Preparation method of nano-particles with nano-grade porous structure

A nanoporous and nanoparticle technology, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of limited material system, uneven particle size distribution, difficulty in mass production and satisfying practical applications Demand and other issues, to achieve the effect of simple method and conducive to large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing nanoparticles with a nanoporous structure, comprising the following steps:

[0039] (1) Weigh Pt, Ni, and Al according to the atomic ratio of 1:1:8, and place them in an electric arc furnace to melt into a PtNiAl alloy;

[0040] (2) The PtNiAl alloy is made into thin strips with a width of 5 mm, a length of 30 mm, and a thickness of 100 μm by the quenching strip method;

[0041] (3) In 0.5mol / L NaOH solution, soak and corrode the PtNiAl alloy for 48 hours to dissolve the active metal component Al; after the corrosion is completed, take out the strips and clean them to obtain a platinum-nickel nanoporous alloy;

[0042] (4) PtNi nanoporous alloys were placed in ethanol and ultrasonicated for 5 min to prepare PtNi alloy nanoparticles with nanoporous structure.

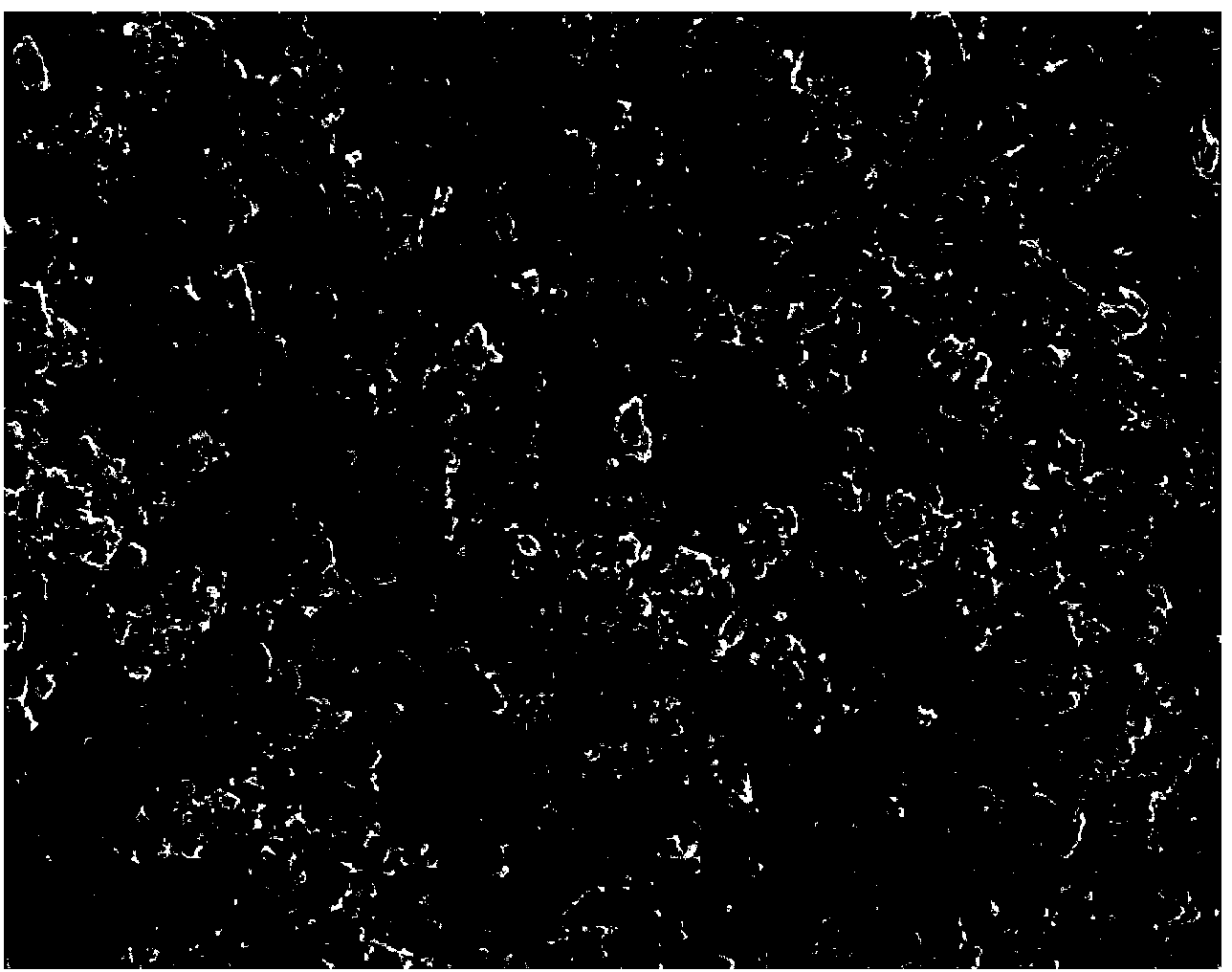

[0043] The scanning electron microscope photos of the prepared PtNi alloy nanoparticles with nanoporous structure are as follows: figure 1 shown by figure 1 It can be seen that the size o...

Embodiment 2

[0052] A method for preparing nanoparticles with a nanoporous structure, comprising the following steps:

[0053] (1) Weigh Pt, Co, and Al according to the atomic ratio of 1:1:8, and place them in an electric arc furnace to melt them into PtCoAl alloys;

[0054] (2) The PtCoAl alloy is made into thin strips with a width of 5 mm, a length of 100 mm, and a thickness of 80 μm by the quenching strip method;

[0055] (3) In 0.1mol / L HCl solution, immerse and corrode the PtCoAl alloy for 48 hours to dissolve the active metal component Al and partially dissolve the moderately active metal Co; after the corrosion is completed, take out the strip and clean it. Prepared platinum-cobalt nanoporous alloy;

[0056] (4) The platinum-cobalt nanoporous alloy was placed in methanol and ultrasonicated for 5 minutes to prepare PtCo alloy nanoparticles with a nanoporous structure.

[0057] The scanning electron micrographs of the prepared PtCo alloy nanoparticles with nanoporous structure are a...

Embodiment 3

[0062] A method for preparing nanoparticles with a nanoporous structure, comprising the following steps:

[0063] (1) Weigh Pt, Cu, and Al according to the ratio of atomic ratio of 1.5:0.5:8, and place them in an electric arc furnace to melt into PtCuAl alloy;

[0064] (2) The PtCuAl alloy is made into thin strips with a width of 3 mm, a length of 35 mm, and a thickness of 200 μm by the quenching strip method;

[0065] (3) In 1.0mol / L NaOH solution, immerse and corrode the PtCuAl alloy for 48 hours to dissolve the active metal component Al; after the corrosion is completed, take out the strips and clean them to obtain a platinum-copper nanoporous alloy;

[0066] (4) Put the platinum-copper nanoporous alloy in ethanol, and ultrasonicate for 8 minutes to prepare platinum-copper nanoporous nanoparticles with a nanoporous structure. The particle length is about 100-300nm and the width is about 50-150nm. The whole particle is three-dimensional Nanoporous structure, the size of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com