Damage-free waste drilling fluid processing process

A technology of drilling waste fluid and treatment process, which is applied in earthwork drilling, wellbore flushing, wellbore/well parts, etc. It can solve the problem that the fluid cannot flow from the reservoir to the wellbore, achieve uniform configuration and ensure circulation flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

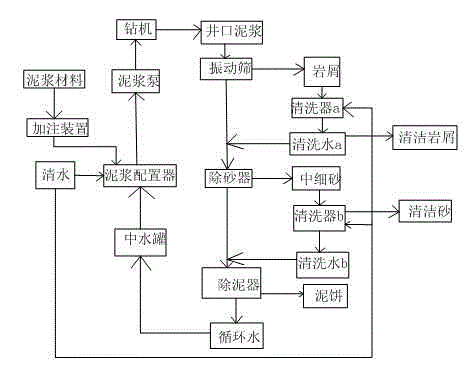

[0021] Such as figure 1 As shown, the present invention includes the non-damaged drilling waste treatment process, comprising the steps of:

[0022] a) First drill the wellhead with a drilling rig and pour in the wellhead mud;

[0023] b) Pass the mixture of drilling waste fluid and wellhead mud through a vibrating screen, filter to obtain cuttings, and send the filtrate to the desander;

[0024] c) Put the obtained cuttings into the cleaner a, and clean them with clean water injected from the outside to obtain clean cuttings and medium-coarse sand, and at the same time pour the cleaning water a into the circulating water;

[0025] d) The filtrate is passed through the desander to obtain medium and fine sand, put the obtained medium and fine sand into the cleaner b, and clean it with clean water to obtain clean sand, and pour the cleaning water b into the circulating water, and at the same time The filtrate obtained after passing through the desander is sent to the desilter;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com