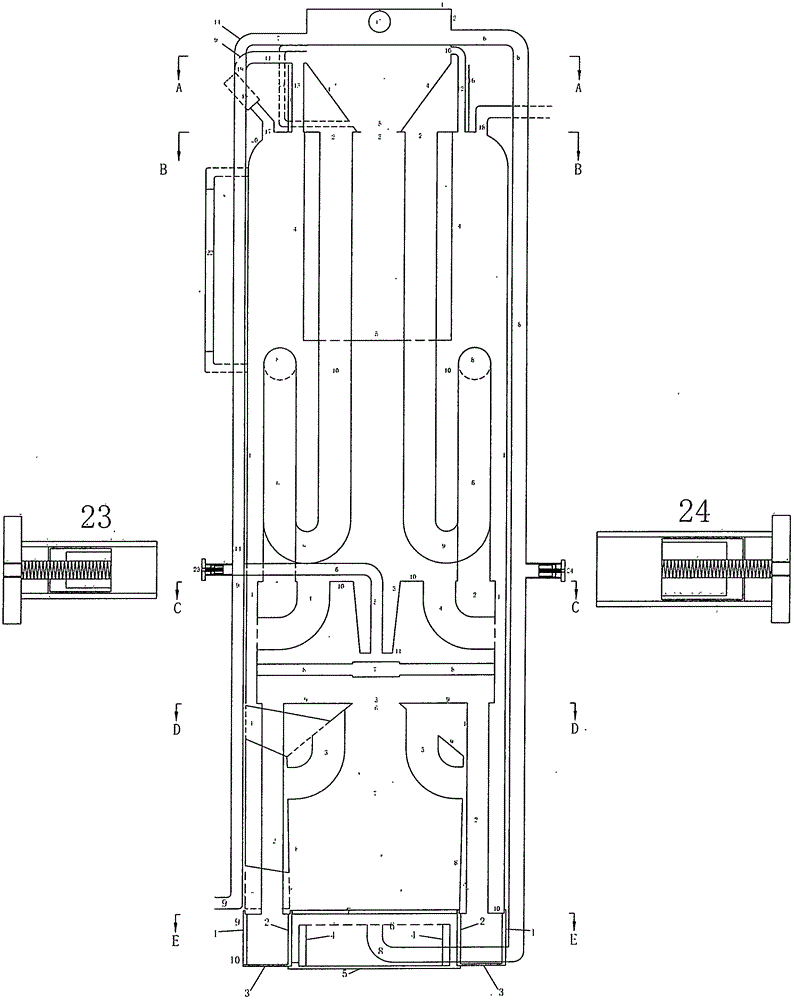

Environment-friendly energy-saving efficient gasification boiler

An environmental protection, energy saving, gasification boiler technology, applied in lighting and heating equipment, solid fuel combustion, combustion equipment, etc., can solve the problems of boiler pollution and other problems, and achieve the effect of improving thermal efficiency, convenient use, and light operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

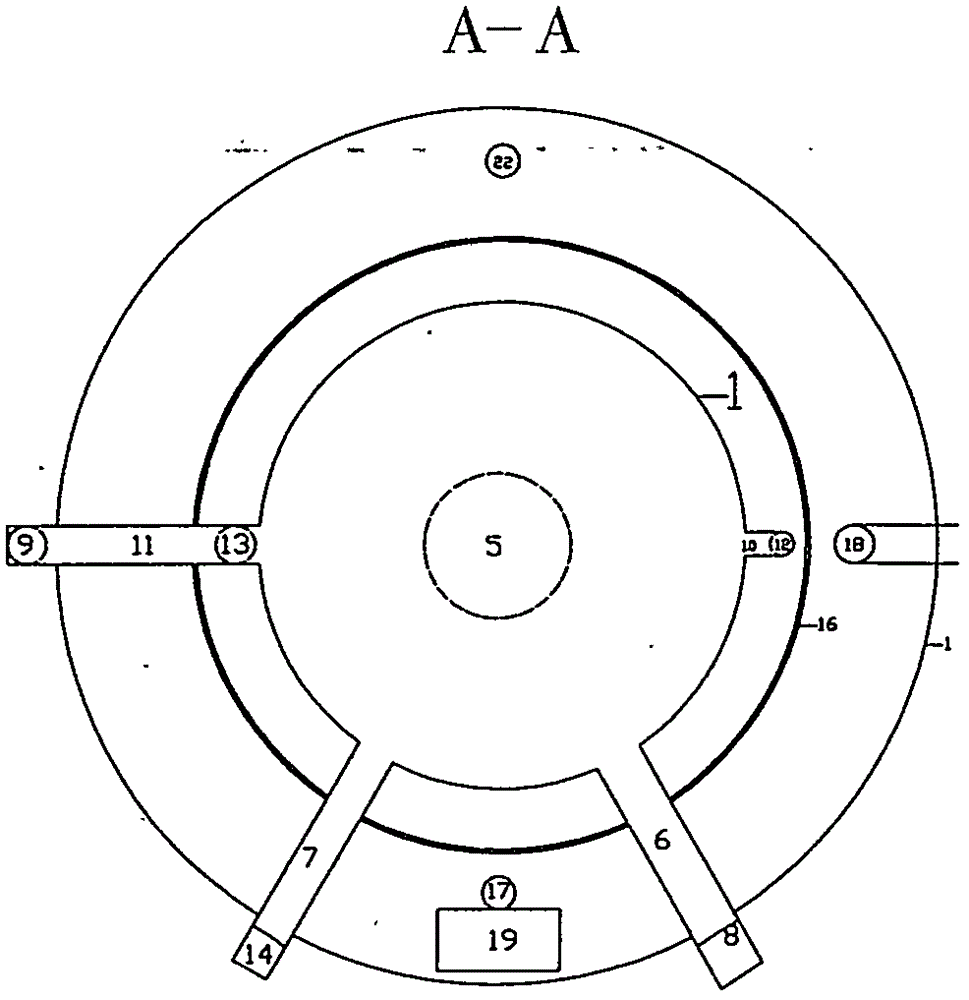

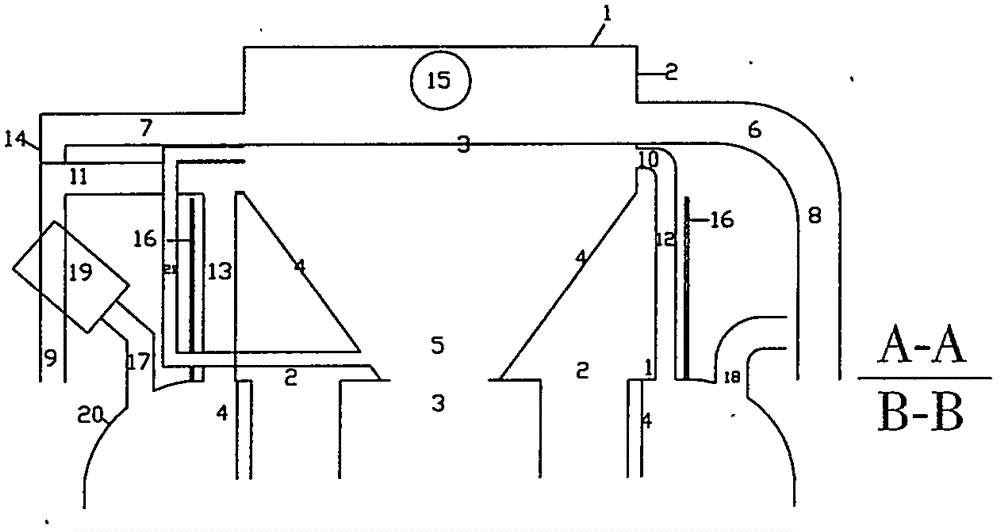

[0083] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS 1. The boiler adopts a wind box installed on the top of the boiler with a small electric fan, and the wind is transported into the wind box through a pipeline.

specific Embodiment approach 2

[0084] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT 2. An oxygen supplement device and a protective tube are designed in the second combustion chamber of the C part, and the hot air pipes (7) (14) are transported from the A part of the bellows to the C part (6) of the second combustion chamber. Achieving supplemental oxygen to support combustion.

specific Embodiment approach 3

[0085] Embodiment 3. A warm water cabinet is designed at the base of the furnace in the E part, and the hot air pipe (6) (8) is conveyed by the bellows in the A part from the elbow to the warm water cabinet in the E part. Dust, smoke, and fine particles are discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com