Growing method of (KxNa1-x)1-yLiyNbO3-based lead-free piezoelectric monocrystal

A potassium-sodium niobate-based, lead-free piezoelectric technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problem of harsh operating conditions and equipment requirements, affecting the integrity of crystal components, and the raw material potassium and sodium are volatile and other issues to achieve the effect of low requirements, improved integrity, and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

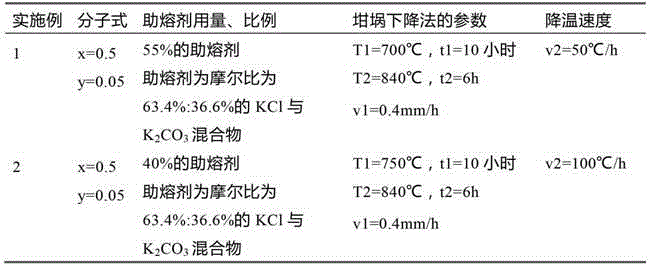

[0032] Embodiment 1~8 crucible descending method growth (K x Na 1-x ) 1-y Li y NbO 3 single crystal

[0033] 1. Will K 2 CO 3 、Na 2 CO 3 , Li 2 CO 3 Dry at 300°C for 3 hours, then press the chemical formula (K x Na 1-x ) 1-y Li y NbO 3 The stoichiometric ratio weighs K 2 CO 3 、Na 2 CO 3 , Li 2 CO 3 and Nb 2 o 5 raw powder.

[0034] 2. Weigh the flux, and mix well to obtain the starting material for crystal growth.

[0035] 3. Put the starting material into the platinum crucible, put the crucible in the alumina ceramic downcomer, and then place it in the crucible drop method crystal growth furnace.

[0036] 4. The crucible is kept at T1 for t1 hours, and then the temperature is raised to T2 for t2 hours, so that all the starting materials are melted, and then the crucible descends at the speed of v1, and when passing through the temperature gradient field between the high temperature zone and the low temperature zone in the growth furnace , the melt gra...

Embodiment 1

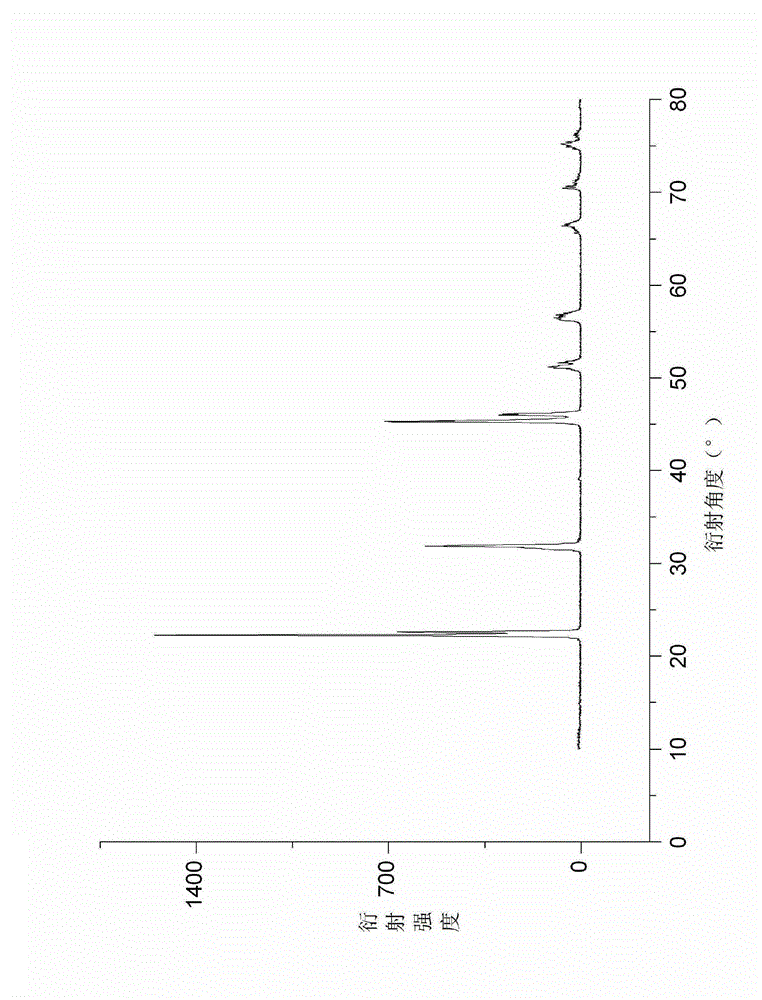

[0042] The potassium sodium niobate-based lead-free piezoelectric single crystal obtained in Example 1 was ground into powder, and its structure was analyzed by X-ray diffraction. figure 1 It can be seen that the structure of potassium sodium niobate-based lead-free piezoelectric single crystal is a pure perovskite structure, and no other impurity phases are formed.

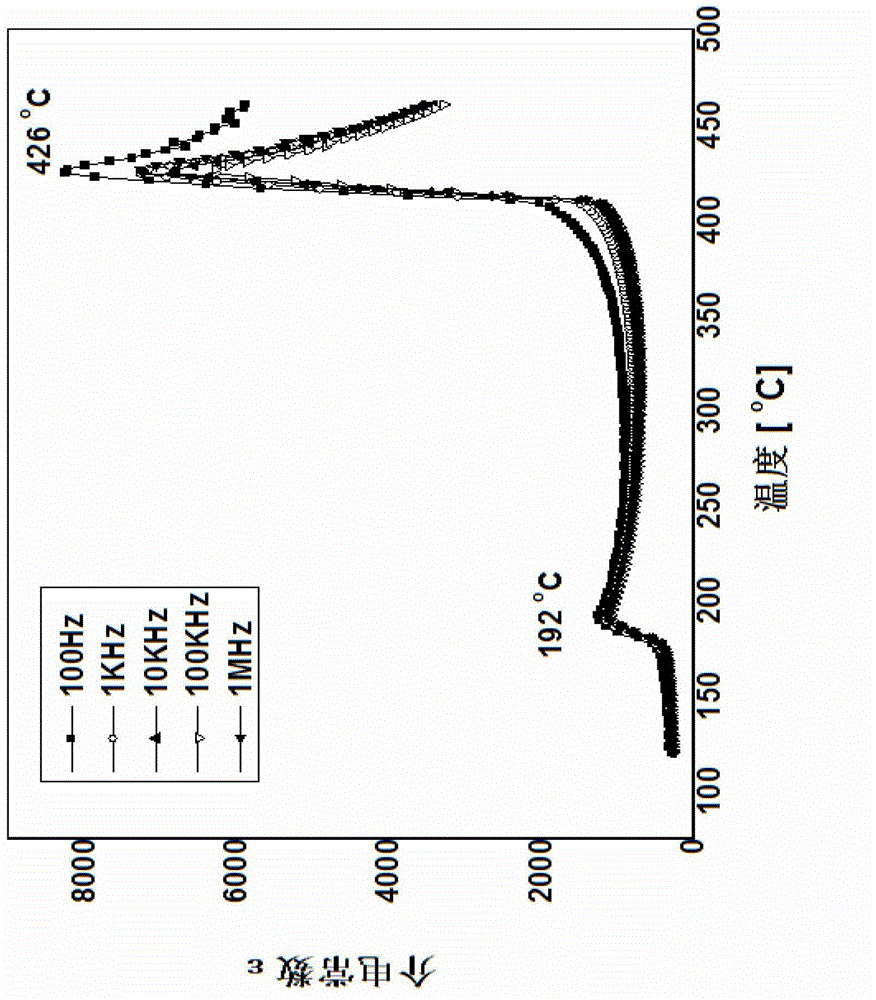

[0043] Then test the obtained potassium-sodium niobate-based lead-free piezoelectric single crystal at different frequencies, the dielectric constant versus temperature curve, the dielectric temperature curve is as follows figure 2 shown, from figure 2 It can be seen that there are two dielectric anomaly peaks at all frequencies, corresponding to the orthorhombic-tetragonal phase transition (192 °C) and the tetragonal-cubic phase transition (Curie temperature T c : 426°C). Finally, the piezoelectric performance of the obtained crystal is tested, and the piezoelectric constant can reach 410pC / N. The obtained c...

Embodiment 9~15

[0044] Growth (K x Na 1-x ) 1-y Li y NbO 3 single crystal

[0045] 1. Will K 2 CO 3 、Na 2 CO 3 , Li 2 CO 3 Dry at 300°C for 3 hours, then press the chemical formula (K x Na 1-x ) 1-y Li y NbO 3 The stoichiometric ratio weighs K 2 CO 3 、Na 2 CO 3 , Li 2 CO 3 and Nb 2 o 5 raw powder.

[0046] 2. Weigh the fluxing agent, mix well and evenly to obtain the starting material for crystal growth.

[0047] 3. Put the starting material into the platinum crucible and seal it. Put the sealed platinum crucible into the glass tube. The glass tube is vacuum-sealed and then placed in the muffle furnace.

[0048] 4. The temperature in the muffle furnace rises from room temperature to T1 after t10 hours and keeps warm for t1 hours, then rises to T2 after t20 hours and keeps warm for t2 hours, then the temperature in the muffle furnace cools to room temperature at v2 speed.

[0049] 5. After the crystal growth is completed, the crystal is released from the furnace, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com