Preparation method of non-rectangular III-V semiconductor quantum well based on bismuth element

A III-V, semiconductor technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of large strain accumulation, limit the scope of material design and growth, and unfavorable growth of high-quality materials, so as to achieve simple and convenient operation process, The effect of large degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

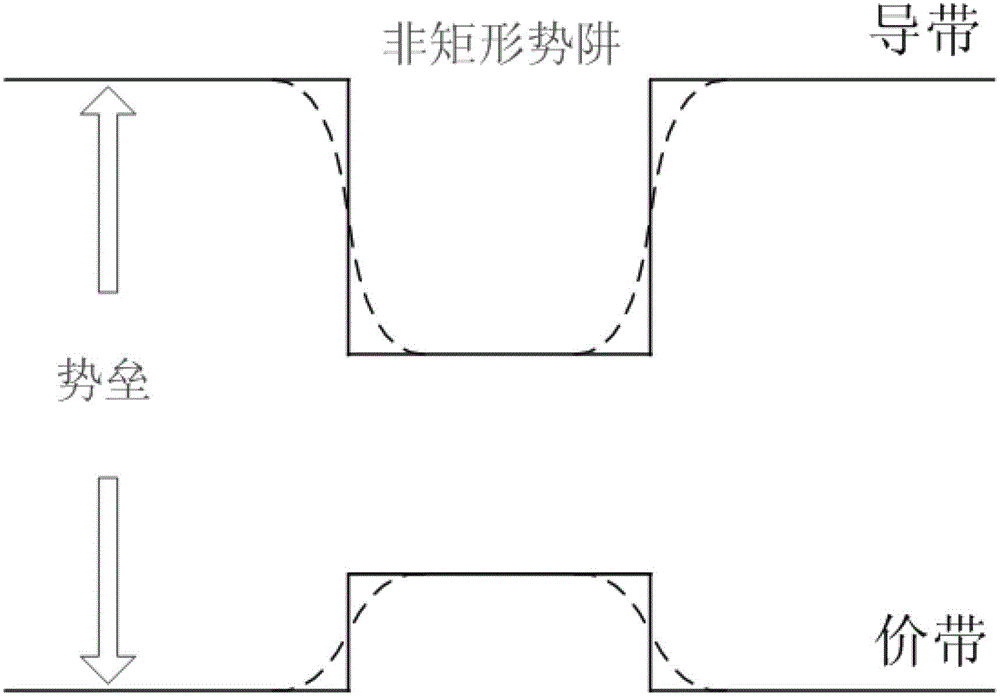

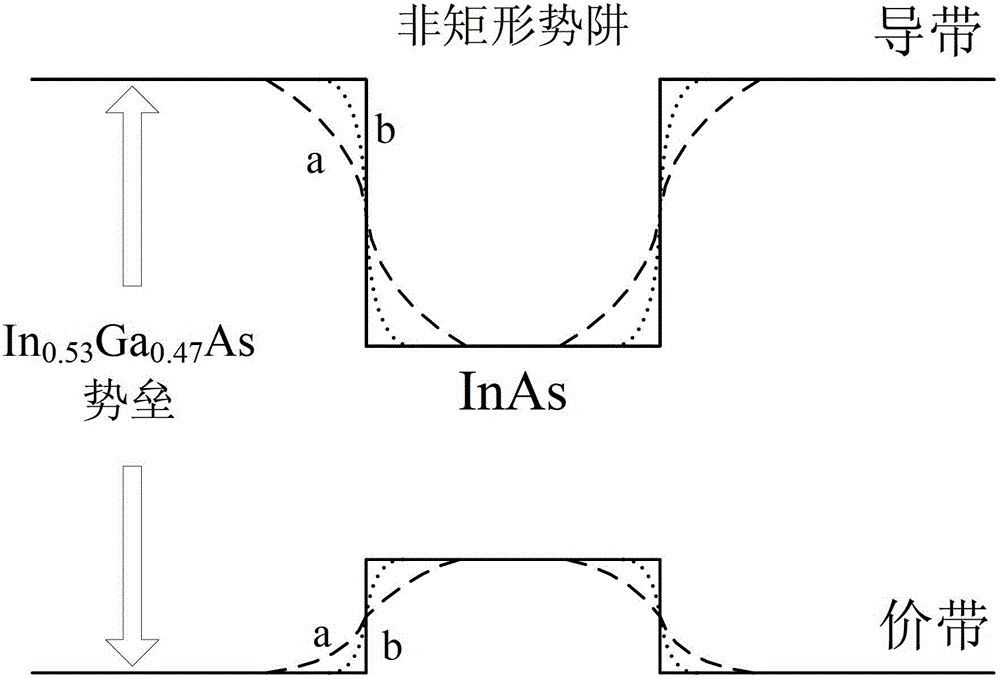

[0018] The following is based on the InP substrate 0.53 Ga 0.47 As / InAs non-rectangular quantum well preparation method is taken as an example to illustrate the preparation method of non-rectangular III-V group semiconductor quantum well based on bismuth:

[0019] (1) Need to grow InP on InP substrate 0.53 Ga 0.47 As is the potential barrier, In 0.53 Ga 0.47 As / InAs is a quantum well structure with a non-rectangular potential well;

[0020] (2) The epitaxial growth adopts the conventional molecular beam epitaxy method, Mr. Long In 0.53 Ga 0.47 As barrier, then grow InAs as the bottom of the potential well, and then grow In 0.53 Ga 0.47 As barrier (such as figure 2 As shown by the middle solid line), when the bismuth beam source shutter is opened during the growth of the quantum well, the bismuth element will cause the inter-diffusion of In and Ga at the interface, making the quantum well form a non-rectangular structure (such as figure 2 Shown by dotted line a and dotted line b)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com