A kind of preparation method of rare metal boride

A rare metal, boride technology, applied in the direction of metal boride, boron/boride, etc., can solve the problems of process energy consumption, high cost, product purity decline, difficult industrial application, etc., to improve the reaction conversion rate and crystallinity. Good, high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

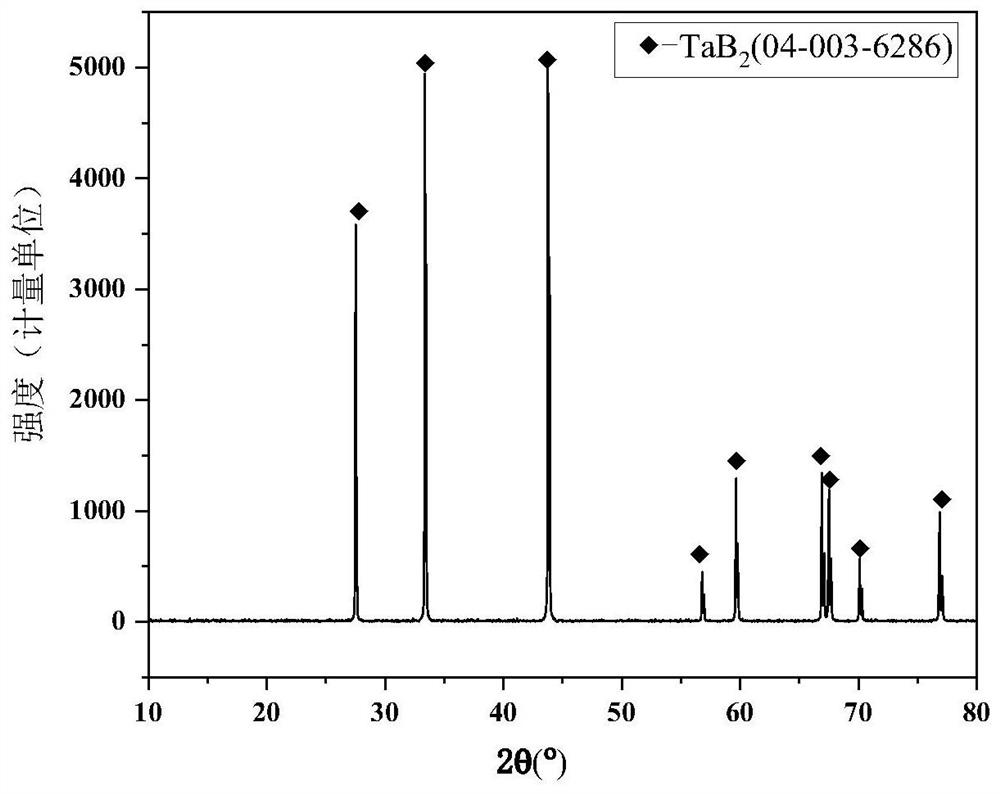

Embodiment 1

[0028] Take 1.2kg of tantalum oxide, 0.6kg of boron carbide, and 0.6kg of metal aluminum powder, mix them evenly, put them into the mold, press them at 70MPa and 120°C for 20min, put the formed sample blocks into the roasting furnace, and vacuum them. After inhalation, the mixed gas of hydrogen and argon with a hydrogen concentration of 2% was introduced at a rate of 1L / min, and the temperature was raised to 600°C at a rate of 2°C / min. After 60 minutes, cool down to room temperature at a cooling rate of 5°C / min. After the product is crushed and sieved, the obtained powder product is mixed with H + Dilute nitric acid with a concentration of 1mol / L was mixed at a solid-to-liquid ratio of 1:10, leached in a water bath at 60°C for 30 minutes and then filtered, and the filter residue was washed and dried to constant weight to obtain tantalum diboride powder. The product XRD pattern is attached figure 1 shown.

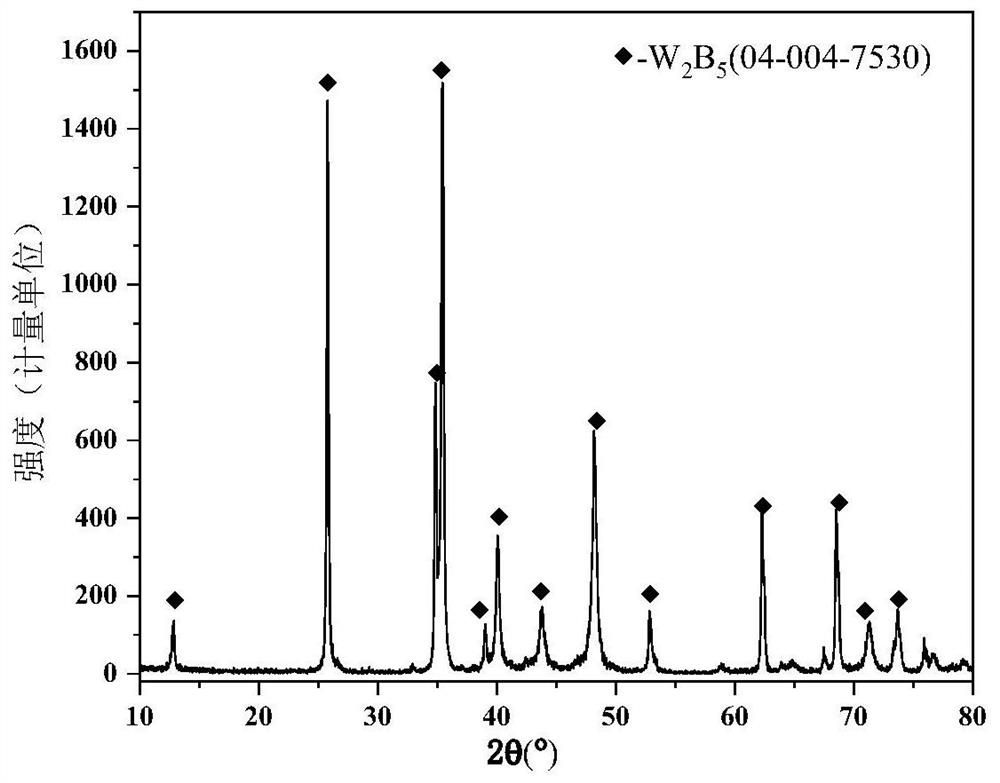

Embodiment 2

[0030] Take 1.6kg of tungsten trioxide, 0.5kg of boron oxide, and 0.4kg of tin powder, mix them evenly, put them into the mold, press them at 20MPa and 100°C for 20min, put the formed sample blocks into the roasting furnace, and vacuum them. After inhalation, a mixed gas of hydrogen and argon with a hydrogen concentration of 10% was introduced at a rate of 1.2L / min, and the temperature was raised to 1000°C at a rate of 5°C / min. After continuing to keep warm for 30 minutes, cool down to room temperature at a cooling rate of 5°C / min. After the product is crushed and sieved, the obtained powder product is mixed with H + Dilute hydrochloric acid with a concentration of 1.5mol / L was mixed at a solid-to-liquid ratio of 1:10, leached in a water bath at 80°C for 30 minutes and then filtered, and the filter residue was washed and vacuum-dried to constant weight to obtain ditungsten pentaboride powder. The product XRD pattern is attached figure 2 shown.

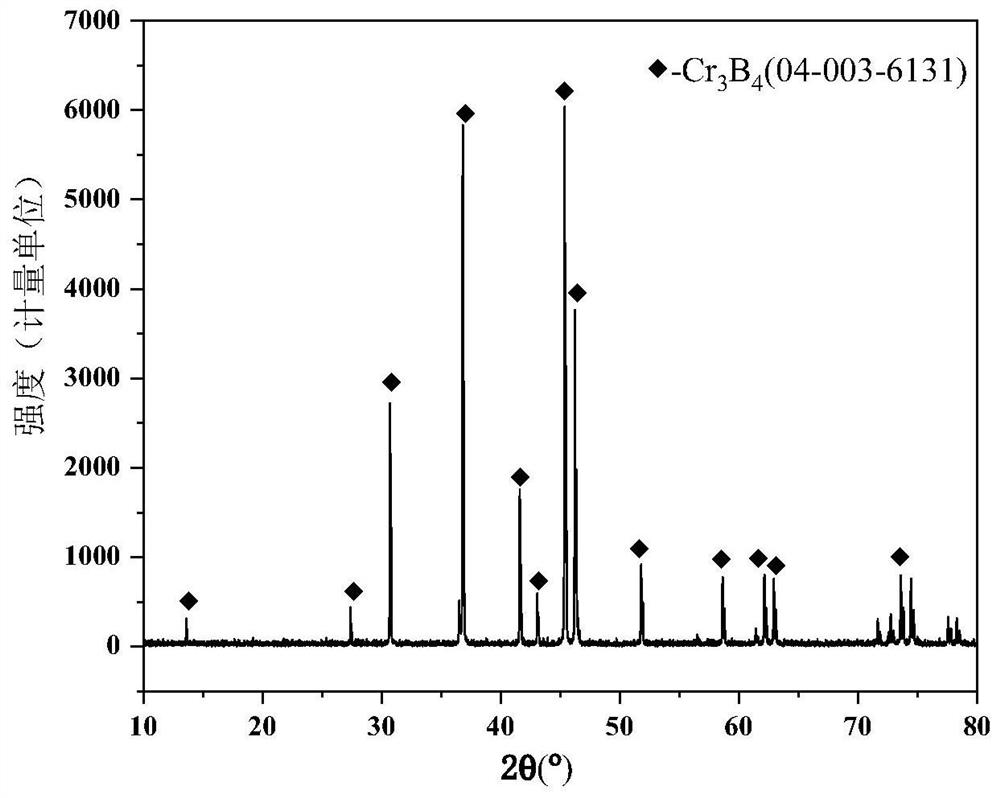

Embodiment 3

[0032] Take 0.6kg of chromium carbide powder, 1.2kg of boron oxide, and 0.1kg of metal aluminum powder, mix them evenly, put them into the mold, press them at 70MPa and 120°C for 20min, put the formed sample block into the roasting furnace, and vacuum After purging, feed a mixed gas of hydrogen and argon with a hydrogen concentration of 10% at a rate of 1 L / min, raise the temperature to 500 °C at a rate of 10 °C / min, keep warm for 360 min, and then continue to heat up to 1600 °C at a rate of 40 °C / min. After 90 minutes of heat preservation, the temperature was lowered to room temperature at a rate of 5°C / min. After the product is crushed and sieved, the obtained powder product is mixed with nitric acid: hydrochloric acid at a ratio of H + Dilute hydrochloric acid with a concentration of 3 mol / L was mixed at a solid-to-liquid ratio of 1:5, leached in a water bath at 60°C for 180 minutes, filtered, and the filter residue was washed and dried to constant weight to obtain tantalum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com