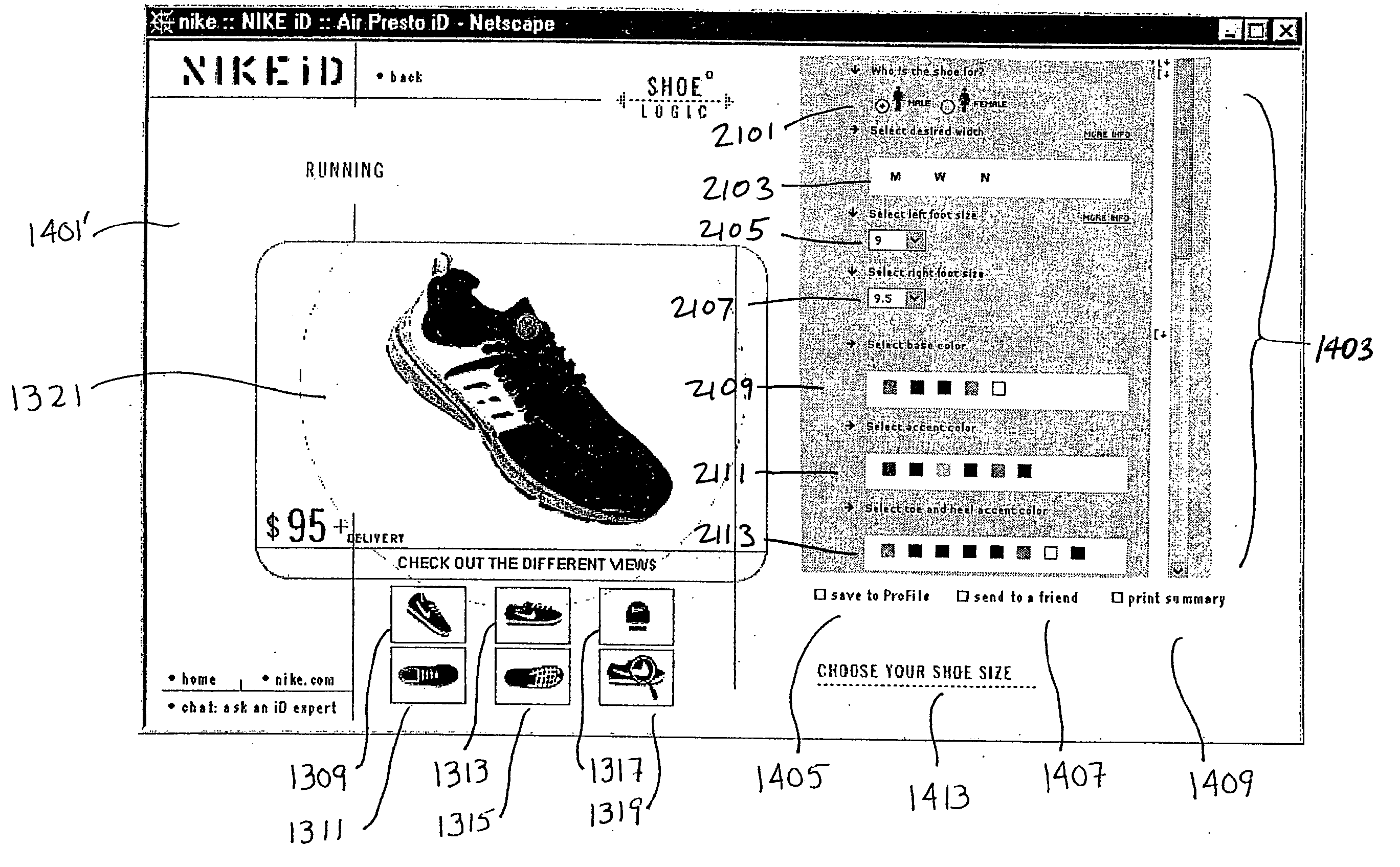

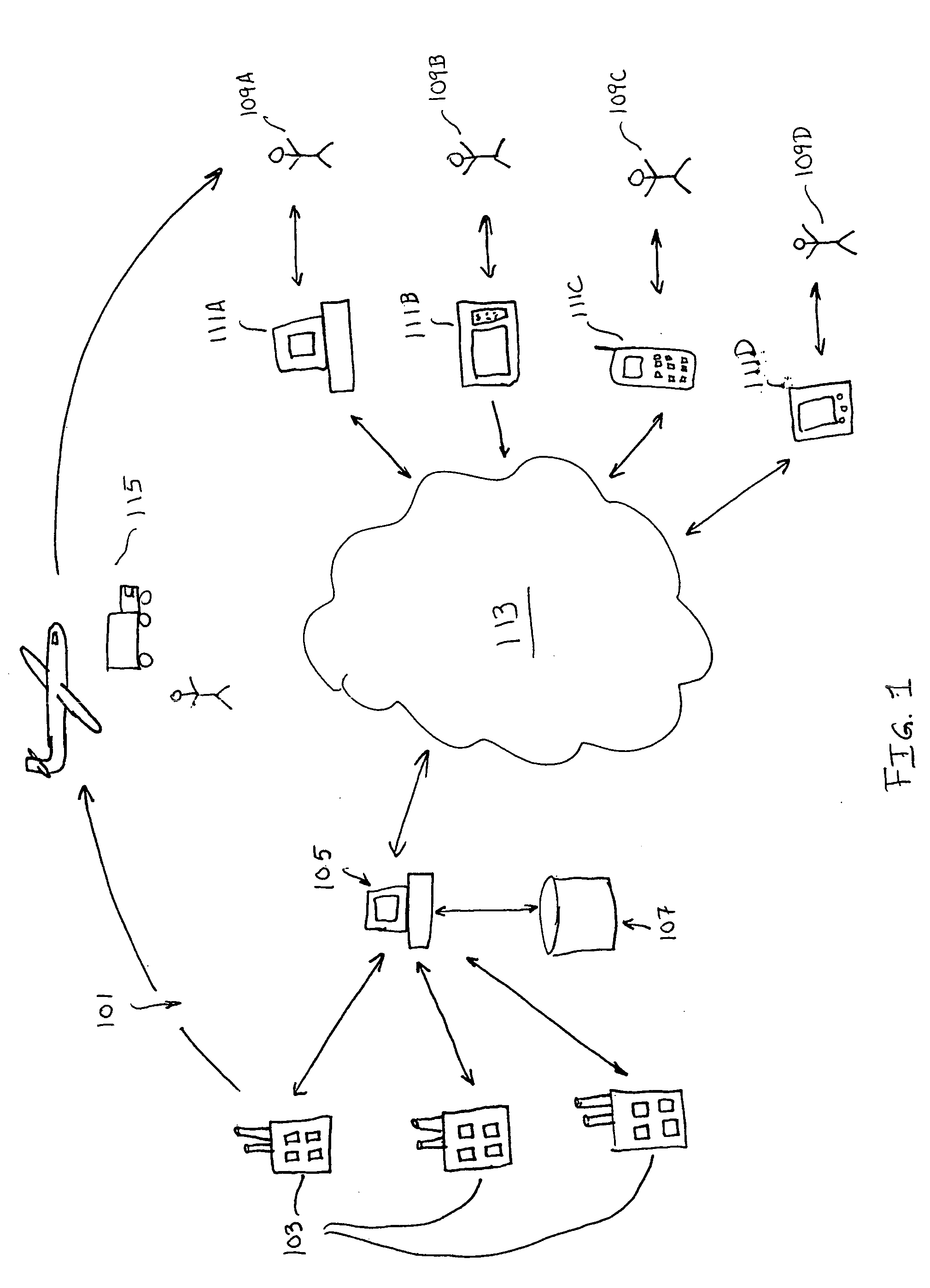

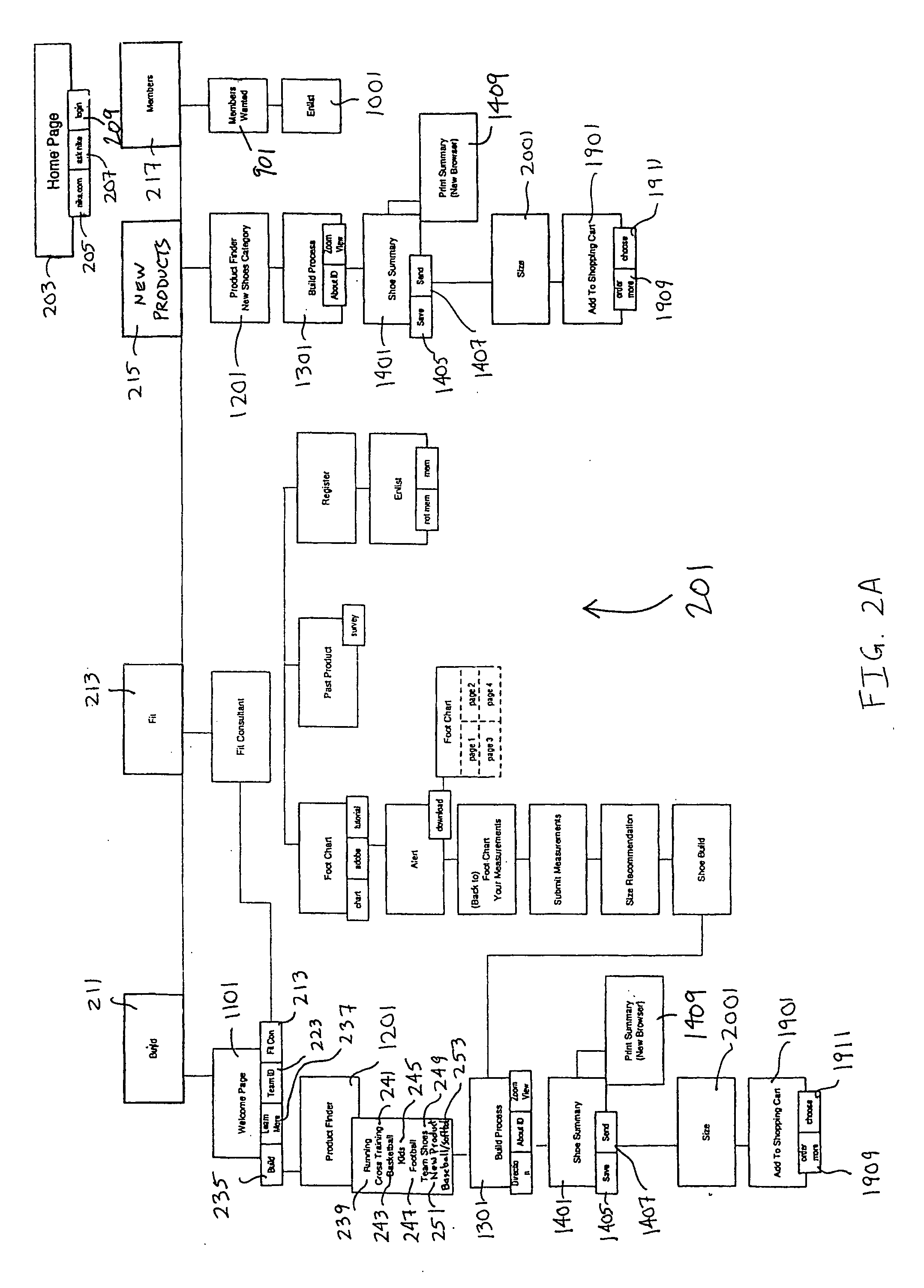

Method and system for custom-manufacturing footwear

A system and method for allowing a customer to custom-order footwear. The system and method may allow a retailer to control the selection of choices given to the customer for custom-manufacturing the footwear, including allowing a customer to order footwear with different sizes for their left and right feet.

Owner:NIKE INTERNATIONAL LTD

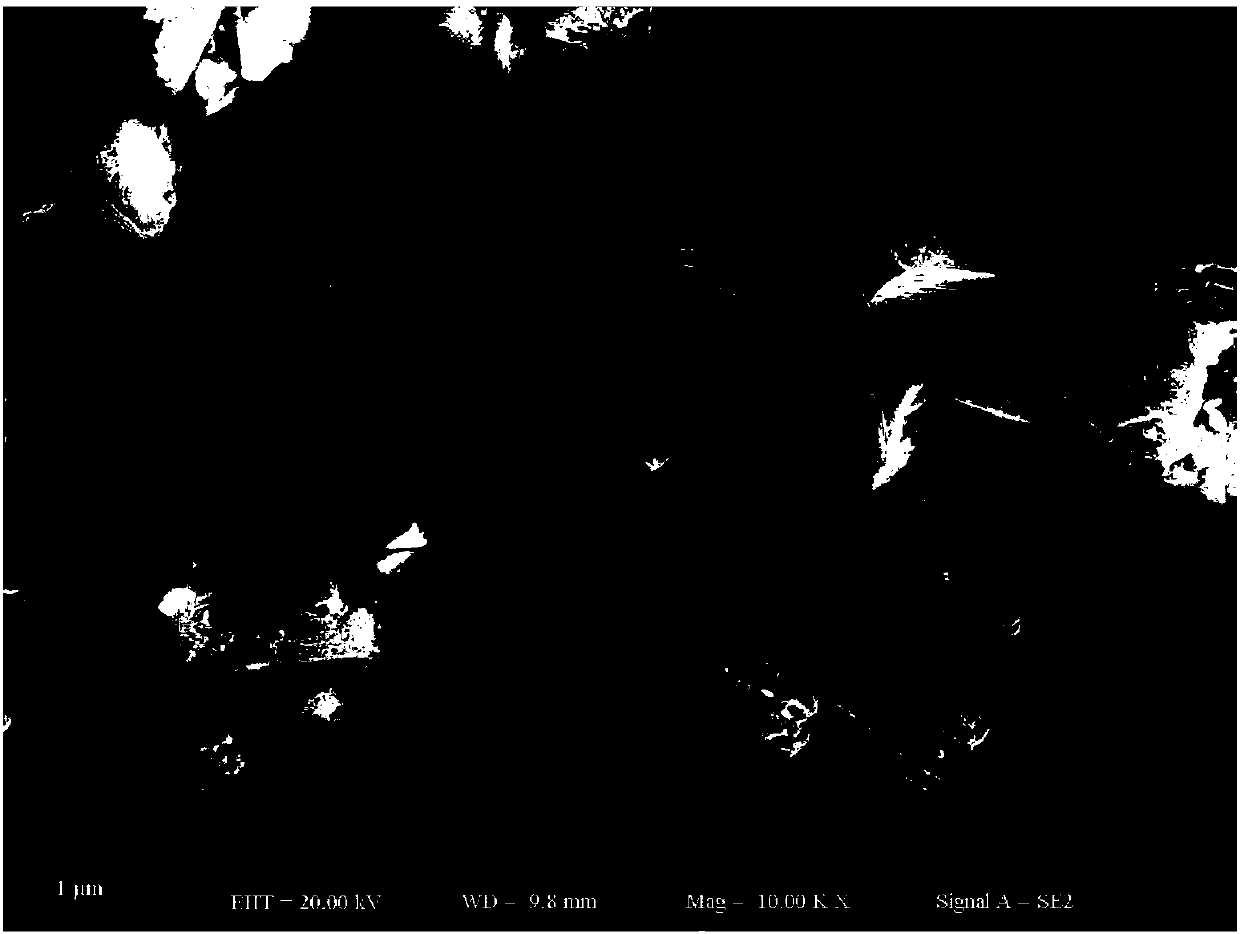

Preparation method of nano-particles with nano-grade porous structure

InactiveCN103406128AControl componentSimple methodMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsElectric arc furnaceOrganic solvent

The invention relates to a preparation method of nano-particles with a nano-grade porous structure. The method comprises the steps that: (1) metals A, M, and N with a certain ratio are smelted in an arc furnace, such that alloy AMN is obtained; (2) with smelting and band-manufacturing processes, the alloy AMN is prepared into a thin band; (3) the alloy AMN thin band is soaked in a corrosion liquid and is corroded for 1-48h, such that the active metal A is dissolved; (4) cleaned nano-grade porous metal N or nano-grade porous alloy MN is placed in an organic solvent; and ultrasonic processing is carried out for 1-1000min, such that the nano-particles with nano-grade porous structure is prepared. The method provided by the invention has the advantages that: (1) various metal components in the alloy can be well controlled; (2) the method is simple; and (3) large amount of the nano-particle sample with the nano-grade porous structure can be prepared, such that the method is suitable for large-scale productions.

Owner:SHANDONG UNIV

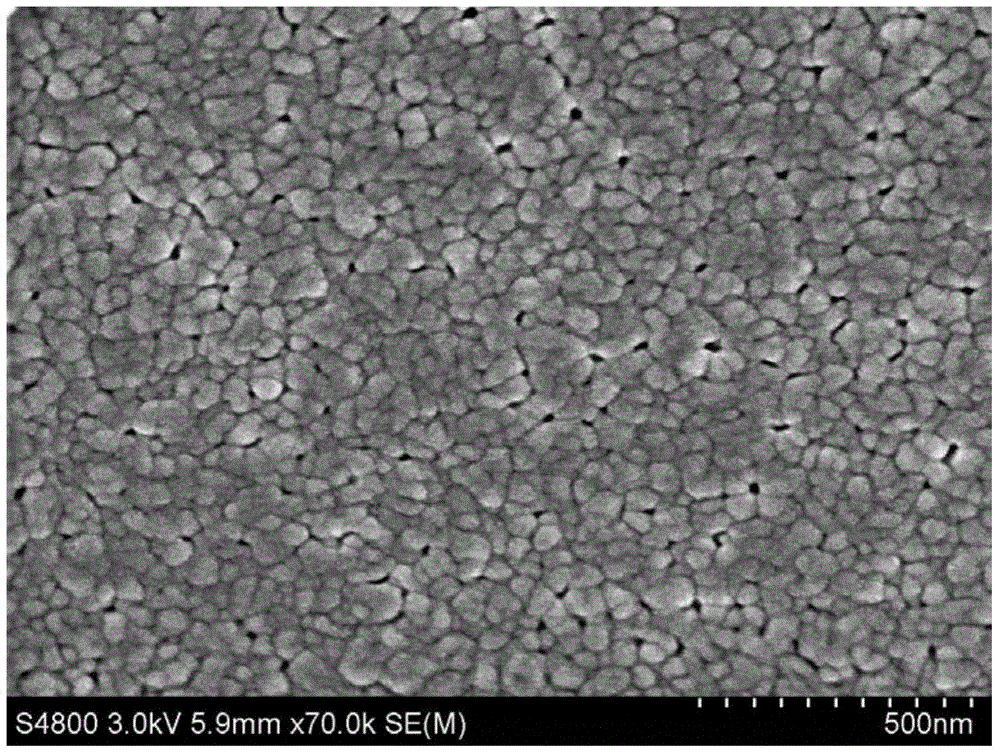

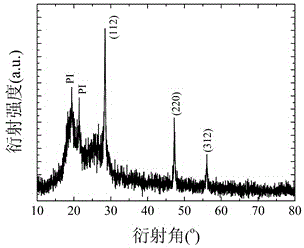

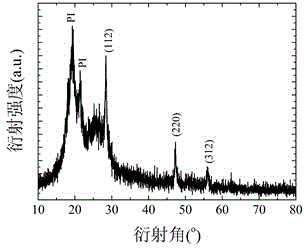

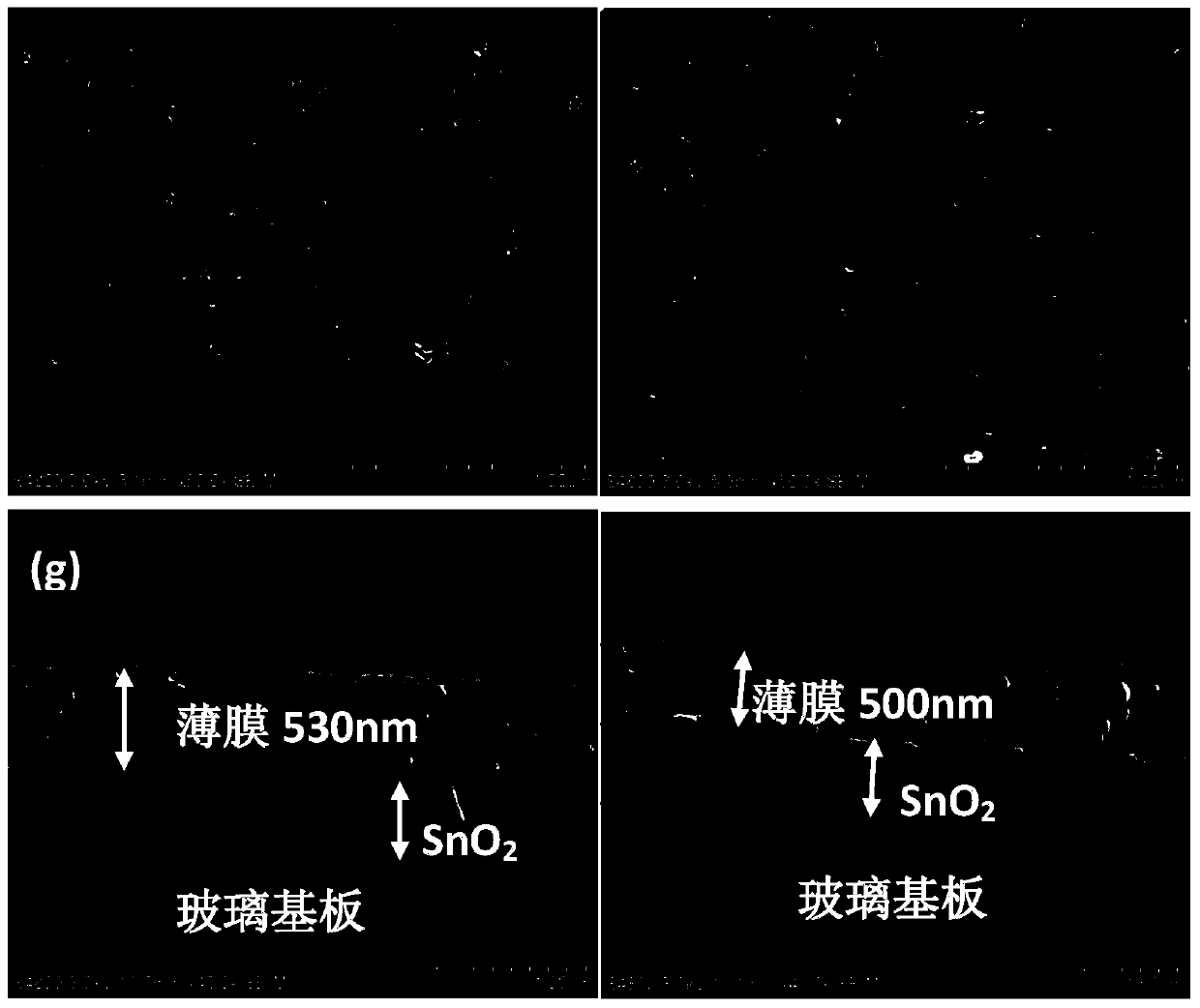

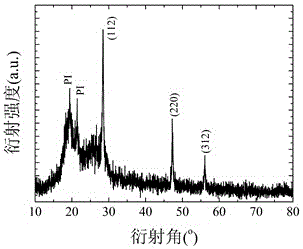

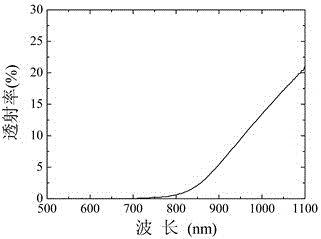

Preparation method of hybridization solar battery for perovskite-like sensitized photoanode

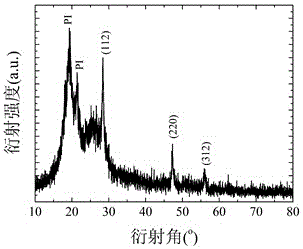

ActiveCN103440988AComponents are easy to controlEasy to control particle sizeLight-sensitive devicesSolid-state devicesSpectral responseIon exchange

The invention provides a preparation method of a hybridization solar battery for a perovskite-like sensitized photoanode. The preparation method includes the following steps that a thin film with a thickness of a submicron and made of wide bandgap semiconductor oxide nano materials is manufactured on a transparent conductive substrate at first, then at least one of lead halide PbC12 or PbBr2 or PbI2 is deposited in the thin film by means of an ion exchange method, and finally deposited lead halide reacts with organic halogenated ammonium salt through an impregnation method to generate organic and inorganic perovskite in the thin film in situ to obtain the perovskite-like sensitized photoanode. According to the preparation method, components, grain diameters, thicknesses and other key parameters of the organic and inorganic perovskite can be conveniently controlled, and thus spectral response wave bands and photoelectric performance of the organic and inorganic perovskite can be controlled.

Owner:HUAQIAO UNIVERSITY

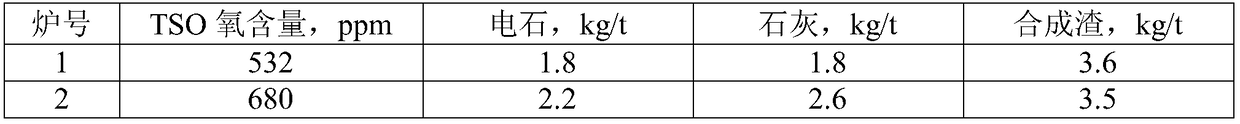

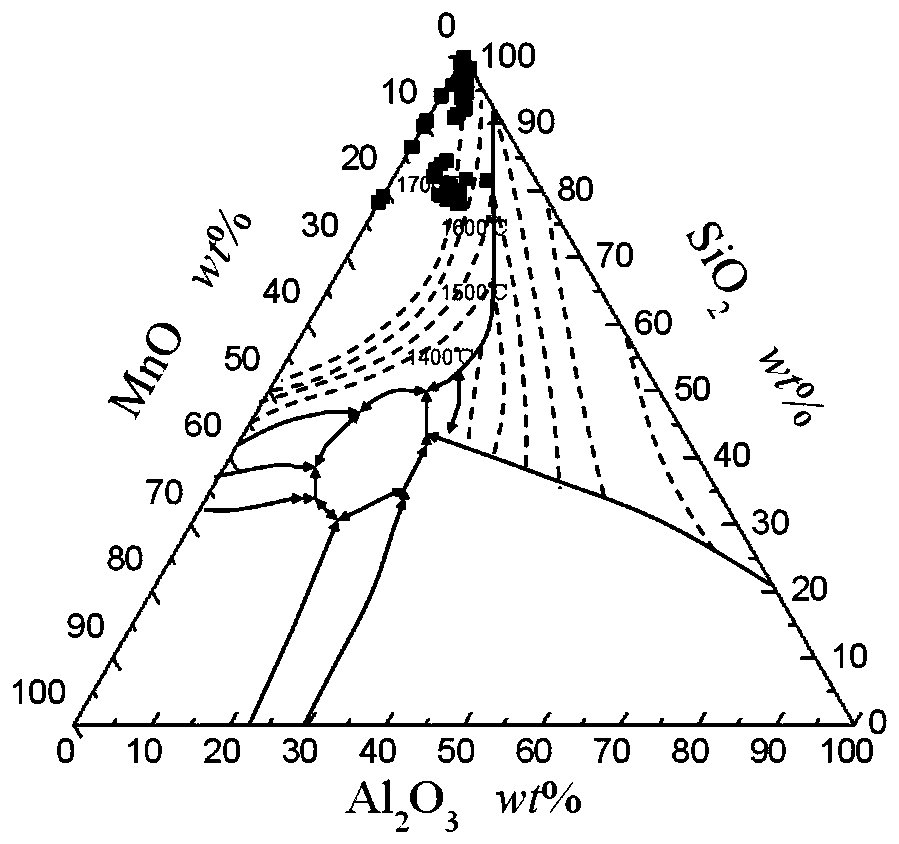

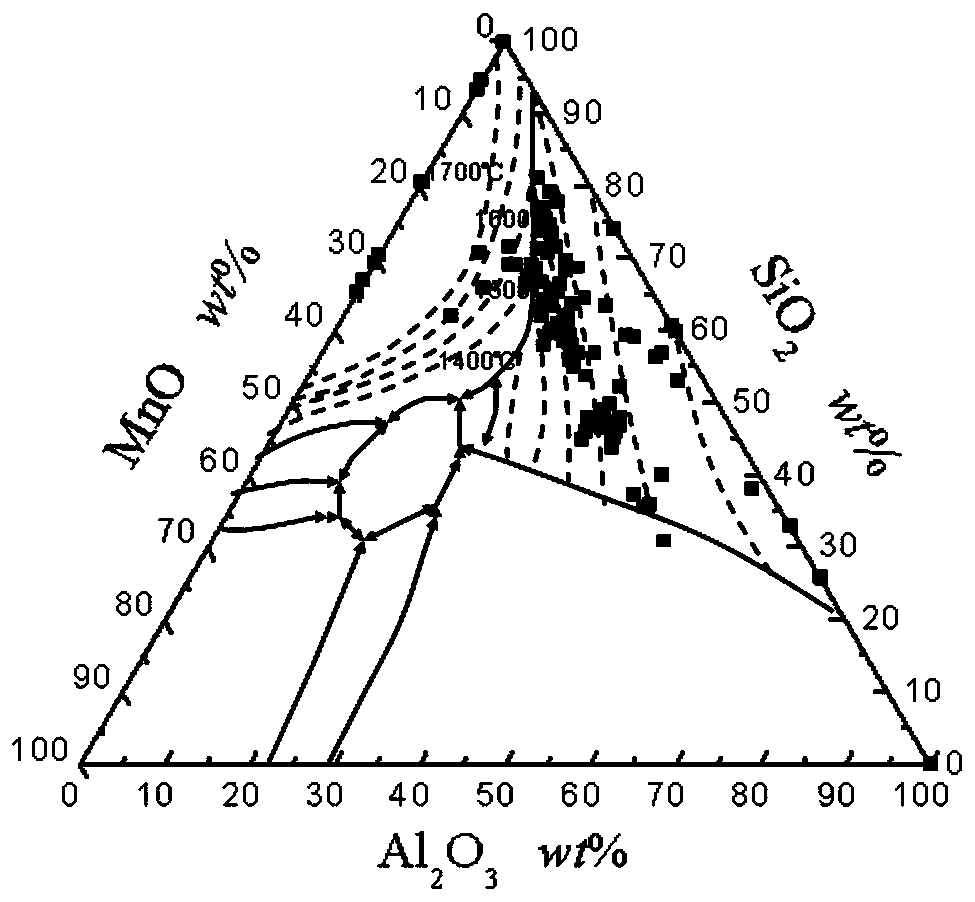

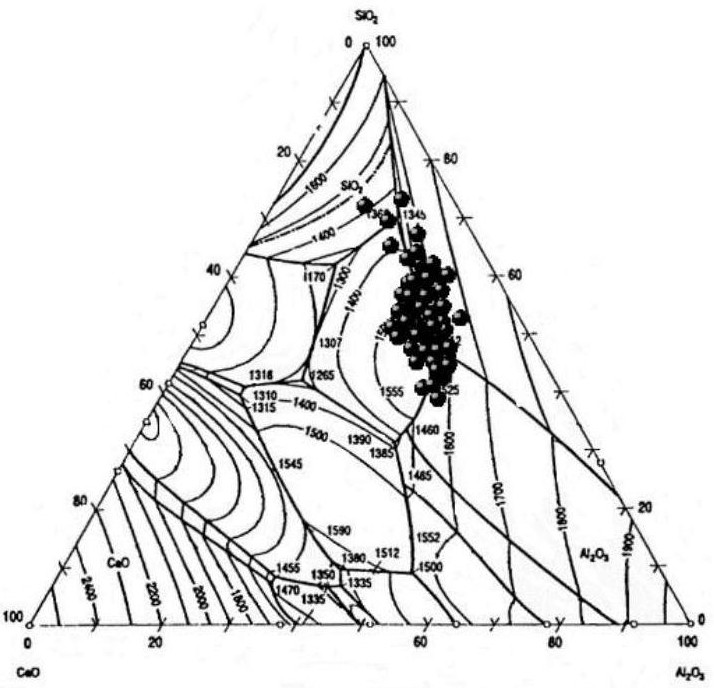

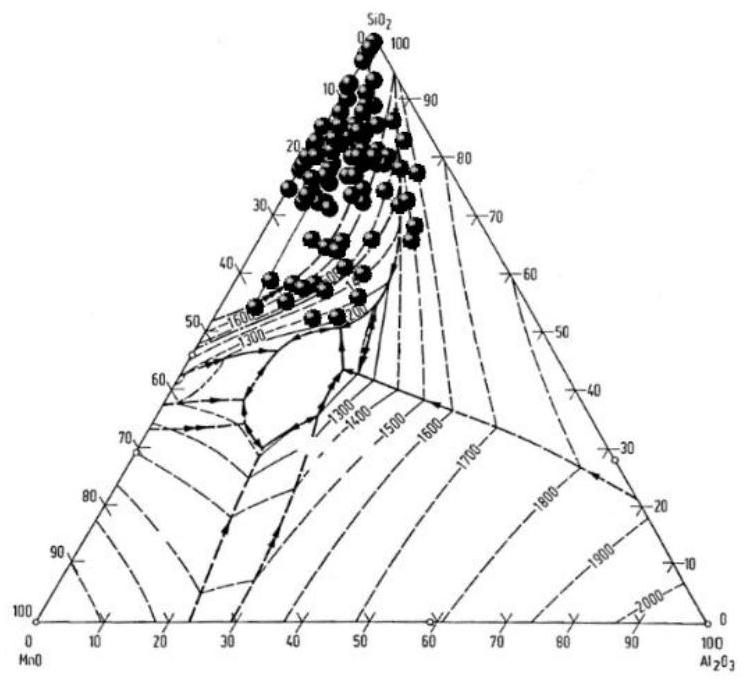

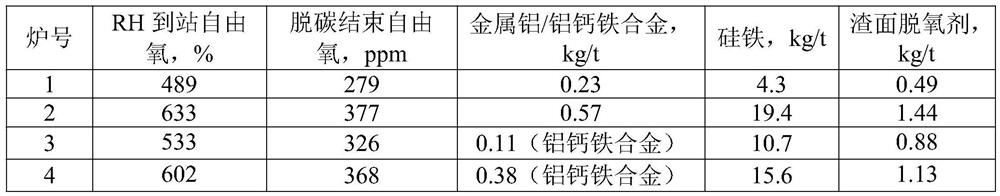

Inclusion control method of Si-Mn-killed non-oriented silicon steel

ActiveCN108660294AOxygen Potential StabilizationReduce oxidationProcess efficiency improvementMetallic aluminumNon-metallic inclusions

The invention provides an inclusion control method of an Si-Mn-killed non-oriented silicon steel, and belongs to the technical field of steel smelting. The non-oriented silicon steel comprises the following chemical components: not greater than 0.005% of C, 0.4-1.0% of Si, 0.20-0.80% of Mn, not greater than 0.04% of P, not greater than 0.005% of S, not greater than 0.005% of Als, and the balance Fe and inevitable impurities. The method comprises the processes of smelting through a converter, refining under RH and vacuum, and continuously casting; the slag amount of the steel from the converteris strictly controlled; lime, synthetic slag and calcium carbide are added to adjust the slag; the refining under HR and vacuum is that a deep decarbonization mode is carried out; after decarbonization, metallic aluminum is added to realize preliminary dexidation, and SiC is added to the ladle slag surface at the same time in order to deoxidize and modify the slag; the operation is circulated for1-3min; then low-carbon low-titanium ferrosilicon is added to realize Low carbon, low titanium ferrosilicon; the operation is circulated for 3-6min, then manganese metal, ferrophosphorus and the likeare added to alloy, and the net circulating time is beyond 8min after alloying. With the adoption of the method, the composition of nonmetal inclusions in the steel can be improved, so that the performances of the non-oriented silicon steel can be improved, and the foundation is supplied to develop high-performance non-oriented silicon steels.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

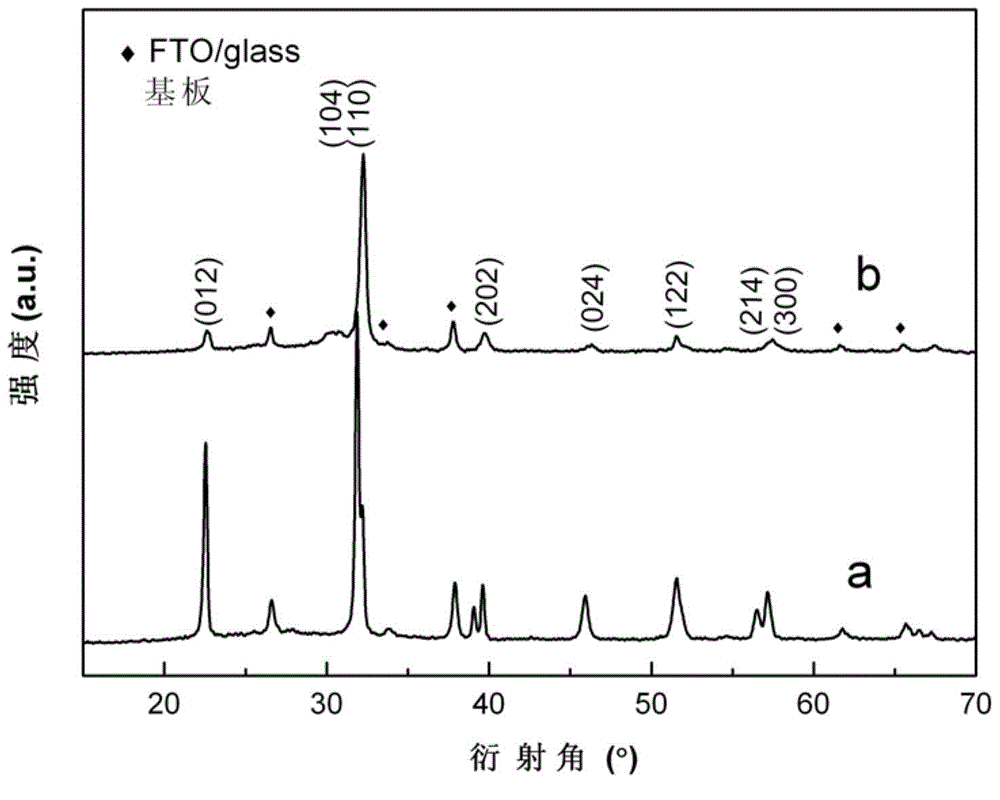

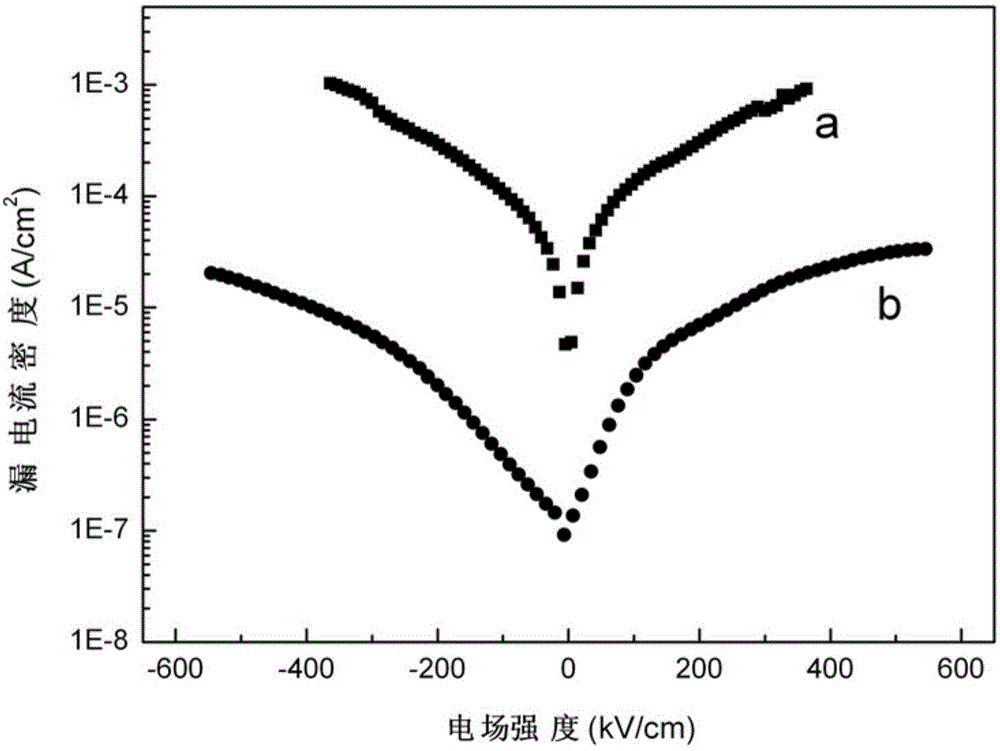

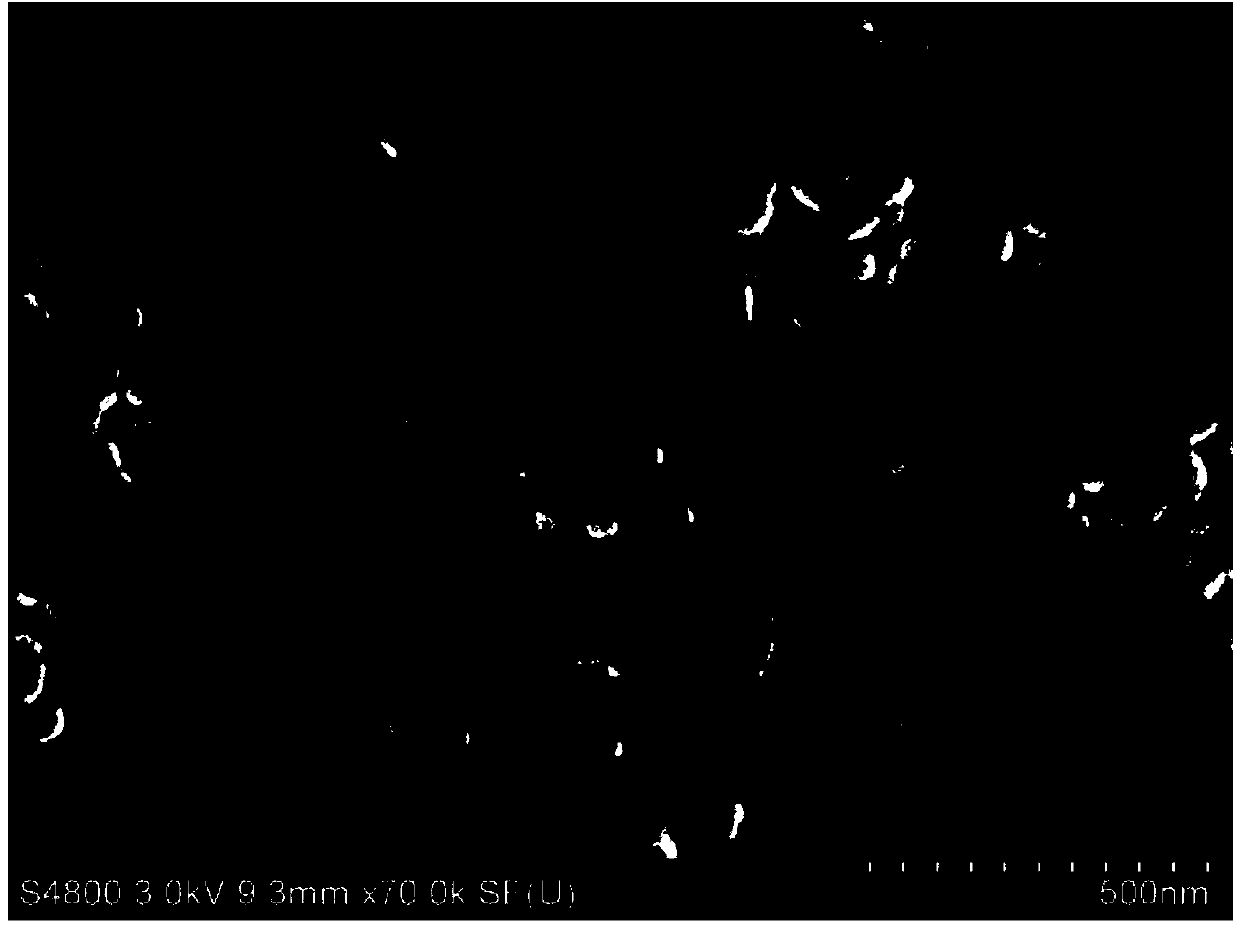

Layer-by-layer alternatively doped low-leakage-current BiFeO3 film and preparation method thereof

ActiveCN103601250AReduce generationImprove insulation performanceIron compoundsNitrateAcetic anhydride

The invention discloses a layer-by-layer alternatively doped low-leakage-current BiFeO3 film and a preparation method thereof. The preparation method comprises the steps of dissolving bismuth nitrate, ferric nitrate and nitric acid into mixed liquid of ethylene glycol monomethyl ether and acetic anhydride so as to obtain a precursor solution A; dissolving bismuth nitrate, ferric nitrate and samarium nitrate in mixed liquid of ethylene glycol monomethyl ether and acetic anhydride so as to obtain a precursor solution B; coating the precursor solution A on a FTO / glass substrate by way of spin coating, baking and annealing the FTO / glass substrate so as to obtain a Tb doped crystalline BiFeO3 film, coating the precursor solution B on the Tb doped crystalline BiFeO3 film by way of spin coating, baking and annealing the Tb doped crystalline BiFeO3 film so as to obtain a Sm doped crystalline BiFeO3 film, and alternatively preparing the Tb doped crystalline BiFeO3 film and the Sm doped crystalline BiFeO3 film on the Sm doped crystalline BiFeO3 film so as to obtain the layer-by-layer alternatively doped low-leakage-current BiFeO3 film. The method disclosed by the invention adopts a sol-gel process, and is simple in equipment requirements and suitable for preparing films on large surfaces and irregularly-shaped surfaces, and chemical components are precise and controllable.

Owner:盐城市鹤业实业投资有限公司

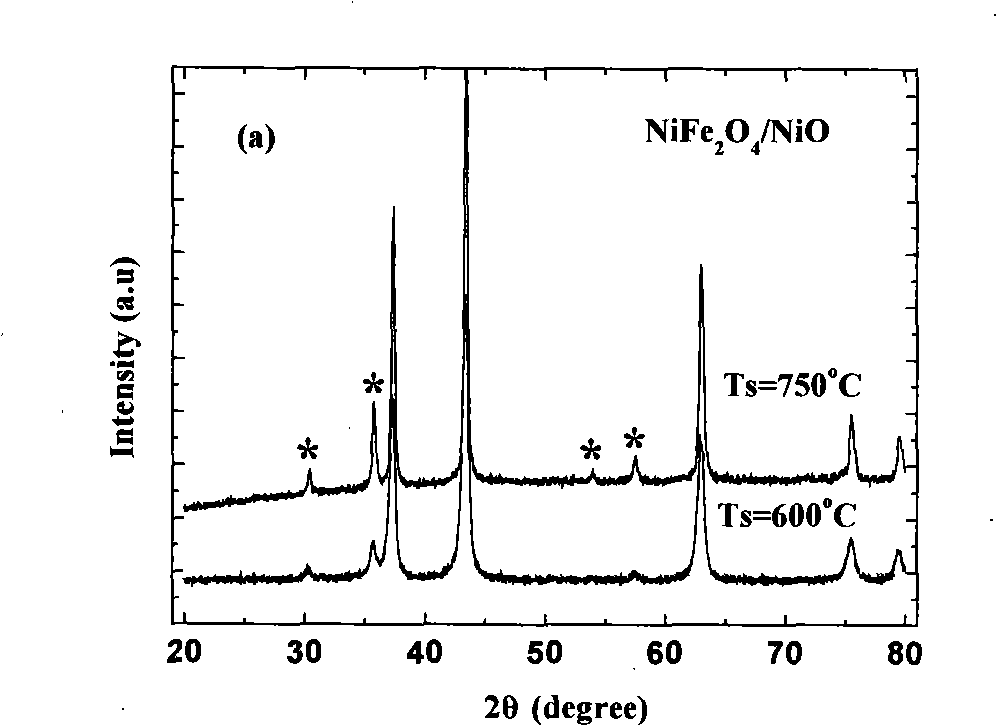

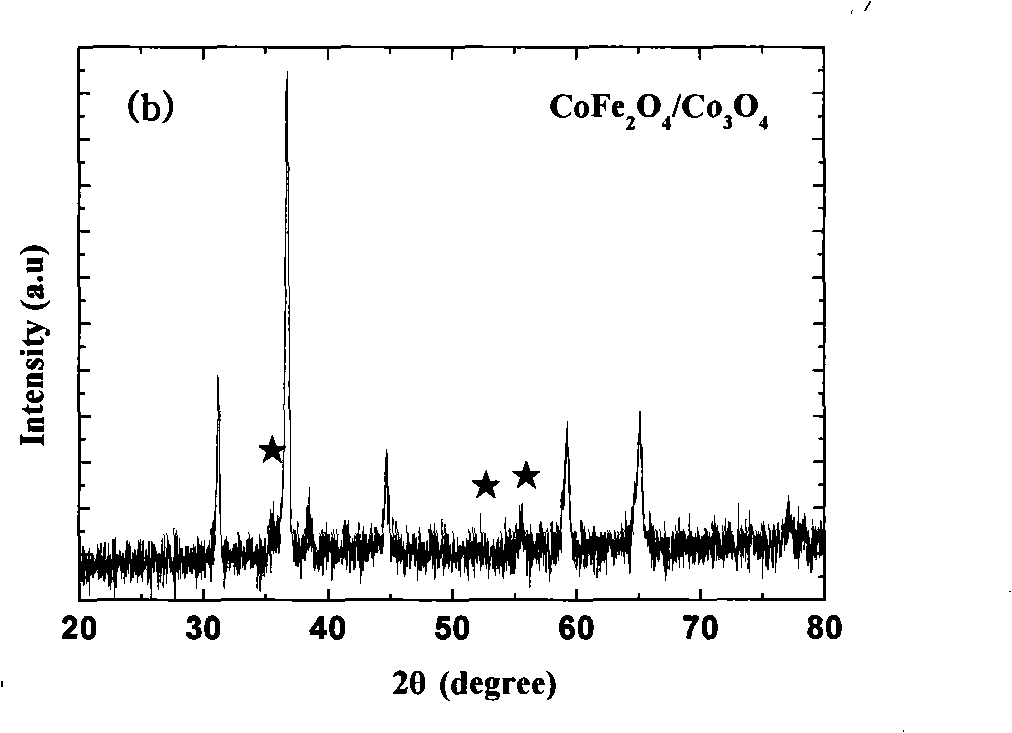

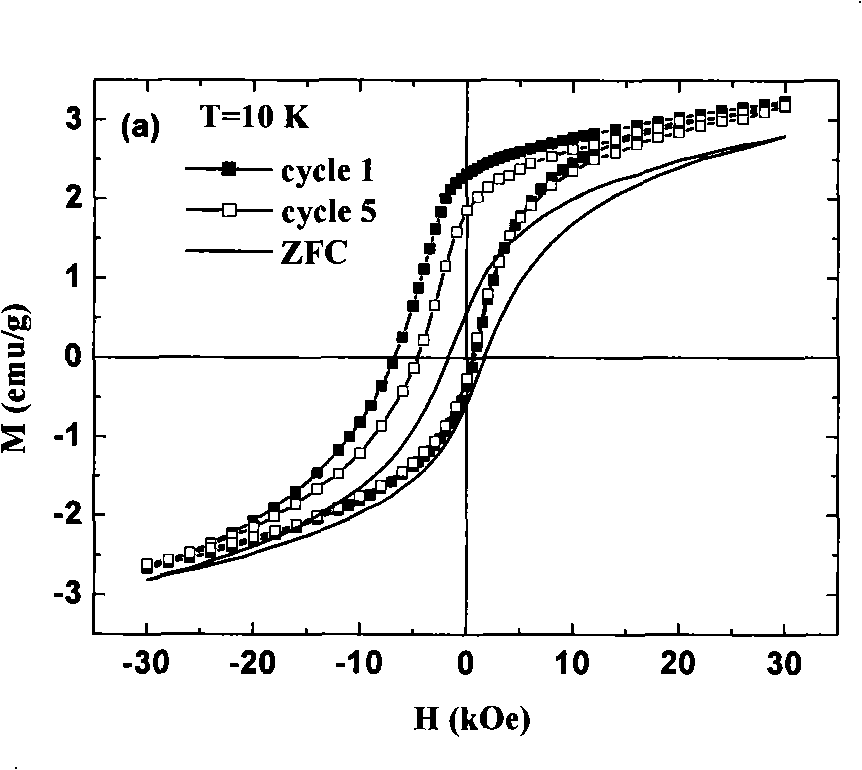

Ferrite nanometer particle embedded antiferromagnetic oxide matrix composite material and preparation method

InactiveCN101286396AControl componentControl stoichiometryInorganic material magnetismIonFerrite nanoparticles

The invention relates to a composite material used for embedding ferrite nanoparticles into antiferromagnetic oxide base and a preparation method thereof. The preparation method comprises the following steps: (1) mixing solution of metal ions is prepared; (2) ammonium hydrogencarbonate aqueous solution is added into the mixing solution of the metal ions so as to form sediment; (3) the obtained sediment is filtered, washed and dried until dry powder is obtained; (4) the obtained powder is sintered in the air at high temperature, thus forming the composite material used for embedding the ferrite nanoparticles into the antiferromagnetic oxide base. The composite material used for embedding the ferrite nanoparticles into the antiferromagnetic oxide base prepared by the method has magnetic exchange bias effect.

Owner:HUAZHONG UNIV OF SCI & TECH

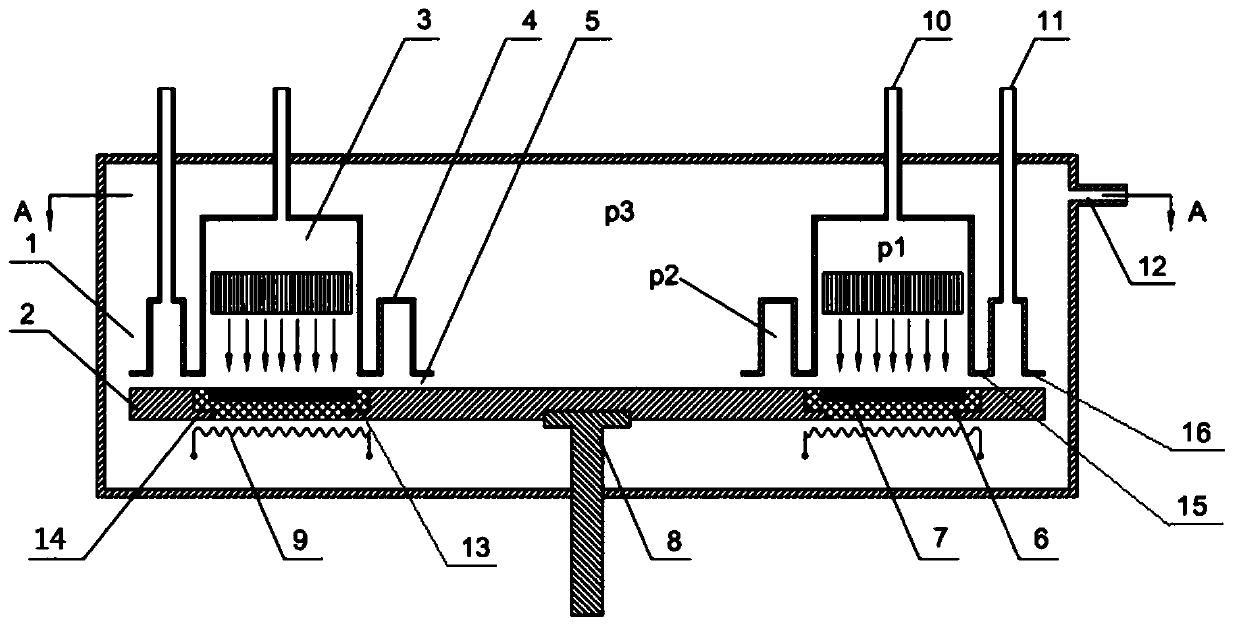

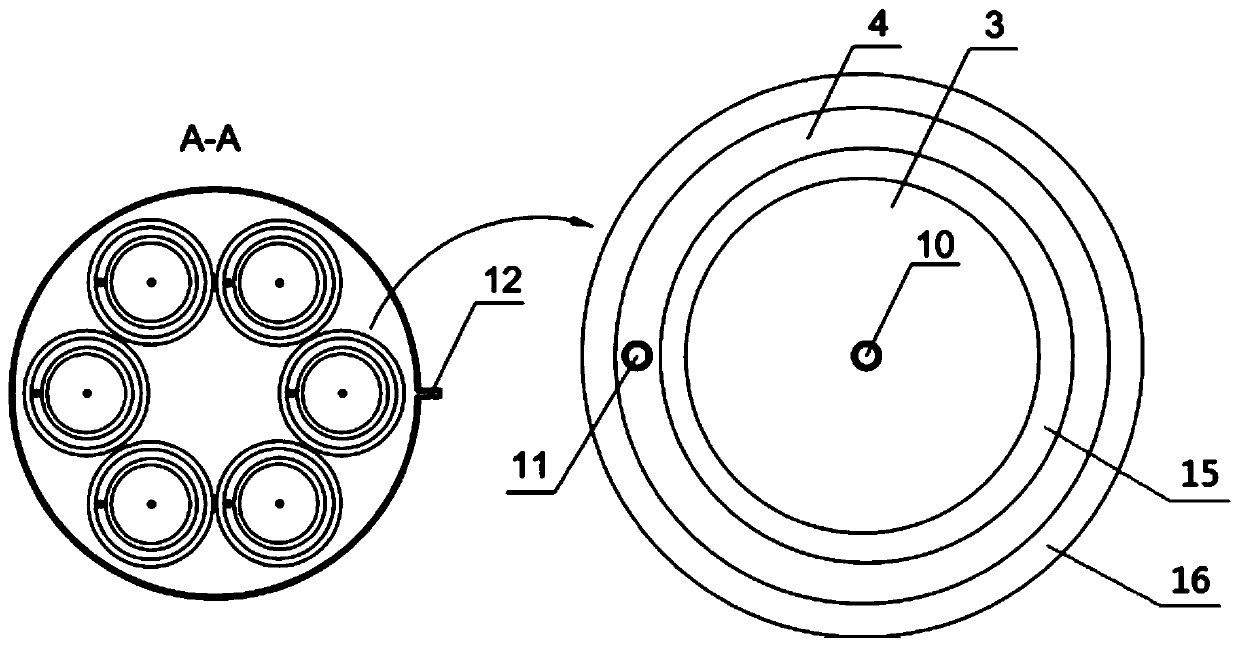

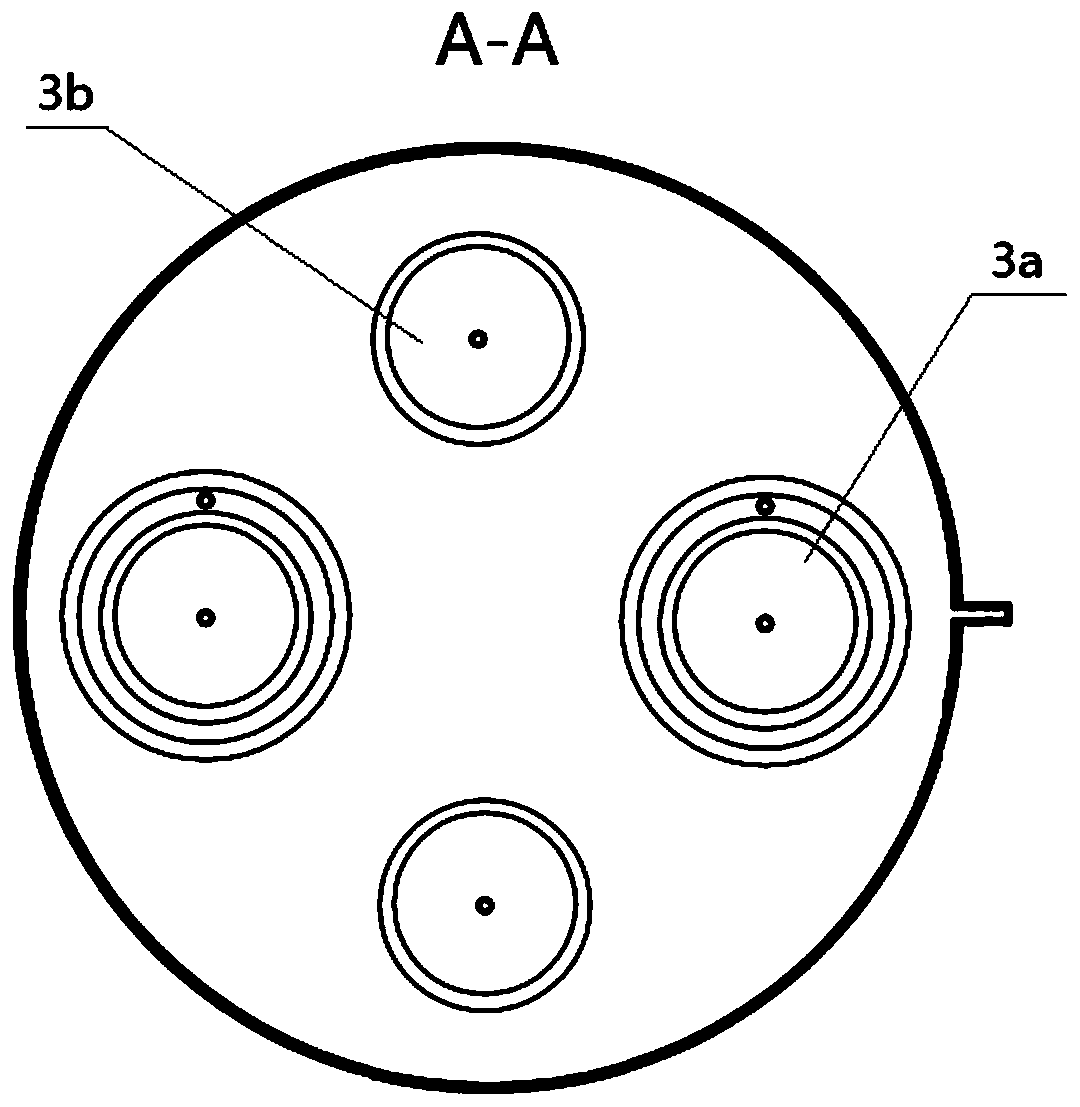

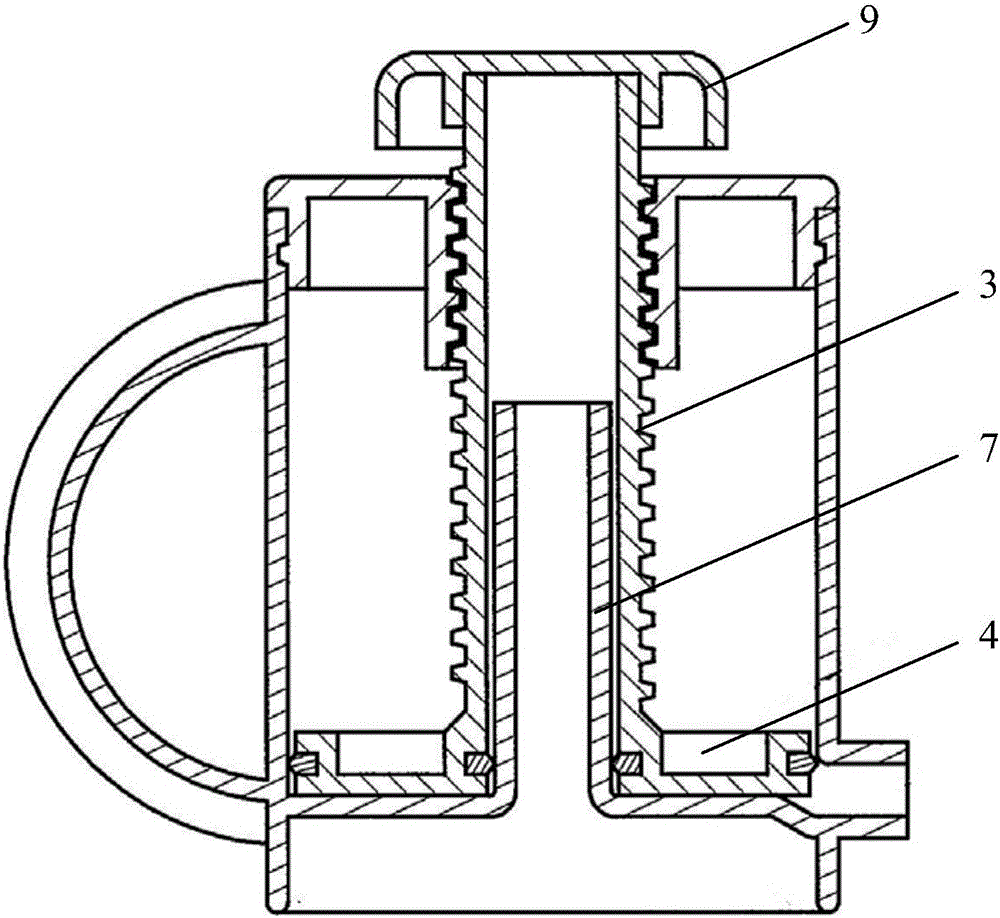

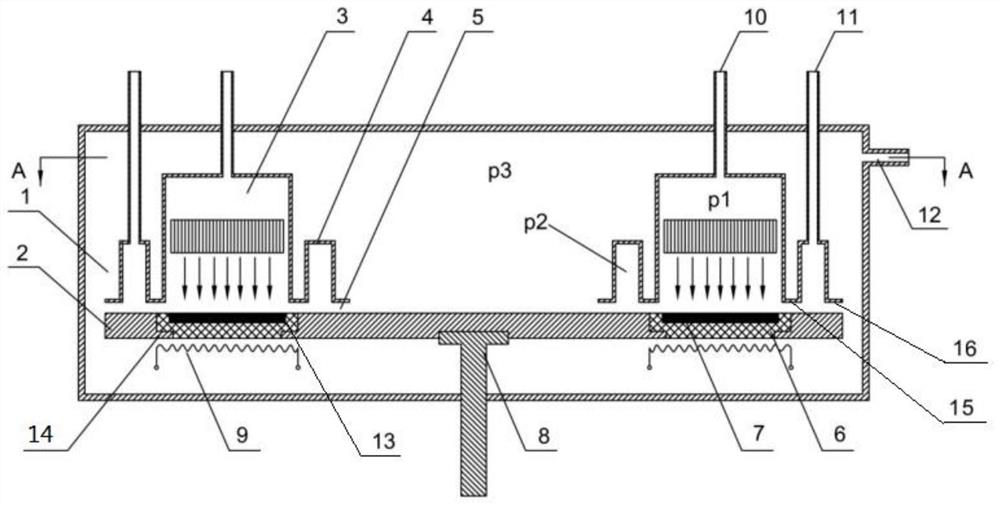

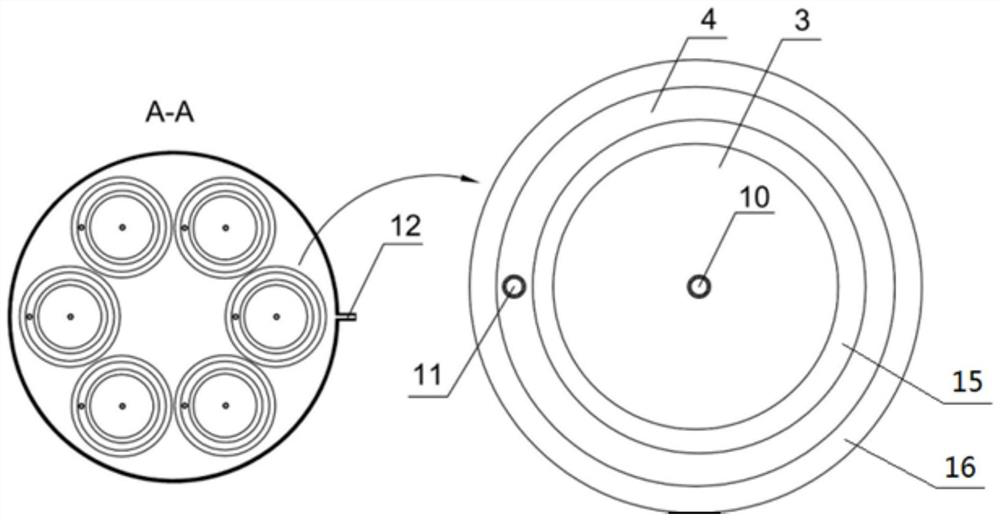

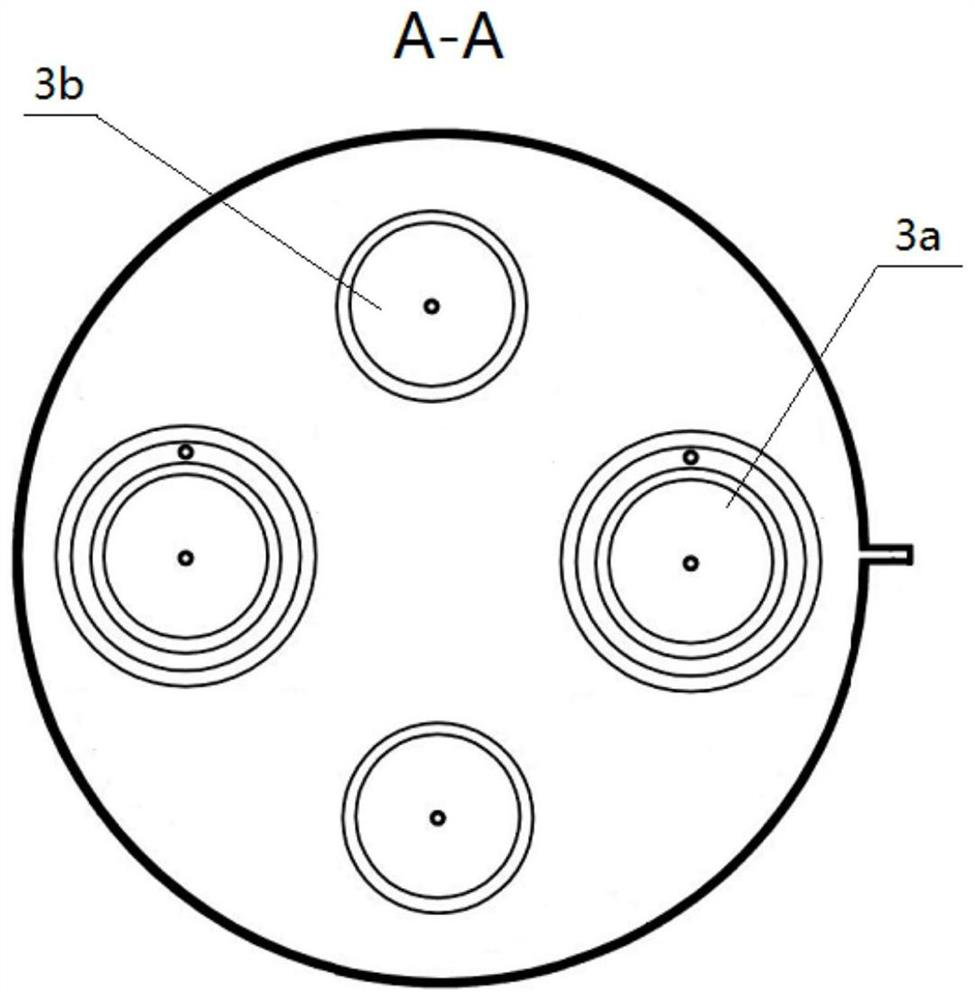

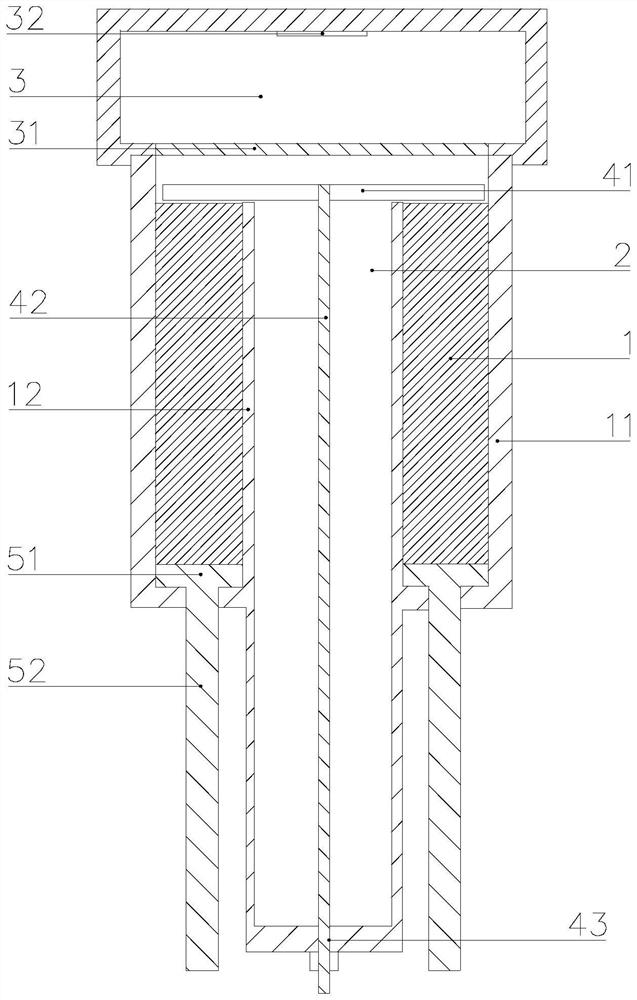

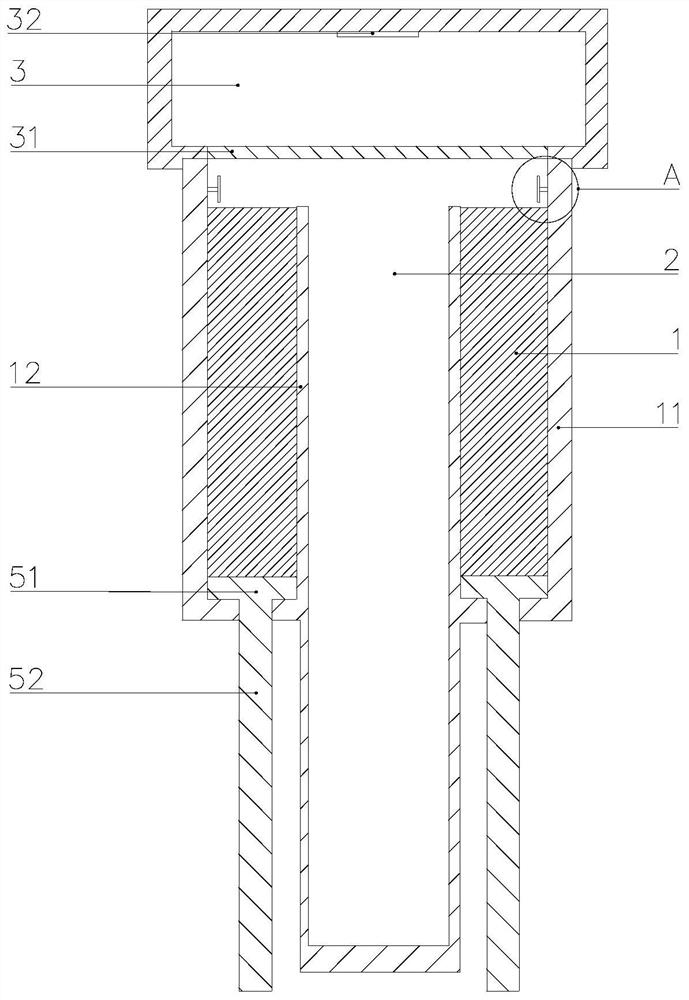

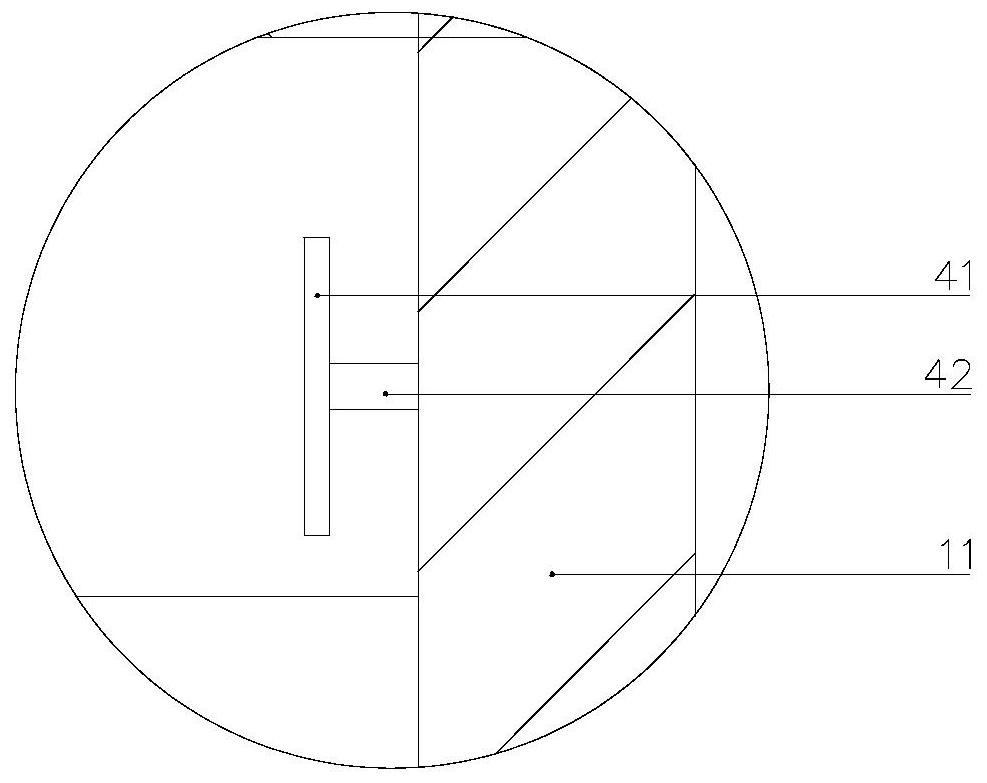

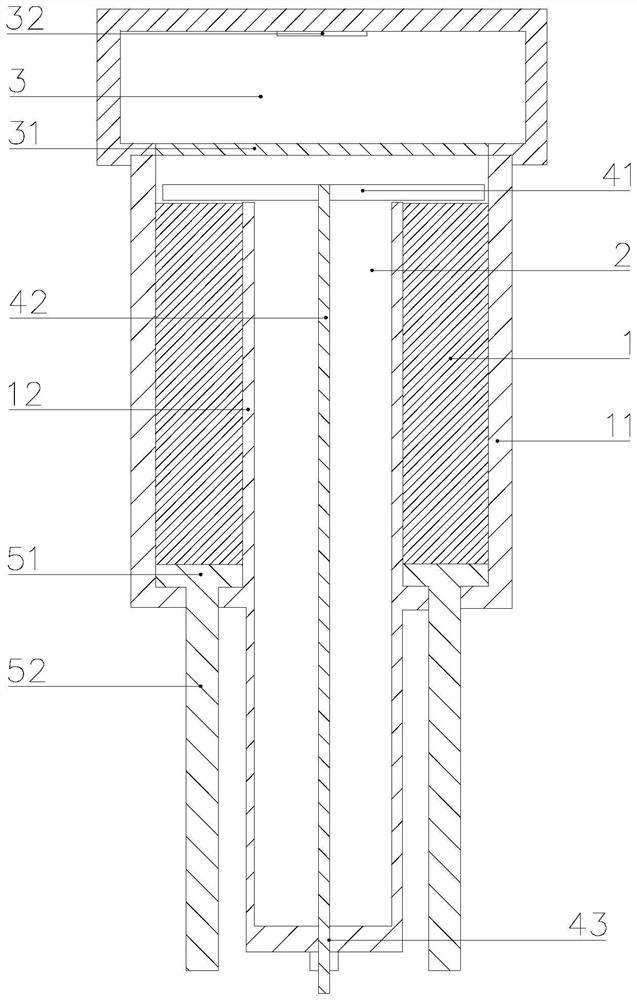

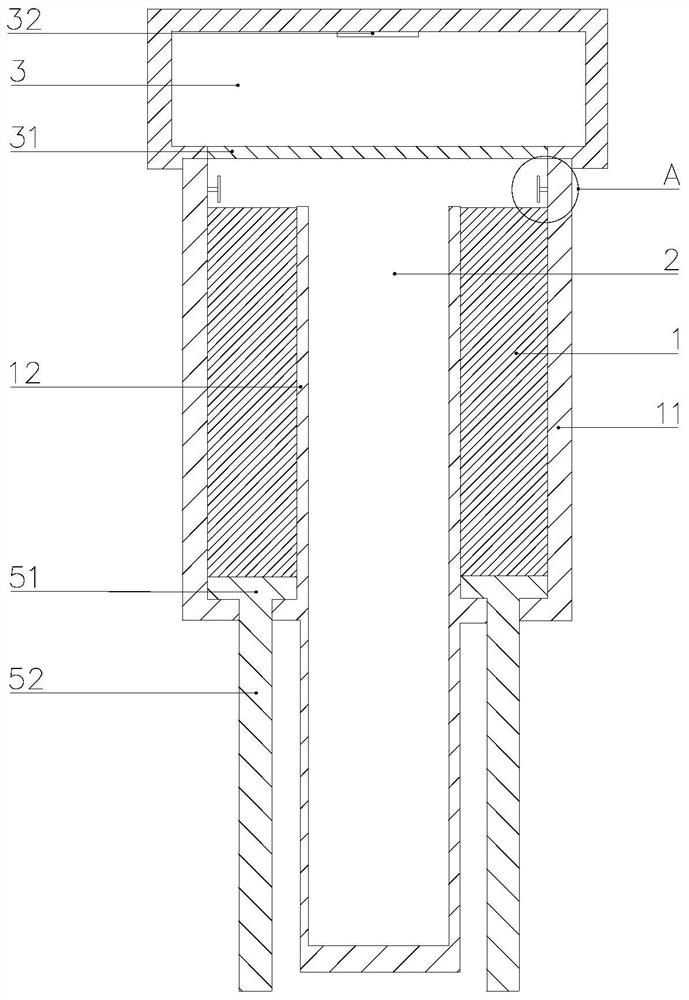

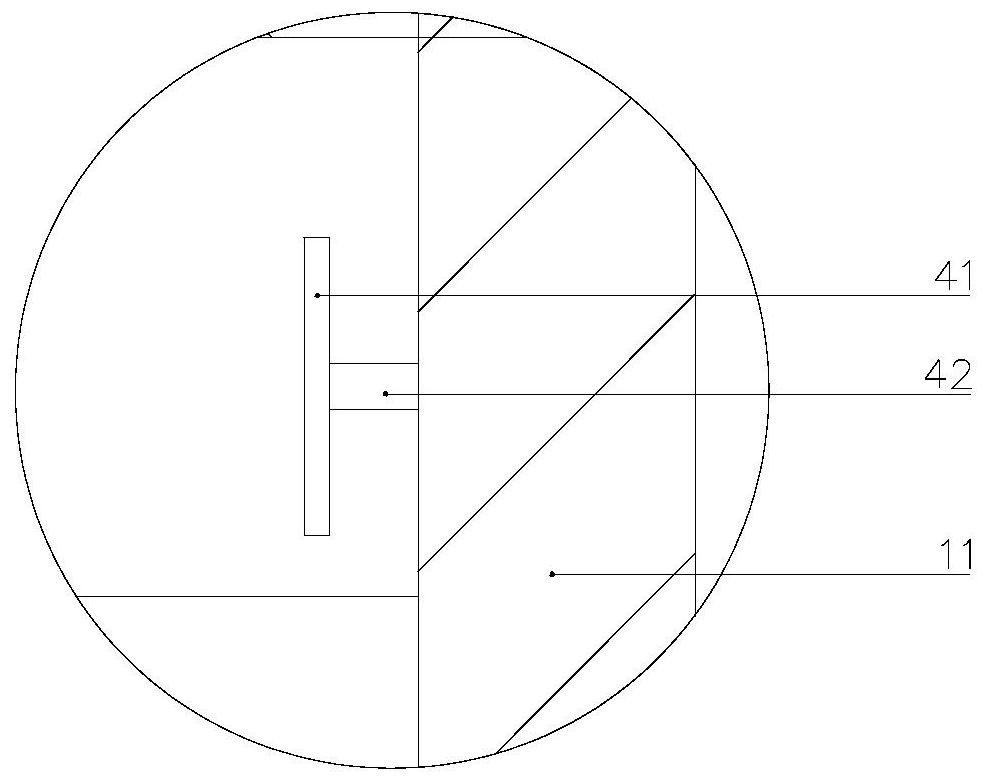

Chemical vapor deposition device and method

ActiveCN110438473AGuaranteed cleanlinessGuaranteed independenceChemical vapor deposition coatingGas phasePhysical chemistry

The invention provides a chemical vapor deposition device and method. The chemical vapor deposition device comprises an outer cavity body, a motion tray, inner cavity bodies, gas exhausting cavity bodies, tray grooves, chip bearing zones, heating devices, gas supply pipelines, first gas exhausting pipelines and a second gas exhausting pipeline; the same or different reaction precursor gases or inert gases are injected into the multiple independent inner cavity bodies, and through sealing of capillary gaps between the inner cavity bodies and the upper surface of the tray, the pressure intensityof the inner cavity bodies is always higher than that of the outer cavity body; and each inner cavity body is independently subjected gas feeding and gas exhausting, and independently heated and cooled; by controlling the motion tray to continuously rotate or rotate in an indexing mode, reaction precursors sprayed by nozzles in the different inner cavity bodies can be sprayed onto chips arrangedon the chip bearing zones on the upper surface of the motion tray by turns, and continuous chemical vapor deposition or periodic atomic layer deposition of a film is achieved. According to the chemical vapor deposition device and method, the different reaction precursors can be isolated, quick temperature raising, temperature lowering and gas switching are achieved, and the semiconductor film growing yield and productive rate are advantageously increased.

Owner:左然 +1

Preparation method of nano-fiber scaffold for promoting cartilage regeneration

InactiveCN107802888AImprove biological activityExtended release timeFilament/thread formingTissue regenerationFiberRelease time

The invention belongs to the field of tissue engineering, and discloses a preparation method of a nano-fiber scaffold for promoting cartilage regeneration to solve the problem that Nell-1 serving as anovel cartilage-derived growth factor can promote cartilage bone cell functions, but is easily inactivated in the process of being integrated into a tissue engineering cartilage scaffold. The preparation method includes the steps: firstly, preparing Nell-1 supported chitosan nano-particle solution and collagen / poly (L-lactic acid)-copolymer (epsilon-caprolactone) mixed solution; secondly, preparing a PLLA-CL / collagen nano-fiber mesh by coaxial electro-spinning and dynamic liquid collection technology; finally, preparing the collagen / HA mixed nano-fiber scaffold by collagen and hyaluronic acid(HA). The operation method is simple, the prepared nano-fiber scaffold is good in biological compatibility, biological activity of the growth factor can be protected, the release time of the growth factor is prolonged, and cartilage repair and regeneration can be promoted.

Owner:WUXI ZHONGKE GUANGYUAN BIOMATERIALS

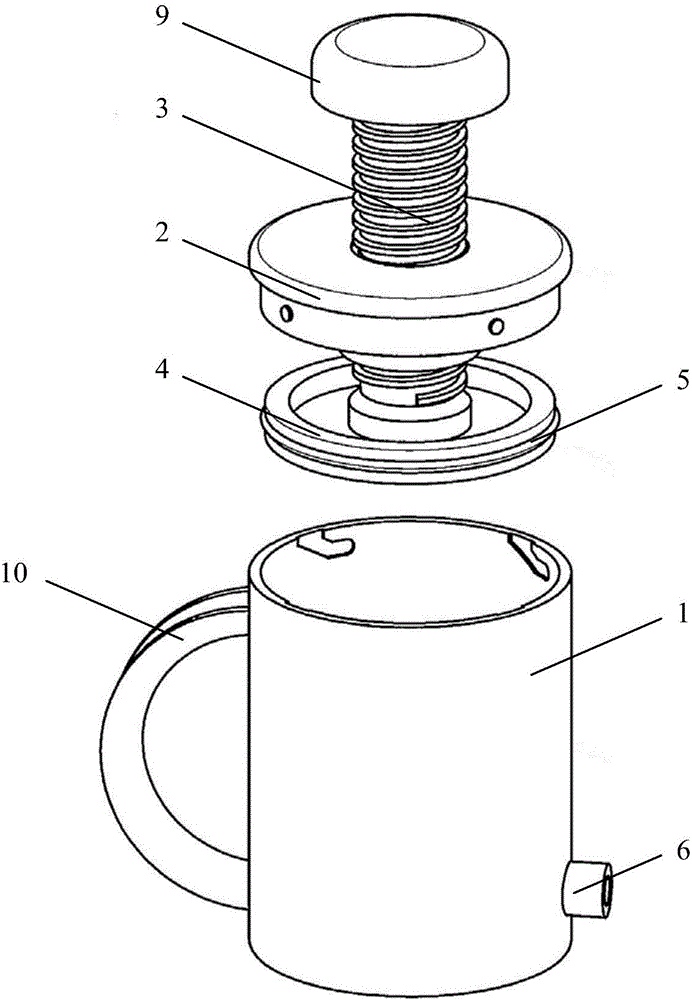

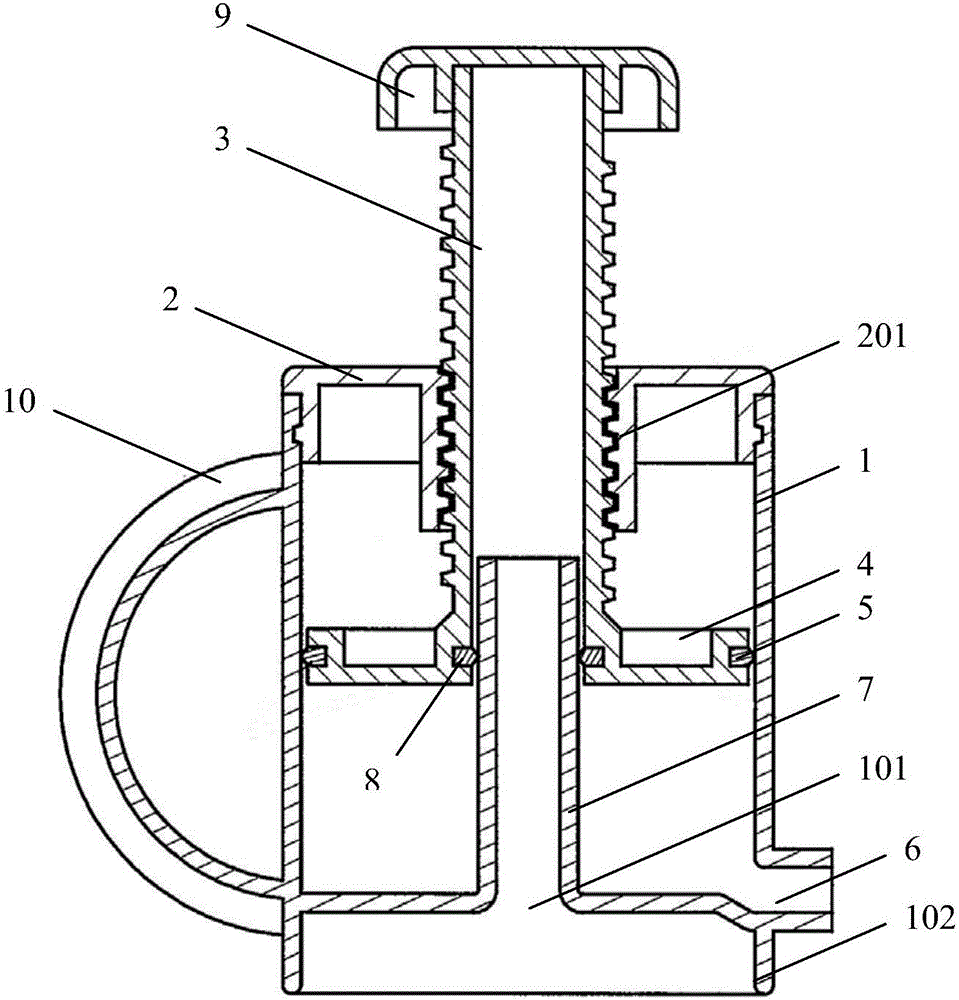

Stirring cup

The invention discloses a stirring cup, and belongs to food processing machinery. The stirring cup comprises a cup body, a cup lid, a rod body, a stirring body, an outer scraping ring and an outlet, wherein a flange hole is formed in the cup lid, and the cup lid covers the rim of the cup body; the rod body penetrates through the flange hole, and the stirring body is fixed at one end of the rod body and is arranged in the cup body; the outer scraping ring is arranged on outer wall of the stirring body in a sleeving manner and is attached to the inner wall of the cup body; and the outlet is formed in the side wall of the cup body, is close to the cup bottom, and is communicated with the inner cavity of the cup body. According to the stirring cup, the stirring body is driven by downward movement of the rod body and is used for extruding toward the cup bottom, and a stirred food is extruded to pass through the outlet in the cup bottom and delivered into a target container along with constant extrusion, so that the food in the stirring cup can be taken out easily, the food output speed and quantity can be conveniently controlled, the food taking process can be further clean, and food waste can be reduced.

Owner:DONGGUAN KIDSME IND LTD

Preparation method of beta-type bismuth oxide

ActiveCN107857300ASynthesis temperature is lowEffective size controlBismuth compoundsAlcoholPhosphate

The invention relates to a preparation method of beta-type bismuth oxide. The preparation method comprises the following steps of S1, preparing a bismuth nitrate solution; S2, adding polyacrylamide tothe bismuth nitrate solution in the step S1 and stirring evenly; S3, disposing an alkaline solution with a concentration of 2-4 mol / L, adding alcohol ether phosphate ester, stirring and mixing, mixing the alkaline solution and the solution obtained in the step S2 in an equal volume ratio, stirring evenly, and adjusting the pH to 8-13 to obtain a bismuth oxide precursor refluxing liquid; S4, performing boiling reflux on the bismuth oxide precursor refluxing liquid with an oil bath, performing water condensation reflux to obtain the product; S5, washing, drying and grinding the product to obtain beta-type bismuth oxide powders. The preparation method adopts a boiling reflux method to prepare bismuth oxide with a single crystal form, greatly reduces the synthesis temperature of the powders,achieves standardized production, can effectively control the size, composition and morphology of crystal grains, and obtains high-purity beta-type bismuth oxide.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

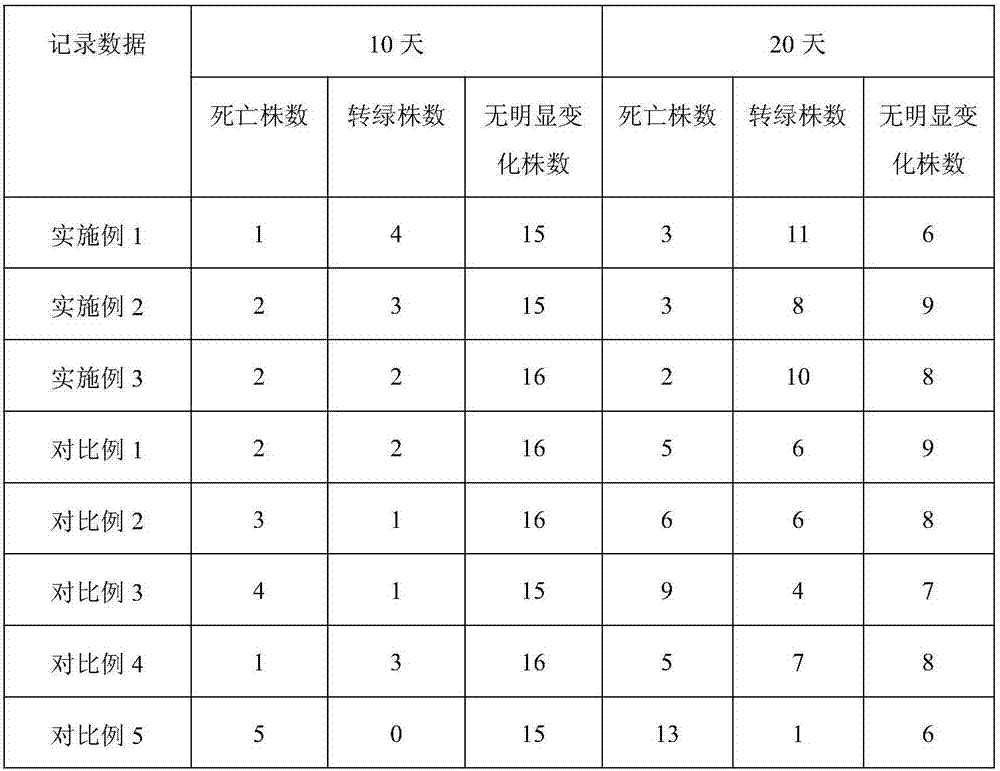

Special compound fertilizer for relieving citrus etiolation and preparation method thereof

InactiveCN107473861ASimple processSuitable for industrializationAlkali orthophosphate fertiliserExcrement fertilisersMicroorganismGeonoma congesta

The invention discloses a special compound fertilizer for relieving citrus etiolation and a preparation method thereof. The special compound fertilizer for relieving citrus etiolation is prepared from, by weight, 40-70 parts of organic fertilizer, 20-35 parts of plant ash, 10-25 parts of inorganic fertilizer, 0.1-0.5 part of rooting agent, 3-5 parts of humate and 2-5 parts of bacterial manure; the bacterial manure comprises bacillus mucilaginosus, trichoderma harzianum and saccharomycetes; the compound fertilizer can provide various nutrient elements required by the growth of citrus and can also improve the soil environment, reproduction of harmful bacteria is inhibited, the growth of beneficial bacteria is promoted, the compound fertilizer helps diseased or infected plants to absorb the nutrient elements, then citrus etiolation diseases are relived, and the recovery of the citrus diseased or infected plants is promoted.

Owner:FOUR FRIENDS OF CHENGDU CHEM IND

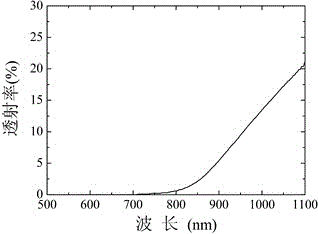

Method for preparing copper zinc tin sulfide thin film on flexible substrate through magnetron sputtering method

ActiveCN103985783AControl componentComponents are easily adjustedFinal product manufactureSemiconductor devicesSputteringZinc

The invention discloses a method for preparing a copper zinc tin sulfide thin film on a flexible substrate through a magnetron sputtering method. According to the method, magnetron sputtering is conducted on a metal Cu-Zn-Sn precursor on a flexible substrate material first, and then a sulfidizing method is used for preparing the copper zinc tin sulfide thin film. The method specifically includes the following steps that metal Cu, Zn and Sn targets are chosen as sputtering target materials; the flexible substrate material is cleaned; the magnetron sputtering method is used, and the metal Cu-Zn-Sn precursor is deposited on the flexible substrate; sulfidizing is conducted on the Cu-Zn-Sn precursor in a sulfur-containing atmosphere, so that the flexible substrate copper zinc tin sulfide thin film is obtained; the prepared flexible substrate copper zinc tin sulfide thin film has an excellent optical absorption property in a visible region. The method for preparing the copper zinc tin sulfide thin film on the flexible substrate through the magnetron sputtering method can be applied to different types of flexible substrate materials, and has the advantages of being capable of effectively adjusting the components of the thin film, improving the crystal quality of the thin film, being good in technological process repeatability and the like.

Owner:GUANGDONG UNIV OF TECH

Health drug used for external-use moxibustion

The invention discloses a health drug used for external-use moxibustion. The health drug is characterized in that adopted moxibustion materials comprise homogeneous moxa and extract of various natural drugs or drug powder. The health drug has the beneficial effects that after being picked, raw material mugwort leaves for manufacturing the moxa are subjected to homogeneous classified picking and winnowing before being dried in the sun, so that the quality of every kind of mugwort leaves, tenderness and length of tomentum as well as content of beneficial substances contained in the tomentum tend to be the same, and thus, the characteristics of the moxa prepared by drying and ageing tend to be the same, and the homogeneous moxa is obtained; a moxibustion material prepared by the homogeneous moxa can be uniformly combusted and is the same in combustion speed, so that the moxibustion component, force, speed and time can be controlled very well, and the moxibustion effect is improved; besides, other natural drug extract or drug powder is added on the moxa, so that the moxibustion material has more curative effects, and thus, a purpose of treating various diseases or achieving health care is achieved.

Owner:李昭

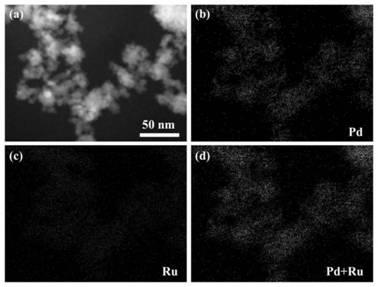

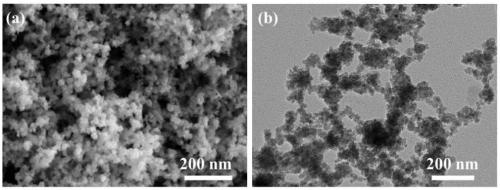

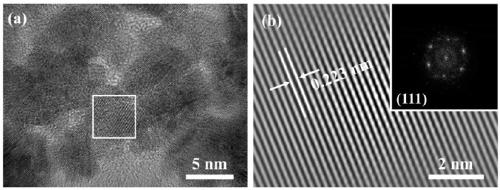

Multihole PdRu alloy catalyst for electrochemically synthesizing ammonia and preparation method thereof

ActiveCN109126782AHigh yieldEasy to synthesizeMetal/metal-oxides/metal-hydroxide catalystsElectrodesAlloy catalystPotassium

The invention discloses a multihole PdRu alloy catalyst for electrochemically synthesizing ammonia and a preparation method thereof. The preparation method comprises the following steps: dissolving potassium chloride and ruthenium chloride in deionized water, and controlling the concentrations of the potassium chloride and the ruthenium chloride between 10 mM and 40 mM; then dissolving sodium borohydride in deionized water, and controlling the concentration between 5 mM and 50 mM; in a stirring state, quickly adding a freshly synthesized sodium borohydride solution into a precious metal precursor solution for reaction, and washing, centrifugating and drying the product after 1 to 5 minutes, thus obtaining the structure and component-controllable PdRu alloy catalyst. The preparation processis simple, and the reaction time is extremely short; at normal temperature and normal pressure, the prepared material is excellent in electrochemically synthesizing ammonia performance.

Owner:ZHEJIANG UNIV OF TECH

A method for controlling inclusions in silicon-manganese killed non-oriented silicon steel

ActiveCN108660294BOxygen Potential StabilizationReduce oxidationProcess efficiency improvementMetallic aluminumChemical composition

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

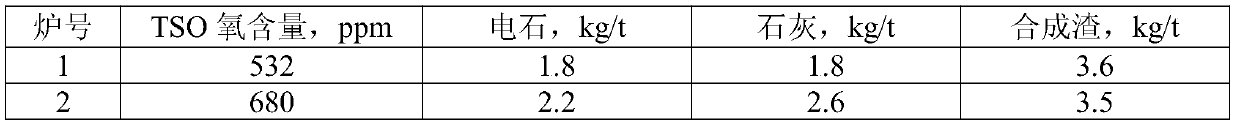

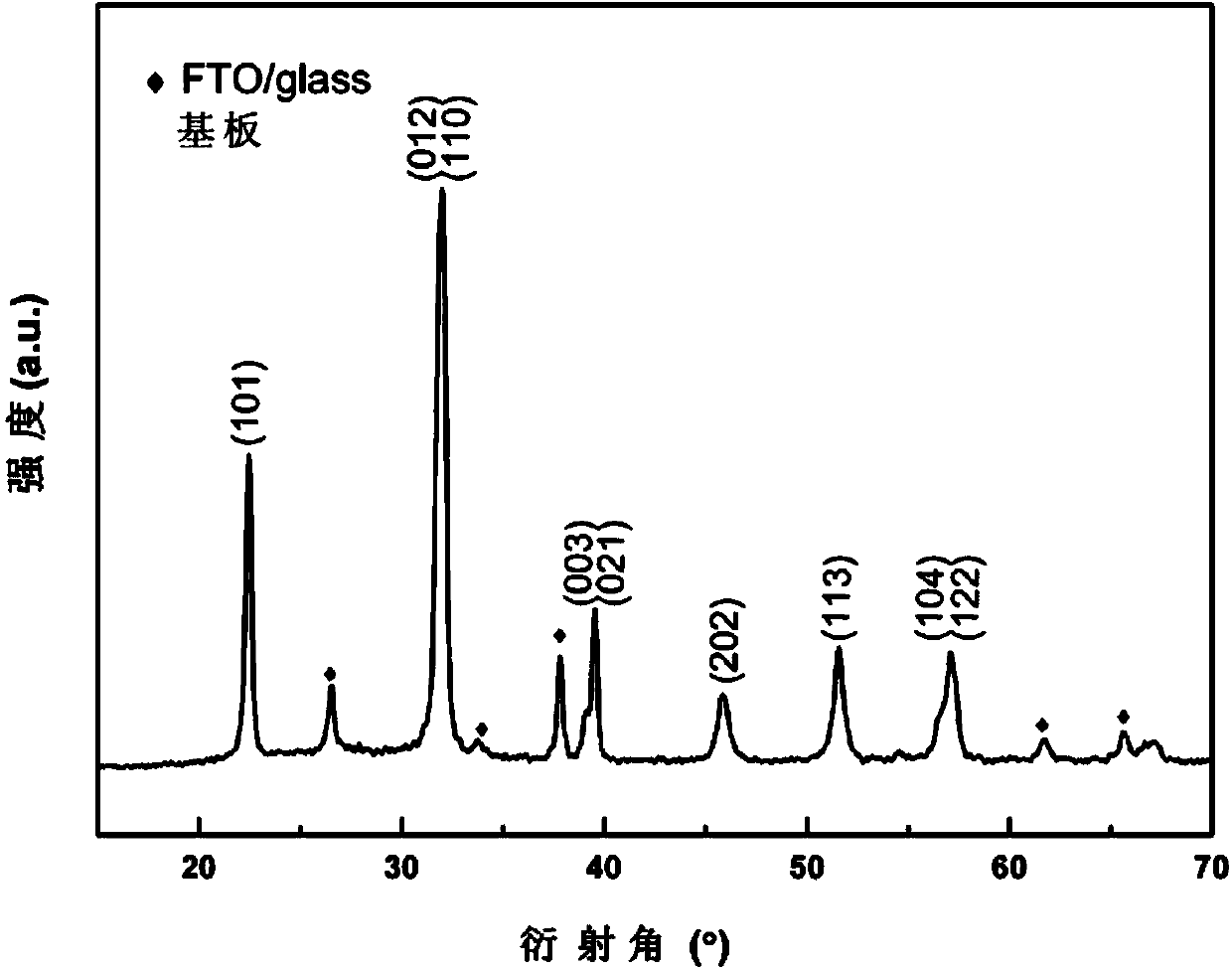

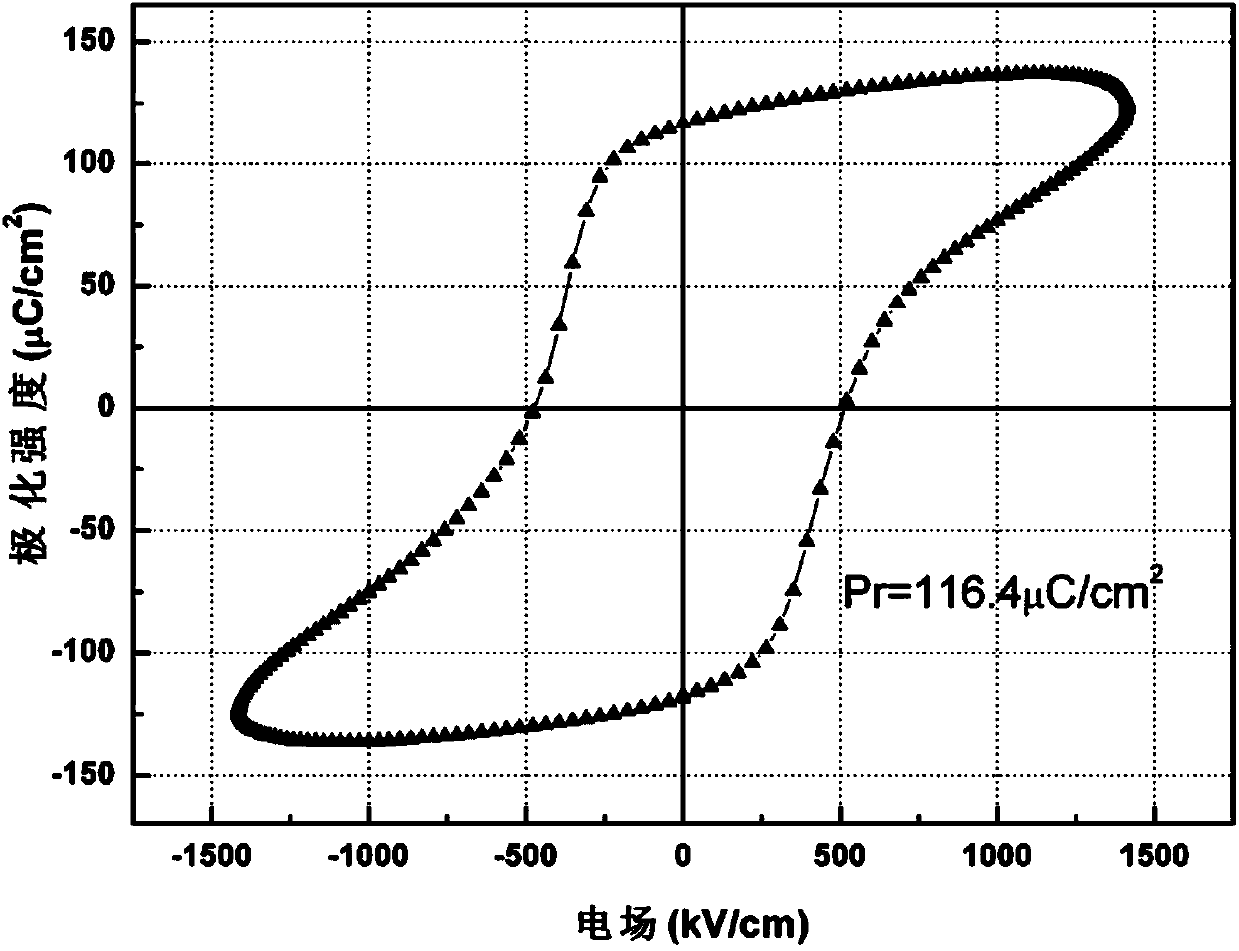

BiFe1-XMnXO3 ferroelectric film with high remnant polarization and preparation method thereof

ActiveCN103739019AImprove electrical performanceInhibition of price changeIron compoundsAcetic acidMANGANESE ACETATE

The invention discloses a BiFe1-XMnXO3 ferroelectric film with high remnant polarization and a preparation method thereof, and x is equal to 0.02-0.08. The BiFe1-XMnXO3 ferroelectric film is of a twisty perovskite structure, belongs to a rhombohedral system, and is good in uniformity. At the frequency of 1kHz, the remnant polarization is 100-130.4mu C / cm<2>. The preparation method comprises the steps of: dissolving bismuth nitrate, ferric nitrate and manganese acetate in a mixed solution of ethylene glycol monomethyl ether and acetic anhydride according to a molar ratio of 1.05:(1-x) to obtain a precursor solution; and spinning the precursor solution on a substrate, homogenating and baking to obtain a dry film; annealing to obtain the BiFe1-XMnXO3 ferroelectric film, repeatedly carrying out the steps of spinning the precursor solution, baking, and annealing till a required film thickness is reached, thus obtainng the BiFe1-XMnXO3 ferroelectric film with high remnant polarization. The BiFe1-XMnXO3 ferroelectric film is simple in requirement of equipment, easily controllable in doping amount, and capable of greatly improving ferroelectric properties and dielectric properties of a BiFeO3 film.

Owner:SHAANXI UNIV OF SCI & TECH

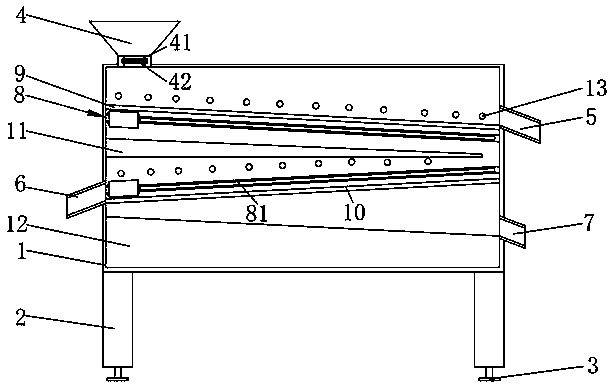

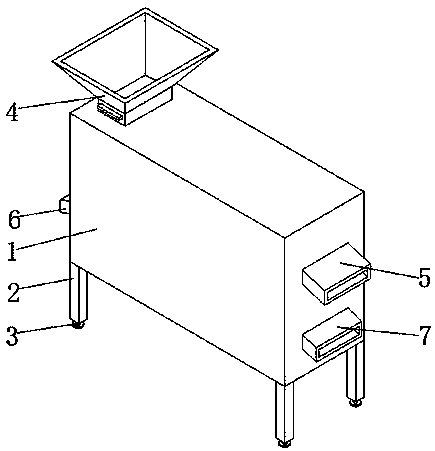

Camellia seed screening device for oil-tea camellia processing

InactiveCN109277292AReasonable designControl the amount of sieveSievingScreeningEngineeringCamellia oleifera

The invention discloses a camellia seed screening device for oil-tea camellia processing. The camellia seed screening device comprises a box body, four sets of supporting legs, a storage box, a firstfilter screen, a second filter screen and a cleaning device, wherein the four sets of supporting legs are fixedly welded to the four corners of the bottom of the box body, the storage box is disposedon the left side of the top of the box body, a first discharge hole is formed in the position, close to the top, of the right side wall of the box body, and a second discharge hole is formed in the middle section of the left side wall of the box body. The first filter screen and the second filter screen are fixedly arranged in the box body from top to bottom, an inclined table is placed at the bottom of the box body, the lowest end of the first filter screen communicates with the feeding end of the first discharge hole, the lowest end of the second filter screen communicates with the feeding end of the second discharge hole, and the lowest end of the inclined table communicates with the lowest end of a third discharge hole. The camellia seed screening device for oil-tea camellia processingis reasonable in design and can effectively screen camellia seeds, can effectively control the screening amount of the camellia seeds, can effectively clean the filter screens, and is suitable for popularization and use.

Owner:耒阳市利荆农林种植专业合作社

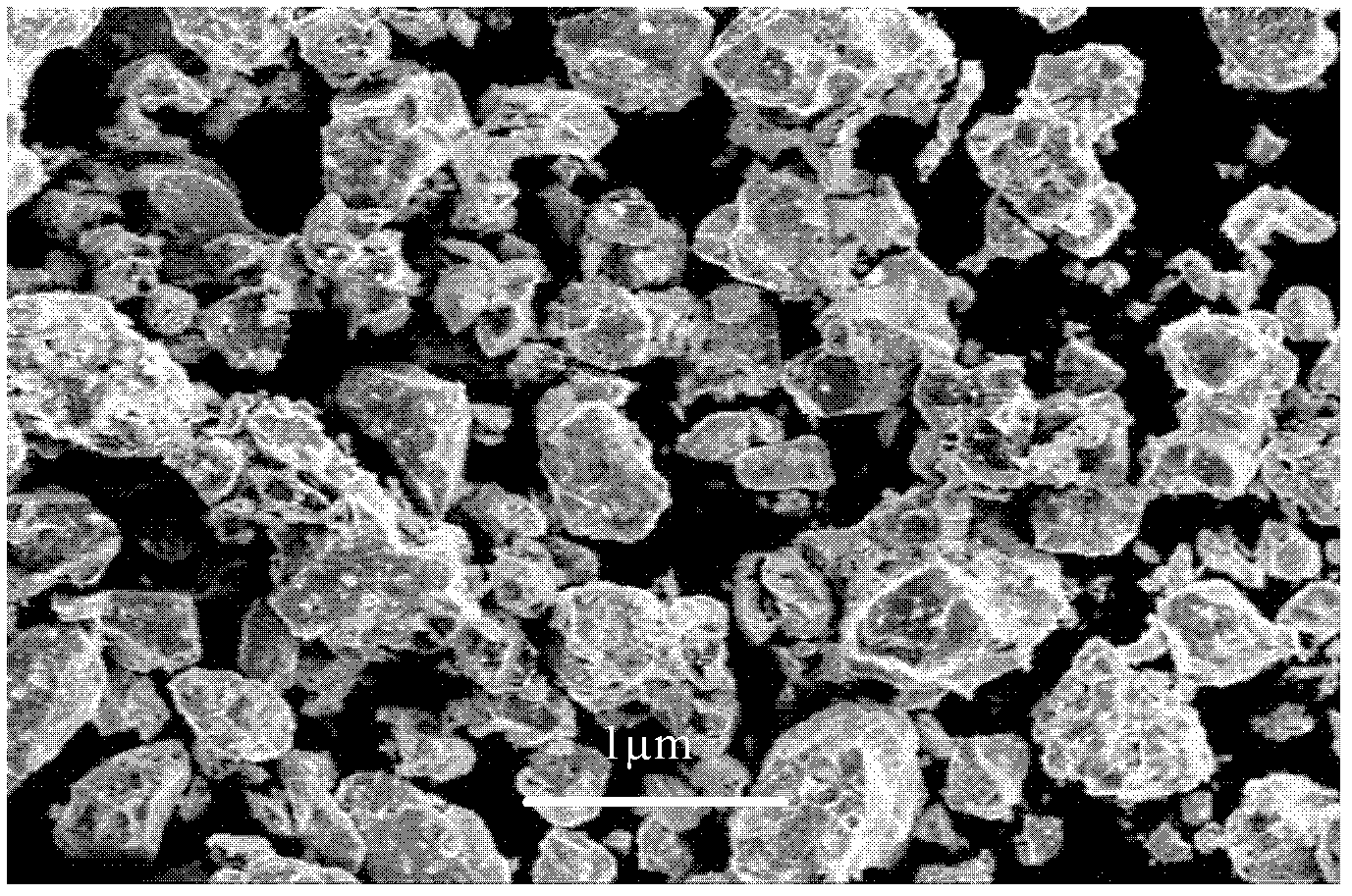

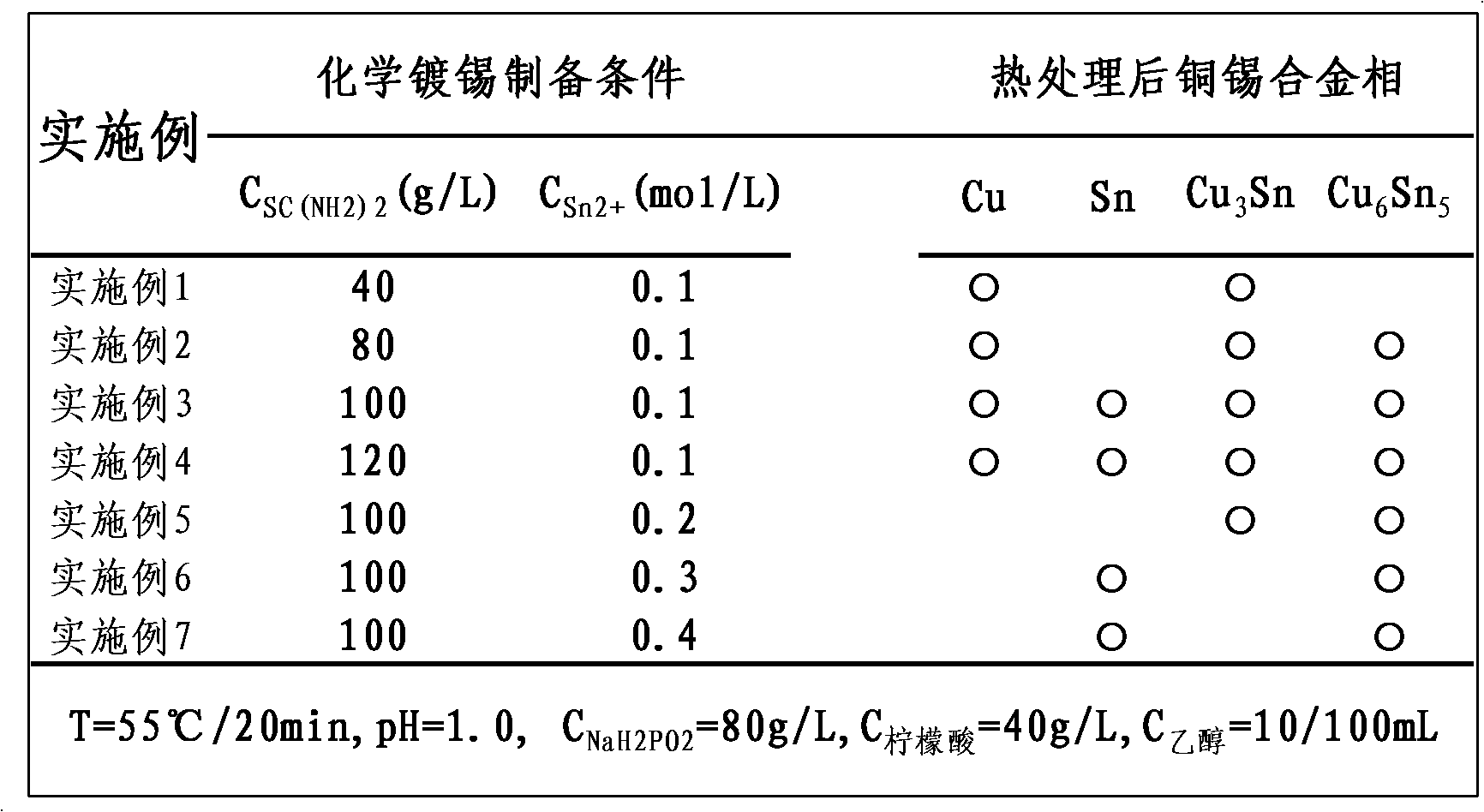

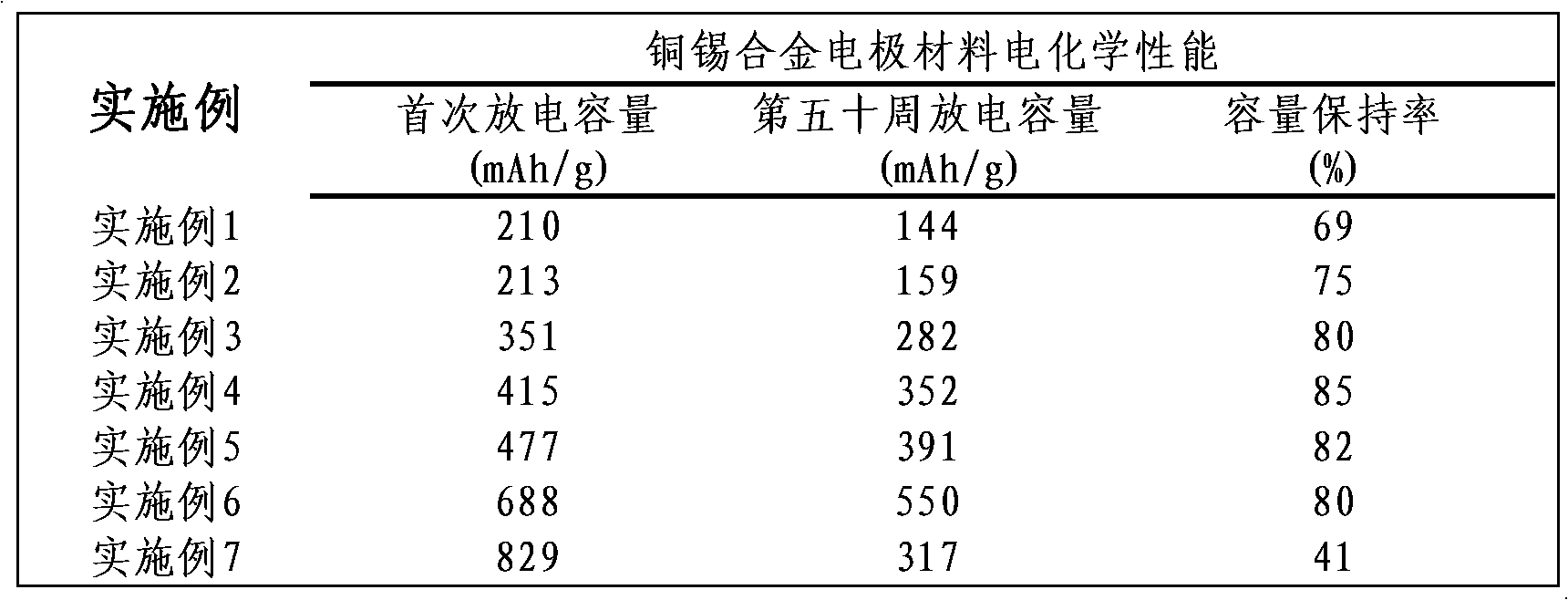

Method for preparing tin-copper alloy materials and carbon covered tin-copper alloy materials

ActiveCN102352496BControl componentSimple processCell electrodesLiquid/solution decomposition chemical coatingLithium-ion batteryLithium electrode

The invention discloses a method for preparing tin-copper alloy materials and carbon covered tin-copper alloy materials, which is characterized in that the process is simple, the particle size is easy to control, and in addition, the prepared tin-copper alloy materials and carbon covered tin-copper alloy materials are used as negative electrode materials of lithium ion batteries and have the advantages of high capacity and stable performance.

Owner:ZHEJIANG UNIV OF TECH

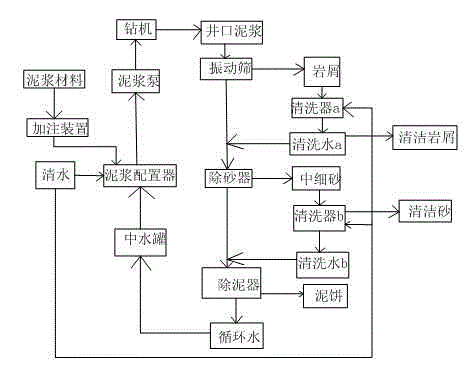

Damage-free waste drilling fluid processing process

InactiveCN104975817AReduce the concentration of densityReduce concentrationFlushingLiquid wasteClay minerals

The invention discloses a damage-free waste drilling fluid processing process, which comprises the following steps of: firstly drilling a wellhead by a drilling machine, and injecting wellhead slurry; passing a mixture of waste drilling fluid and the wellhead slurry through a vibration sieve to be filtered for obtaining rock debris, and meanwhile, feeding filter liquid into a desander; putting the obtained rock debris into a cleaner a, performing cleaning through externally injected clean water to obtain clean rock debris and medium-coarse sand, and meanwhile, merging the clean water a into circulation water; passing the filter liquid through the desander to obtain medium-fine sand; putting the obtained medium-fine sand into a cleaner b; using introduced clean water for cleaning to obtain clean sand; merging cleaning water b into the circulation water; and meanwhile, feeding the filter liquid obtained after passing through the desander into a desilter. The damage-free waste drilling fluid processing process has the advantages that through the principle, on the premise of not easily causing rock framework collapse due to clay mineral swelling and transportation, various different solid-phase particles in the waste drilling fluid can be processed; the circulation flowing use of the waste drilling fluid is ensured; and the condition that the fluid cannot reach a borehole from a flow storage layer is avoided.

Owner:CHENGDU GAOPU PETROLEUM ENG TECH

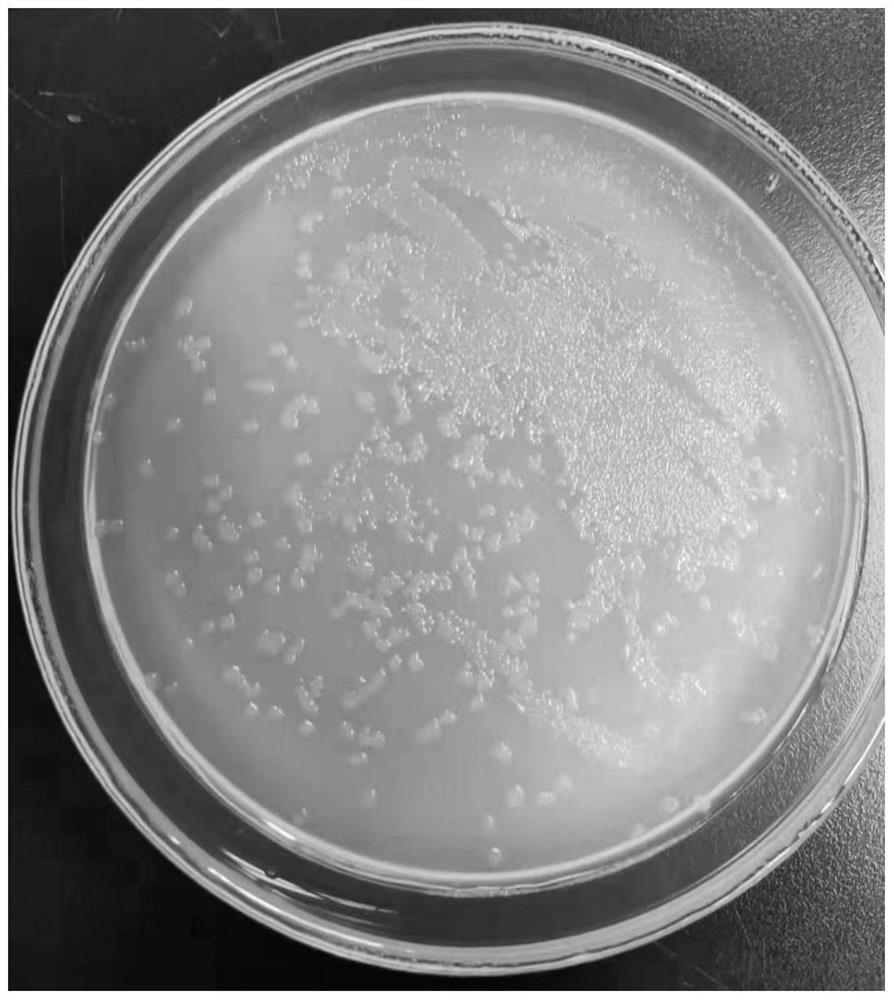

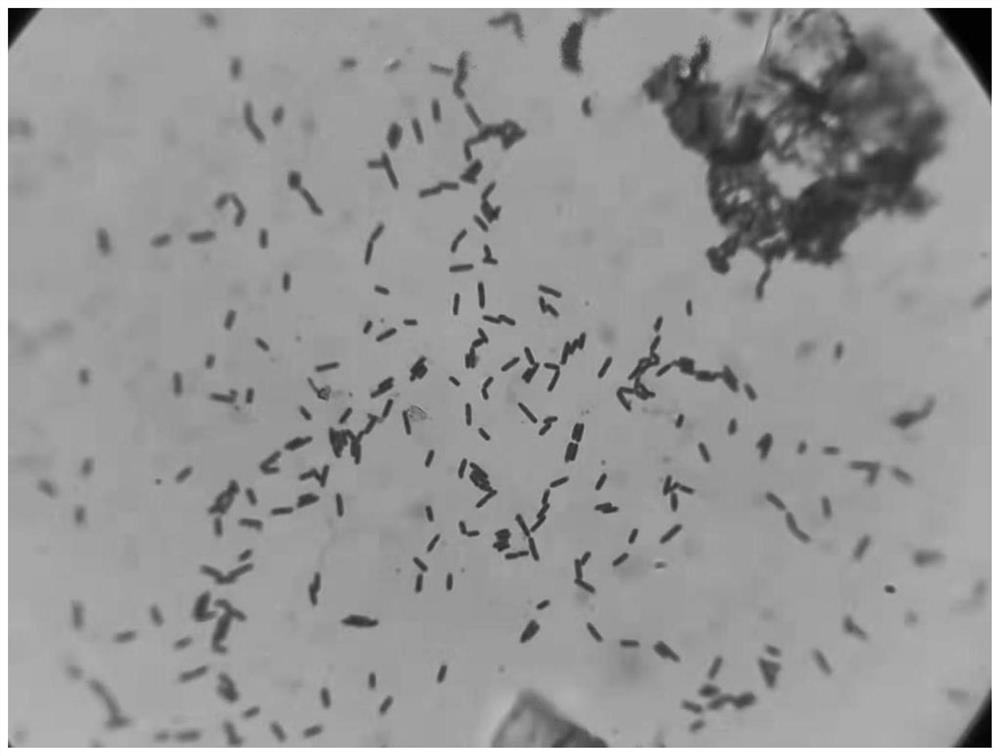

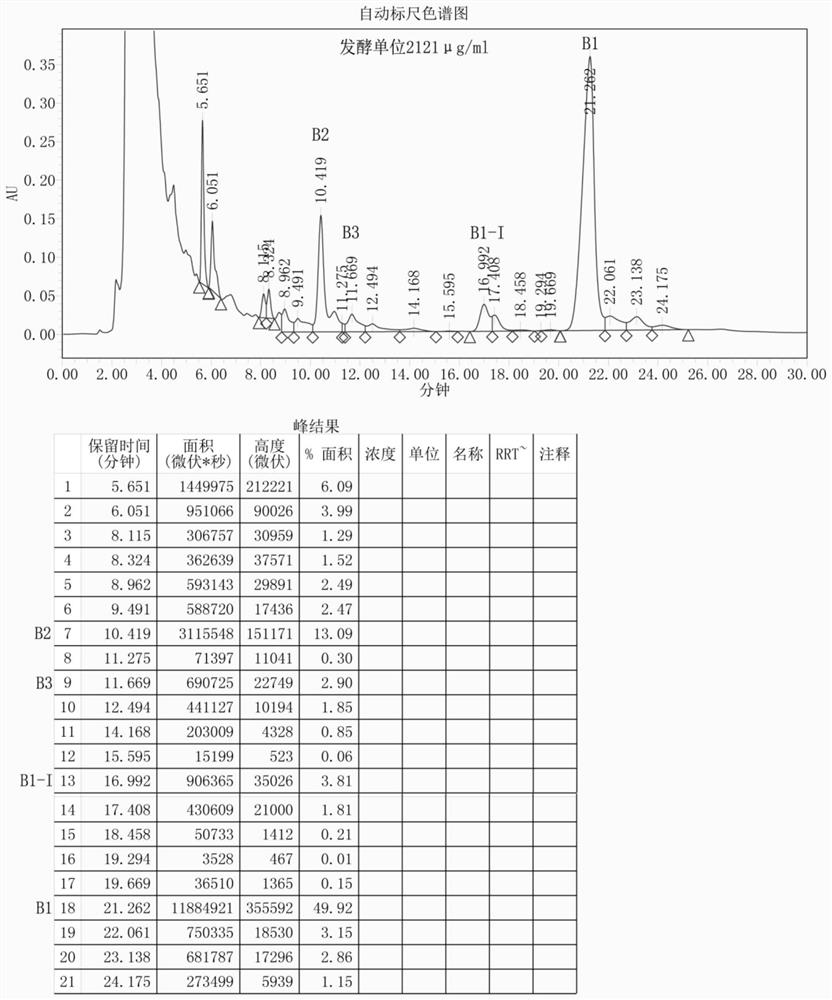

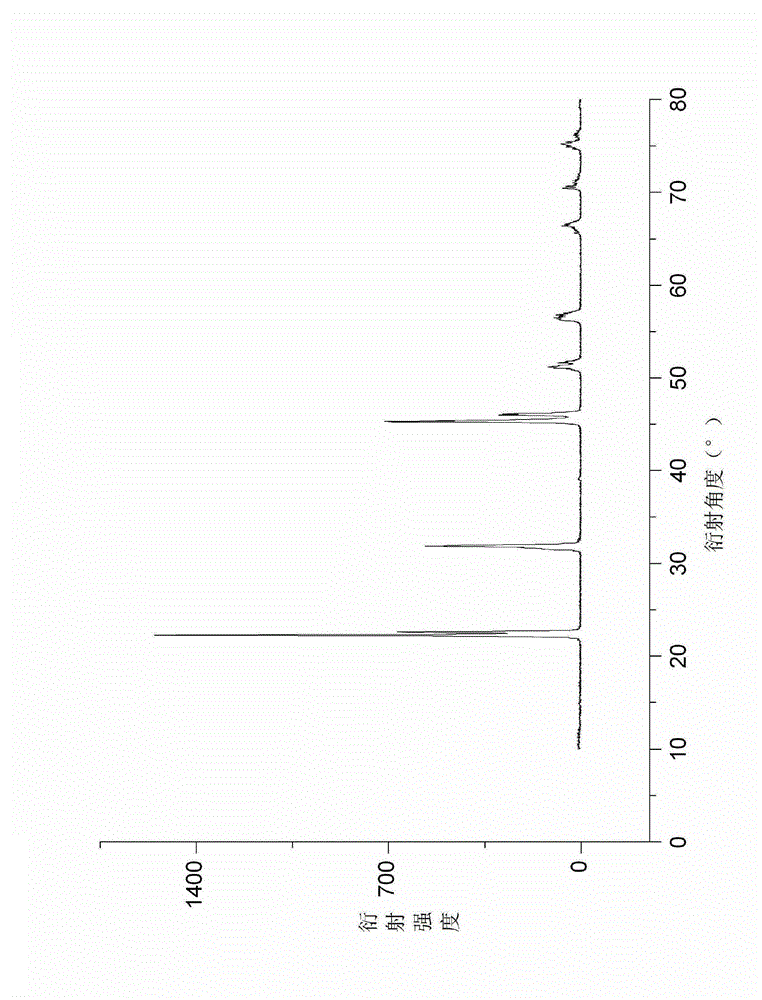

A kind of polymyxin b sulfate production strain, preparation method and application of polymyxin b sulfate

ActiveCN111100823BStrong ability to produce polymyxin B sulfateImprove abilitiesBacteriaMutant preparationBiotechnologyMetabolite

The invention belongs to the technical field of biological fermentation, and in particular relates to a polymyxin B sulfate production strain, a preparation method and application of polymyxin B sulfate. The present invention obtains a polymyxin B sulfate production strain through mutagenesis breeding, and optimizes the carbon source and nitrogen source of the fermentation medium, precisely regulates the fermentation conditions such as the inoculum amount, fermentation temperature, fermentation time, and tank pressure, and controls the The metabolite components finally utilize the bacterial strain obtained by mutagenesis of the present invention to produce polymyxin B sulfate in a tank unit of 2.0 g / L, exceeding the industry average level by 20%. The proportions of several impurity peaks specified by the USP / EP Pharmacopoeia in the fermented liquid in tanks are far lower than the levels recorded in domestic literature. Separation and purification of the fermentation broth to obtain high-purity and high-content polymyxin B sulfate, the biometric titer of the finished product is greater than 8100u / mg, the purity and content are both greater than 90%, the single impurities and components are all qualified, and the total impurities are less than 8 %, product quality is much higher than USP / EP standard.

Owner:黄石曼菲特生物科技有限公司

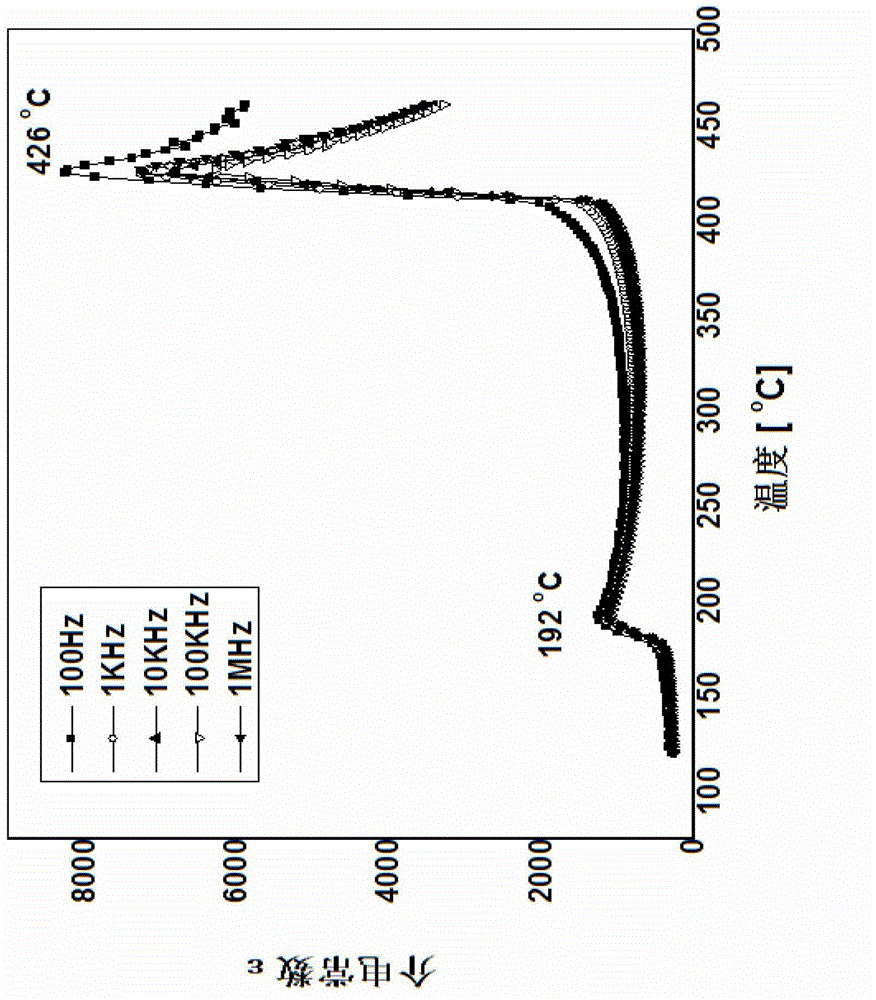

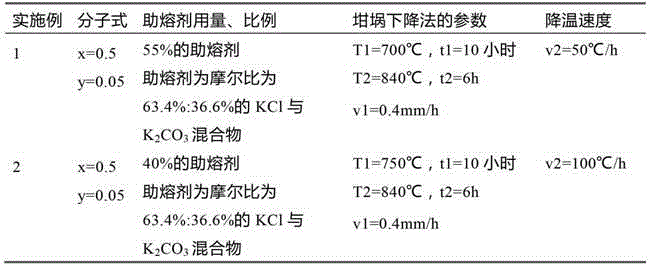

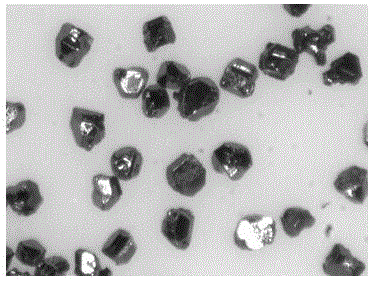

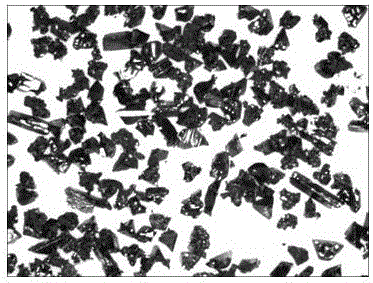

Growing method of (KxNa1-x)1-yLiyNbO3-based lead-free piezoelectric monocrystal

InactiveCN104152982ALow growth temperatureImprove integrityPolycrystalline material growthFrom frozen solutionsCrucibleRoom temperature

The invention discloses a method for growing a (KxNa1-x)1-yLiyNbO3-based lead-free piezoelectric monocrystal. The method comprises the following steps: weighing raw material powder; weighing a fluxing agent and mixing with the raw material powder; putting the starting material into a crucible and putting the crucible into a furnace; carrying out heat preservation on the crucible at a temperature of 400 DEG C to 900 DEG C for 2 to 20 hours, then heating to 700 DEG C to 1000 DEG C, carrying out heat preservation for 2 to 20 hours until the starting material is completely molten and cooling the interior of the furnace to a room temperature at the speed of 1 to 200 DEG C / h so as to obtain the (KxNa1-x)1-yLiyNbO3-based lead-free piezoelectric monocrystal. The (KxNa1-x)1-yLiyNbO3-based lead-free piezoelectric monocrystal grown by virtue of a low-temperature preparation technology is of a pure perovskite structure and cannot generate impure phases. The method has the advantages that 1, the crystal grows at a low temperature and has a short growth period; 2, the requirement on a growing instrument is low during a low-temperature growing process; 3, the raw material powder contained in the crucible can be conveniently sealed and is nearly not volatilized due to a low growing temperature, so that the components of the growing crystal can be well controlled so as to prevent the deviation of the components.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

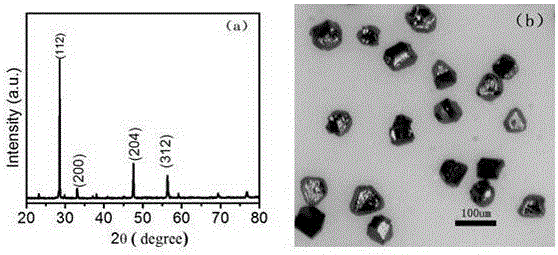

Preparation method for copper-iron-zinc-tin-sulfur micron monocrystal particles

ActiveCN105742385AInhibition of nonequilibrium growthControl shapeFinal product manufacturePhotovoltaic energy generationPhysical chemistrySulfide

The invention discloses a preparation method for copper-iron-zinc-tin-sulfur micron monocrystal particles. Elementary substance copper powder, elementary substance zinc powder, elementary substance tin powder, metal sulfide powder, elementary substance sulfur powder, a fluxing agent and the like are combined to form the reaction raw material; the reaction raw material is grinded and mixed based on a determined formula; the mixed powder is vacuum packaged in a quartz reaction container at a temperature of 600-1,000 DEG C for 48-120h; the quartz reaction container is cooled rapidly to the room temperature; and then the sample is taken out, washed and dried to obtain the copper-iron-zinc-tin-sulfur micron monocrystal particles. The dimensions of the prepared monocrystal particles can be regulated and controlled according to recrystallization temperature and time; the components of the particles can be effectively blended within a certain range based on the molar ratio of elements in the precursor; and in addition, the obtained monocrystal particles are uniform in particles, controllable in dimensions, and better in performance than that of the monocrystal particles prepared by the conventional method.

Owner:LINGNAN NORMAL UNIV

B-site Mn and Ni co-doped high-remanent-polarization BiFeO3 film and preparation method thereof

ActiveCN103626236AImprove multiferroic propertiesPromote productionIron compoundsMANGANESE ACETATEAcetic anhydride

The invention discloses a B-site Mn and Ni co-doped high-remanent-polarization BiFeO3 film and a preparation method thereof. The preparation method comprises the following steps: dissolving bismuth nitrate, ferric nitrate, manganese acetate and nickel acetate according to a molar ratio of 1.05:[(0.92-0.98)-x]:(0.02-0.08):x in a mixed solution of ethylene glycol monomethyl ether and acetic anhydride, uniformly stirring to obtain a BiFeO3 precursor solution, wherein the total metal ion concentration in the BiFeO3 precursor solution is 0.1-0.5mol / L, and x is equal to 0.01 to 0.03; spin coating the BiFeO3 precursor solution on a FTO / glass substrate to prepare a wet film, baking the wet film to obtain a dried film, annealing at the temperature of 550 DEG C for 8-13 minutes, thus obtaining a crystalline state BiFeO3 film; repeatedly operating until the BiFeO3 film reaches the needed thickness after the crystalline state BiFeO3 film is cooled, thus obtaining the B-site Mn and Ni co-doped high-remanent polarization BiFeO3 film. According to the method, a sol-gel process is adopted, the equipment requirement is simple, the method is suitable for preparing films on large surfaces and out-of-shape surfaces, the chemical constituents are accurately controlled, and the crystal structure is regulated through co-doping, so that the ferroelectric properties of the film are greatly improved.

Owner:SHAANXI UNIV OF SCI & TECH

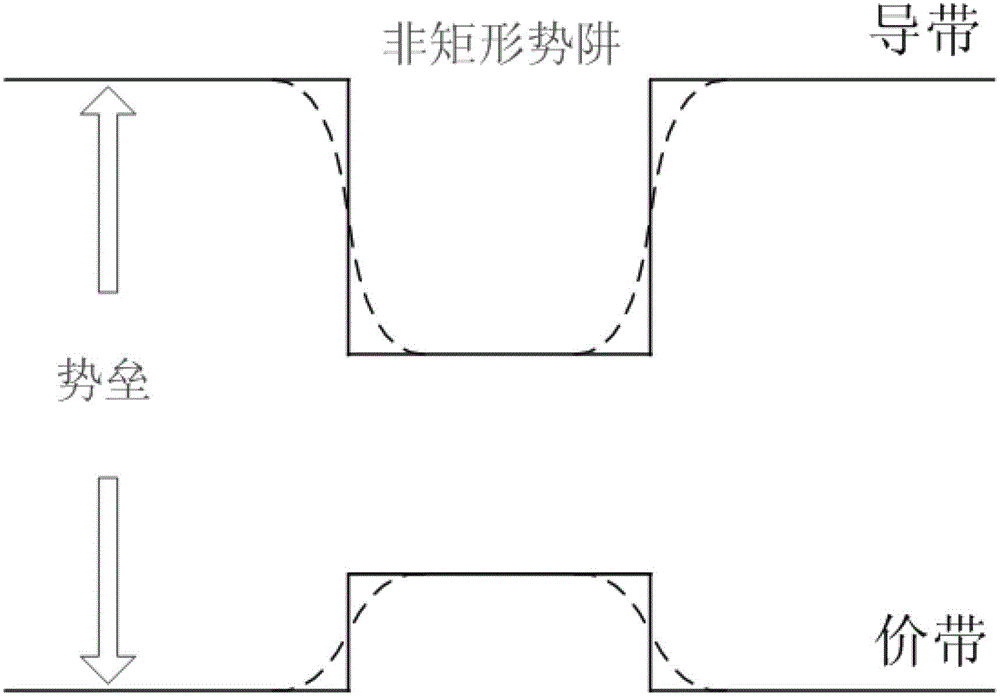

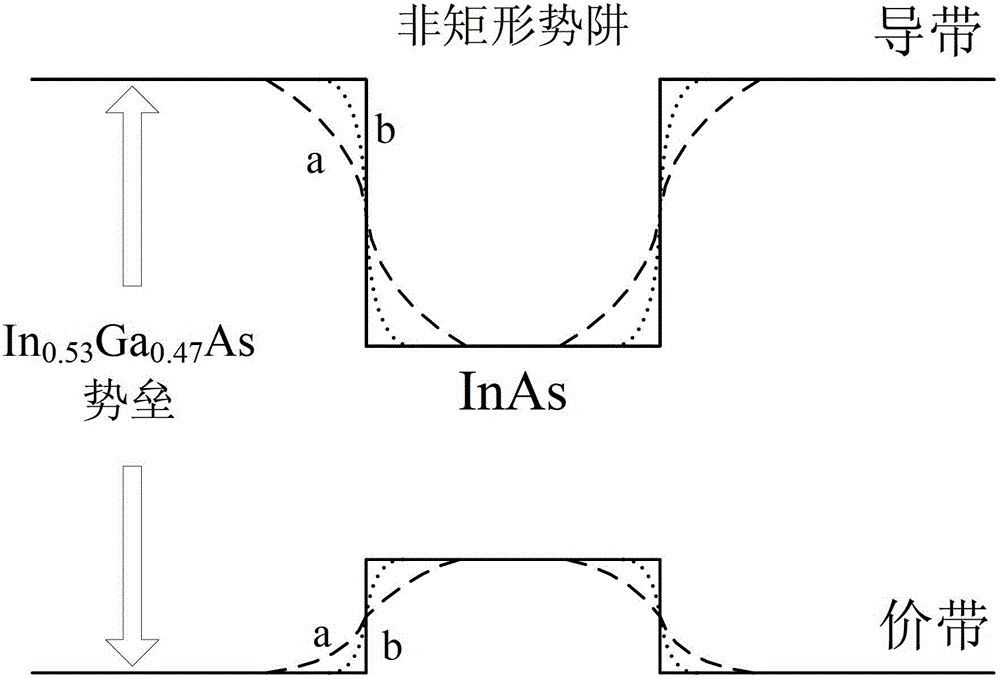

Preparation method of non-rectangular III-V semiconductor quantum well based on bismuth element

ActiveCN103367567BGood workmanshipControl componentSemiconductor devicesSemiconductor quantum wellsPotential well

The invention relates to a preparation method for a bismuth-based non-rectangular group III-V semiconductor quantum well. The preparation method comprises the step of growing a potential well material and a potential barrier material of a group III-V semiconductor quantum well, wherein bismuth is added in the growth processes of both the potential well material and the potential barrier material. According to the preparation method, bismuth beam source shutters are opened simultaneously in the processes of growing the potential well material and the potential barrier material of the quantum well, and a non-rectangular quantum well structure is realized by utilizing the group III element interdiffusion caused by the bismuth. By the method, material components can be controlled effectively; the problem that the conventional growth method is only suitable for growing a rectangular quantum well structure with component mutations is solved; greater freedom is introduced to the design and the implementation of the structure and the functional of quantum; the preparation method disclosed by the invention is suitable for adopting a plurality of material growth means, such as molecular beam epitaxy and atomic layer deposition; and the operation process is simple and convenient.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

A chemical vapor deposition device and method

ActiveCN110438473BGuaranteed cleanlinessGuaranteed independenceChemical vapor deposition coatingGas passingEngineering

Owner:安徽微迈思科技有限公司

A kind of reactor assembly for preparing crystal by pvt method and its use method and application

ActiveCN113215654BSame degree of carbonizationIncrease speedPolycrystalline material growthFrom condensed vaporsSemiconductor materialsPhysical chemistry

The application discloses a reactor component for preparing crystals by PVT method, which belongs to the field of semiconductor material preparation. The reactor assembly includes: a reaction chamber, the reaction chamber includes a raw material chamber and a waste material chamber, the bottom end of the waste material chamber is lower than the bottom end of the raw material chamber; a heating mechanism, the heating mechanism is sleeved on the raw material The outer side of the chamber is used to heat the raw material chamber; the crystal growth chamber is connected to the raw material chamber through the gas phase transmission channel, and the raw material gas generated by the sublimation of the raw material in the raw material chamber is transported to the crystal growth at the seed crystal in the crystal growth chamber; and a plugging flow mechanism, the plugging flow mechanism moves the waste generated during the crystal growth process in the raw material chamber to the waste material chamber. The reactor assembly can move the waste material to the waste material cavity in time, improve the sublimation rate and utilization rate of the raw material, and reduce crystal defects.

Owner:SICC CO LTD

A kind of silicon carbide crystal and preparation method thereof

ActiveCN113151900BReduce defectsIncrease speedPolycrystalline material growthFrom condensed vaporsCarbide siliconSemiconductor materials

Owner:SICC CO LTD

A method for controlling inclusions in ultra-low aluminum non-oriented silicon steel

The invention provides a method for controlling inclusions in ultra-low aluminum non-oriented silicon steel. The chemical composition mass percentage of the steel is C≤0.005%, Si: 0.25%‑1.50%, Mn: 0.15%‑0.55%, P: 0.02%‑0.06%, S≤0.005%, Als≤0.005%, and the balance is Fe and unavoidable impurities. The process flow is: KR→BOF→RH→continuous casting. Converter tapping strictly controls the amount of slag, adding lime and slag surface deoxidizer to adjust slag at the end of tapping; after RH decarburization, first add low-carbon and low-sulfur ferrosilicon, metal aluminum or aluminum-calcium-iron alloy compound deoxidation, and finally add metal manganese , ferrophosphorus for alloying, and then a net cycle of 6-10min, the steel is broken out and transported to continuous casting. The obtained molten steel is mainly SiO 2 ‑Al 2 o 3 System inclusions, avoiding the formation of low melting point SiO 2 ‑MnO-based inclusions make the rolling elongation longer and affect the grain growth; at the same time, it also avoids the formation of high SiO 2 The components are acidic inclusions, leading to corrosion of refractory materials. It can significantly improve the type of non-metallic inclusions in steel, improve the performance of non-oriented silicon steel, and improve the pouring performance of molten steel.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Method for preparing copper-zinc-tin-sulfur thin film on flexible substrate by magnetron sputtering

ActiveCN103985783BControl componentComponents are easily adjustedFinal product manufactureSemiconductor devicesSputteringCopper

The invention discloses a method for preparing a copper zinc tin sulfide thin film on a flexible substrate through a magnetron sputtering method. According to the method, magnetron sputtering is conducted on a metal Cu-Zn-Sn precursor on a flexible substrate material first, and then a sulfidizing method is used for preparing the copper zinc tin sulfide thin film. The method specifically includes the following steps that metal Cu, Zn and Sn targets are chosen as sputtering target materials; the flexible substrate material is cleaned; the magnetron sputtering method is used, and the metal Cu-Zn-Sn precursor is deposited on the flexible substrate; sulfidizing is conducted on the Cu-Zn-Sn precursor in a sulfur-containing atmosphere, so that the flexible substrate copper zinc tin sulfide thin film is obtained; the prepared flexible substrate copper zinc tin sulfide thin film has an excellent optical absorption property in a visible region. The method for preparing the copper zinc tin sulfide thin film on the flexible substrate through the magnetron sputtering method can be applied to different types of flexible substrate materials, and has the advantages of being capable of effectively adjusting the components of the thin film, improving the crystal quality of the thin film, being good in technological process repeatability and the like.

Owner:GUANGDONG UNIV OF TECH

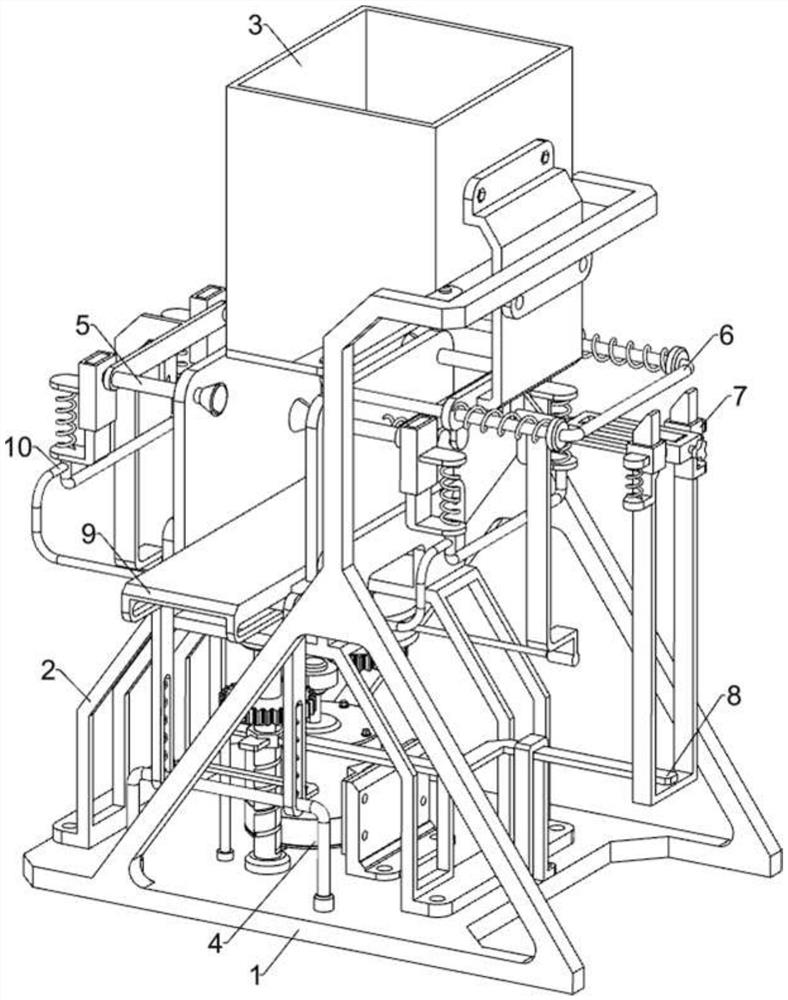

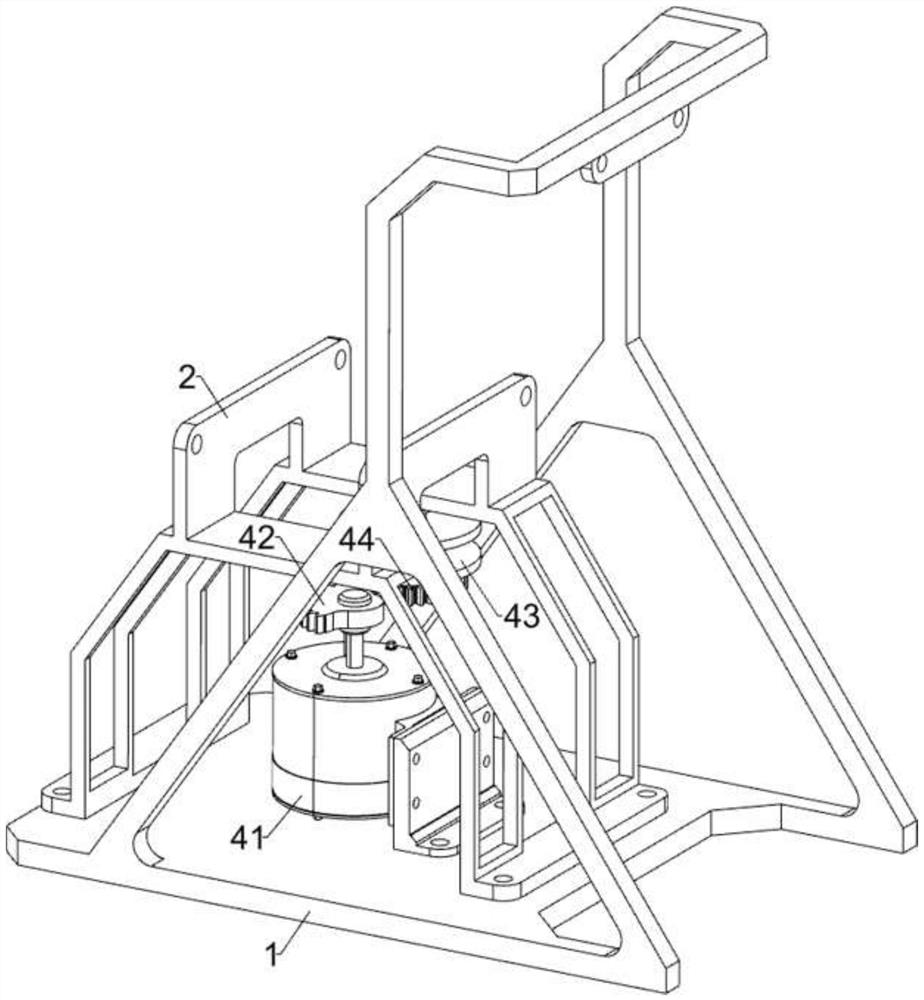

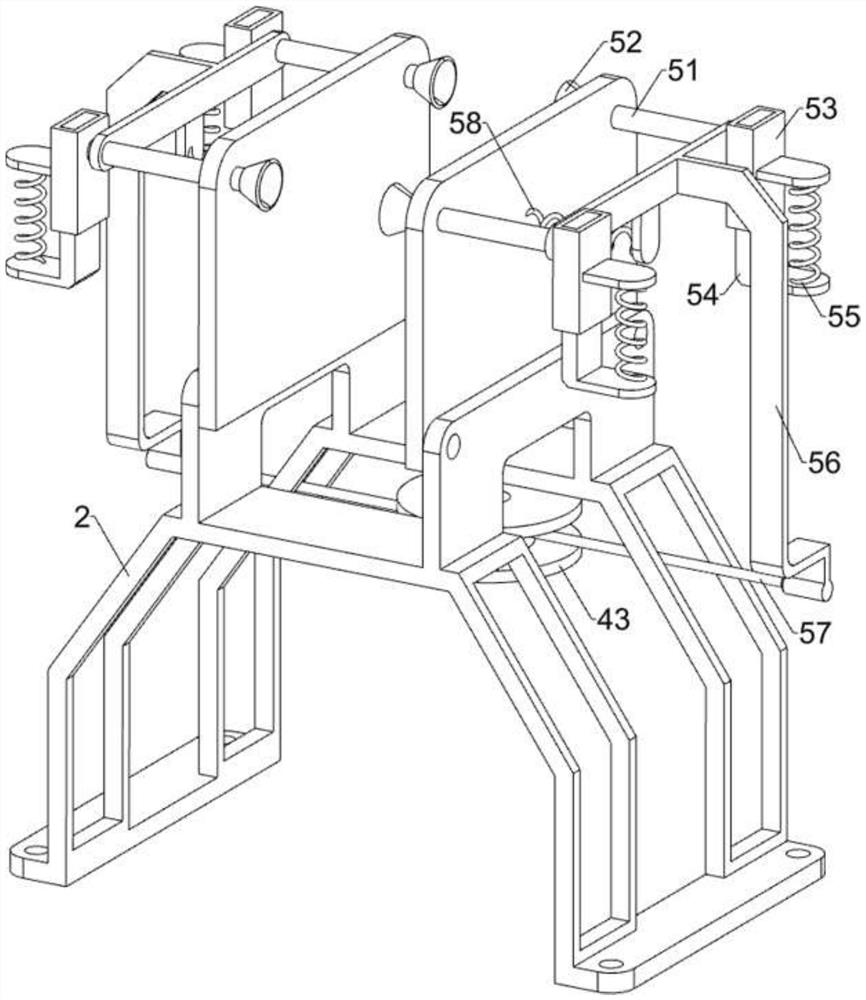

Quantity-controllable dry packaging equipment for mandarin orange coarse grain powder

PendingCN113022905AReduce the burden onControl componentSolid materialBio-packagingIndustrial engineeringCitrus nobilis

The invention relates to packaging equipment, in particular to quantity-controllable dry packaging equipment for mandarin orange coarse grain powder. The technical problem to be solved by the invention is to provide the quantity-controllable dry packaging equipment for mandarin orange coarse grain powder, which is simple, convenient and efficient. The quantity-controllable dry packaging equipment for the mandarin orange coarse grain powder comprises a rack, a supporting frame, a material storage box, a driving assembly, an opening assembly and a blocking assembly. The supporting frame is mounted on the rack. The material storage box is mounted on the rack. The driving assembly is mounted between the rack and the supporting frame. The opening assembly is mounted on the supporting frame. And the blocking assembly is mounted on the rack. The equipment is provided with a pushing assembly, so that workers do not need to manually control a connecting rod for discharging, and the burdens of the workers are reduced; and meanwhile, the falling amount of dried mandarin orange coarse grain powder can be controlled by controlling a first lead screw. The equipment is provided with a downward pressing assembly, so that the workers do not need to manually control a pushing plate to reset a blocking plate, and then the operation trouble of the worker is saved again.

Owner:JIANGXI BOJUN ECOLOGICAL AGRI DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com