A method for controlling inclusions in silicon-manganese killed non-oriented silicon steel

A technology of oriented silicon steel and control method, which is applied in the field of iron and steel smelting, can solve the problems of small grain size of non-oriented silicon steel, deteriorate the magnetic properties of silicon steel, and high iron loss, reduce the fluctuation of inclusion composition, reduce the oxygen potential of slag, improve The effect of magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

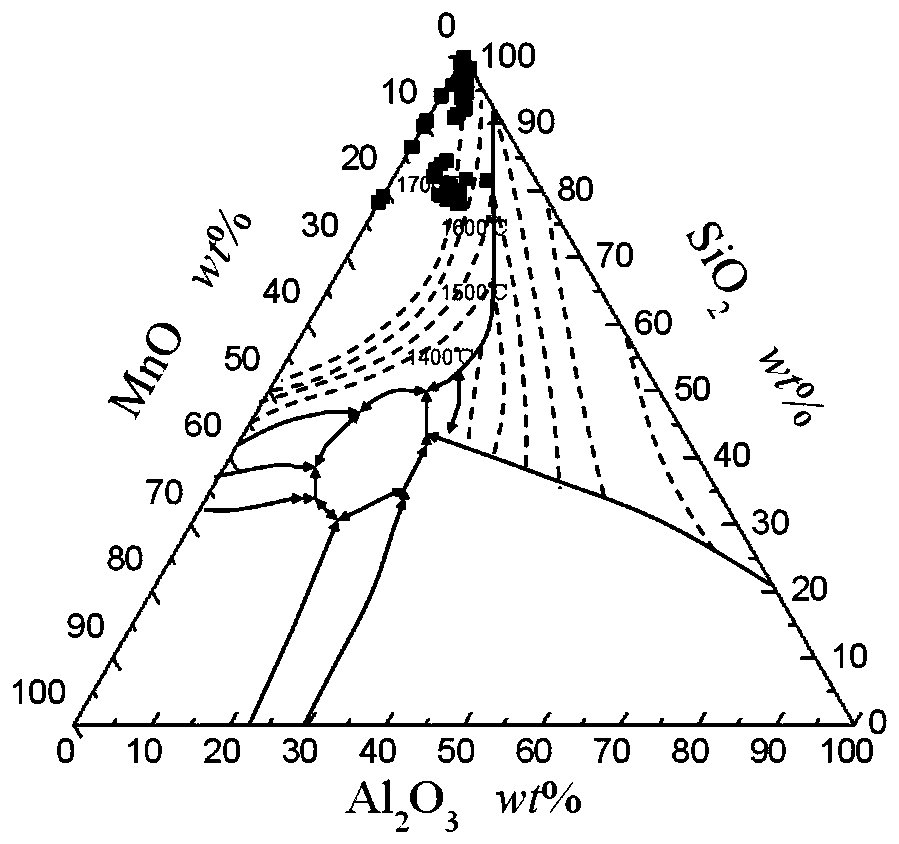

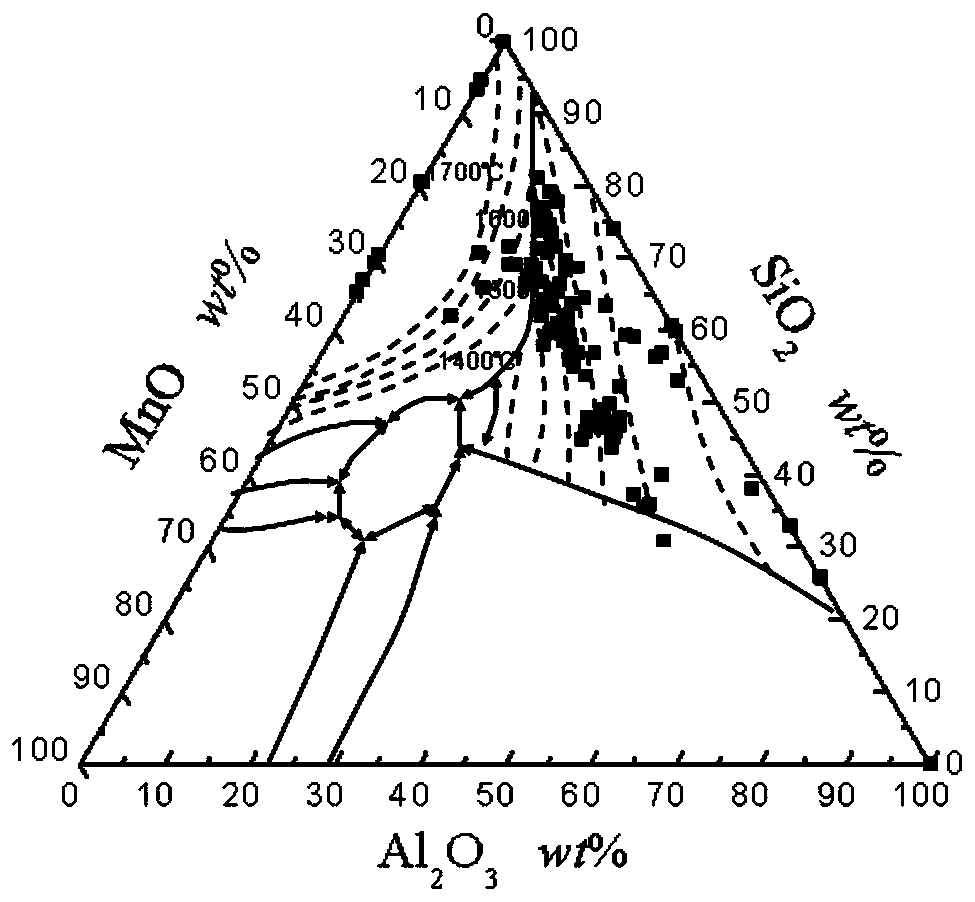

[0024] The silicon-manganese killed non-oriented silicon steel is produced on the non-oriented silicon steel production line of a steel factory. Its technological process is: converter smelting→RH vacuum refining→continuous casting. The specification of the ladle used is 200t, and the weight of molten steel is 175-185t. Taking the process of the present invention as an example, the present invention will be further described.

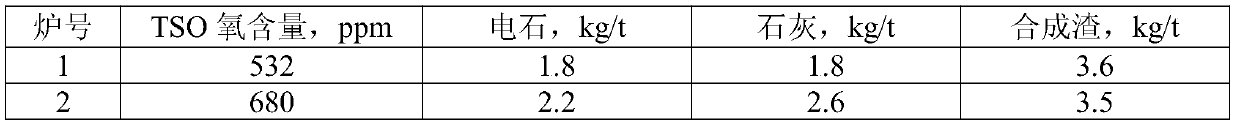

[0025] (1) Boil the steel at the end of the converter, strictly control the slag drop, and evenly add calcium carbide, lime, and synthetic slag to the slag surface of the ladle according to the TSO oxygen content. See Table 1 below for other process parameters. After feeding treatment according to Table 1, the oxygen content in the molten steel is 455-600ppm, and the T.Fe in the slag is 7%-12%. After the converter is tapped, the water is transported to RH for treatment.

[0026] Table 1 Process parameters of converter smelting

[0027]

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com