A chemical vapor deposition device and method

A chemical vapor deposition and heating device technology, which is applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of poor film growth consistency and low growth rate, and achieve reduced processing costs and less heating Effects of area, guaranteed cleanliness and relative independence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

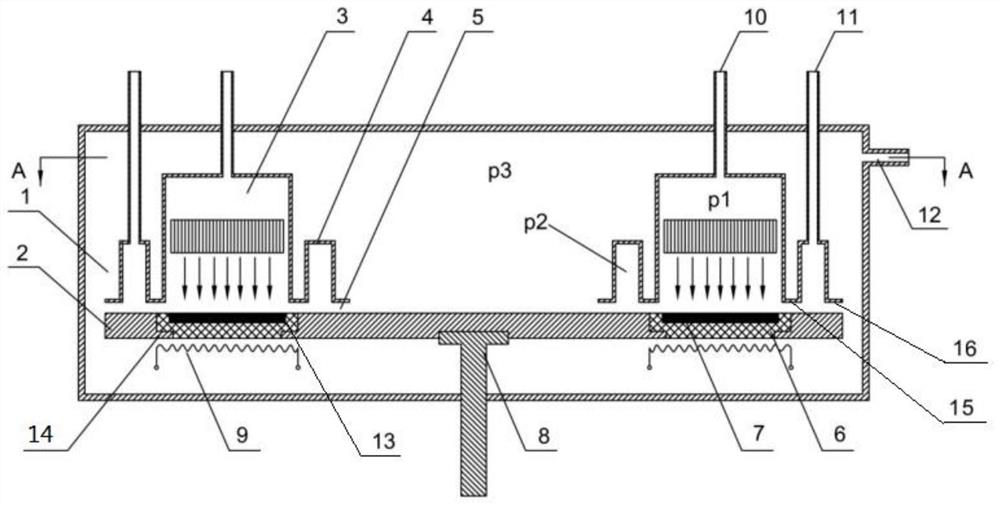

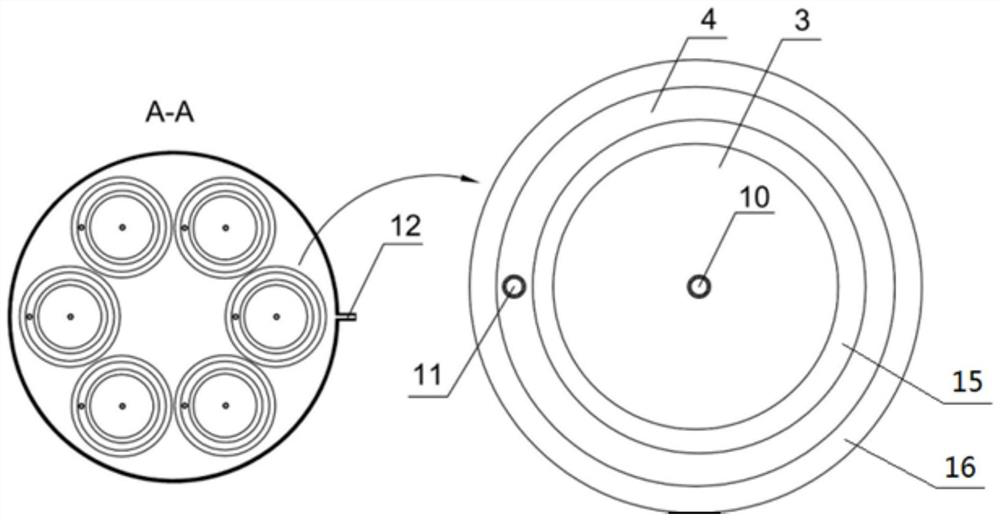

[0049] Such as figure 1 , 2 and 3, figure 1 It is a schematic structural diagram of a chemical vapor deposition device provided by the present invention, figure 2 It is a schematic top view of a structure of the chemical vapor deposition device provided by the present invention after removing the outer cavity, image 3 It is a schematic top view of another structure of the chemical vapor deposition device provided by the present invention after removing the outer cavity. The chemical vapor deposition device includes an outer cavity 1, a moving tray 2, an inner cavity 3, an exhaust cavity 4, a tray groove 14, a wafer loading area 6, a heating device 9, a gas supply pipeline 10, a second An exhaust duct 11 and a second exhaust duct 12;

[0050] The outer cavity 1 is a cylindrical airtight cavity structure; the moving tray 2 is thin cylindrical, the diameter of the moving tray 2 is slightly smaller than the diameter of the outer cavity 1, and the moving tray 2 is horizontall...

Embodiment 2

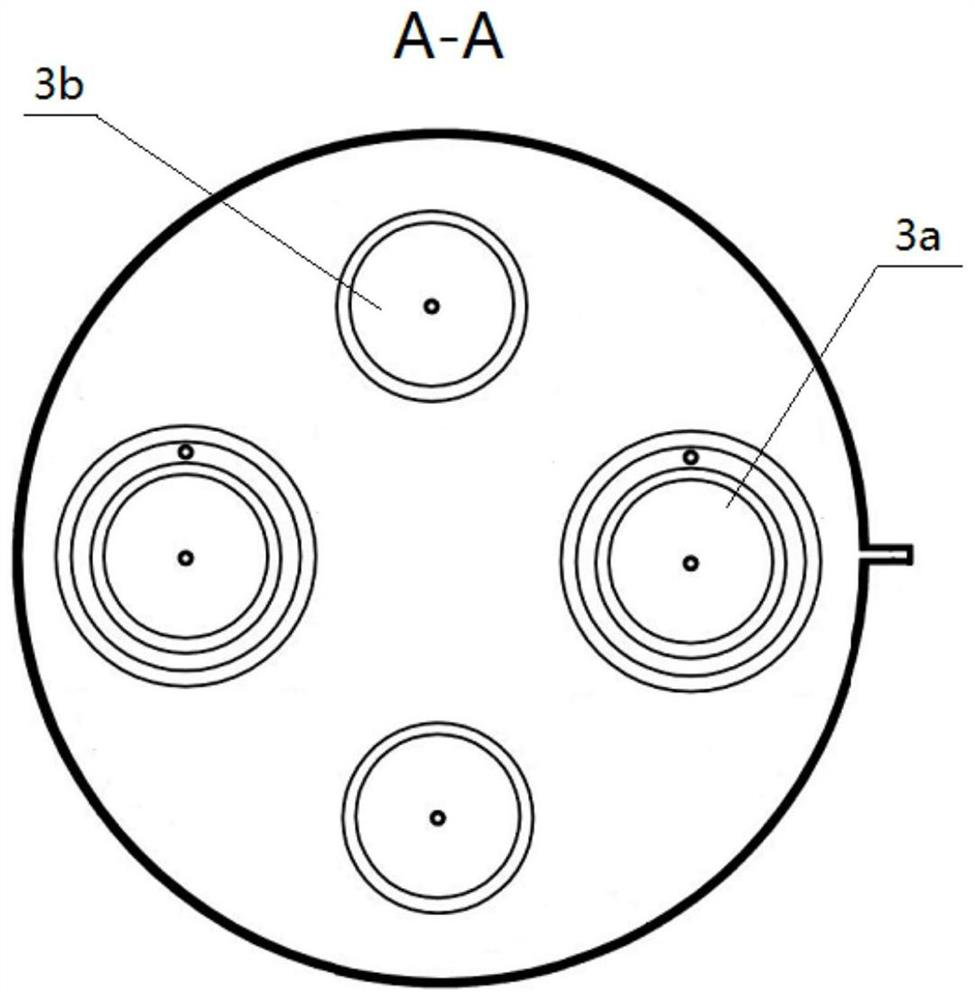

[0076] Such as Figure 4 Shown is one embodiment of the chemical vapor deposition apparatus of the present invention. The moving tray 2 is indexed and rotated between the inner cavity 3a and the inner cavity 3b, and the wafers 7 that are separately arranged on each wafer loading area 6 on the upper surface of the moving tray 2 stay in different inner cavities 3a or 3b for a while in turn, The reaction precursor in the inner chamber 3a and the purge gas in the inner chamber 3b are received alternately, with a typical residence time of 1-5 seconds. For example, the wafer carrying area 6 first passes through the inner chamber 3 for transporting the Group III precursor, and the surface adsorbs the Group III precursor; 2 The inner cavity 3 of the group III gas-phase precursor is purged away, leaving only the surface adsorbed particles; and then the group V precursor is continuously adsorbed on the surface of the group III precursor through the inner cavity 3 of the group V; Final...

Embodiment 3

[0078] Such as Figure 5 Shown is another embodiment of the chemical vapor deposition apparatus of the present invention. The introduction of inert gas into the inner chamber 3 is canceled, and only the reaction precursor is introduced into the inner chamber 3 . The moving tray 2 is indexed and rotated among a plurality of inner cavities 3 , and the wafers arranged on each wafer carrying area 6 on the upper surface of the moving tray 2 pass through different inner cavities 3 in turn, but do not stay. Due to the lack of inert gas purge, when the wafer 7 is switched from one cavity 3 to another, the boundary layer above the surface of the wafer 7 will carry a small amount of the reaction precursor of the previous cavity 3 . Due to the capillary isolation between the inner chamber 3 and the outer chamber 1, the amount of the former reaction precursor in the gas phase above the wafer 7 is very small, and there is still only one reaction precursor, thus greatly reducing the gas ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com