A kind of polymyxin b sulfate production strain, preparation method and application of polymyxin b sulfate

A technology for producing polymyxin sulfate and producing strains, which is applied to the preparation methods of peptides, polymyxins, and methods based on microorganisms, etc. The effect of the strong ability of prime B

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 The acquisition of production strains

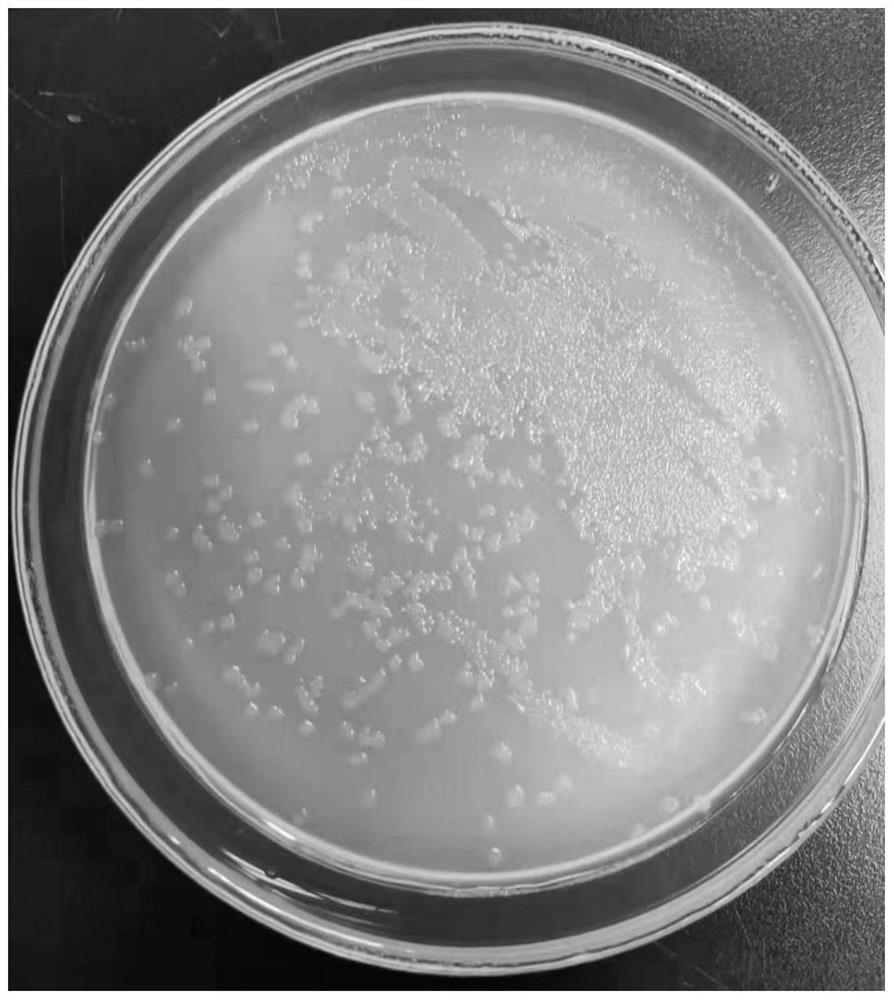

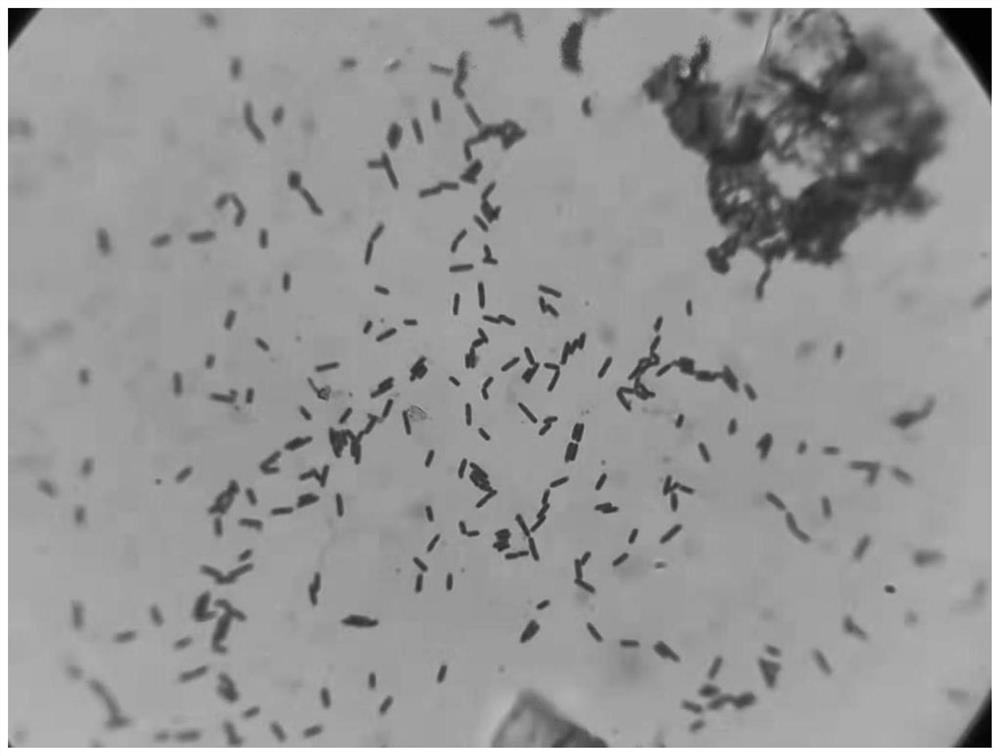

[0038]Use sterile water to elute the well-grown polymyxin B strains from the slope, and then use an ultraviolet lamp for 20 to 40 seconds of mutagenesis. DES) concentration is 0.05-0.5 mol / L, in this embodiment, 0.25 mol / L sterile water is used for 5-30 min, and in this embodiment, 20 min is selected. Then it is coated with polymyxin B 0.6 ~ 1.0g / L in the dark, and in the present embodiment, 0.7 g / L slant medium (a) is selected, and a single colony is picked and inoculated into the shake flask seed medium (a) after cultivation. b) Fermentation in medium, screening out strains that are higher than the control unit and less heterogeneous, passed to the third generation, the strains are more stable, and the mutagenized polymyxin B strains are obtained, the strains are Bacteroides pilaris Bacillus ( Paenibacillus peoriae ), single colony morphology is smooth surface, no wrinkle, milky white, oval, rod-shaped under the mic...

Embodiment 2

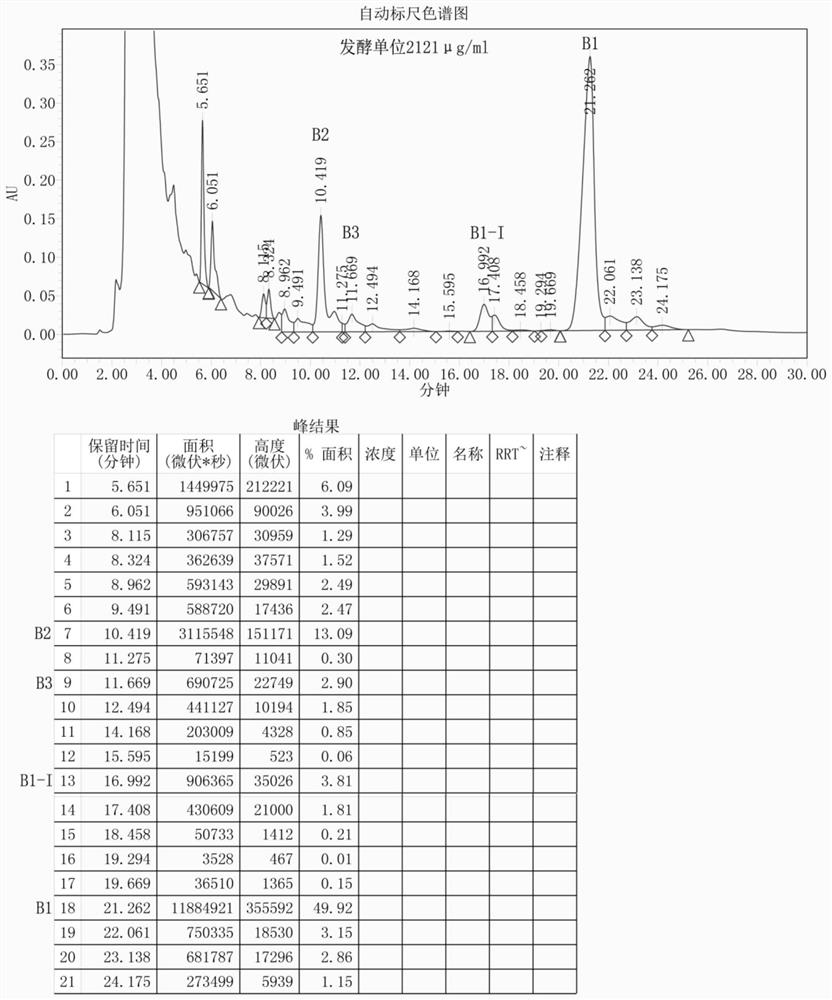

[0041] The preparation of embodiment 2 polymyxin B sulfate

[0042] 1. Strain fermentation

[0043] (1) Inoculate the mutagenized polymyxin B strain obtained in Example 1 into the shake flask seed medium (b) for cultivation to obtain shake flask seed liquid.

[0044] (2) Inoculate the shake flask seed liquid into a 10L seed tank for cultivation to obtain seed liquid.

[0045] (3) Transplant the seed liquid from the seed tank into a 50L fermenter for cultivation to obtain a fermented liquid.

[0046] Wherein: step (2) the formula of the seed tank culture medium is the same as that of the shake flask seed culture medium (b). Step (3) Fermentation medium formula: soluble starch 5.0~7.0 (6.5 in this example), yeast powder 0.5~0.8 (0.55 in this example), dipotassium hydrogen phosphate 0.01~0.05 (in this example 0.04), ammonium sulfate 0.2~0.4 (0.3 in this embodiment), calcium sulfate 0.2~0.4 (35 in this embodiment), defoamer 0.05, and the balance is water.

[0047] Carbon sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com