Catalyst for preparing peracetic acid disinfectant and preparation method of disinfectant

A peracetic acid and catalyst technology, which is applied in the field of preparation of catalysts and disinfectants, can solve the problems of flammable and explosive hazards, fire, and high risk of transshipment, and achieve the advantages of avoiding dependence on production equipment, improving stability, and simplifying the process route Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

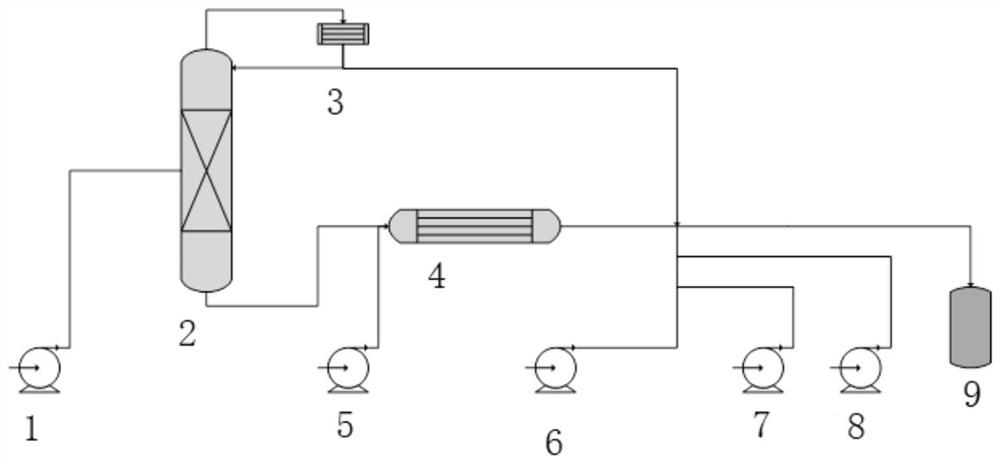

Image

Examples

Embodiment 1

[0052] Dissolve 5g of cetyltripropylammonium bromide in a mixture of 60mL of 0.5mol / L NaOH and 2.4L of deionized water, stir at 80°C for 15min, add 0.1L of 3.7wt% formaldehyde solution, and Add 0.1L 0.05mol / L potassium chloropalladate aqueous solution. After stirring for 10 min, 50 g of ethanol was slowly added dropwise, centrifuged after 1 h of reaction, washed 4 times with deionized water and once with ethanol, and dried at 60° C. for 24 h. Raise the temperature to 600°C at a rate of 1°C / min under an air atmosphere and keep it for calcination for 6 hours to remove hexadecyltripropylammonium bromide to obtain the final catalyst.

Embodiment 2

[0054] The mass ratio of ruthenium and aluminum is 2:3, that is, the atomic ratio is 15:85. In order to avoid the arc from rushing the material out of the crucible during the melting process, the cross-sectional area is 9mm 2 The bulk ruthenium metal, the wire-shaped aluminum metal with a length of 5mm and an inner diameter of 1mm are used as auxiliary materials. According to the principle of easy splashing and high melting point metals placed below, the ruthenium metal is first placed on the bottom of the copper crucible, and then covered with aluminum metal. Evacuate the electric arc furnace to 6×10 -3 Pa, filled with inert gas as a protective atmosphere and then smelted. After smelting, it is continuously turned over and cooled into an ingot. In order to ensure that the alloy is smelted evenly, each alloy sample is repeatedly smelted many times. Under a nitrogen atmosphere, the temperature was raised to 600°C at a rate of 1°C / min and kept for calcination for 6h. The act...

Embodiment 3

[0056] Powdered platinum metal and aluminum metal are used as alloy raw materials. The mass ratio of platinum and aluminum is 1:4. After adding a certain amount of process control agent, mix the powder evenly. Then put the mixture into the ball mill jar, add the balls whose mass is 20 times that of the raw material, seal the jar and evacuate it. Rotate at a speed of 500rpm, switch the direction of rotation every 2 hours, and grind continuously for a certain period of time. After a long time of ball milling, the particle size of the powder is generally less than 1 μm. Put the ball mill tank into a vacuum glove box, open the tank, take samples under the protection of nitrogen, and finally store it in a container with a valve. After the alloy powder is passivated by the air diffused into it, the 400-mesh powder is sieved for later use. Under a nitrogen atmosphere, the temperature was raised to 600°C at a rate of 1°C / min and kept for calcination for 6h. The activation process i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com